1946

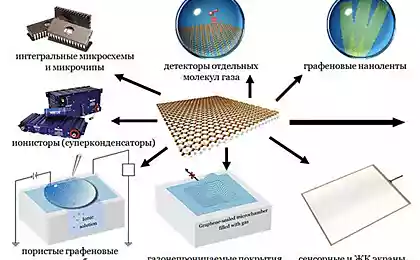

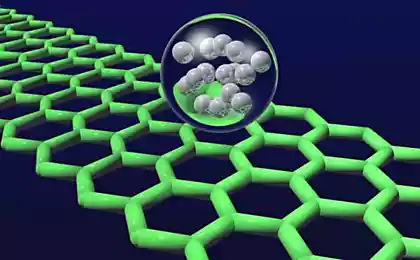

A new application of graphene: high water filters

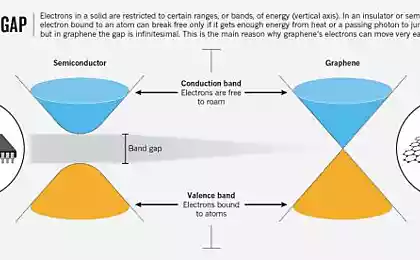

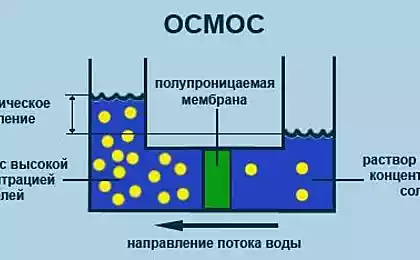

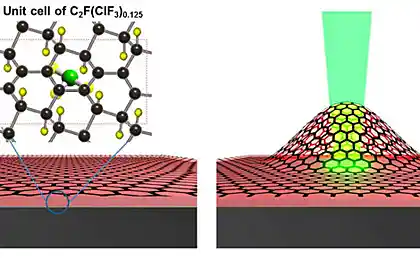

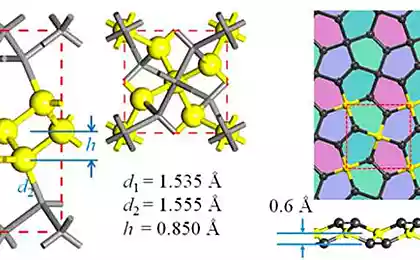

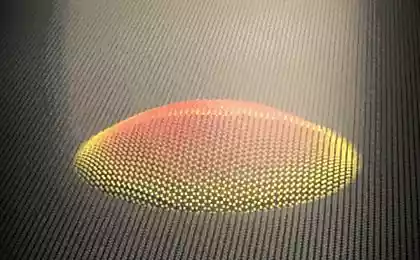

Scientists at the Massachusetts Institute of Technology разработали technology that allows to make holes in sheets of graphene certain diameter. Received a "sieve", depending on the size of the holes can filter particles of various sizes - from ions to large organic molecules. Membrane filters made of traditional materials do have quite thick in order to be strong enough (for reverse osmosis sea water desalination, pressure may reach up to 70 atmospheres). Graphene is ten times stronger than the plastic used to make conventional membrane and therefore the membrane can be much thinner and pass water more quickly.

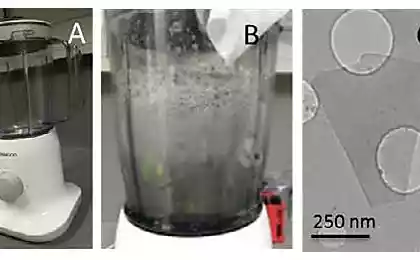

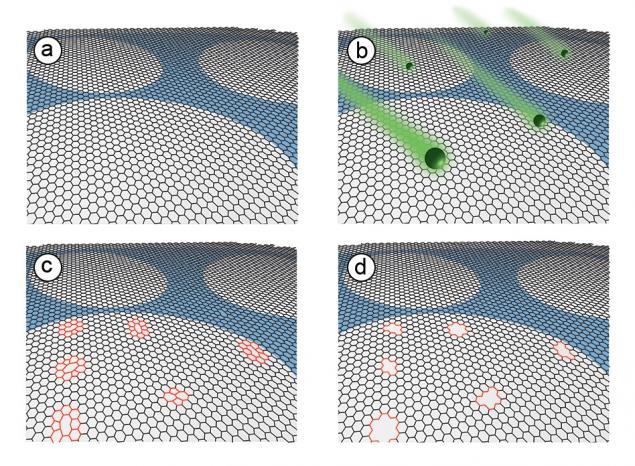

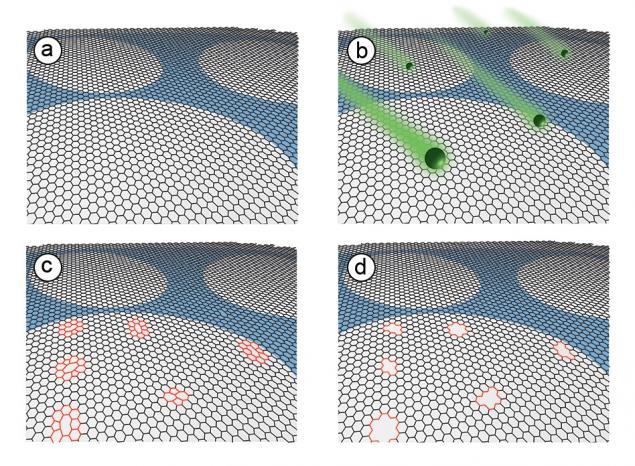

Openings in the graphene sheet do in two stages. First graphene gallium ions bombarded with enough energy to disrupt its structure in a place subject. The membrane was then immersed in an oxidizer which breaks graphene primarily defect locations - holes in the sheet appear approximately the same size. The longer graphene etched, the greater diameter of the holes.

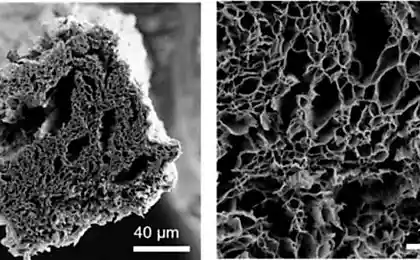

Per square centimeter of graphene for about five trillion of these microscopic pores. With a diameter of the order of one nanometer distance between the pores is four nanometers. Experiments to create pores in graphene by using different particle bombardment carried out before, but until now there was no way to precisely control and vary widely their size.

It is too early to talk about the application of graphene filter on an industrial scale, since there is no technology inexpensive mass production of large sheets of graphene, but the new membrane can now be used in chemical and biological laboratories, small-scale installations. Computer simulation shows that the permeability of graphene filter may be 50 times longer than conventional.

Source: habrahabr.ru/post/214001/

Openings in the graphene sheet do in two stages. First graphene gallium ions bombarded with enough energy to disrupt its structure in a place subject. The membrane was then immersed in an oxidizer which breaks graphene primarily defect locations - holes in the sheet appear approximately the same size. The longer graphene etched, the greater diameter of the holes.

Per square centimeter of graphene for about five trillion of these microscopic pores. With a diameter of the order of one nanometer distance between the pores is four nanometers. Experiments to create pores in graphene by using different particle bombardment carried out before, but until now there was no way to precisely control and vary widely their size.

It is too early to talk about the application of graphene filter on an industrial scale, since there is no technology inexpensive mass production of large sheets of graphene, but the new membrane can now be used in chemical and biological laboratories, small-scale installations. Computer simulation shows that the permeability of graphene filter may be 50 times longer than conventional.

Source: habrahabr.ru/post/214001/

Rolls-Royce plans to build a giant unmanned ships for ocean shipping

21 questions to be asking yourself every Sunday