571

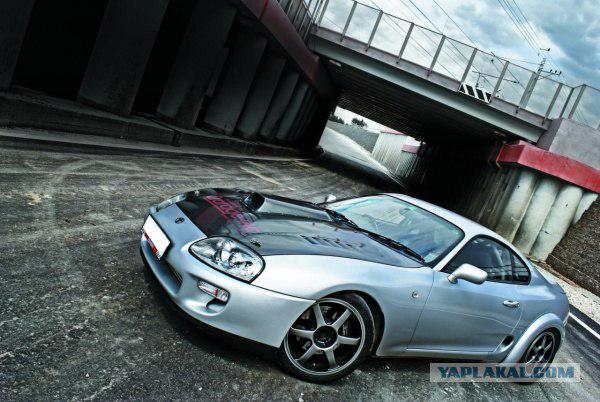

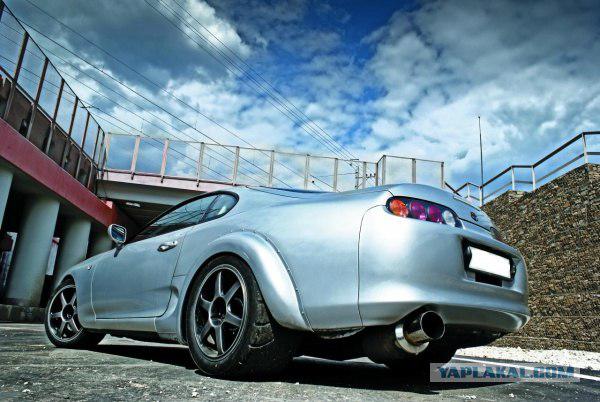

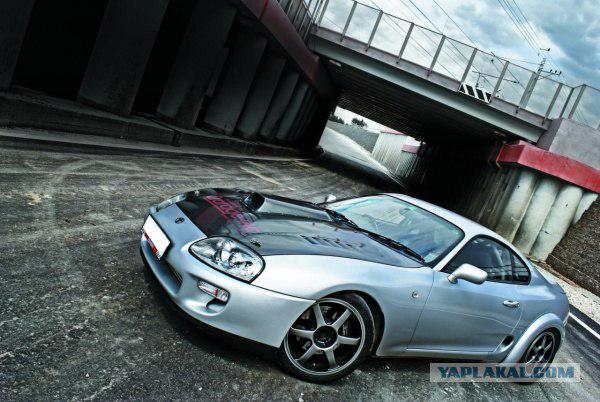

Furious Supra

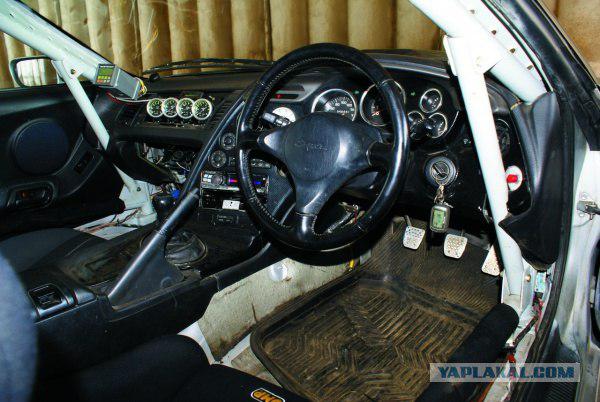

Experts from the Garage Inc. We decided to depart from the traditional concept of

creating dregovyh writhing and offered his vision of the device hood space built for 402 meters Toyota Supra.

However, the machine goes not only in a straight line.

On the assembly line of Toyota in Japan silver Supra

He left in 1996, driven by a three-liter atmospheric engine 2JZ-GE through

Automatic transmission. The local reesaa (racer in Japanese) realized too late that it is necessary

was immediately taken, turbo 2JZ-GTE. It was necessary to equip yourself "aspirated" two turbines and change the "machine" in the mechanics of Getrag.Primerno neubivaemaya in this form Supra arrived in Russia. I came in to

once again become a semi-finished product from which the Garage Inc. build

uncompromising sports car.

Interesting Engineering

Home "trick" silver Supra - a combination of compressor and

turbine under the hood. To make it easier to understand the advantages and disadvantages of this scheme, we briefly recall the difference in device mechanical compressor and turbine. Mechanical compressor crankshaft using untwisted by the drive belt. Air injection into the cylinders starts with minimal

revolutions, immediately after starting the engine. The turbine, in turn, consists of an impeller (hot part), which is driven by exhaust

gases and compressor (cold part) - like impeller, whose task, unwind, take the maximum amount of air to compress and inflate vkameru combustion. The main drawback in the turbinyobuslovlensposobom received energy. While the engine is running at low speed, the impeller can not effectively loose and coldest part - to create the desired pressure. It turns turboyamu,

the depth of which depends on the characteristics of a particular turbine. Some

cars turbine is switched on (here we must understand "begins to create

positive pressure ") only after the engine certain

rpm, and the engine is on bottoms atmospheric (negative pressure - even worse). The lack of a mechanical compressor is lower efficiency due to weaning power directly from the engine and greater fuel consumption for the same reason. But - no turboyam, motor driven

directly from

start.

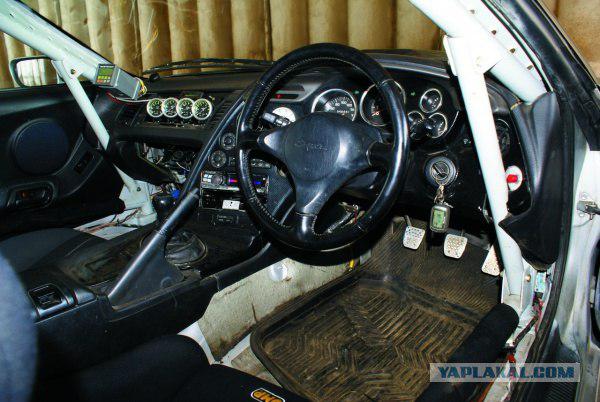

At built in Garage Inc. Toyota Supra mechanical

the compressor and the turbine operated in series. Already in Russia Toyota

instead of two turbines appeared one Garrett 51. The compressor and first blowing until a pressure of one atmosphere. This happens about two thousand revolutions, it is adequate for the effective operation of the compressor turbiny.Posle its activation

is disabled until a new fall speed. The operation of the turbine and compressor

controlled by two bustkontrollera. The first follows the work and off

the compressor and the second turbine operates. Familiar design?

Conceptually also arranged 1, 4-liter 140-horsepower engine with Volkswagen

index TSI. But in the Garage Inc. Such a scheme was first implemented even before volfsburgskogo engine. They first tested this configuration in the Subaru. However, in the construction of a turbo compressor to the Japanese engineers

task was to remove turboyamu, and to increase the power of the question. As

consequently, the speech did not go about rebuilding the entire engine. Toyota Supra in

this plan required a much larger alterations.

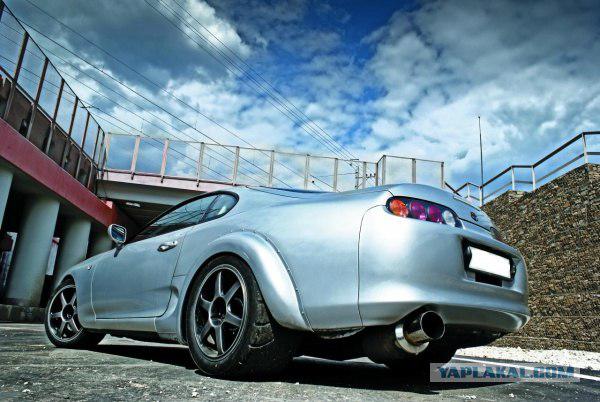

The compressor and turbine high (theoretically, up to 2, 5 bar) pressure seriously

increase the load on the piston group and part of the head unit. For once the engine is not turned into a meat grinder, its serious efforts with the help of rods and camshafts Crover, titanium valves, liners, crankshaft, and other belts, rollers and collector stainless steel constructed

specifically for the mechanical compressor. The intake manifold, by the way, are equipped with water injection, in order to knock knock. It allows to raise the pressure of the turbine, avoiding the use of fuels with higher octane number. Now silver coupe digests civilian "ninety-eight", although in race mode using fuel with an octane rating of up to 116. In these completions

It took two rows of nozzles 1200 cubic meters. cm / min, and a pair of four benzonasa: dvaWallbro to lodge and two on the swap. Turbine, by the way, dropped almost under the engine to leave the place for a mechanical compressor. Against this background, "nulevik" in the front fender is perceived as a matter of course. Oh, I almost forgot about intercooler GReddy, here he works on mechanical compressor and the turbine. (all)

Source:

creating dregovyh writhing and offered his vision of the device hood space built for 402 meters Toyota Supra.

However, the machine goes not only in a straight line.

On the assembly line of Toyota in Japan silver Supra

He left in 1996, driven by a three-liter atmospheric engine 2JZ-GE through

Automatic transmission. The local reesaa (racer in Japanese) realized too late that it is necessary

was immediately taken, turbo 2JZ-GTE. It was necessary to equip yourself "aspirated" two turbines and change the "machine" in the mechanics of Getrag.Primerno neubivaemaya in this form Supra arrived in Russia. I came in to

once again become a semi-finished product from which the Garage Inc. build

uncompromising sports car.

Interesting Engineering

Home "trick" silver Supra - a combination of compressor and

turbine under the hood. To make it easier to understand the advantages and disadvantages of this scheme, we briefly recall the difference in device mechanical compressor and turbine. Mechanical compressor crankshaft using untwisted by the drive belt. Air injection into the cylinders starts with minimal

revolutions, immediately after starting the engine. The turbine, in turn, consists of an impeller (hot part), which is driven by exhaust

gases and compressor (cold part) - like impeller, whose task, unwind, take the maximum amount of air to compress and inflate vkameru combustion. The main drawback in the turbinyobuslovlensposobom received energy. While the engine is running at low speed, the impeller can not effectively loose and coldest part - to create the desired pressure. It turns turboyamu,

the depth of which depends on the characteristics of a particular turbine. Some

cars turbine is switched on (here we must understand "begins to create

positive pressure ") only after the engine certain

rpm, and the engine is on bottoms atmospheric (negative pressure - even worse). The lack of a mechanical compressor is lower efficiency due to weaning power directly from the engine and greater fuel consumption for the same reason. But - no turboyam, motor driven

directly from

start.

At built in Garage Inc. Toyota Supra mechanical

the compressor and the turbine operated in series. Already in Russia Toyota

instead of two turbines appeared one Garrett 51. The compressor and first blowing until a pressure of one atmosphere. This happens about two thousand revolutions, it is adequate for the effective operation of the compressor turbiny.Posle its activation

is disabled until a new fall speed. The operation of the turbine and compressor

controlled by two bustkontrollera. The first follows the work and off

the compressor and the second turbine operates. Familiar design?

Conceptually also arranged 1, 4-liter 140-horsepower engine with Volkswagen

index TSI. But in the Garage Inc. Such a scheme was first implemented even before volfsburgskogo engine. They first tested this configuration in the Subaru. However, in the construction of a turbo compressor to the Japanese engineers

task was to remove turboyamu, and to increase the power of the question. As

consequently, the speech did not go about rebuilding the entire engine. Toyota Supra in

this plan required a much larger alterations.

The compressor and turbine high (theoretically, up to 2, 5 bar) pressure seriously

increase the load on the piston group and part of the head unit. For once the engine is not turned into a meat grinder, its serious efforts with the help of rods and camshafts Crover, titanium valves, liners, crankshaft, and other belts, rollers and collector stainless steel constructed

specifically for the mechanical compressor. The intake manifold, by the way, are equipped with water injection, in order to knock knock. It allows to raise the pressure of the turbine, avoiding the use of fuels with higher octane number. Now silver coupe digests civilian "ninety-eight", although in race mode using fuel with an octane rating of up to 116. In these completions

It took two rows of nozzles 1200 cubic meters. cm / min, and a pair of four benzonasa: dvaWallbro to lodge and two on the swap. Turbine, by the way, dropped almost under the engine to leave the place for a mechanical compressor. Against this background, "nulevik" in the front fender is perceived as a matter of course. Oh, I almost forgot about intercooler GReddy, here he works on mechanical compressor and the turbine. (all)

Source: