713

Clean water DIY: homemade filter

If you are going to provide a country house with independent water supply by wells, it should be borne in mind that the water quality and the durability of the system largely corresponds to the filter, which is immersed in the aquifer. Therefore, its quality should be given special attention, and best of all, in General, to produce a filter for wells with their hands. Next we will look at how to do it correctly.

Filter well is the bottom element of the casing, which is also called work area. Its main task is to prevent the ingress of large particles of soil inside the structure and the provision of clean water, free access to the column. In addition, it additionally protects the walls from crumbling and caving of the barrel.

Perforated pipe filter

Most often used well filters two types:

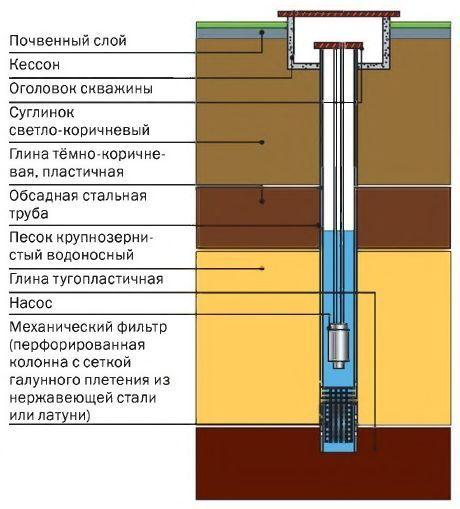

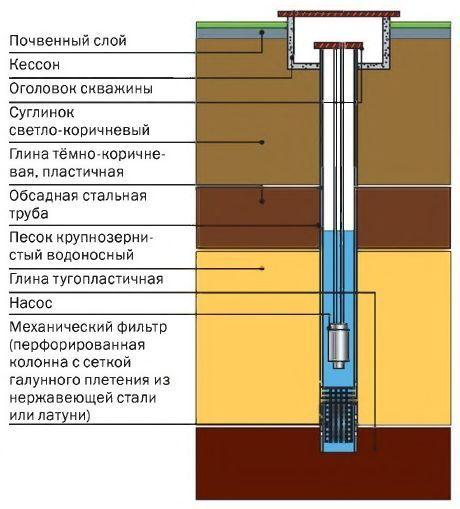

The scheme of the device well

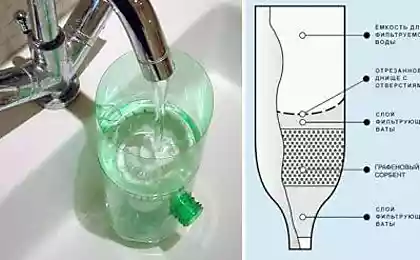

Perforated filters perforatedthe Most common water purification system from the well – perforated. It is a conventional perforated pipe covered with mesh, so making a filter for wells with their hands is not a big deal.In addition, this device has excellent performance properties.

So, if you are going to do a filter on the well with your hands, then you can stay on this design. The main advantage of this system is low cost. To use a structure in different species, most often it is used in the artesian wells, which have a fragile aquifer and a small head.

The design consists of several parts:

Plastic filter

Necessary tools and materialsFor the manufacture of the device will need:

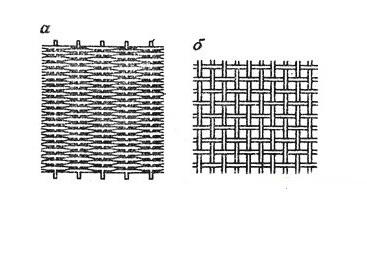

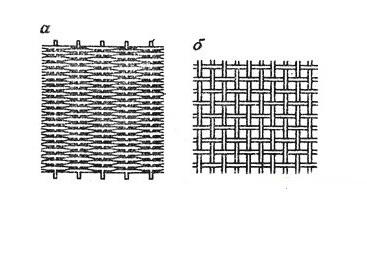

Options mesh netting

Tip!

Choose the size of the mesh openings by sifting sand from the aquifer.

Use the grid, which transmits about 50 percent sand.Fabricationinstructions for manufacture of the device as follows:

Slotted plastic filters

Gap-type filtersFilters plane type is usually used in breeds that are prone to collapse.Their design is preferred because it has more capacity. On the surface of such products do not exist "blind" areas, and the area of the slit is much greater than the area of the hole.

The main disadvantage of the design is less bending strength, given this point in the manufacture it is necessary to provide the belt stiffness, i.e., sections without perforations.

Necessary tools and materialsFor the manufacture of the device will be needed pipe, the same as in the first case as well:

As in the first case, on top of the pipe, you must use a metal grid. As practice shows, the best option is brass mesh lace weaving.

Before you lay the pipe grid must spirally wound on her stainless steel wire pitch of about 20 mm. every half-meter along the length of the pipe, the wire must be soldered to provide maximum rigidity.

The photo — ready filter with a fine mesh of plastic pipe

This homemade filter for well durability and excellent throughput. At the same time, the cost of its production will be significantly lower than the price of the finished product.

Tip!

The mesh can be soldered to the wire that will allow you to obtain a solid construction.Sand filter construction ofThis filtration system is the most simple in manufacture and also efficiently cope with the task. To build such a structure in small and clogged.

Work is performed in the following order:

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor in recovery — EN

Conclusion

The wells of the filter is advisable to perform yourself. You do not need a lot of time and effort. The only thing you should keep in mind that this work is very responsible, and to do it must be strictly in accordance with the above technology. published

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: kolodec.guru/scvazhiny/filtraciya/104-filtr-dlya-skvazhiny-svoimi-rukami

Filter well is the bottom element of the casing, which is also called work area. Its main task is to prevent the ingress of large particles of soil inside the structure and the provision of clean water, free access to the column. In addition, it additionally protects the walls from crumbling and caving of the barrel.

Perforated pipe filter

Most often used well filters two types:

- Perforated;

- Slotted.

The scheme of the device well

Perforated filters perforatedthe Most common water purification system from the well – perforated. It is a conventional perforated pipe covered with mesh, so making a filter for wells with their hands is not a big deal.In addition, this device has excellent performance properties.

So, if you are going to do a filter on the well with your hands, then you can stay on this design. The main advantage of this system is low cost. To use a structure in different species, most often it is used in the artesian wells, which have a fragile aquifer and a small head.

The design consists of several parts:

- The filter;

- Nadterechnogo of the site;

- Sump, in which accumulates large particles of soil (located at the bottom of the barrel).

Plastic filter

Necessary tools and materialsFor the manufacture of the device will need:

- Steel pipe of the required diameter. You can also use plastic pipe, but need to pay attention to, it was made of a material that can be used for food purposes.

- Will also need a drill of the required diameter. The size of the holes selected in accordance with the granulometric composition of the soil.

- The power drill.

- The mesh of the filter.

Options mesh netting

Tip!

Choose the size of the mesh openings by sifting sand from the aquifer.

Use the grid, which transmits about 50 percent sand.Fabricationinstructions for manufacture of the device as follows:

- Is primarily measured by the length of the sump.

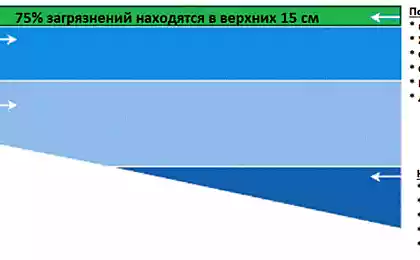

- The tube is then placed on a smooth horizontal surface, whereupon it is applied to the markup. Note that the perforated area, according to the technology, should be about 25 percent of the total length.

- The next step is the production of holes. From the edge should fall at least a meter. The interval between the holes should be 1-2 cm, it is Desirable to drill at an angle of 30-60 degrees in the direction from the bottom up.

- After work need to clean up all sharp edges and carefully headed hammer, tap the product that it has no metal shavings.

- Lower part of the tube are preferably closed with a wooden cork.

- To protect the holes from clogging, the pipe is wrapped in the mesh of the filter wells.

Slotted plastic filters

Gap-type filtersFilters plane type is usually used in breeds that are prone to collapse.Their design is preferred because it has more capacity. On the surface of such products do not exist "blind" areas, and the area of the slit is much greater than the area of the hole.

The main disadvantage of the design is less bending strength, given this point in the manufacture it is necessary to provide the belt stiffness, i.e., sections without perforations.

Necessary tools and materialsFor the manufacture of the device will be needed pipe, the same as in the first case as well:

- Cutting torch;

- Wire diameter of 3 mm;

- Mesh.

As in the first case, on top of the pipe, you must use a metal grid. As practice shows, the best option is brass mesh lace weaving.

Before you lay the pipe grid must spirally wound on her stainless steel wire pitch of about 20 mm. every half-meter along the length of the pipe, the wire must be soldered to provide maximum rigidity.

The photo — ready filter with a fine mesh of plastic pipe

This homemade filter for well durability and excellent throughput. At the same time, the cost of its production will be significantly lower than the price of the finished product.

Tip!

The mesh can be soldered to the wire that will allow you to obtain a solid construction.Sand filter construction ofThis filtration system is the most simple in manufacture and also efficiently cope with the task. To build such a structure in small and clogged.

Work is performed in the following order:

- The hole for the well is drilled somewhat larger diameter than you need.

- Carefully chosen and calibrated the gravel fraction should be approximately the same size. The average size of rock particles must be less than fractions of 5-10 times.

- Then the borehole is filled with gravel from the mouth. The thickness of the covering should be about 50 mm.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor in recovery — EN

Conclusion

The wells of the filter is advisable to perform yourself. You do not need a lot of time and effort. The only thing you should keep in mind that this work is very responsible, and to do it must be strictly in accordance with the above technology. published

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: kolodec.guru/scvazhiny/filtraciya/104-filtr-dlya-skvazhiny-svoimi-rukami

What to cook from physalis -7 interesting recipes

How to make a mini garden from the mirrors on the fridge