807

The notorious "Chinese cellars" (40 ph + text)

Chinese factories for the production of headphones, mice and webcams

Have you ever seen a real bio-robots? Working models? I have seen. In China. The plant for the production of headphones. They sit at the tables and make dozens of identical operations per minute. Their brains off. Their hands are moving at lightning speed along a predetermined path. Their fingers convulsively clenched and unclenched in extreme positions. Minute after minute. Hour after hour. Day after day. Year after year ...

From respected sergeydolya

01. Every morning the hotel I took away another manufacturer and takes to his factory. Depending on the "steepness" of his company takes several buildings to the small room with a couple of workers. The first factory is engaged in the production of headphones.

On the ground floor there is heavy machinery, dies plastic parts headphones. Every 20 seconds in the oven baked another item. The operator pulls it trims the excess pieces of plastic layers and folds neatly into boxes:

02. Here is a warehouse with accessories - special molds, allowing to obtain the details of the relevant type of plastic. Each earphone - its shape. Accordingly, for each model needs its own accessories:

03. The floor above is the production itself. Along the long pipeline workers sitting at desks. Each of them is responsible for any minor surgery. He takes a passing semi-finished product, doing his actions and sends it to the way forward:

04.

05.

06. In general, the tables sit young girls aged 18 to 25 years. The hostess explained that they are more diligent, do not drink and do not fight:

07.

08.

09. The finished products stacked in boxes:

10.

11. On this machine produces kilometers of cables for the headphone:

12. Ready-wire first is stored in a bucket:

13. And then cut into short pieces of the desired length:

14. Workers have a counter that they press after each operation. Salary depends on the performance, and all are struggling:

15. Paint shop is separated from the rest of the production of heavy doors. Inside, all work in respirators or gauze bandages:

16.

17. Small headphones spread on special trays:

18. flaunt them in bulk, and then pull out their work and spread in layers of cardboard boxes, paving the paper yesterday:

19. After painting for inserts glued decorative metal rings:

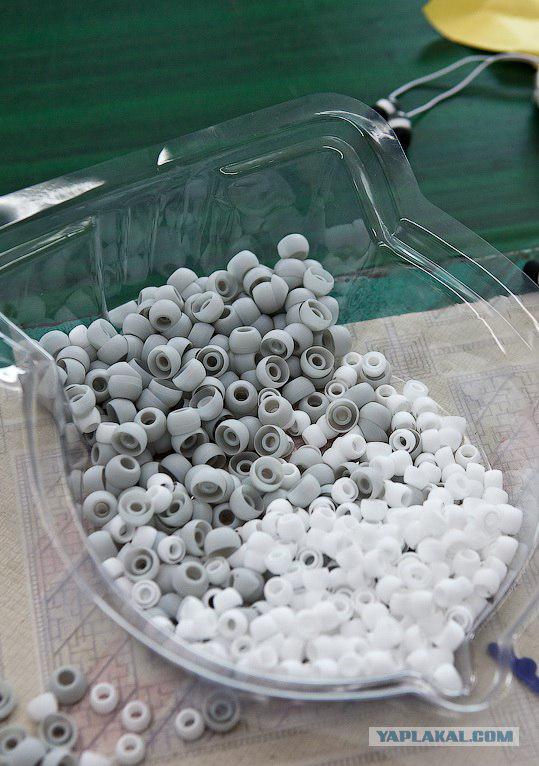

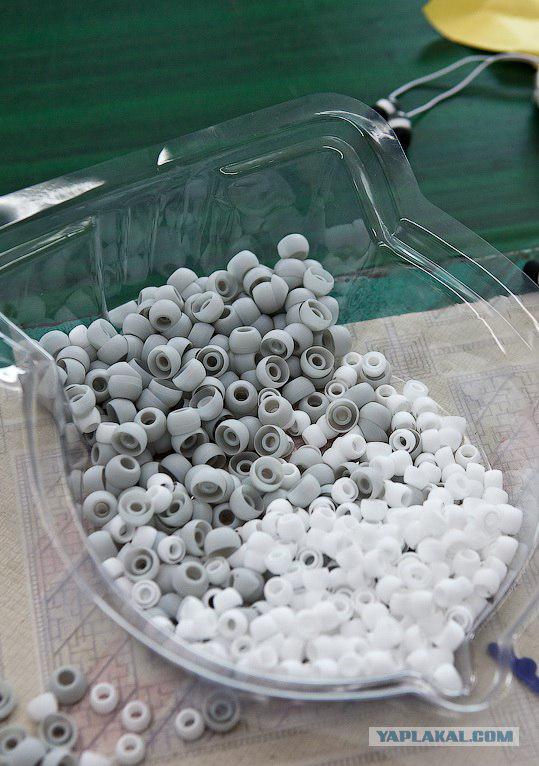

20. Put on silicone lining:

21. At the end of 100% of the products tested on special equipment. If the frequency characteristics do not coincide with the ideal, the headphones back on the conveyor:

22. Before each workshop is a bookcase with cups. Drink in production is prohibited. Every two hours declared a break, and workers can regain its water balance in the stairwell:

23. Dine all the local dining. Each has its own dishes, which he washes after meal:

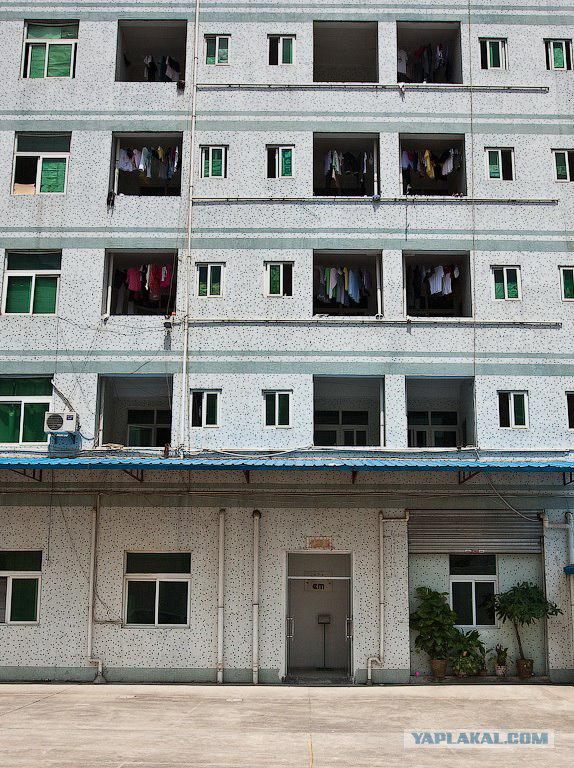

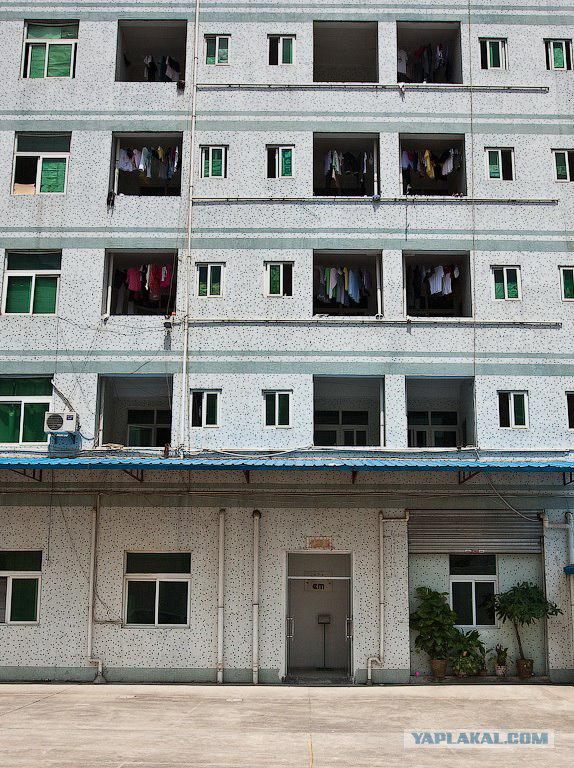

24. The workers spend the night in a nearby hostel:

25. Our Factory Owner told that pays workers 10 000 rubles per month, despite the fact that the minimum wage in China is 6000 rubles per month. Many other factories where we were in the next few days, pay workers Minimal. The working day lasts 10 hours. During the processing of the owners are forced to pay wages in double amount. Over the last 10 years, wages in China rose 10-fold.

We often write that China is hardly affected by the crisis. Judging by the reviews of manufacturers - it is not. All of them were called about the same numbers. About 30% of factories and plants have already gone bankrupt. The decline in production in the rest of the range from 40% to 70%. Before the crisis, the country has a labor shortage, but now this is no problem.

Next manufacturer came after us in a taxi. Introduced coolest manufacturer of computer mice, and the owner of a large trade house, which occupies almost 30% of the Chinese electronics market. Factory size it was little more than a classroom. In the middle there was one assembly line and the rest of the space was used as a warehouse:

26.

27. All the furniture in the office of "president" for some reason, was glued price lists and inventory numbers. The impression that I talk with some crook, whose company is on the verge of financial collapse and he is trying to find any means though any unsuspecting customers who are ready to transfer him to an advance payment. A few hard workers created the appearance of feverish activity:

28.

29.

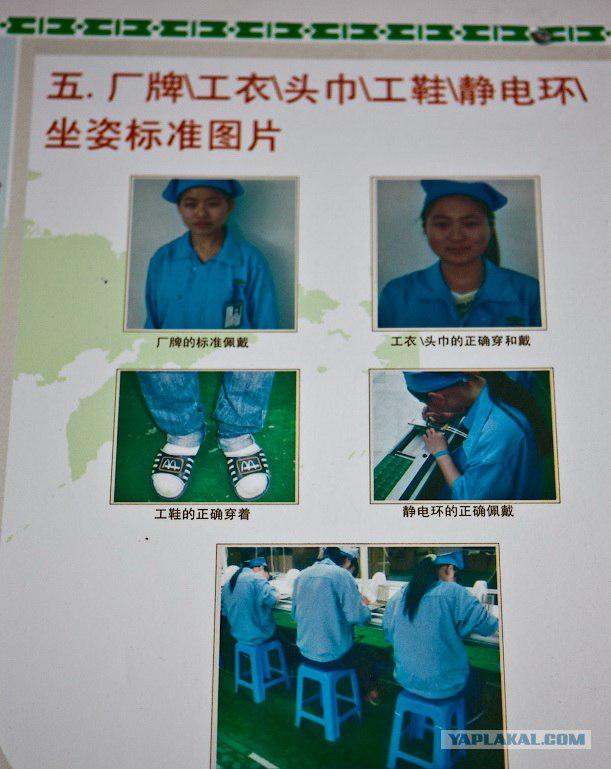

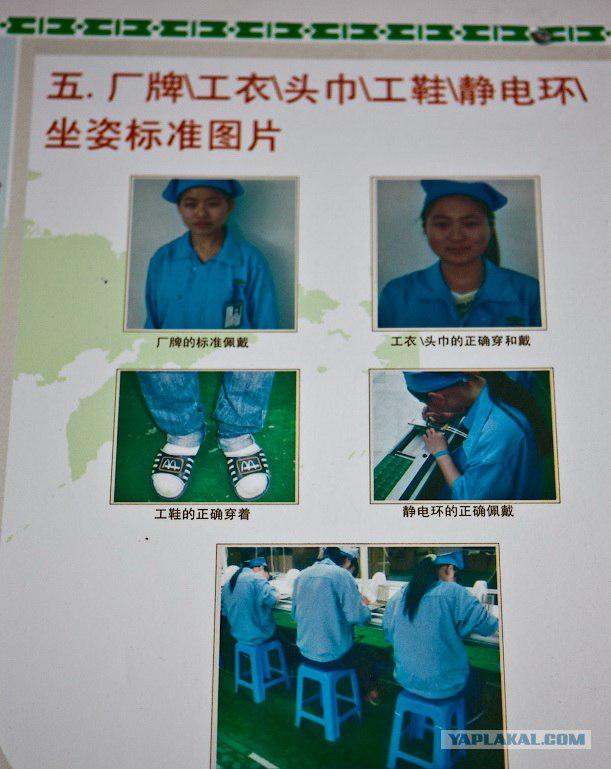

30. Last factory of webcams pleasantly surprised. There I was asked to put on shoe covers, and some shops are not allowed without the robe. On the wall hung a poster should look like a model worker:

31. Before the start of production of all materials tested the ad hoc group for the presence of harmful impurities and quality:

32. The plant itself is much bigger and cleaner than the previous two:

33.

34.

35.

36.Kak at previous plants, the age of some employees too reminiscent of Soviet propaganda abroad for criticizing exploitation of child labor:

37.

38. Each webcam is tested and tuned to the sharpness of the special multi-colored grid:

39.

40. All.

Taken verbatim from sergeydolya.livejournal.com

Source:

Have you ever seen a real bio-robots? Working models? I have seen. In China. The plant for the production of headphones. They sit at the tables and make dozens of identical operations per minute. Their brains off. Their hands are moving at lightning speed along a predetermined path. Their fingers convulsively clenched and unclenched in extreme positions. Minute after minute. Hour after hour. Day after day. Year after year ...

From respected sergeydolya

01. Every morning the hotel I took away another manufacturer and takes to his factory. Depending on the "steepness" of his company takes several buildings to the small room with a couple of workers. The first factory is engaged in the production of headphones.

On the ground floor there is heavy machinery, dies plastic parts headphones. Every 20 seconds in the oven baked another item. The operator pulls it trims the excess pieces of plastic layers and folds neatly into boxes:

02. Here is a warehouse with accessories - special molds, allowing to obtain the details of the relevant type of plastic. Each earphone - its shape. Accordingly, for each model needs its own accessories:

03. The floor above is the production itself. Along the long pipeline workers sitting at desks. Each of them is responsible for any minor surgery. He takes a passing semi-finished product, doing his actions and sends it to the way forward:

04.

05.

06. In general, the tables sit young girls aged 18 to 25 years. The hostess explained that they are more diligent, do not drink and do not fight:

07.

08.

09. The finished products stacked in boxes:

10.

11. On this machine produces kilometers of cables for the headphone:

12. Ready-wire first is stored in a bucket:

13. And then cut into short pieces of the desired length:

14. Workers have a counter that they press after each operation. Salary depends on the performance, and all are struggling:

15. Paint shop is separated from the rest of the production of heavy doors. Inside, all work in respirators or gauze bandages:

16.

17. Small headphones spread on special trays:

18. flaunt them in bulk, and then pull out their work and spread in layers of cardboard boxes, paving the paper yesterday:

19. After painting for inserts glued decorative metal rings:

20. Put on silicone lining:

21. At the end of 100% of the products tested on special equipment. If the frequency characteristics do not coincide with the ideal, the headphones back on the conveyor:

22. Before each workshop is a bookcase with cups. Drink in production is prohibited. Every two hours declared a break, and workers can regain its water balance in the stairwell:

23. Dine all the local dining. Each has its own dishes, which he washes after meal:

24. The workers spend the night in a nearby hostel:

25. Our Factory Owner told that pays workers 10 000 rubles per month, despite the fact that the minimum wage in China is 6000 rubles per month. Many other factories where we were in the next few days, pay workers Minimal. The working day lasts 10 hours. During the processing of the owners are forced to pay wages in double amount. Over the last 10 years, wages in China rose 10-fold.

We often write that China is hardly affected by the crisis. Judging by the reviews of manufacturers - it is not. All of them were called about the same numbers. About 30% of factories and plants have already gone bankrupt. The decline in production in the rest of the range from 40% to 70%. Before the crisis, the country has a labor shortage, but now this is no problem.

Next manufacturer came after us in a taxi. Introduced coolest manufacturer of computer mice, and the owner of a large trade house, which occupies almost 30% of the Chinese electronics market. Factory size it was little more than a classroom. In the middle there was one assembly line and the rest of the space was used as a warehouse:

26.

27. All the furniture in the office of "president" for some reason, was glued price lists and inventory numbers. The impression that I talk with some crook, whose company is on the verge of financial collapse and he is trying to find any means though any unsuspecting customers who are ready to transfer him to an advance payment. A few hard workers created the appearance of feverish activity:

28.

29.

30. Last factory of webcams pleasantly surprised. There I was asked to put on shoe covers, and some shops are not allowed without the robe. On the wall hung a poster should look like a model worker:

31. Before the start of production of all materials tested the ad hoc group for the presence of harmful impurities and quality:

32. The plant itself is much bigger and cleaner than the previous two:

33.

34.

35.

36.Kak at previous plants, the age of some employees too reminiscent of Soviet propaganda abroad for criticizing exploitation of child labor:

37.

38. Each webcam is tested and tuned to the sharpness of the special multi-colored grid:

39.

40. All.

Taken verbatim from sergeydolya.livejournal.com

Source: