434

Scientists have found a way to improve the quality of graphene

A simple and inexpensive method of spraying, which allows to obtain graphene without any defects, suggested the researchers from the University of Illinois and Korea University.

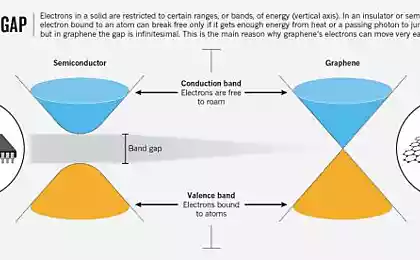

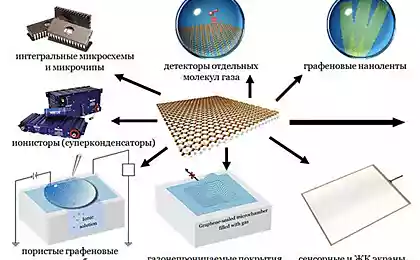

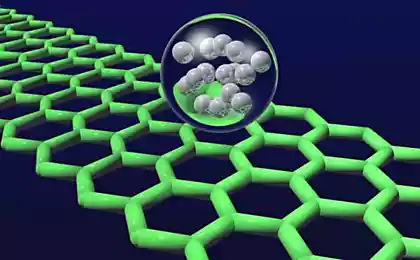

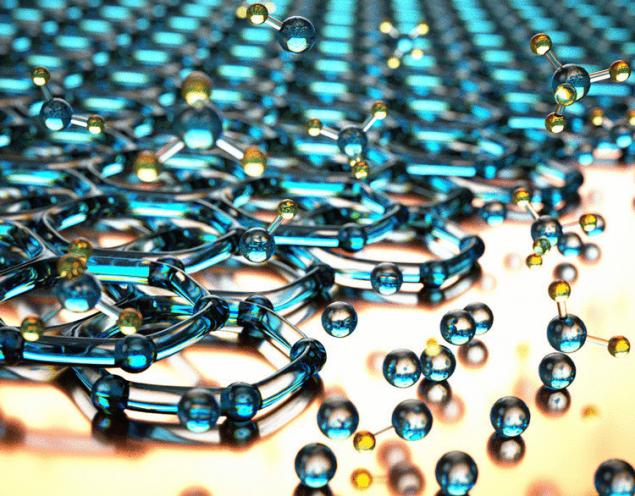

The two-dimensional material of a single layer of carbon atoms is an excellent conductor of electricity. He has the potential in development of fast integrated circuits, touch screens and plastics. However, the production of graphene for any type of extension, from microscopic to large scale, is impossible without defects. As explained by Professor Alexander Yarin: "normally, graphene is produced in small flakes, and even these small flakes have defects. Worse, when you try to transfer them to a large-scale area, defects increase, and the useful properties of graphene are lost."

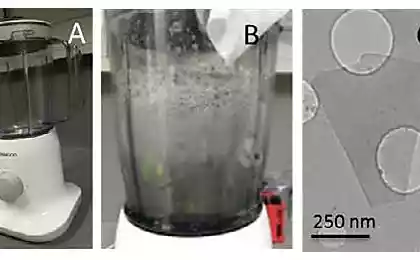

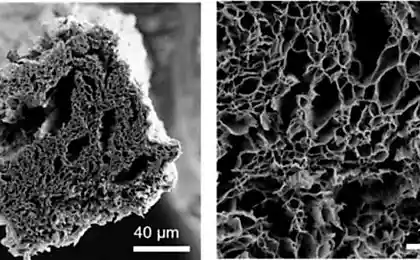

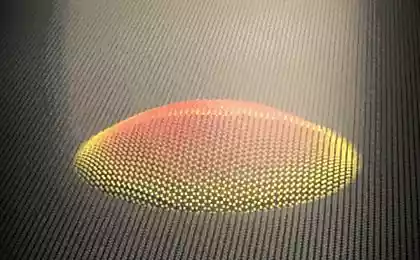

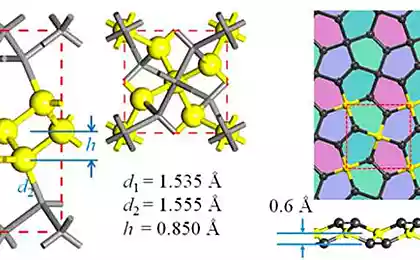

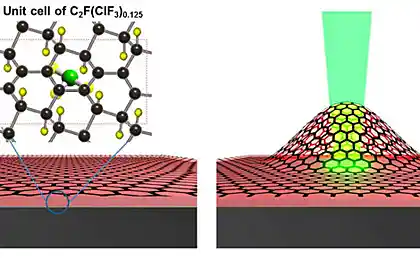

During the experiments, Yarin and Sam young of Korea University has developed a unique kinetic system, deposition by sputtering, which uses the acceleration of droplets through a Laval nozzle. The received supersonic spray system produces very small droplets of graphene, which are distributed evenly, evaporate quickly, and reduce the tendency of the graphene flakes to aggregate. The defects inherent in the flakes "miracle material" has disappeared, and the result was a layer of graphene of high quality.

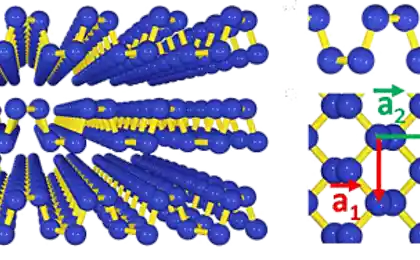

The experiments showed that the force of the impact stretches the graphene and rekonstruiruet the arrangement of its atoms into the perfect hexagons. A new method of deposition allows to "cure" graphene defect during application. Thus, a simple, inexpensive method can be performed on any substrate without the need for subsequent processing.

Source: nauka24news.ru/