1469

Supersonic spraying produces high quality grafenovove coverage without post-processing

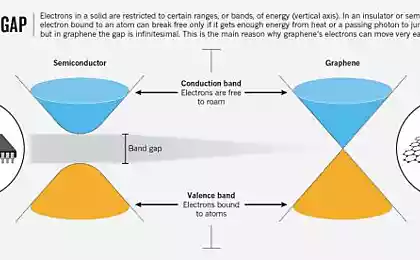

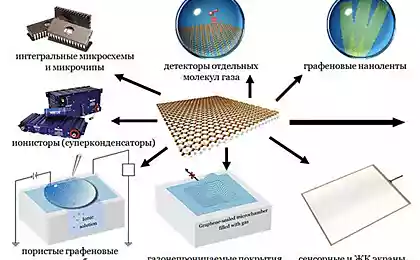

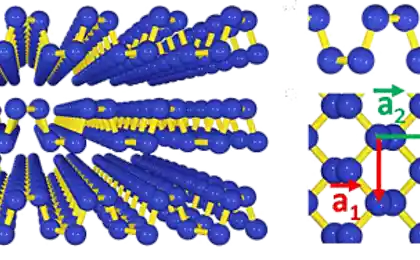

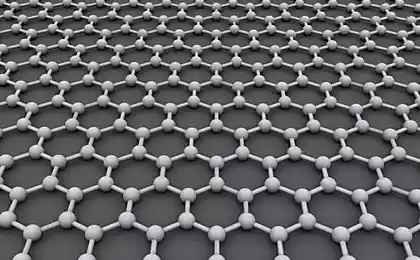

The unique properties of graphene - its electrical and thermal conductivity, and mechanical strength - make it a very promising material for a variety of films and coatings. Two basic approaches to the creation of such coverage, there is today - it's growing crystals of graphene by deposition of carbon atoms of the carbon-containing gas to the substrate and application on the surface of the slurry containing graphene flakes up to several micrometers. The first method allows you to get the perfect single crystals, however, requires high temperatures, perfectly pure ingredients, special substrates. It is applicable especially in microelectronics to generate graphene electronic components.

The second way - much more unpretentious, but instead of a single-crystal graphene on the surface layer is formed from a plurality of overlapping flakes of graphene from a far from ideal structure - for many applications, and this is enough. To improve the quality of the coatings are used in many ways - a joke, plasma or chemical treatment. Scientists from the University of Illinois at Chicago, together with colleagues from South Korea разработали simple and highly scalable variant of the second method for producing graphene coating without any post-processing.

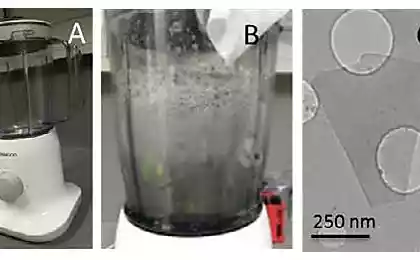

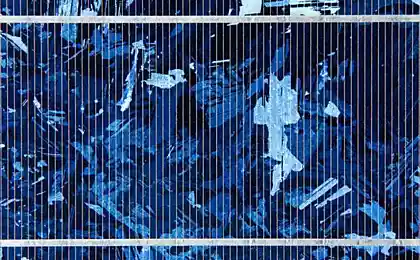

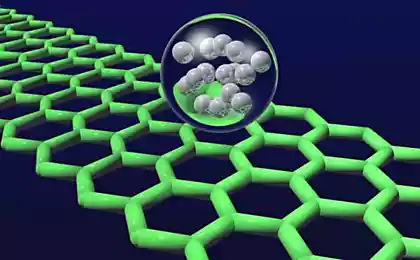

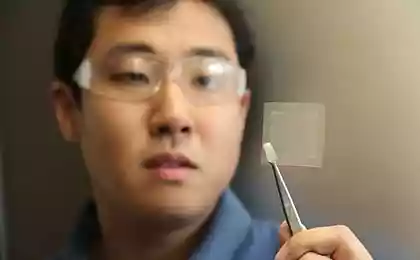

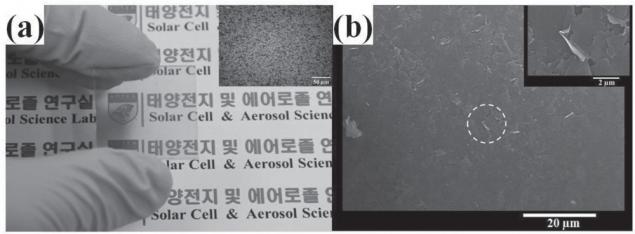

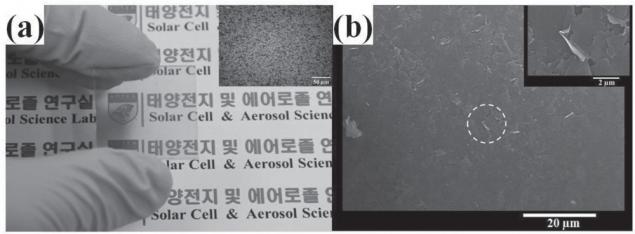

The glass plate coated with graphene and its surface under an electron microscope i>

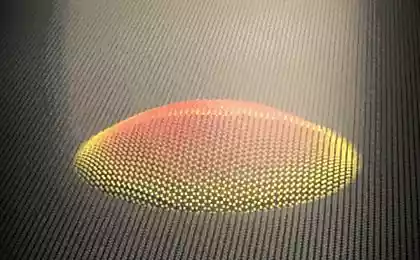

Their method consists in that a slurry containing flakes of graphene oxide is sprayed onto the product through сопла Laval . This kind of a nozzle widely used in rocket engines and jet and allows to achieve supersonic gas flow skorosety. With this suspension is sprayed into tiny droplets, allowing separate individual scales and apply them very evenly. At subsonic speeds often flakes fall onto the surface in the form of agglomerated lumps. In addition, the tiny droplets, blown by supersonic flow dries almost instantly.

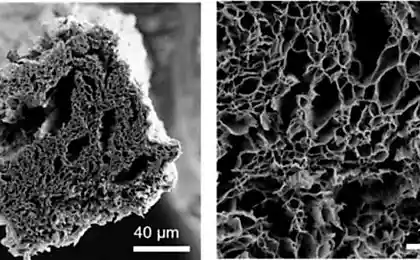

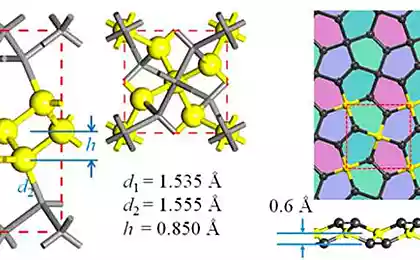

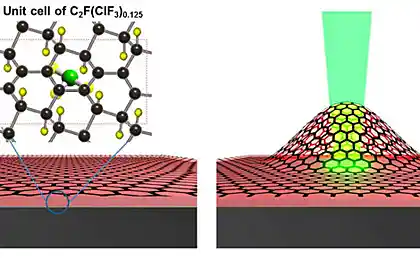

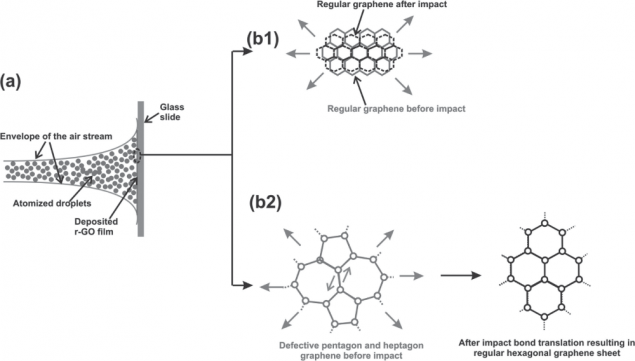

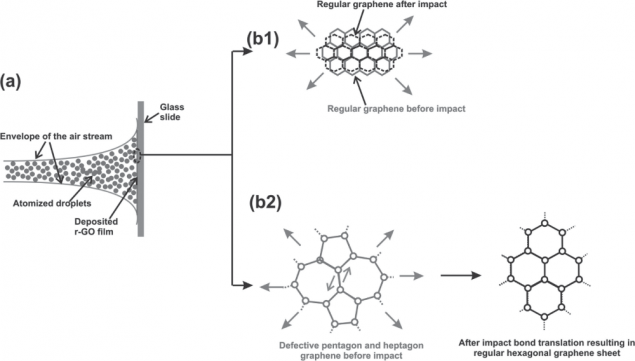

Another advantage - the kinetic energy that hits the surface of graphene products, is sufficient to scales not just stuck to it, but smoothed, "healed" with many structural defects. Graphene at supersonic speeds acquires a certain elasticity, stretched, and the carbon atoms in the defect is the correct way to form perfect hexagonal lattice.

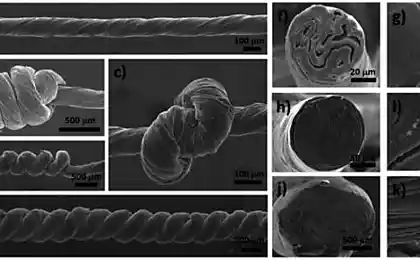

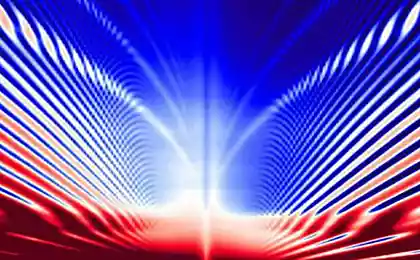

Stretching due to the kinetic energy of the supersonic flow corrects defects in graphene i>

This method is very simple and highly scalable. By varying the slurry concentration of graphene oxide, pressure and gas flow rate can easily control the thickness and quality of the coating. No need for treatment coverage expands the range of materials that can be coated with graphene-coated - can be widely used polymers and plastics that would not survive the post-processing plasma or high temperatures.

Source: habrahabr.ru/post/224611/

The second way - much more unpretentious, but instead of a single-crystal graphene on the surface layer is formed from a plurality of overlapping flakes of graphene from a far from ideal structure - for many applications, and this is enough. To improve the quality of the coatings are used in many ways - a joke, plasma or chemical treatment. Scientists from the University of Illinois at Chicago, together with colleagues from South Korea разработали simple and highly scalable variant of the second method for producing graphene coating without any post-processing.

The glass plate coated with graphene and its surface under an electron microscope i>

Their method consists in that a slurry containing flakes of graphene oxide is sprayed onto the product through сопла Laval . This kind of a nozzle widely used in rocket engines and jet and allows to achieve supersonic gas flow skorosety. With this suspension is sprayed into tiny droplets, allowing separate individual scales and apply them very evenly. At subsonic speeds often flakes fall onto the surface in the form of agglomerated lumps. In addition, the tiny droplets, blown by supersonic flow dries almost instantly.

Another advantage - the kinetic energy that hits the surface of graphene products, is sufficient to scales not just stuck to it, but smoothed, "healed" with many structural defects. Graphene at supersonic speeds acquires a certain elasticity, stretched, and the carbon atoms in the defect is the correct way to form perfect hexagonal lattice.

Stretching due to the kinetic energy of the supersonic flow corrects defects in graphene i>

This method is very simple and highly scalable. By varying the slurry concentration of graphene oxide, pressure and gas flow rate can easily control the thickness and quality of the coating. No need for treatment coverage expands the range of materials that can be coated with graphene-coated - can be widely used polymers and plastics that would not survive the post-processing plasma or high temperatures.

Source: habrahabr.ru/post/224611/

Traps thinking. How to protect your mind from mistakes

Lumo Lift: miniature fitness tracker and "controller" posture