2230

Graphene can be obtained using a blender kitchen and dishwashing liquid

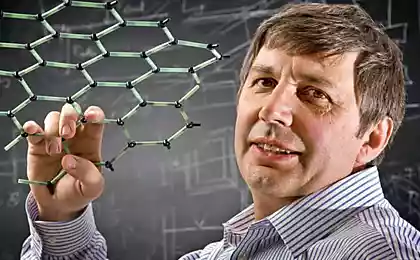

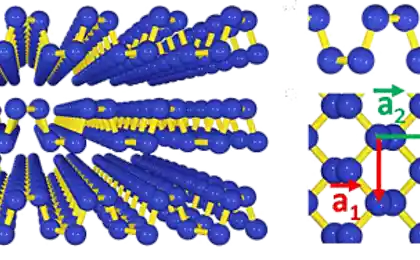

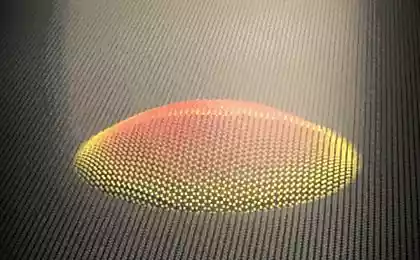

Despite the fact that the problem of obtaining graphene on an industrial scale has not yet been solved, laboratory methods for its production are sometimes extremely simple and accessible. The classic version - mechanical cleavage of graphite grains with a conventional adhesive tape, described in Konstantin Novoselov and colleagues in 2004. With this work actually began the modern era of mass properties of graphene research and Novoselov and his colleague Andre Geim for graphene research received the Nobel Prize in Physics in 2010.

Unfortunately, the method of mechanical splitting practically does not scale - after repeated delamination have to look for tiny length of the order of a micron, and almost transparent crystals with a microscope. Developed several methods for chemical-mechanical delamination graphene using ultrasound, solvents and surfactants. Using these techniques, a suspension of graphene flakes in water or solvent - the method is quite useful in the laboratory, but as mechanical cleavage, it's not very good scalability.

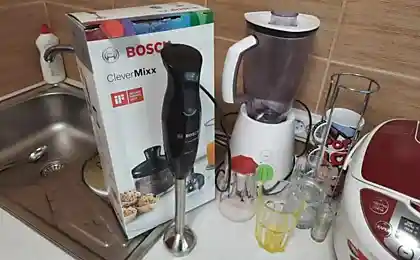

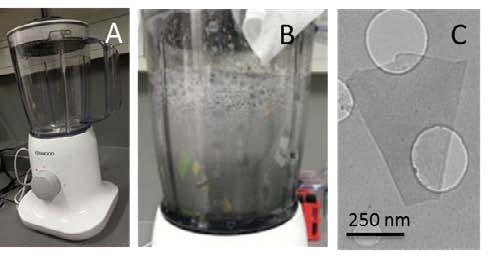

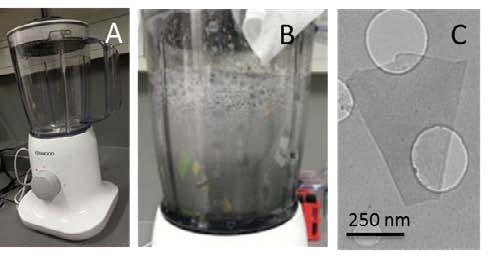

In the April issue of the journal Nature materials опубликовано research team of scientists from the UK and Ireland, have developed a very simple and at the same time having good prospects for scaling method for producing graphene. It turns out that tiny flakes of graphene can be prepared by treating graphite slurry mixer with a fairly high turnover. In their work, scientists mainly used laboratory mixer L5M company Silverson and specially selected reagents, but they tried their method and conventional kitchen blender Kenwood BL370 and dishwashing liquid Fairy as a surfactant, not giving graphene flakes stick together. The results were quite comparable.

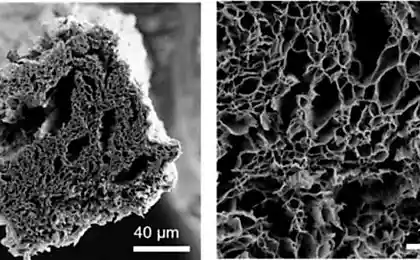

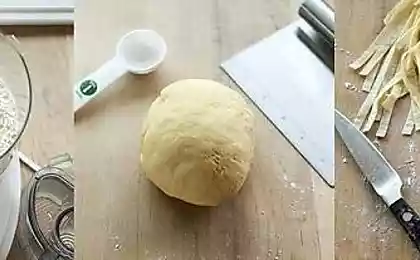

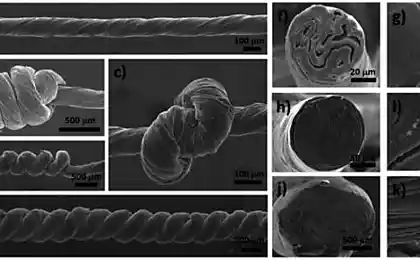

Blender, the process of "beating" of graphene and graphene flakes one under a microscope i>

The only device that is hard to find in every kitchen, and you want to separate the graphene flakes from the remaining decomposed grains graphene - a centrifuge. The fact that for all methods of graphene slurry of graphite powder, yield graphene suitable for further use or experimentation rather small - because, in experiments with household blender with graphite concentration in the feed solution 100 mg / ml after 30 minutes' whipping "obtained concentration graphs of order 0, 15 mg \ ml.

Although these figures do not capture the imagination, in comparison with other methods of production of graphene using a mixer is very effective - to get the same amount of graphene spent much less energy than using ultrasound. In addition, this method is highly scalable - in the lab received up to 100 liters of graphene suspension in one go - ultrasonic devices usually work with volumes of several orders of magnitude smaller. Scientists have calculated that industrial plant capable of stirring a solution of 10 cubic meters per hour, can deliver up to 7, 5 kg of graphene.

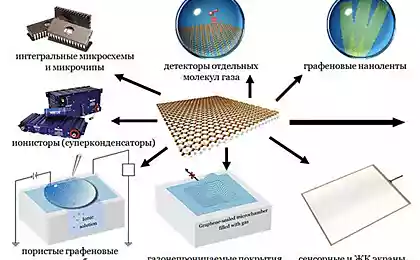

The resulting suspension graphene flakes can be used to create a graphene thin coatings of high electrical and thermal conductivity and also as reinforcing additives significantly improves the mechanical properties of plastics. On the basis of graphene flakes and coatings of them can make solar cells, sensors and supercapacitors.

Although the article on the site Nature is only available on a fee basis, where you can download a very detailed and informative supplementary material ( PDF , 4, 3 MB) with a detailed description of all the experiments and comparing the new method for producing graphene existing.

Source: habrahabr.ru/post/220273/

Unfortunately, the method of mechanical splitting practically does not scale - after repeated delamination have to look for tiny length of the order of a micron, and almost transparent crystals with a microscope. Developed several methods for chemical-mechanical delamination graphene using ultrasound, solvents and surfactants. Using these techniques, a suspension of graphene flakes in water or solvent - the method is quite useful in the laboratory, but as mechanical cleavage, it's not very good scalability.

In the April issue of the journal Nature materials опубликовано research team of scientists from the UK and Ireland, have developed a very simple and at the same time having good prospects for scaling method for producing graphene. It turns out that tiny flakes of graphene can be prepared by treating graphite slurry mixer with a fairly high turnover. In their work, scientists mainly used laboratory mixer L5M company Silverson and specially selected reagents, but they tried their method and conventional kitchen blender Kenwood BL370 and dishwashing liquid Fairy as a surfactant, not giving graphene flakes stick together. The results were quite comparable.

Blender, the process of "beating" of graphene and graphene flakes one under a microscope i>

The only device that is hard to find in every kitchen, and you want to separate the graphene flakes from the remaining decomposed grains graphene - a centrifuge. The fact that for all methods of graphene slurry of graphite powder, yield graphene suitable for further use or experimentation rather small - because, in experiments with household blender with graphite concentration in the feed solution 100 mg / ml after 30 minutes' whipping "obtained concentration graphs of order 0, 15 mg \ ml.

Although these figures do not capture the imagination, in comparison with other methods of production of graphene using a mixer is very effective - to get the same amount of graphene spent much less energy than using ultrasound. In addition, this method is highly scalable - in the lab received up to 100 liters of graphene suspension in one go - ultrasonic devices usually work with volumes of several orders of magnitude smaller. Scientists have calculated that industrial plant capable of stirring a solution of 10 cubic meters per hour, can deliver up to 7, 5 kg of graphene.

The resulting suspension graphene flakes can be used to create a graphene thin coatings of high electrical and thermal conductivity and also as reinforcing additives significantly improves the mechanical properties of plastics. On the basis of graphene flakes and coatings of them can make solar cells, sensors and supercapacitors.

Although the article on the site Nature is only available on a fee basis, where you can download a very detailed and informative supplementary material ( PDF , 4, 3 MB) with a detailed description of all the experiments and comparing the new method for producing graphene existing.

Source: habrahabr.ru/post/220273/