531

A simple way of obtaining high quality graphene: 2 seconds in the microwave

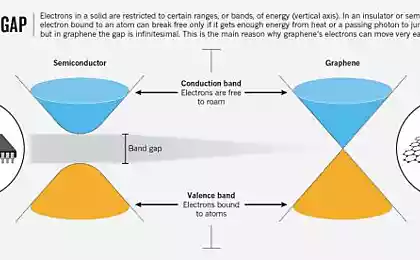

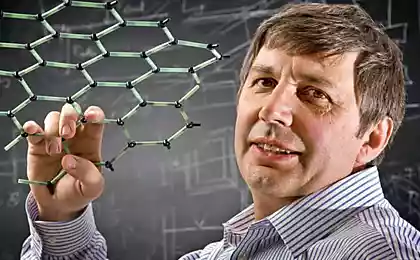

Graphene — 2D carbon modification formed by a layer with a thickness of one carbon atom. The material has high strength, high conductivity and unique physico-chemical properties. It shows a maximum electron mobility among all known materials on Earth. It almost makes graphene an ideal material for the most diverse applications, including in electronics, catalysts, batteries, composite materials, etc. the Case for small — to learn how to obtain high-quality layers of graphene on an industrial scale.

Chemists from Rutgers University (USA) found a simple and quick method of production of high quality graphene by treatment of graphene oxide in a conventional microwave oven. The method is surprisingly primitive and effective.

The graphite oxide — a compound of carbon, hydrogen and oxygen, in different proportions, which is formed during the processing of graphite with strong oxidizing agents. To get rid of the remaining oxygen in the graphite oxide, and then get a clean two-dimensional graphene sheets, it is necessary to make considerable efforts.

The graphite oxide is mixed with a strong alkali and further restore the material. The result is a monomolecular sheets with the remnants of oxygen. These sheets are called graphene oxide (GO). Chemists have tried different ways of removing excess oxygen from GO, but restored such methods GO (rGO) is a highly disordered material that is remote in its properties from this pure graphene, obtained by chemical deposition from the gas phase (CVD or HALL).

Even in the form of disordered rGO could potentially be useful for energy and catalysts, but to derive maximum benefit from the unique properties of graphene in electronics you need to learn how to obtain clean high quality graphene from GO.

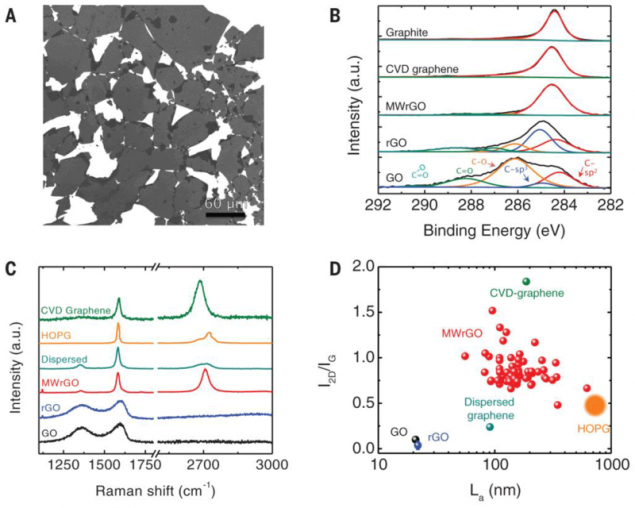

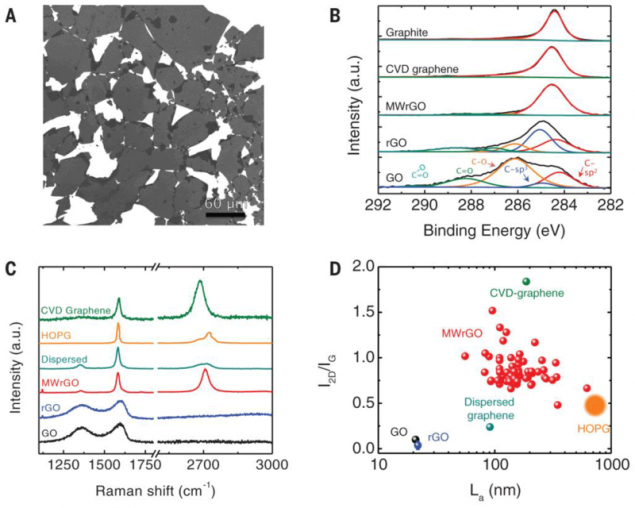

Chemists from Rutgers University offer the simplest and quickest method restore GO to pure graphene using 1-2 second pulse of microwave radiation. As can be seen in the graphs, graphene obtained "microwave recovery" (MW-rGO) has properties much closer to pure graphene, obtained using HALL.

Physical characteristics MW-rGO, compared with pristine graphene oxide GO, restored by graphene oxide rGO and graphene obtained by chemical vapor deposition (CVD). Shows a typical the GO flakes deposited on a silicon substrate (A); x-ray photoelectron spectroscopy (B); Raman spectroscopy © and the ratio of crystal size (La) of the ratio of peaks l2D/lG in the Raman spectrum for MW-rGO, GO and HALL (CVD). Illustration: Rutgers University

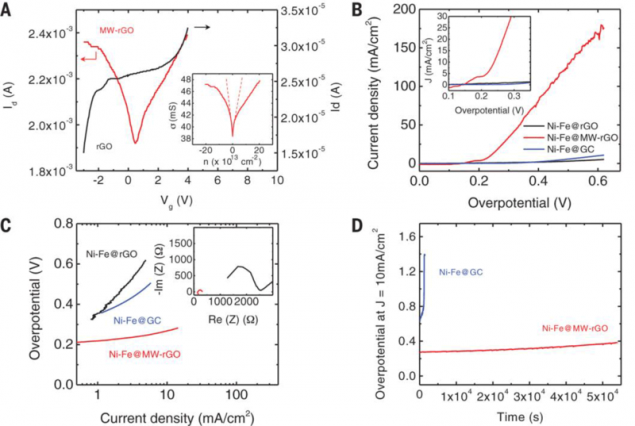

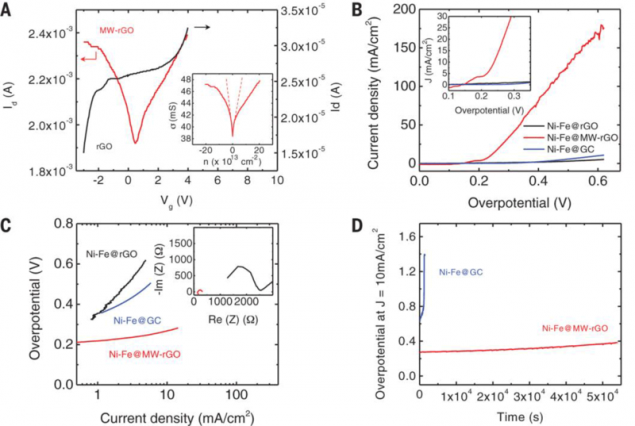

Electronic and electrocatalytic properties of MW-rGO compared to rGO. Illustration: Rutgers University

The process of obtaining MW-rGO consists of several stages.

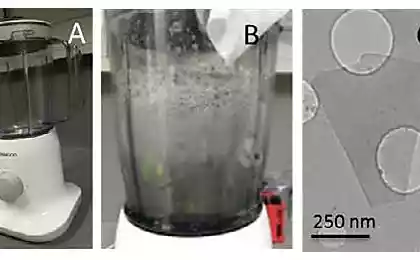

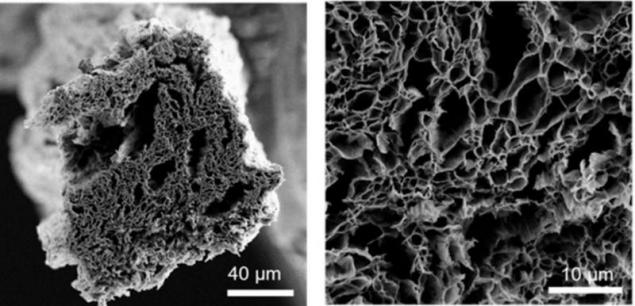

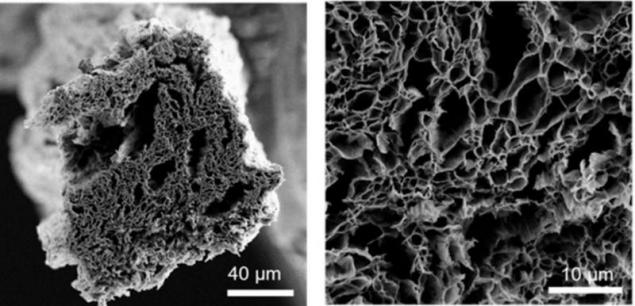

The oxidation of graphite modified method of Hummers and dissolving it to a single-layer flakes of graphene oxide in water. Annealing GO to the material was more susceptible to microwave irradiation. Irradiation of the GO flakes in a conventional microwave oven with a power of 1000 W for 1-2 seconds. During this procedure, the GO is rapidly heated to a high temperature, the desorption of oxygen groups and the magnificent structure of the carbon lattice. Survey transmission electron microscope shows that after treatment, the microwave emitter is formed of the highly organized structure in which oxygen functional groups are almost completely destroyed.

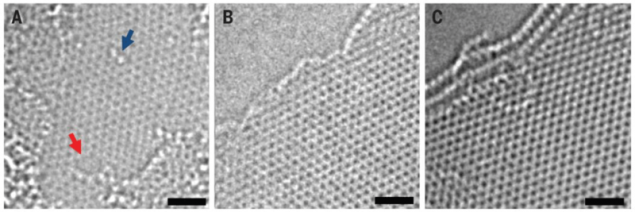

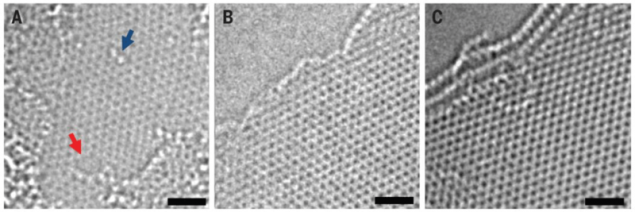

On images with a transmission electron microscope shows the structure of the graphene sheets with a scale of 1 nm. Left — single-layer rGO, in which many defects, including functional groups of oxygen (blue arrow) and holes in the carbon layer (red arrow). Center and right — well-structured two-layer and three-layer MW-rGO. Photo: Rutgers University

Great structural properties MW-rGO when used in field-effect transistors permit to increase the maximum electron mobility of about 1500 cm2/V·s, which is comparable with the outstanding features of modern transistors with high electron mobility.

In addition to electronics, MW-rGO useful in the manufacture of catalysts: it showed the exceptionally small value of the coefficient of Tafel when using as a catalyst the reaction of oxygen: about 38 mV per decade. Catalyst MW-rGO has also maintained stability in the reaction of hydrogen evolution, which lasted more than 100 hours.

All this implies a great potential to use the restored microwave radiation of graphene in industry. published

Source: geektimes.ru/post/280030/

Chemists from Rutgers University (USA) found a simple and quick method of production of high quality graphene by treatment of graphene oxide in a conventional microwave oven. The method is surprisingly primitive and effective.

The graphite oxide — a compound of carbon, hydrogen and oxygen, in different proportions, which is formed during the processing of graphite with strong oxidizing agents. To get rid of the remaining oxygen in the graphite oxide, and then get a clean two-dimensional graphene sheets, it is necessary to make considerable efforts.

The graphite oxide is mixed with a strong alkali and further restore the material. The result is a monomolecular sheets with the remnants of oxygen. These sheets are called graphene oxide (GO). Chemists have tried different ways of removing excess oxygen from GO, but restored such methods GO (rGO) is a highly disordered material that is remote in its properties from this pure graphene, obtained by chemical deposition from the gas phase (CVD or HALL).

Even in the form of disordered rGO could potentially be useful for energy and catalysts, but to derive maximum benefit from the unique properties of graphene in electronics you need to learn how to obtain clean high quality graphene from GO.

Chemists from Rutgers University offer the simplest and quickest method restore GO to pure graphene using 1-2 second pulse of microwave radiation. As can be seen in the graphs, graphene obtained "microwave recovery" (MW-rGO) has properties much closer to pure graphene, obtained using HALL.

Physical characteristics MW-rGO, compared with pristine graphene oxide GO, restored by graphene oxide rGO and graphene obtained by chemical vapor deposition (CVD). Shows a typical the GO flakes deposited on a silicon substrate (A); x-ray photoelectron spectroscopy (B); Raman spectroscopy © and the ratio of crystal size (La) of the ratio of peaks l2D/lG in the Raman spectrum for MW-rGO, GO and HALL (CVD). Illustration: Rutgers University

Electronic and electrocatalytic properties of MW-rGO compared to rGO. Illustration: Rutgers University

The process of obtaining MW-rGO consists of several stages.

The oxidation of graphite modified method of Hummers and dissolving it to a single-layer flakes of graphene oxide in water. Annealing GO to the material was more susceptible to microwave irradiation. Irradiation of the GO flakes in a conventional microwave oven with a power of 1000 W for 1-2 seconds. During this procedure, the GO is rapidly heated to a high temperature, the desorption of oxygen groups and the magnificent structure of the carbon lattice. Survey transmission electron microscope shows that after treatment, the microwave emitter is formed of the highly organized structure in which oxygen functional groups are almost completely destroyed.

On images with a transmission electron microscope shows the structure of the graphene sheets with a scale of 1 nm. Left — single-layer rGO, in which many defects, including functional groups of oxygen (blue arrow) and holes in the carbon layer (red arrow). Center and right — well-structured two-layer and three-layer MW-rGO. Photo: Rutgers University

Great structural properties MW-rGO when used in field-effect transistors permit to increase the maximum electron mobility of about 1500 cm2/V·s, which is comparable with the outstanding features of modern transistors with high electron mobility.

In addition to electronics, MW-rGO useful in the manufacture of catalysts: it showed the exceptionally small value of the coefficient of Tafel when using as a catalyst the reaction of oxygen: about 38 mV per decade. Catalyst MW-rGO has also maintained stability in the reaction of hydrogen evolution, which lasted more than 100 hours.

All this implies a great potential to use the restored microwave radiation of graphene in industry. published

Source: geektimes.ru/post/280030/