1649

Graphene learned to make flexible and strong thread

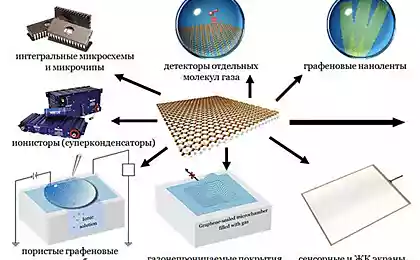

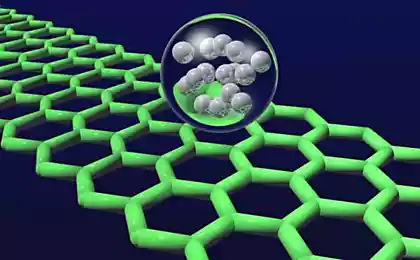

Although graphene itself is very durable material, use this strength at the macro level is not easy. Although there are options for using the mechanical properties of graphene in the form of flakes in the bulk material, which makes it durable, playing the role of "reinforcement", looks much more interesting prospect of manufacturing graphene fibers and yarns from which it will be possible to do heavy-duty fabric or rope, having, besides same electrically conductive properties.

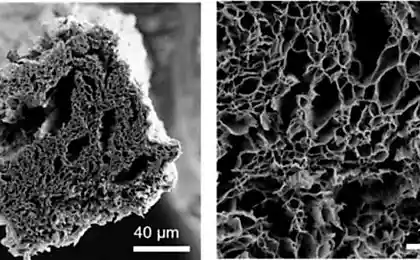

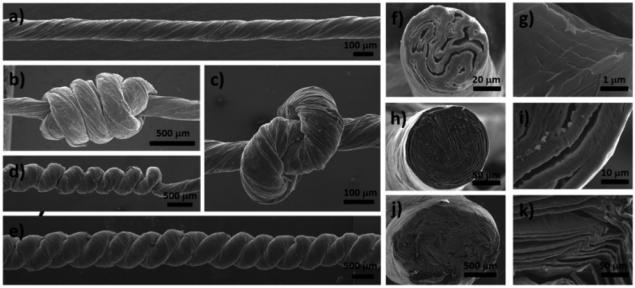

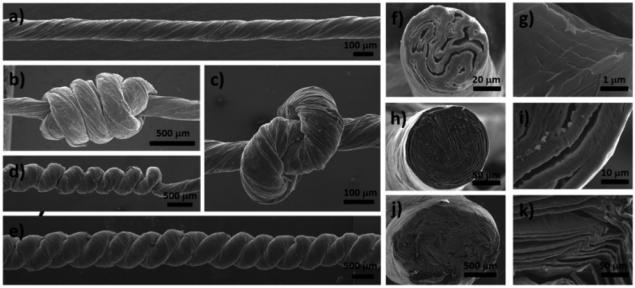

Scientists from the University of Pennsylvania and the University of Shinshu in Japan managed to make graphene oxide thread comparable in strength with Kevlar, and it is very flexible and elastic, with a smooth surface and a regular internal strukutroy. Such filaments can easily twist and knit them nodes - a unique result, because all previous attempts allowed, though strong, but rigid and brittle fibers. After annealing, in which graphene oxide loses oxygen and pervraschaetsya in pure graphite, the thread becomes more brittle, but acquire a high electrical conductivity.

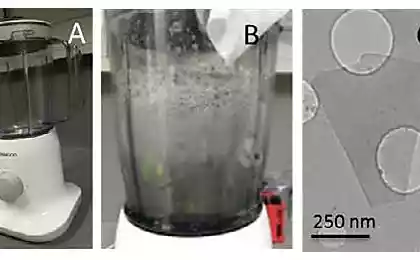

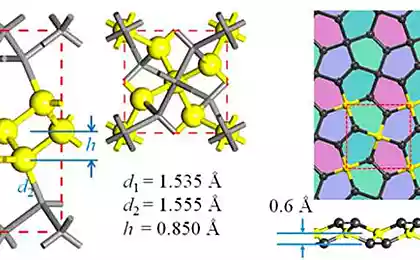

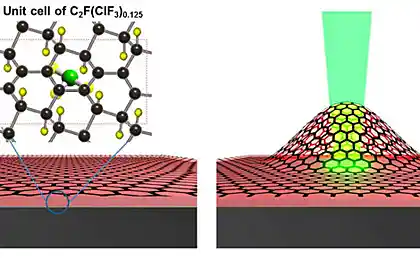

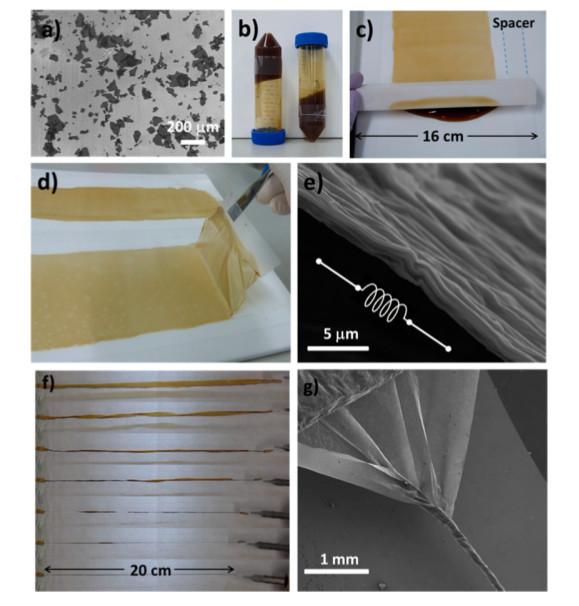

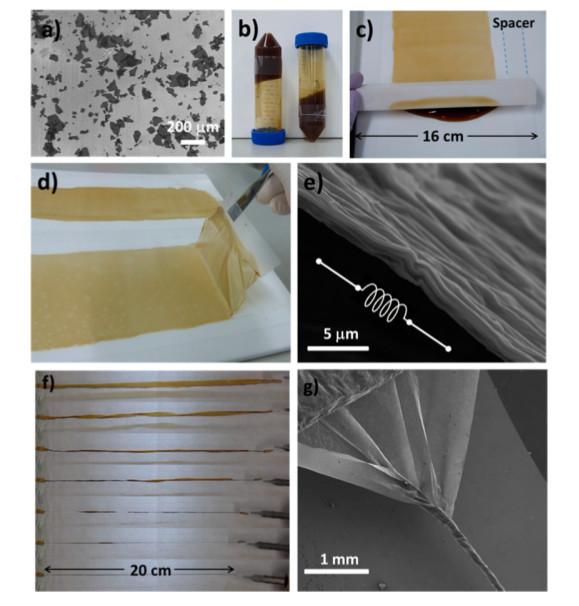

Technology for manufacturing yarns is quite simple. Flakes of graphene oxide slurry is poured onto a Teflon plate and is smoothed to a uniform thickness with a Teflon bar and two strips of adhesive tape around the edges, which define the thickness of the layer. Then a layer of the slurry dries out and in its place a thin (2, 9 micron) film of adherent scales. Long strips of such a film is then twisted into yarn thickness from hundreds of micrometers to one and a half millimeters. The key point of this technology - is twisted into yarn completely dry film, whereas in previous attempts to twist occurred when the film has not yet dried. The fact that the dried without tension film has many fine lines that remain in the thickness of thread after twisting and play the role of "springs", making elastic thread.

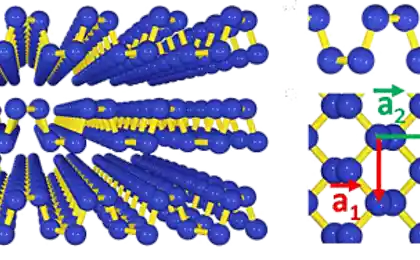

In the original graphene suspension can add various additives that alter the properties of the filaments, such as nylon fiber, yarn dealyuschie softer and more flexible, or silver nanowires, which significantly increase the electrical conductivity of the filaments. After annealing at high temperature conductivity of a graphene doped with silver thread is comparable with copper wire, thread only much lighter and stronger.

Article describing technology and properties of the yarns is published in the May issue of the journal ACSNano.

Source: habrahabr.ru/post/228189/

Scientists from the University of Pennsylvania and the University of Shinshu in Japan managed to make graphene oxide thread comparable in strength with Kevlar, and it is very flexible and elastic, with a smooth surface and a regular internal strukutroy. Such filaments can easily twist and knit them nodes - a unique result, because all previous attempts allowed, though strong, but rigid and brittle fibers. After annealing, in which graphene oxide loses oxygen and pervraschaetsya in pure graphite, the thread becomes more brittle, but acquire a high electrical conductivity.

Technology for manufacturing yarns is quite simple. Flakes of graphene oxide slurry is poured onto a Teflon plate and is smoothed to a uniform thickness with a Teflon bar and two strips of adhesive tape around the edges, which define the thickness of the layer. Then a layer of the slurry dries out and in its place a thin (2, 9 micron) film of adherent scales. Long strips of such a film is then twisted into yarn thickness from hundreds of micrometers to one and a half millimeters. The key point of this technology - is twisted into yarn completely dry film, whereas in previous attempts to twist occurred when the film has not yet dried. The fact that the dried without tension film has many fine lines that remain in the thickness of thread after twisting and play the role of "springs", making elastic thread.

In the original graphene suspension can add various additives that alter the properties of the filaments, such as nylon fiber, yarn dealyuschie softer and more flexible, or silver nanowires, which significantly increase the electrical conductivity of the filaments. After annealing at high temperature conductivity of a graphene doped with silver thread is comparable with copper wire, thread only much lighter and stronger.

Article describing technology and properties of the yarns is published in the May issue of the journal ACSNano.

Source: habrahabr.ru/post/228189/