671

Rice husk as material for the construction of affordable houses in the Philippines

Rice husk used to be considered a waste product, but now enterprising companies are beginning to realize its potential as a sustainable building material. The group of students from the College of engineering Riverside''s Bourns College of Engineering at the University of California have used rice husks for the production of termite-resistant composite panels supported by the Agency for environmental protection (EPA) and subsidies in the amount of 75 000 USD for the development and construction of affordable housing in the Philippines.

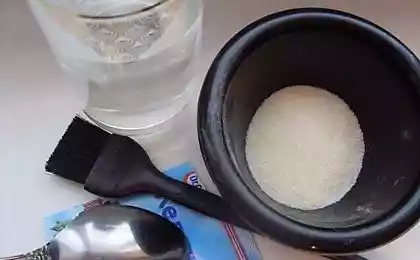

In addition to protecting rice during the growing period of rice husk can be used as a building material, fertilizer, insulation material or fuel. College students used the husk for the manufacture of panels, ideal for building shelters for rescuers and affordable housing.

Team Husk-to-Home developing a project the student-ecologist Colin Eckerle, who works him over with 2014. The students received a biennial grant from the EPA, which is aimed at financing of production equipment and will allow the team to move to full-scale production of panels.

Rice husk is waste from rice milling — replaces the commonly used wood chips. Obtained construction material is an excellent alternative to plywood, bamboo and coconut tree. Eckerle says that the new material will cost about $ 7 per panel size of 4 feet by 8 feet — and it's the same cost as that of plywood panels, which are currently used the IDEA. Recycled high density polyethylene (HDPE), also a waste product, rice husks binds and provides strength and resistance to moisture.

"Despite the fact that the way of obtaining material which is strong enough and persistent enough to create homes there was a lot of trial and error, we finally reached the stage where I can make a prototype panel, comparable in strength with the commercially available particle Board, said Eckerle. — "Our tests have shown that termites will not eat rice husks our or building material that will increase the life expectancy of houses in the Philippines". published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.energy-fresh.ru/tech/building/?id=14181

In addition to protecting rice during the growing period of rice husk can be used as a building material, fertilizer, insulation material or fuel. College students used the husk for the manufacture of panels, ideal for building shelters for rescuers and affordable housing.

Team Husk-to-Home developing a project the student-ecologist Colin Eckerle, who works him over with 2014. The students received a biennial grant from the EPA, which is aimed at financing of production equipment and will allow the team to move to full-scale production of panels.

Rice husk is waste from rice milling — replaces the commonly used wood chips. Obtained construction material is an excellent alternative to plywood, bamboo and coconut tree. Eckerle says that the new material will cost about $ 7 per panel size of 4 feet by 8 feet — and it's the same cost as that of plywood panels, which are currently used the IDEA. Recycled high density polyethylene (HDPE), also a waste product, rice husks binds and provides strength and resistance to moisture.

"Despite the fact that the way of obtaining material which is strong enough and persistent enough to create homes there was a lot of trial and error, we finally reached the stage where I can make a prototype panel, comparable in strength with the commercially available particle Board, said Eckerle. — "Our tests have shown that termites will not eat rice husks our or building material that will increase the life expectancy of houses in the Philippines". published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.energy-fresh.ru/tech/building/?id=14181