674

How to make a stove for baths from a pipe

To choose the right stove for a bath is very difficult. Because every kind (whether of metal construction, or of brick) has a number of advantages.

But if you need a furnace for a country house, which you too often will use, you may well will cost a piece of metal. Moreover, the stove for baths from a pipe can be manufactured in any other place, and then install directly in the bath.

Metal stove has many significant advantages, among which are high speed heating (about one hour). However it also cools down quickly, for this reason, you will be required to maintain a fire until, until you finish sweating.

This pizza oven is inexpensive, but the estate certain skills it can be easily done on their own.

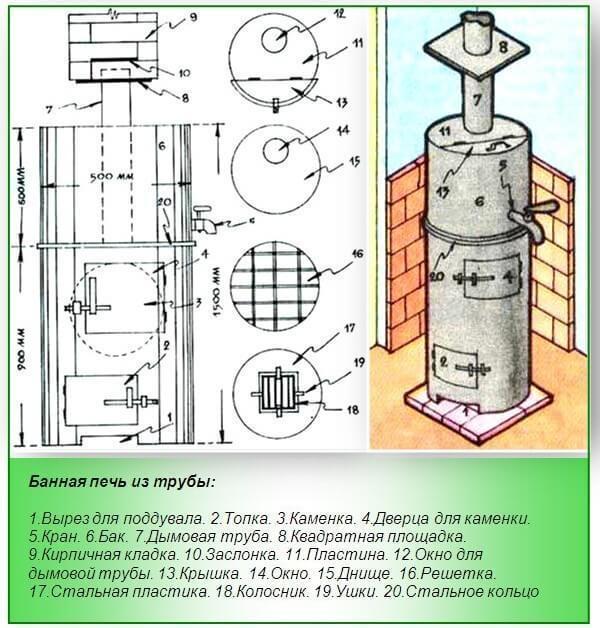

Design featuresToday, there are several options for making an iron stove for baths. For this you can use the side steel or iron barrel, with the placement of the furnace in another building and so on.

But the easiest and most convenient method is to make a stove for baths from a pipe. This is because in the process the use of welding will be minimal.

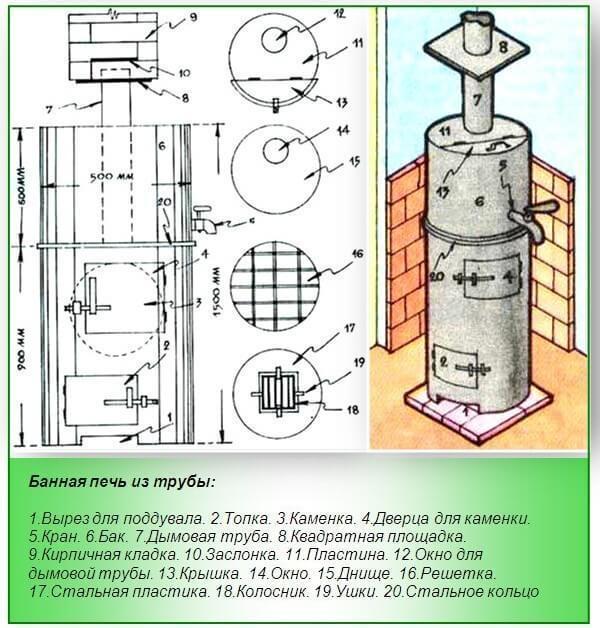

The height of such a furnace is about to make 1.6 meters, and the total diameter is about 0.7 meters.

Fully enclosed heater is to be installed over the furnace and you can get to it is through a special door.

Also there will be a tank of liquid, the temperature which we will adjust by adding cold/hot water in the heater.

The necessary tools for the manufacture of the furnace from the chimneyThat we may need in the manufacture of furnace? Here is a sample list:

The soapstone without any impurities, which we will fill the stove. A steel pipe with an approximate diameter of 0.6 meters and a length of about 1.7 meters. Faucet with hot water. Desyatiballnoy sheet steel. Fireplace. Iron rod. Greetings to you and all that is needed to secure the door. The grate is preferably round. Everything you need can be purchased at almost any hardware store. Regarding the tools, then we need a welder and "Bulgarian".

The preparatory phaseis Most important for oven is the Foundation, which, as you know, must be at distance at least one meter from the wall. For this purpose, even at the stage of laying the Foundation you need to pour a concrete Foundation for furnace, which with a common Foundation should not be contaminated.

The Foundation for the furnace, by the way, not such stringent requirements, because it does not have to be perfectly smooth. When the Foundation has dried (this takes at least a month), we are two rows of stacked brick, wait a few weeks and all our oven ready!

Do the heater for furnace pipeCut iron pipe into two approximately equal parts: one is used for the furnace as well as heater and the other for the heater tank. Don't forget about podduvalom — it is at the bottom of the pipe make a hole in 5 to 20 centimeters. Also weld special mounts, which will hold the grate.

Above the firebox we will have the heater, the bottom of which is made from the same grate.

In the heater must be provided with special holes through which you could pour water on the stones with water. It is desirable that they were on the other side of the door.

On the grate set to a chimney, then you can put the stones.

A reservoir for heating waterTake welding and with it wretham in the bottom half of the metal faucet. After that, we formed a cylinder attached to the heater. It is crucial to obtain a weld of the highest quality, because it needs to be sealed.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/2/9/2pw7yvtu4brn/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

The tank top will be closed with a lid. For this purpose, take a pre-made blank from a sheet of steel with a round shape and cut it into two parts, the proportions of 1 to 2. In the most part should make the hole smaller, suitable for a chimney, then pull the tank and weld. Regarding the lower half, then we attach to the special hinges, fixed to a straight section.

This will be our door. Remember that the door is recommended to make a pen with an overlay of the tree — this will protect us from getting burned in the future (after the tank, as we remember, very fast and very hot).

Make a chimney for stovespart of the chimney, which is beyond the design of the furnace must be protected by a casing made of a sandwich pipe (which, in turn, should be between the layers of metal topoisomerase elements). If possible, the insulation can be done using conventional masonry.

Also recall that iron oven will be quite hot and for this reason, nearby furniture or paneling may not be something that melt, and even ignite. So should pay special attention to fire safety: the surface of furniture and walls should be covered with thin sheets of metal or foil topoisomerase.

But there is best option — need to overlay the surface of stone or brick, because it will look quite attractive, and protection from burns is also reliable.

Some recommendations for the construction of the furnace from the chimney for bath

The door to the furnace should be directed to the door. The portion of pipe that lies between the roof and furnace, needs to be plastered. Above the roof the pipe should be at least 0.5 meters. Actually, our stove for baths from a pipe is ready.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: boldproject.ru/pechi-kotly/pech-dlya-bani-iz-truby.html

But if you need a furnace for a country house, which you too often will use, you may well will cost a piece of metal. Moreover, the stove for baths from a pipe can be manufactured in any other place, and then install directly in the bath.

Metal stove has many significant advantages, among which are high speed heating (about one hour). However it also cools down quickly, for this reason, you will be required to maintain a fire until, until you finish sweating.

This pizza oven is inexpensive, but the estate certain skills it can be easily done on their own.

Design featuresToday, there are several options for making an iron stove for baths. For this you can use the side steel or iron barrel, with the placement of the furnace in another building and so on.

But the easiest and most convenient method is to make a stove for baths from a pipe. This is because in the process the use of welding will be minimal.

The height of such a furnace is about to make 1.6 meters, and the total diameter is about 0.7 meters.

Fully enclosed heater is to be installed over the furnace and you can get to it is through a special door.

Also there will be a tank of liquid, the temperature which we will adjust by adding cold/hot water in the heater.

The necessary tools for the manufacture of the furnace from the chimneyThat we may need in the manufacture of furnace? Here is a sample list:

The soapstone without any impurities, which we will fill the stove. A steel pipe with an approximate diameter of 0.6 meters and a length of about 1.7 meters. Faucet with hot water. Desyatiballnoy sheet steel. Fireplace. Iron rod. Greetings to you and all that is needed to secure the door. The grate is preferably round. Everything you need can be purchased at almost any hardware store. Regarding the tools, then we need a welder and "Bulgarian".

The preparatory phaseis Most important for oven is the Foundation, which, as you know, must be at distance at least one meter from the wall. For this purpose, even at the stage of laying the Foundation you need to pour a concrete Foundation for furnace, which with a common Foundation should not be contaminated.

The Foundation for the furnace, by the way, not such stringent requirements, because it does not have to be perfectly smooth. When the Foundation has dried (this takes at least a month), we are two rows of stacked brick, wait a few weeks and all our oven ready!

Do the heater for furnace pipeCut iron pipe into two approximately equal parts: one is used for the furnace as well as heater and the other for the heater tank. Don't forget about podduvalom — it is at the bottom of the pipe make a hole in 5 to 20 centimeters. Also weld special mounts, which will hold the grate.

Above the firebox we will have the heater, the bottom of which is made from the same grate.

In the heater must be provided with special holes through which you could pour water on the stones with water. It is desirable that they were on the other side of the door.

On the grate set to a chimney, then you can put the stones.

A reservoir for heating waterTake welding and with it wretham in the bottom half of the metal faucet. After that, we formed a cylinder attached to the heater. It is crucial to obtain a weld of the highest quality, because it needs to be sealed.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/2/9/2pw7yvtu4brn/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

The tank top will be closed with a lid. For this purpose, take a pre-made blank from a sheet of steel with a round shape and cut it into two parts, the proportions of 1 to 2. In the most part should make the hole smaller, suitable for a chimney, then pull the tank and weld. Regarding the lower half, then we attach to the special hinges, fixed to a straight section.

This will be our door. Remember that the door is recommended to make a pen with an overlay of the tree — this will protect us from getting burned in the future (after the tank, as we remember, very fast and very hot).

Make a chimney for stovespart of the chimney, which is beyond the design of the furnace must be protected by a casing made of a sandwich pipe (which, in turn, should be between the layers of metal topoisomerase elements). If possible, the insulation can be done using conventional masonry.

Also recall that iron oven will be quite hot and for this reason, nearby furniture or paneling may not be something that melt, and even ignite. So should pay special attention to fire safety: the surface of furniture and walls should be covered with thin sheets of metal or foil topoisomerase.

But there is best option — need to overlay the surface of stone or brick, because it will look quite attractive, and protection from burns is also reliable.

Some recommendations for the construction of the furnace from the chimney for bath

The door to the furnace should be directed to the door. The portion of pipe that lies between the roof and furnace, needs to be plastered. Above the roof the pipe should be at least 0.5 meters. Actually, our stove for baths from a pipe is ready.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: boldproject.ru/pechi-kotly/pech-dlya-bani-iz-truby.html