944

17% of the country's steel

Writes Stepanov Glory:

Novolipetsk Steel - the third largest metallurgical combine in the country. It produces about 17% of the total Russian steel production (12 million tons per year), 21% - rental, 55% of coated steel. The plant employs about 30 000 people. NLMK area - 28 square kilometers, and the length of the perimeter - 38 kilometers. Located in Lipetsk, 350 km away from the Kursk magnetic anomaly - the main supplier of raw materials for the company.

35 photos and letters.

2.Kupol cast house of a blast furnace №6

Blast furnace used for processing of prepared iron ore charge in the molten iron (pig iron).

Cast iron smelted from a mixture of weed from the sinter fines with GOK, with the addition of the flux converter slag of local production.

Currently in operation at NLMK are four blast furnaces:

AP №4 (capacity of 1, 8 million tonnes), DP №5 (2, 7 million tons), DP №6 (2, 9 million tonnes) and BF №7 «Rossiyanka» (3, 4 million tons).

3. Foundry Yard DP-6

The furnace runs continuously for 35 years.

Stop process ("quenching furnace") can not be as hot metal inside hardens, and the resulting mass would no longer be retrieved.

4. Gornova take samples of iron

The temperature of metal in the furnace reaches 1500 degrees Celsius.

5. The resulting reaction of the molten metal flows down on the hot coke, carbon feasting.

6.Napolnenie liquid iron ladle

7.

8.Trasportirovka buckets with iron in the converter shop

9.Zhidky iron from the blast furnace enters the converter shop.

In the converter, molten iron is melted in a steel.

10.Kislorod blown to remove carbon and other impurities from the melt. As a result of the reactions taking place a large amount of heat, so the metal is added to maintain the temperature of the melt at 1700 ° C.

The volume of the converter 350 tons.

11.Shlak on the surface of the liquid metal

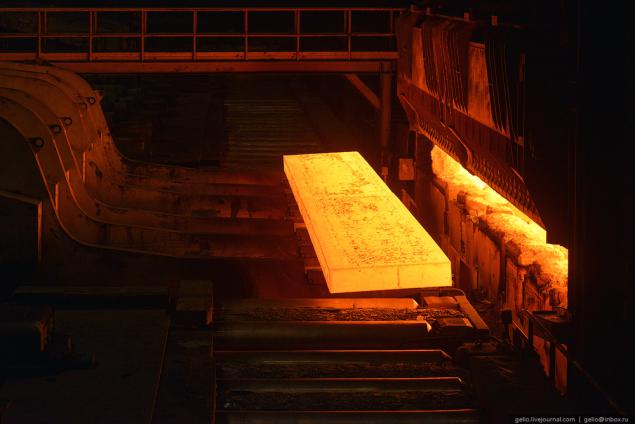

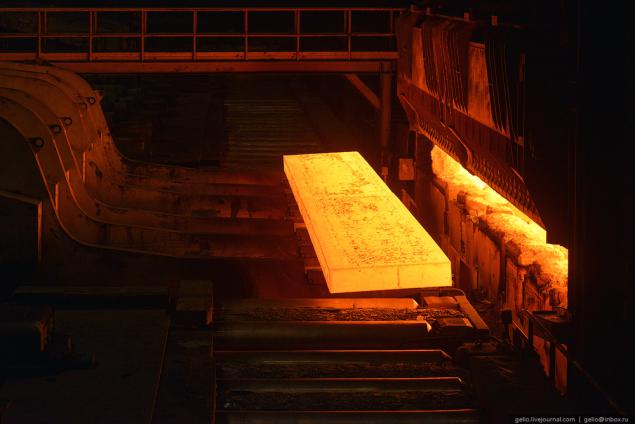

12.Iz converter shop metal enters here, in hot rolling plant, where the pre-heated to a high temperature slab is rolled while undergoing plastic deformation, until the desired thickness of the steel strip.

The length of this line is more than a kilometer

13.Vydacha heated slabs of the reheating furnace prior to hot rolling

14.Temperatura slab of about 800 degrees

15.Promezhutochny roller mill 2000

The metal is rolled from the bar in a steel sheet through a special roller press. Each pass reduces the thickness of the metal bar.

The speed of advancement of steel strips through the pipeline - 40 km / h.

16 Hot rolled strip

17.Chistovye stand

It produces rolling to the final thickness of the strip.

18.Temperatura reduced due to the constant cooling water.

19.Ustanovka accelerated cooling

20. In the end of the line cooled metal coiled

21.Dlina sheet roll up one kilometer.

22.Goryachekatanny roll

The weight of one of the roll can reach 20 tons

23.Takoy rentals intended for the manufacture of oil and gas pipelines (including pipelines, designed to operate at low temperatures and under high pressure), shipbuilding and construction vessels working under high pressure.

24.Rulony in the workshop production of cold rolled and coating (PHPP)

Changes in the structure and its shape is achieved by rolling steel at a low temperature (often room temperature). Used to increase the hardness and strength of steel. When rolling these efforts cause a change in composition of the steel, the improvement of certain properties.

25.Stan 2030

Metal comes up to 6 mm. At the beginning it is directed through pickling (pickling speed of 10-20 m / s).

26.Potom sheet passes the site where it is washed and cleaned of dross by special rolls with a synthetic coating.

Thereafter, the metal is rolled into a roll and is rolled on site.

27.Tolschina metal sheet after rolling 0 5 - 2 to 7 mm.

Cold-rolled steel is used to manufacture car bodies, tractors and combine harvesters, metal, stamped parts, housings of electrical appliances, roofing and finishing.

28.Markirovka cold-roll

29.Agregat continuous hot-dip galvanizing

The line is intended for the production of hot-rolled steel thickness 0, 22-0, 8 mm and a width of 900-1270 mm on the basis of low-carbon steel grades.

This metal products used primarily in the construction industry and production of household appliances.

30.Post management galvanizing bath

31.Otsinkovka.

Special sheet passes through the zinc bath. The coating thickness of a few hundredths of a millimeter

32.

33. NLMK supplies its products to all industrial sectors of the economy - construction, manufacture of machinery and equipment, transport, energy and agricultural machine building, pipe production.

34. In 2012, the company has sold more than 70 countries.

35. Many thanks to the press service of NLMK for photo ops!

Source:

Novolipetsk Steel - the third largest metallurgical combine in the country. It produces about 17% of the total Russian steel production (12 million tons per year), 21% - rental, 55% of coated steel. The plant employs about 30 000 people. NLMK area - 28 square kilometers, and the length of the perimeter - 38 kilometers. Located in Lipetsk, 350 km away from the Kursk magnetic anomaly - the main supplier of raw materials for the company.

35 photos and letters.

2.Kupol cast house of a blast furnace №6

Blast furnace used for processing of prepared iron ore charge in the molten iron (pig iron).

Cast iron smelted from a mixture of weed from the sinter fines with GOK, with the addition of the flux converter slag of local production.

Currently in operation at NLMK are four blast furnaces:

AP №4 (capacity of 1, 8 million tonnes), DP №5 (2, 7 million tons), DP №6 (2, 9 million tonnes) and BF №7 «Rossiyanka» (3, 4 million tons).

3. Foundry Yard DP-6

The furnace runs continuously for 35 years.

Stop process ("quenching furnace") can not be as hot metal inside hardens, and the resulting mass would no longer be retrieved.

4. Gornova take samples of iron

The temperature of metal in the furnace reaches 1500 degrees Celsius.

5. The resulting reaction of the molten metal flows down on the hot coke, carbon feasting.

6.Napolnenie liquid iron ladle

7.

8.Trasportirovka buckets with iron in the converter shop

9.Zhidky iron from the blast furnace enters the converter shop.

In the converter, molten iron is melted in a steel.

10.Kislorod blown to remove carbon and other impurities from the melt. As a result of the reactions taking place a large amount of heat, so the metal is added to maintain the temperature of the melt at 1700 ° C.

The volume of the converter 350 tons.

11.Shlak on the surface of the liquid metal

12.Iz converter shop metal enters here, in hot rolling plant, where the pre-heated to a high temperature slab is rolled while undergoing plastic deformation, until the desired thickness of the steel strip.

The length of this line is more than a kilometer

13.Vydacha heated slabs of the reheating furnace prior to hot rolling

14.Temperatura slab of about 800 degrees

15.Promezhutochny roller mill 2000

The metal is rolled from the bar in a steel sheet through a special roller press. Each pass reduces the thickness of the metal bar.

The speed of advancement of steel strips through the pipeline - 40 km / h.

16 Hot rolled strip

17.Chistovye stand

It produces rolling to the final thickness of the strip.

18.Temperatura reduced due to the constant cooling water.

19.Ustanovka accelerated cooling

20. In the end of the line cooled metal coiled

21.Dlina sheet roll up one kilometer.

22.Goryachekatanny roll

The weight of one of the roll can reach 20 tons

23.Takoy rentals intended for the manufacture of oil and gas pipelines (including pipelines, designed to operate at low temperatures and under high pressure), shipbuilding and construction vessels working under high pressure.

24.Rulony in the workshop production of cold rolled and coating (PHPP)

Changes in the structure and its shape is achieved by rolling steel at a low temperature (often room temperature). Used to increase the hardness and strength of steel. When rolling these efforts cause a change in composition of the steel, the improvement of certain properties.

25.Stan 2030

Metal comes up to 6 mm. At the beginning it is directed through pickling (pickling speed of 10-20 m / s).

26.Potom sheet passes the site where it is washed and cleaned of dross by special rolls with a synthetic coating.

Thereafter, the metal is rolled into a roll and is rolled on site.

27.Tolschina metal sheet after rolling 0 5 - 2 to 7 mm.

Cold-rolled steel is used to manufacture car bodies, tractors and combine harvesters, metal, stamped parts, housings of electrical appliances, roofing and finishing.

28.Markirovka cold-roll

29.Agregat continuous hot-dip galvanizing

The line is intended for the production of hot-rolled steel thickness 0, 22-0, 8 mm and a width of 900-1270 mm on the basis of low-carbon steel grades.

This metal products used primarily in the construction industry and production of household appliances.

30.Post management galvanizing bath

31.Otsinkovka.

Special sheet passes through the zinc bath. The coating thickness of a few hundredths of a millimeter

32.

33. NLMK supplies its products to all industrial sectors of the economy - construction, manufacture of machinery and equipment, transport, energy and agricultural machine building, pipe production.

34. In 2012, the company has sold more than 70 countries.

35. Many thanks to the press service of NLMK for photo ops!

Source: