430

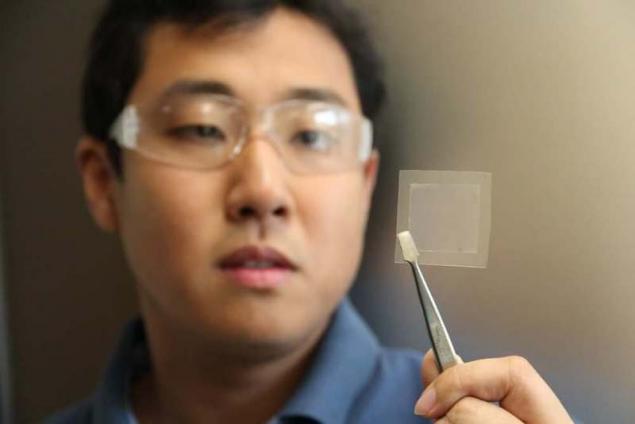

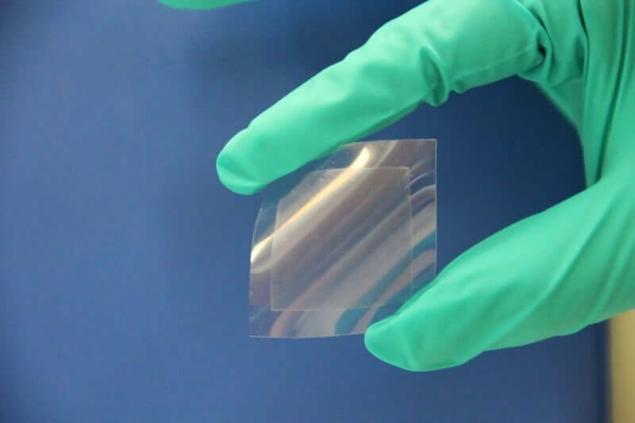

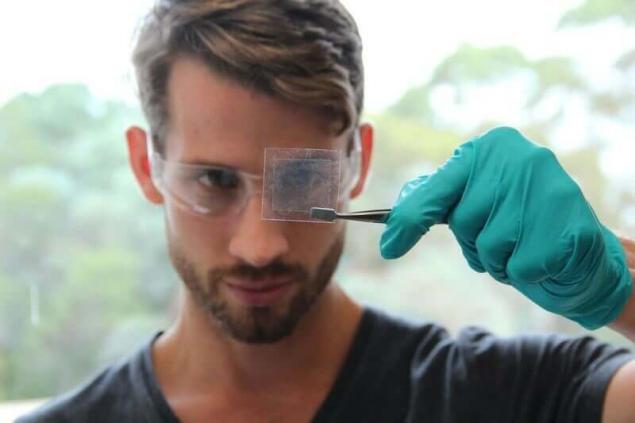

Scientists have turned soybean oil into graphene

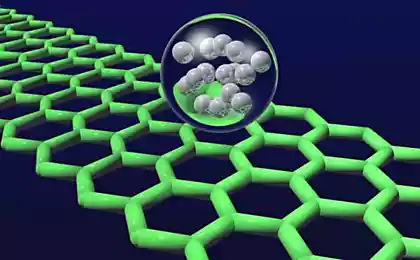

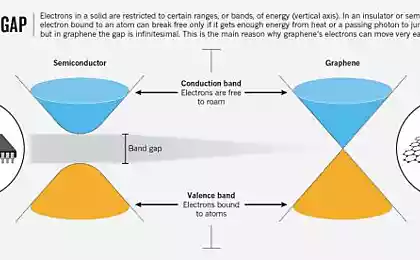

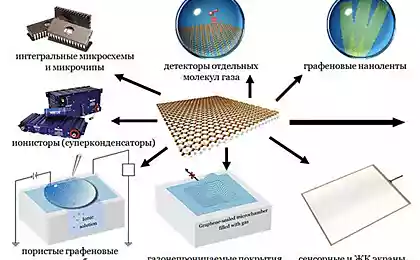

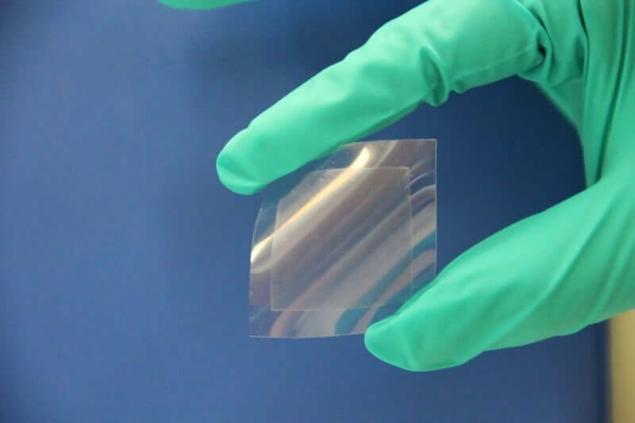

Graphene is very thin and promising material, but the creation of this magnificent material expensive costs, and therefore the objects constructed with it can have an incredibly high cost that can wipe out all the plans of scientists, doctors and engineers. Researchers from CSIRO in Australia have found a method of obtaining graphene without exotic gases, high cost, and quickly.

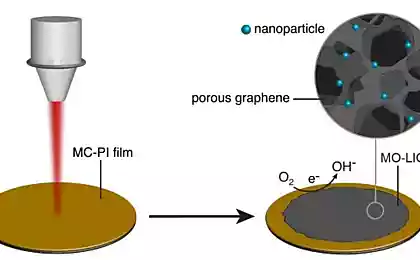

Scientists have used the technology GraphAir for growing graphene without explosive gases, like methane or hydrogen, instead they used regular soy oil, which also avoids vacuum processing and high temperature furnaces.

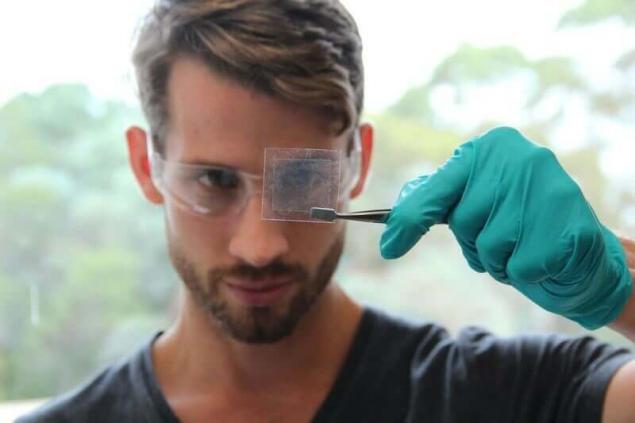

"The process of obtaining graphene is a quick, easy, secure, potentially scalable, and integrated," said the scientist Zhao Jun Han: "Our unique technology is expected to reduce the cost of graphene production, and will allow to more effectively use it in new applications".

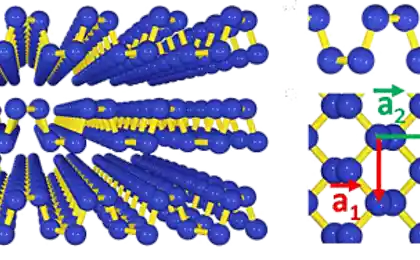

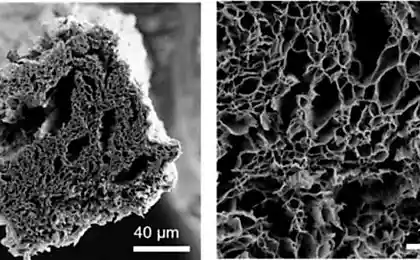

To grow graphene using the technology GraphAir, the scientists used a catalyst made from inexpensive polycrystalline Nickel. All production takes place in sealed quartz tube where soybean oil is heated to a temperature of 800 degrees Celsius for approximately 26 minutes, after which it breaks down into carbon elements, which are necessary for the synthesis of graphene, after which the temperature is maintained for a few minutes. Since in the quartz tube restricted the flow of air, there is not produced any gases, and that helps to safely create strong graphene.

"Now we can recycle waste oils that otherwise would be thrown away, to turn them into something useful," says Dr. SEO. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: ecotechnology

Scientists have used the technology GraphAir for growing graphene without explosive gases, like methane or hydrogen, instead they used regular soy oil, which also avoids vacuum processing and high temperature furnaces.

"The process of obtaining graphene is a quick, easy, secure, potentially scalable, and integrated," said the scientist Zhao Jun Han: "Our unique technology is expected to reduce the cost of graphene production, and will allow to more effectively use it in new applications".

To grow graphene using the technology GraphAir, the scientists used a catalyst made from inexpensive polycrystalline Nickel. All production takes place in sealed quartz tube where soybean oil is heated to a temperature of 800 degrees Celsius for approximately 26 minutes, after which it breaks down into carbon elements, which are necessary for the synthesis of graphene, after which the temperature is maintained for a few minutes. Since in the quartz tube restricted the flow of air, there is not produced any gases, and that helps to safely create strong graphene.

"Now we can recycle waste oils that otherwise would be thrown away, to turn them into something useful," says Dr. SEO. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: ecotechnology

Physics accidentally cheapen the process of production of graphene

Running the world's most powerful substation in lithium-ion batteries