999

Tour of the mine closure

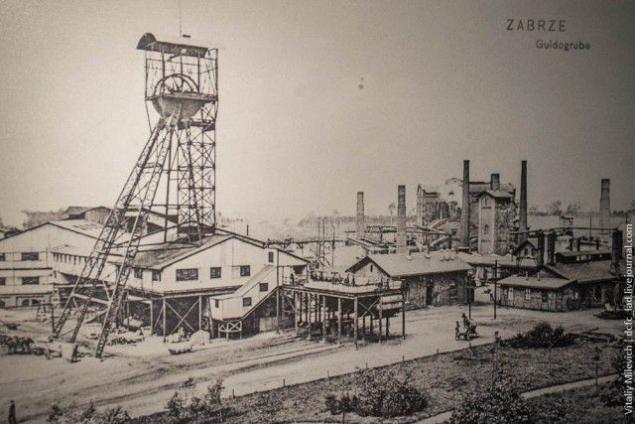

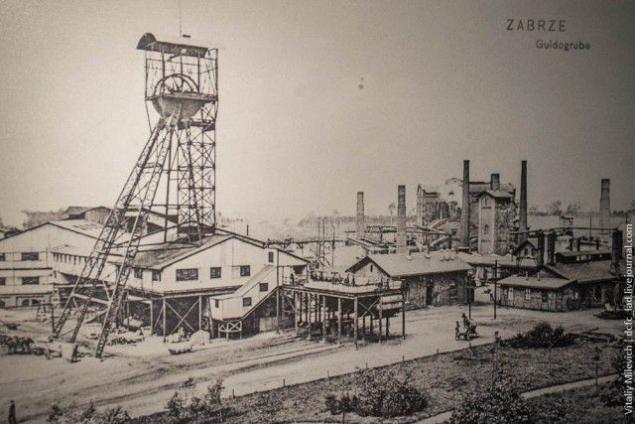

Zabrze - a small town in southern Poland, in Katowice agglomeration. It is an industrial area, where tourists rarely call in. The attractions are almost there, except that a couple of old mansions, yes ruins of several castles one of the largest in Poland concert halls. Well, also near Auschwitz, but it's not for everybody. Mine Guido - the pearl industry in the region.

It turned out that our friend in his spare time, earns a guide here. So we got lucky with an exclusive tour

At the entrance to all give a helmet and flashlight. And it's not just the entourage, they do come in handy. The mine is dark, the ceiling sometimes something fray, can hit his head on the iron structure.

Mine is named after the former owner, Guido Henckel von Donnersmarck. In the second half of the 19th century, this figure belonged to almost all industrial enterprises in the area.

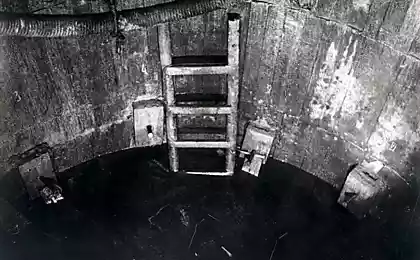

Lifting system. Nearby sits the operator, which controls the descent and raised elevators. The second one is near the cockpit. They do not see each other, so communicate using bells. White arrow indicates where the elevator, which operates at a lower level, right - the one on top.

And here is the elevator. Workers at the mine, he kept his speed at 10 meters per second. Tourists descend slowly - only 4 m / s. With the same speed elevators in high-rise buildings go.

The museum was opened relatively recently, there is always something changes and improves. Downstairs there is a bar and a concert hall. We were in the mine before Easter - alas, it was closed. If you wish, you can even underground marry. At the entrance to the first level - the stables and classical stands with inventory and rescue equipment.

Before the process is mechanized coal mining in the mine worked 80 horses - 40 on each of the levels. Down they rappel, the process takes about 48 hours. Getting into the mine, horses stay here forever. If in real life horses live 25-30 years, under the ground - no more than ten

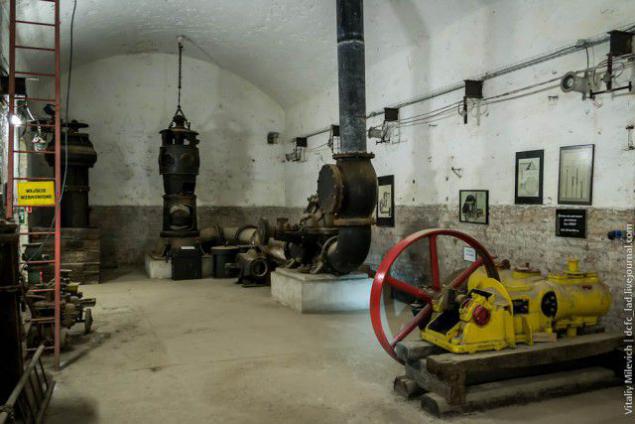

Coal mine Guido stopped back in 1928. But after the miners down the mine in the neighboring. There is also a drainage system, the pumps pumped the water from all the surrounding mines.

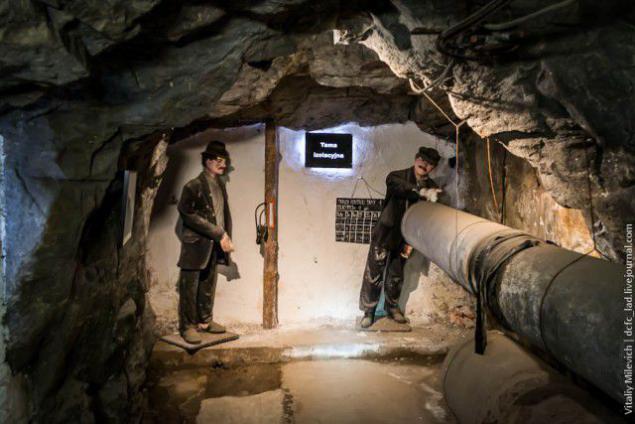

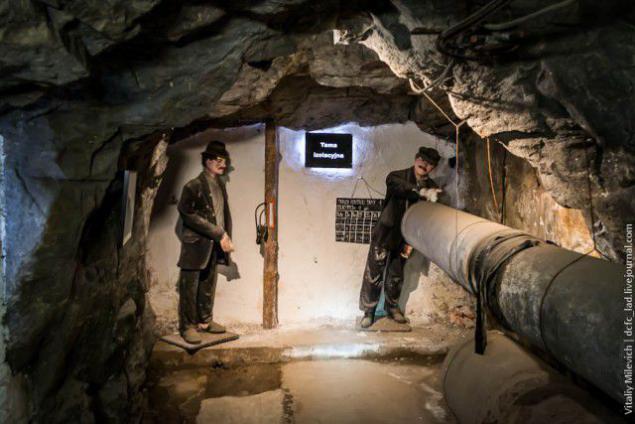

When coal came to an end, the tunnel was filled, and the wall painted over with white paint. In such places normally accumulated methane. To determine the concentration of the gas used canaries. If the dead birds - so the marginal rate exceeded. Two hundred years later we came up with a special device.

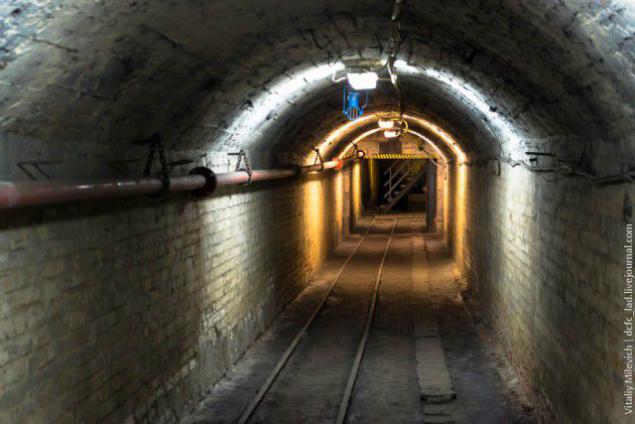

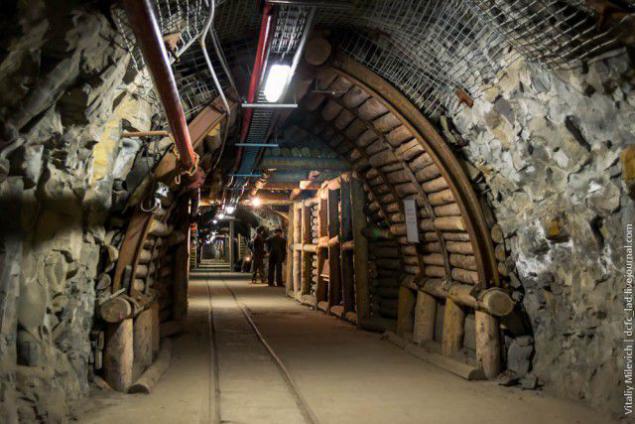

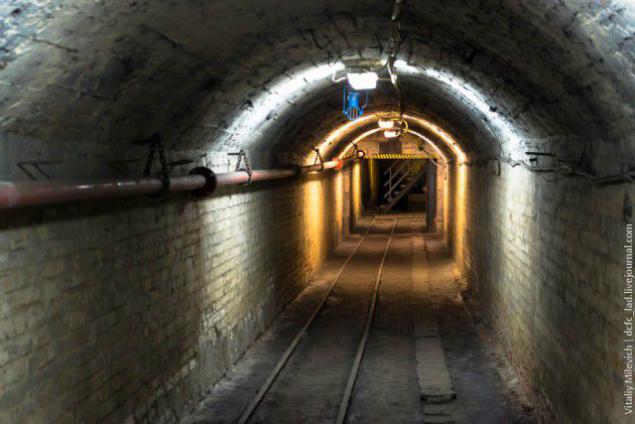

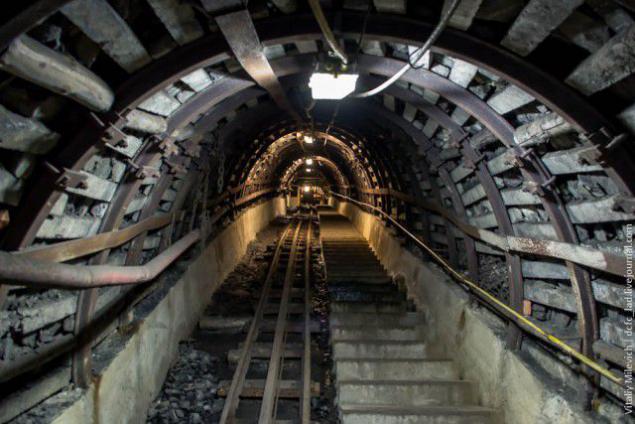

Poterna. Something similar to the underground passages in the Museum of missile forces under the Pervomaisky.

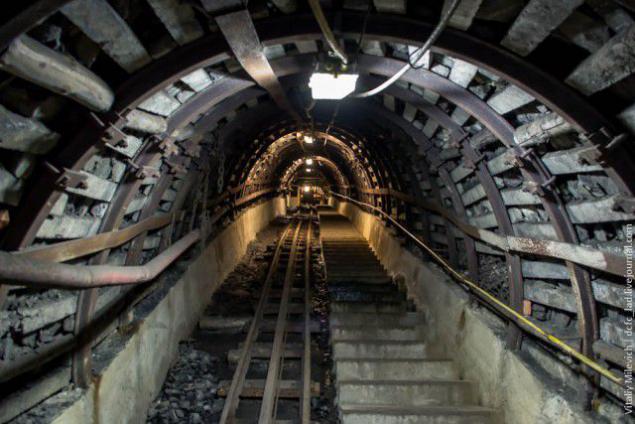

In this tunnel loaded trucks rises to the top.

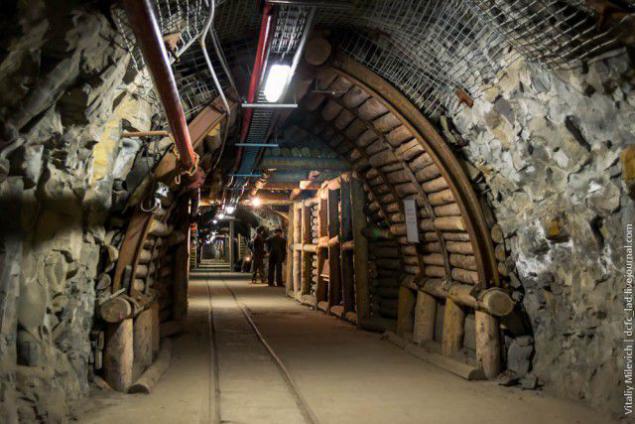

Initially, tunnels were wooden. Design gets very unstable. When the coal is in the specific area ended, the construction was transferred deep into the mine. Manually, of course. Often these piles and walls fell on the heads of the miners.

Over time, the wooden beams were replaced with concrete. Designs made strong, but from time to time still collapsed.

In our time, they were replaced by special props. The boom is lowered, the platform is a step forward. Spent parts of mines, just as before, fall down. Just now with none killed.

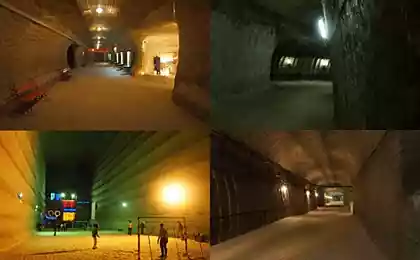

This - is the lower level. There is much more interesting. Official depth - 320 meters. In reality - more than 340. This level is dug in the late 19th century. The underground corridors are a lot of machines and units. All - in working condition.

Conveyor belt. After the automation of the process, the top coal raised by this tape. Everything works now.

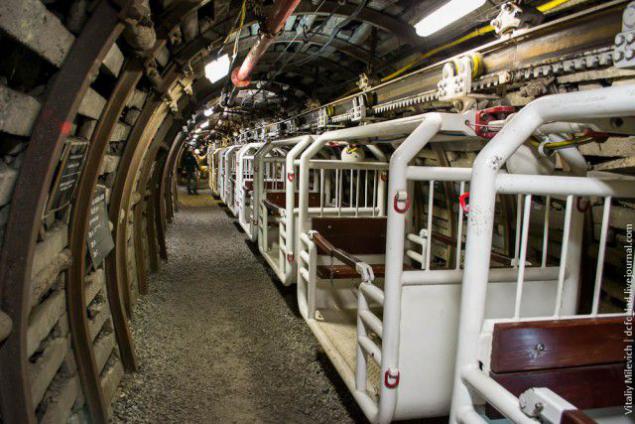

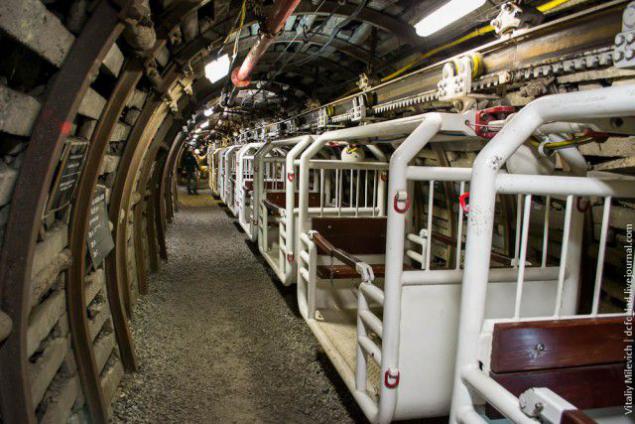

The underground tram. Their are several types. We have even swept. Before he took the miners now - tourists. They say it is - the only one in Europe miner suspended road.

Suspension system.

Another conveyor. Very loud buzzing and rattling metal.

Fork in the tunnel.

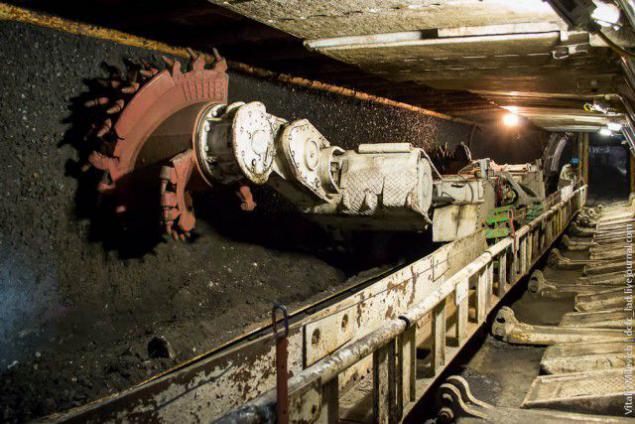

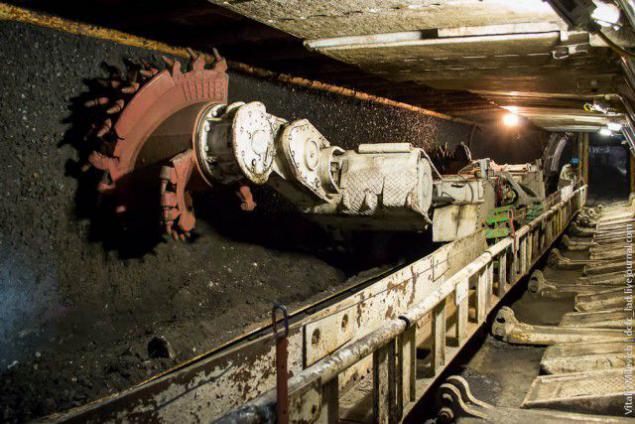

This section still remains a bit of coal. Work includes a tunneling machine and shows how it works.

Tunneling processor name Alpina. Milo) Previously, he worked at the mines in the Alps. Serious unit.

The other type of processor. It also includes not to explain the principle of the fingers. Effectively. And no one do not come to mind all this and bury both to be scrapped as we usually do.

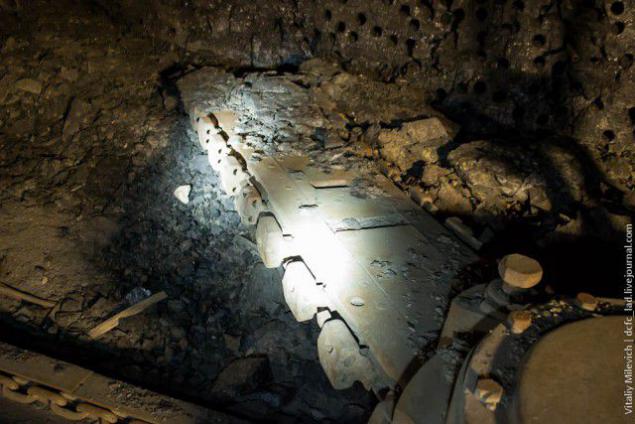

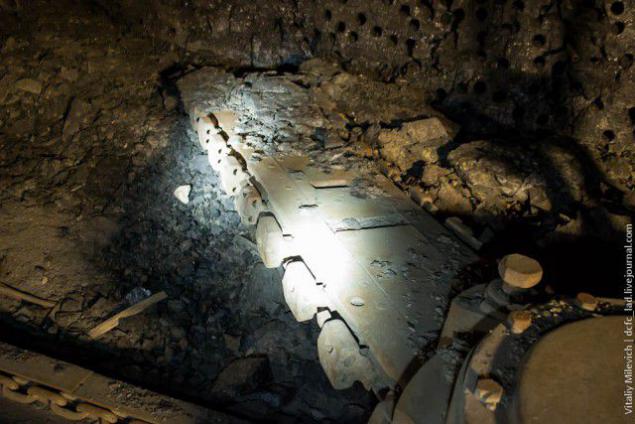

Rocks. Black pieces - the remains of coal deposits.

In some places to go to bend in a knot.

Small saw for cuts. The holes in the wall - by testing different types of drill bits. After the coal has ended, the shaft was research. The miners came from the bottom and retrained in the guides. Double profit - not the miners out of work, and no one better than them about the mine will not tell.

Hello Donbas. There when you wish you could do at least as good.

That's all. Thanks to all.

Source: dcfc-lad.livejournal.com

It turned out that our friend in his spare time, earns a guide here. So we got lucky with an exclusive tour

At the entrance to all give a helmet and flashlight. And it's not just the entourage, they do come in handy. The mine is dark, the ceiling sometimes something fray, can hit his head on the iron structure.

Mine is named after the former owner, Guido Henckel von Donnersmarck. In the second half of the 19th century, this figure belonged to almost all industrial enterprises in the area.

Lifting system. Nearby sits the operator, which controls the descent and raised elevators. The second one is near the cockpit. They do not see each other, so communicate using bells. White arrow indicates where the elevator, which operates at a lower level, right - the one on top.

And here is the elevator. Workers at the mine, he kept his speed at 10 meters per second. Tourists descend slowly - only 4 m / s. With the same speed elevators in high-rise buildings go.

The museum was opened relatively recently, there is always something changes and improves. Downstairs there is a bar and a concert hall. We were in the mine before Easter - alas, it was closed. If you wish, you can even underground marry. At the entrance to the first level - the stables and classical stands with inventory and rescue equipment.

Before the process is mechanized coal mining in the mine worked 80 horses - 40 on each of the levels. Down they rappel, the process takes about 48 hours. Getting into the mine, horses stay here forever. If in real life horses live 25-30 years, under the ground - no more than ten

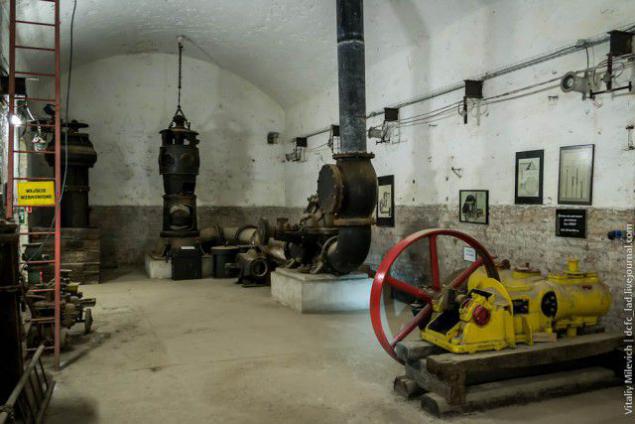

Coal mine Guido stopped back in 1928. But after the miners down the mine in the neighboring. There is also a drainage system, the pumps pumped the water from all the surrounding mines.

When coal came to an end, the tunnel was filled, and the wall painted over with white paint. In such places normally accumulated methane. To determine the concentration of the gas used canaries. If the dead birds - so the marginal rate exceeded. Two hundred years later we came up with a special device.

Poterna. Something similar to the underground passages in the Museum of missile forces under the Pervomaisky.

In this tunnel loaded trucks rises to the top.

Initially, tunnels were wooden. Design gets very unstable. When the coal is in the specific area ended, the construction was transferred deep into the mine. Manually, of course. Often these piles and walls fell on the heads of the miners.

Over time, the wooden beams were replaced with concrete. Designs made strong, but from time to time still collapsed.

In our time, they were replaced by special props. The boom is lowered, the platform is a step forward. Spent parts of mines, just as before, fall down. Just now with none killed.

This - is the lower level. There is much more interesting. Official depth - 320 meters. In reality - more than 340. This level is dug in the late 19th century. The underground corridors are a lot of machines and units. All - in working condition.

Conveyor belt. After the automation of the process, the top coal raised by this tape. Everything works now.

The underground tram. Their are several types. We have even swept. Before he took the miners now - tourists. They say it is - the only one in Europe miner suspended road.

Suspension system.

Another conveyor. Very loud buzzing and rattling metal.

Fork in the tunnel.

This section still remains a bit of coal. Work includes a tunneling machine and shows how it works.

Tunneling processor name Alpina. Milo) Previously, he worked at the mines in the Alps. Serious unit.

The other type of processor. It also includes not to explain the principle of the fingers. Effectively. And no one do not come to mind all this and bury both to be scrapped as we usually do.

Rocks. Black pieces - the remains of coal deposits.

In some places to go to bend in a knot.

Small saw for cuts. The holes in the wall - by testing different types of drill bits. After the coal has ended, the shaft was research. The miners came from the bottom and retrained in the guides. Double profit - not the miners out of work, and no one better than them about the mine will not tell.

Hello Donbas. There when you wish you could do at least as good.

That's all. Thanks to all.

Source: dcfc-lad.livejournal.com