528

Ipresname and purifying the graphene water filter

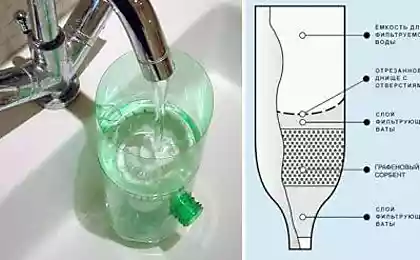

For the manufacture of filters, purifying the water quickly and long retains its properties, some scientists suggest the use of graphene. This thin but strong sheet of carbon can be used for the manufacture of ultrathin membranes that are able to quickly clear large volumes of water from pollutants. But on the way to the wide application of such high-tech membranes is one major obstacle is the production of membranes from graphene sheets with a thickness of only one layer of atoms is a process that requires high precision. The delicate material may tear, and through the formed gaps to penetrate contaminants. Now engineers have found a way to patch such holes. Water filters received in today's world widespread.

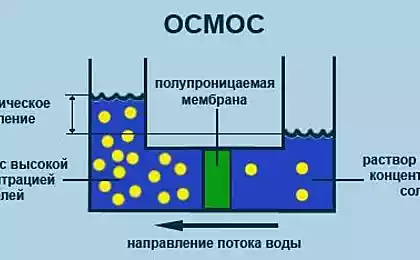

The unique properties of graphene make it potentially an ideal membrane for filtration and desalination. Now engineers at mit (Massachusetts Institute of Technology, MIT), oak ridge national laboratory (Oak Ridge National Laboratory) and University of petroleum and minerals king Fahd (King Fahd University of Petroleum and Minerals, KFUPM) was found in the way of patching holes, filling them with a mix of technology chemical vapor deposition and polymerization. The engineering team used a previously developed process for the creation of the material's tiny pores of the same shape, which are sufficiently small in order to allow to pass through them only water.

The combination of these two technologies has allowed researchers to develop graphene membrane without defects the size of a small coin. The size of the membrane is important. After all, to be used as a filter membrane, the width of the graphene should be measured in centimetres, at least.

In the experiment, the researchers conducted the water through the graphene membrane, which is pre-processed, by eliminating defects and forming pores. And came to the conclusion that the water meets standards typical for currently used presnaya membranes. Graphene is capable of filtering the larger molecules of pollutants, including sulphate of magnesium and dextran.

Associate Professor at mit, Karnik Rohit (Rohit Karnik) noted that the results achieved by the team was published in the journal "Nano Letters" and reflect the first success of the procedure for closing gaps holes in graphene:

We are able to rectify the defects at least in laboratory scale, to carry out molecular filtration through the surface of the graphene of macroscopic size, that was previously impossible. If we have a better control over the process, maybe in the future we do not need to repair the damage. But I think it is very unlikely that we'll ever be to arrange the perfect graphene will always be a need to control leak. The two [technologies] are examples of how to provide the filtering.The first author is research assistant, researcher Shin O Gern (Sean O'hern), a graduate of this institution. Among the authors — a student-the student Dugun Jang (Doojoon Jang), an ex-student-student Suman Bose (Suman Bose) and Professor Jing Kong (Jing Kong).

Shin Gern O clarifies features of the process:

Types of existing membranes that are able to produce fresh water from salty, quite thick and about 200 nanometers [in thickness]. The advantage of the graphene membrane is that is the thickness of hundreds of nanometers it is about three angstroms (tomellini a fraction of a centimeter) is 600 times thinner than existing membranes. This will allow you to have a higher flow rate at the same area.O Gern and Karnik explored the potential of graphene as a material of membrane filter within a few recent years. In 2009, the team began to make membranes from graphene grow lengthen for copper — the metal which supports the growth of graphene on relatively large area. Because graphene growth needed basis — for example, silver. Of course, copper waterproof, and scientists in the manufacturing process it was necessary to transfer graphene on a porous Foundation.

Of course, O Gern noted that this migration can generate gaps in graphene. Moreover, he also observed defects that appear in graphene in the process of growing. Their reason was probably contamination of the source material.

First, the team eliminated the less significant faults in the process of growing graphene. Then it's time for significant deficiencies encountered during the transfer. For defects encountered in the growing process, the researchers used a process called "atomic layer deposition" ("atomic layer deposition"), by placing a graphene membrane in the vacuum container, and then sending the impulses in the containing hafnium chemical compound that usually does not interact with the graphene. If a chemical comes in contact with a small hole in graphene, it will try to close this hole, attracted by the energy on the surface.

A team of researchers conducted several cycles of atomic layer deposition, finding that the precipitating oxide of hafnium has successfully filled in the slight gaps formed in the process of growing graphene. Of course, O Gern understood that the use of this process to fill the wider holes and gaps with a width of hundreds of nanometers — will take much more time.

Instead, he and his colleagues approached the problem by using the second technology is aimed at filling the wider defects. This process is called "polymerization on the phase boundary" ("interfacial polymerization") and is often used in the synthesis of membranes. After it was filled defects in graphene, the researchers immersed the membrane in the interfacial boundary of the two compounds — water bath and the organic solvent, which, like oil does not mix with water.

In the two compounds, the researchers dissolved the molecules of two different types, which reacts to form nylon. When O Gern was placed graphene membrane at the phase boundary of the two solutions, it was observed that the nylon pads are formed only on the gaps and holes — areas where the molecules of the two types can overlap, as in places the gap graphene becomes permeable. In the result the gaps have been effectively patched.

Using technology that the researchers developed last year, they did a graphene with small uniform holes that are small enough to allow it to penetrate through the water molecules, not missing the larger pollutants. In the experiment, a team of researchers has been tested by the membrane. Through it passed the water with admixtures of several other different molecules, including salt. The researchers found that the membrane repels up to 90% of larger molecules. Of course, Sol is higher speed than water.

Preliminary testing shows that graphene may be a real alternative to the current filtration membranes. Karnik notes that the technology of elimination of defects and control of permeability need further improvements:

Desalination and nanofiltration water are significant areas of application, if it is designed and the technology will stand during different tasks when testing in the real world, it can have a big impact. But you can also imagine other applications for the process, a beautiful, biologically and chemically, when these membranes will be ready to use. This is the first report of graphene membrane cm width, which can be used for various tasks of molecular filtration. It's inspiring.Graphene is intended for use mainly in high technologies. In solar cells they can replace platinum. Now scientists have found this great material is another important for humanity application.

How, in your opinion, might change purification technology and desalination in the case if the process of production of graphene membranes would be as simple as possible? published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: hi-news.ru

Quick simple drugstore remedies from edema and wrinkles

Soda is a great remedy that is always at hand