789

A day in the life of a farmer and metallurgist

Writes met_vyksa

Hello! My name is Sergey, I'm from the city Navashino. I want to show you my usual weekday (April 2), which, I think, many seem not quite so common, because a large part of the day I spend at the metallurgical plant - watch the operation of the equipment in the workshop where steel is melted. I work as a mechanic-repairman in Casting and Rolling Complex in the town of Vyksa. And after work, almost all my free time, take care of the household - mini chicken farm and other denizens of the animal kingdom in a particular corner of the Nizhny Novgorod region.

1. Here we go! Lifting at 5:15 am local time ...

2. The first step is to feed the young Caesar. They are 12 days old, they are our first-born:

3. Only then - breakfast and charges for work:

4. leave the house early in the seventh, the food in a nearby town - Vyksa to work - 19 km:

5. On the way I pass here such settlements:

6. This is the area of the plant. It is forbidden to shoot, so I leave my camera in the car. During the working day I agreed to help me shoot my friend - a photographer from the factory newspaper. In the administrative building, I change clothes, and then go to the shop:

7. The clock at the entrance reminded how much time and what day it is:

8. Well, I'm in full uniform and ready to go. Without overalls in production can not be:

9. I go to the shop that's such a ground transition:

10. This arc-furnace plant where, in fact, I work. There melted steel, and then it is prepared from a solid blank (which in the language metallurgy called a "slab"). Slabs in another shop is rolled into a thin sheet metal, which is then wound into rolls. This is called rolled coil. Because it is made of pipe:

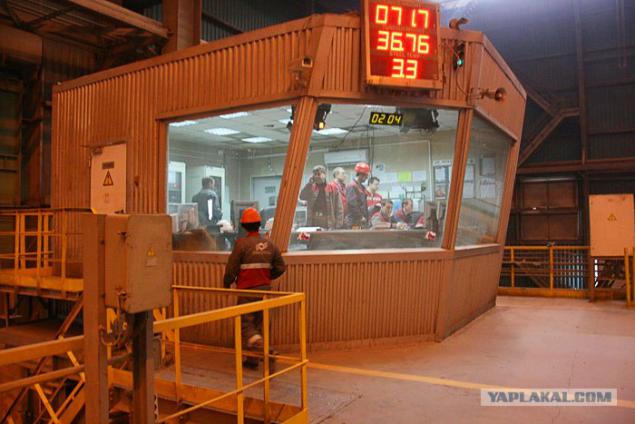

11. Every morning we start with the operational meeting, in other words, RAM. I work in the area of maintenance and repair of mechanical equipment (hydraulic) day shift foreman. In total we have 12 people on the site, in the change of work by two attendants, plus three - day staff, and master. Our job is to control the hydraulic equipment in the shop, and repair if necessary. On the RAM is received, the transmission shifts, discussed plans for the day and all the current issues:

12. In the shop a lot of hydraulic equipment, and all involved in the process technology, the mechanisms are driven by hydraulics:

13.Na RAM bell staff is assigned to the shift, but before that, we will, as always, we will do a full crawl of the equipment. We will visit several sites and I think that in the process you will understand how and what is happening in our shop. Also I get the Craftsman - check the pressure at the control point on one of the plots:

14.Nachinayu area with an electric arc furnace (abbreviated - CPD). By name it is clear that this is where the steel is melted. Iron scrap, or in our "batch" is charged to the electric furnace, the temperature of which can reach 1600 degrees Celsius. Warming up is due to special electrodes to which electric current is applied. All movements of the major mechanisms and pieces of equipment are due hydraulics:

15.Idu in gidropomeschenie particleboard, it is on the lower level of the oven. I produce a visual inspection equipment. This electric motors that rotate the hydraulic pumps, whereby fluid under pressure supplied to the actuators. Here I check the pressure reading on the pressure gauge:

16.Dalshe go to the control panel chipboard. Here you can see all the information about the operation of the equipment, including the hydraulic. Checking basic sensor readings and make an appropriate note on the availability of equipment in the journal "reception and transmission shift»:

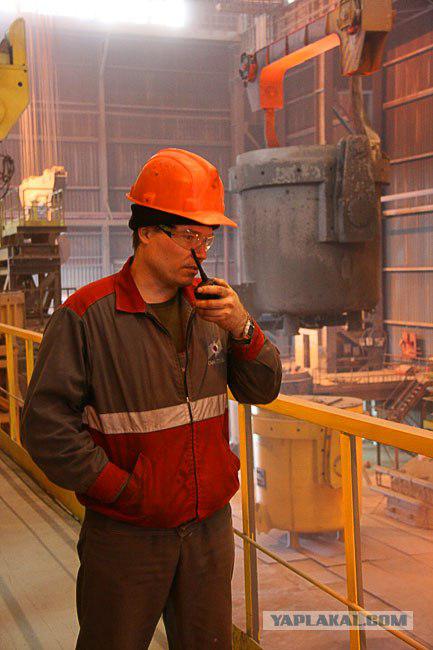

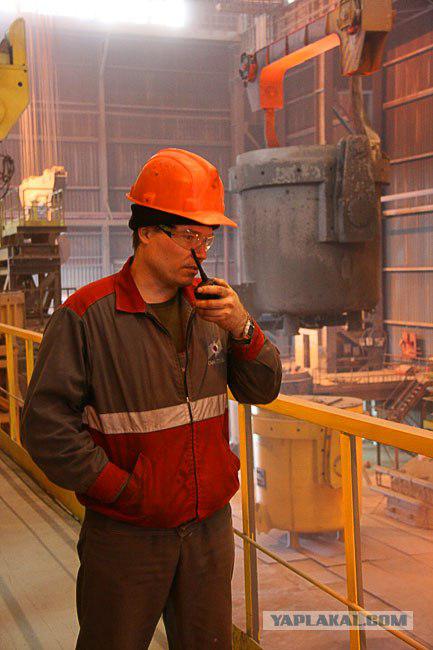

17. At the enterprise production management all happens automatically, operators only control the process, if necessary, make adjustments. Here it can be seen from the window of the EAF operators:

18. This remote disaster tilting. Now steelmaker produces steel production:

19. ... that's what happens - the liquid metal is poured into a ladle:

20. Then I go to the area "ladle furnace" (abbreviated - PC) where after the release of the oven gets steel. Here, by the addition of the various components (in our opinion - "additives") brought the desired steel grade. It electrodes, lifting and lowering which is performed by hydraulics. They are the same as the area of the arc furnace, only smaller:

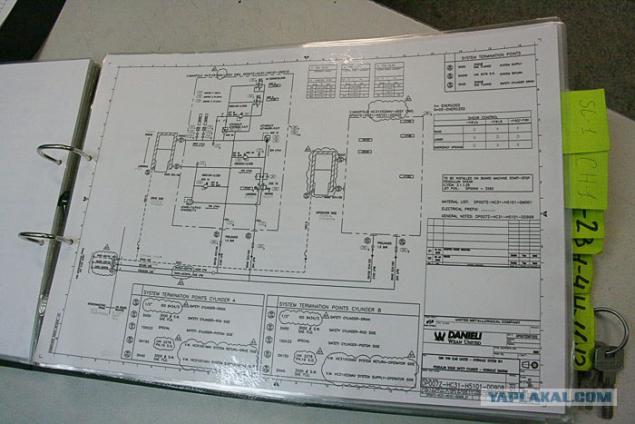

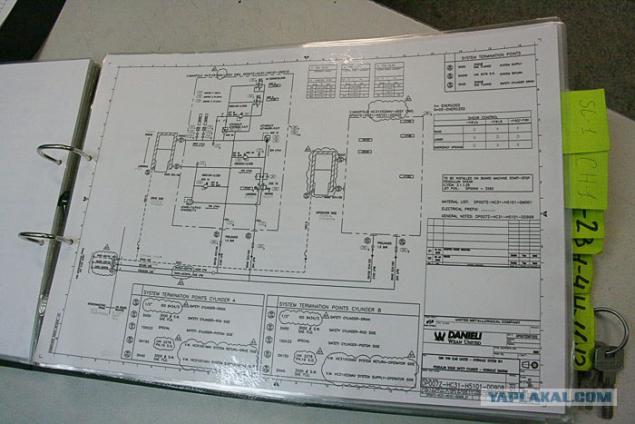

21. Go to the gidropomeschenie PC. There also need to inspect all equipment and take readings from the gauges. Moreover, at this site on the instructions of the master I need to check pressure at a certain point, to compare the readings with a hydraulic circuit. Connect a pressure gauge to the desired point on the valve block:

22. ... and watch the testimony:

23.Podnimayus on the remote PC:

24. Look indications on the monitor, and make an entry in the journal "reception and transmission shift»:

25. Here is the first challenge for today ... Hydraulics caller continuous casting machine (CCM), has commented on the hydraulic equipment. At this site, the liquid steel is cast into a solid billet (slab), which is subsequently rolled into a sheet metal. Go there:

26.Snachala go to gidropomeschenie CCM:

27.Delayu necessary measurements at the control points to make sure that the particular site and to draw conclusions on the observation of equipment:

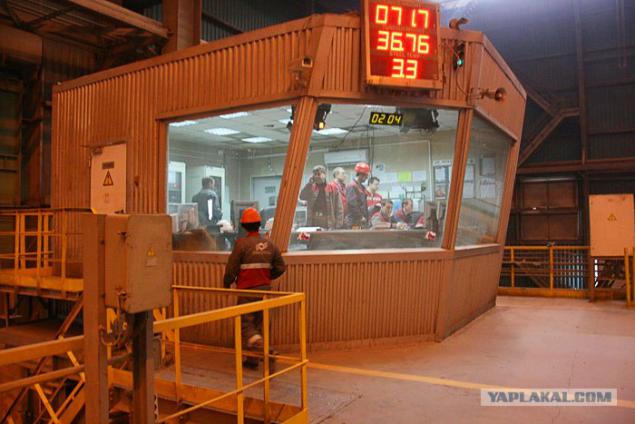

28. Then go to the control panel of CCM to talk with the operators of casting and figure out what caused them questions:

29. Operators noticed a slight change in the testimony of electronic sensors, and they have doubts about the correct operation of the hydraulic cylinder:

30.Proveryayu all indicators on the monitor, compare them with the data received in gidropomeschenii. These coincide, and hence there is no error. Small jumps indicators to notice operators are acceptable. You can continue pouring in operation:

31. At work, time flies quickly, going back to the studio, it's time to make a small break:

32.Posle break according to plan - inspection of the hydraulic pump, which we dismantled a portion of the furnace and disassembled for inspection. Spend check back cover pump:

33. ... I prepare the O-rings of the control channels, to replace:

34. Also today, I need to have time for another two sites - in a workshop for inspection and mold segments and lime kiln site. In the workshop need to take the equipment after repair. My task - to check the equipment for leaks of hydraulic fluid and ensure that it is fully operational:

35. The hydraulic fluid is fed to the equipment ... make sure everything is working properly, and there are no leaks, make an entry in the appropriate register:

36. Now go to the site of lime kiln, where also a lot of hydraulic equipment, which we should maintain. This oven baked limestone required in the process of steel production:

37. The plant as a small city with its own infrastructure. Getting around the area - strictly on the SDA!

38. That is our goal. The hydraulic equipment is including at the highest point (40 meters):

39. All signs at the plant are duplicated in two languages, as the work here and come to visit many foreign specialists ...

40. As always, we begin with a tour of the equipment:

41.Proveryayu fluid level in the hydraulic tank and its temperature, controls the pressure in the hydraulic system:

42. On the control panel communicate with the operator, ask whether he comments on the hydraulics:

43. The clock - is already beginning of the fourth. My shift ends at 15:30, so come back to the studio in time to remove the working tool, take a shower and change of clothes:

44. The working day is over, go home!

45. Weather this spring is not happy. This is the area in front of our central building - 2 April and the snow more than in February:

46. ... A lot of snow!

47. Homeward Bound. I do not drive anywhere, except to the grocery store, because the house is waiting for me, my family and pets. Today we say goodbye to the Vyksa:

48. Well, I put the car at home ... in the garage, and wasted no time in embarking on household chores:

49. It does not matter how hard the day was at work, I want to eat everything! The first in the queue, and the most hungry - Cupid, he was no longer so young, he was 12 years old but feels hearty:

50. The following - rabbits. It Karolinka, she is waiting for the offspring:

51. Then go to the granary to make the mixture of feed (a kind of "buffet") for our mini chicken farm. The grain from rodents protects our cat Ginger, he likes to hunt here:

52. That's our bird's courtyard, there are two kinds of chickens, guinea fowl, turkeys and ducks:

53. Getting meal:

54. Ducks are separate, because sitting on the nest will soon forward to the first litter:

55. Duck nest not stand:

56. We also have here are beauties here:

57. This incubator him in late March we laid an egg, chicken and turkey. Every day you need to monitor the temperature and humidity, turn-off slope of the incubator, the eggs overturned:

58. Last in line, as the patient, - Fedor. This red-eared sliders, he was 15 years old. It likes fresh fish and eggs.

59. After feeding of their pets, finally, dinner themselves:

60.Poslednyaya.

After dinner, do homework together.

So, in the household chores, and the evening passed ... soon all the costs of their rooms to rest. Tomorrow - a new day and new business!

Source:

Hello! My name is Sergey, I'm from the city Navashino. I want to show you my usual weekday (April 2), which, I think, many seem not quite so common, because a large part of the day I spend at the metallurgical plant - watch the operation of the equipment in the workshop where steel is melted. I work as a mechanic-repairman in Casting and Rolling Complex in the town of Vyksa. And after work, almost all my free time, take care of the household - mini chicken farm and other denizens of the animal kingdom in a particular corner of the Nizhny Novgorod region.

1. Here we go! Lifting at 5:15 am local time ...

2. The first step is to feed the young Caesar. They are 12 days old, they are our first-born:

3. Only then - breakfast and charges for work:

4. leave the house early in the seventh, the food in a nearby town - Vyksa to work - 19 km:

5. On the way I pass here such settlements:

6. This is the area of the plant. It is forbidden to shoot, so I leave my camera in the car. During the working day I agreed to help me shoot my friend - a photographer from the factory newspaper. In the administrative building, I change clothes, and then go to the shop:

7. The clock at the entrance reminded how much time and what day it is:

8. Well, I'm in full uniform and ready to go. Without overalls in production can not be:

9. I go to the shop that's such a ground transition:

10. This arc-furnace plant where, in fact, I work. There melted steel, and then it is prepared from a solid blank (which in the language metallurgy called a "slab"). Slabs in another shop is rolled into a thin sheet metal, which is then wound into rolls. This is called rolled coil. Because it is made of pipe:

11. Every morning we start with the operational meeting, in other words, RAM. I work in the area of maintenance and repair of mechanical equipment (hydraulic) day shift foreman. In total we have 12 people on the site, in the change of work by two attendants, plus three - day staff, and master. Our job is to control the hydraulic equipment in the shop, and repair if necessary. On the RAM is received, the transmission shifts, discussed plans for the day and all the current issues:

12. In the shop a lot of hydraulic equipment, and all involved in the process technology, the mechanisms are driven by hydraulics:

13.Na RAM bell staff is assigned to the shift, but before that, we will, as always, we will do a full crawl of the equipment. We will visit several sites and I think that in the process you will understand how and what is happening in our shop. Also I get the Craftsman - check the pressure at the control point on one of the plots:

14.Nachinayu area with an electric arc furnace (abbreviated - CPD). By name it is clear that this is where the steel is melted. Iron scrap, or in our "batch" is charged to the electric furnace, the temperature of which can reach 1600 degrees Celsius. Warming up is due to special electrodes to which electric current is applied. All movements of the major mechanisms and pieces of equipment are due hydraulics:

15.Idu in gidropomeschenie particleboard, it is on the lower level of the oven. I produce a visual inspection equipment. This electric motors that rotate the hydraulic pumps, whereby fluid under pressure supplied to the actuators. Here I check the pressure reading on the pressure gauge:

16.Dalshe go to the control panel chipboard. Here you can see all the information about the operation of the equipment, including the hydraulic. Checking basic sensor readings and make an appropriate note on the availability of equipment in the journal "reception and transmission shift»:

17. At the enterprise production management all happens automatically, operators only control the process, if necessary, make adjustments. Here it can be seen from the window of the EAF operators:

18. This remote disaster tilting. Now steelmaker produces steel production:

19. ... that's what happens - the liquid metal is poured into a ladle:

20. Then I go to the area "ladle furnace" (abbreviated - PC) where after the release of the oven gets steel. Here, by the addition of the various components (in our opinion - "additives") brought the desired steel grade. It electrodes, lifting and lowering which is performed by hydraulics. They are the same as the area of the arc furnace, only smaller:

21. Go to the gidropomeschenie PC. There also need to inspect all equipment and take readings from the gauges. Moreover, at this site on the instructions of the master I need to check pressure at a certain point, to compare the readings with a hydraulic circuit. Connect a pressure gauge to the desired point on the valve block:

22. ... and watch the testimony:

23.Podnimayus on the remote PC:

24. Look indications on the monitor, and make an entry in the journal "reception and transmission shift»:

25. Here is the first challenge for today ... Hydraulics caller continuous casting machine (CCM), has commented on the hydraulic equipment. At this site, the liquid steel is cast into a solid billet (slab), which is subsequently rolled into a sheet metal. Go there:

26.Snachala go to gidropomeschenie CCM:

27.Delayu necessary measurements at the control points to make sure that the particular site and to draw conclusions on the observation of equipment:

28. Then go to the control panel of CCM to talk with the operators of casting and figure out what caused them questions:

29. Operators noticed a slight change in the testimony of electronic sensors, and they have doubts about the correct operation of the hydraulic cylinder:

30.Proveryayu all indicators on the monitor, compare them with the data received in gidropomeschenii. These coincide, and hence there is no error. Small jumps indicators to notice operators are acceptable. You can continue pouring in operation:

31. At work, time flies quickly, going back to the studio, it's time to make a small break:

32.Posle break according to plan - inspection of the hydraulic pump, which we dismantled a portion of the furnace and disassembled for inspection. Spend check back cover pump:

33. ... I prepare the O-rings of the control channels, to replace:

34. Also today, I need to have time for another two sites - in a workshop for inspection and mold segments and lime kiln site. In the workshop need to take the equipment after repair. My task - to check the equipment for leaks of hydraulic fluid and ensure that it is fully operational:

35. The hydraulic fluid is fed to the equipment ... make sure everything is working properly, and there are no leaks, make an entry in the appropriate register:

36. Now go to the site of lime kiln, where also a lot of hydraulic equipment, which we should maintain. This oven baked limestone required in the process of steel production:

37. The plant as a small city with its own infrastructure. Getting around the area - strictly on the SDA!

38. That is our goal. The hydraulic equipment is including at the highest point (40 meters):

39. All signs at the plant are duplicated in two languages, as the work here and come to visit many foreign specialists ...

40. As always, we begin with a tour of the equipment:

41.Proveryayu fluid level in the hydraulic tank and its temperature, controls the pressure in the hydraulic system:

42. On the control panel communicate with the operator, ask whether he comments on the hydraulics:

43. The clock - is already beginning of the fourth. My shift ends at 15:30, so come back to the studio in time to remove the working tool, take a shower and change of clothes:

44. The working day is over, go home!

45. Weather this spring is not happy. This is the area in front of our central building - 2 April and the snow more than in February:

46. ... A lot of snow!

47. Homeward Bound. I do not drive anywhere, except to the grocery store, because the house is waiting for me, my family and pets. Today we say goodbye to the Vyksa:

48. Well, I put the car at home ... in the garage, and wasted no time in embarking on household chores:

49. It does not matter how hard the day was at work, I want to eat everything! The first in the queue, and the most hungry - Cupid, he was no longer so young, he was 12 years old but feels hearty:

50. The following - rabbits. It Karolinka, she is waiting for the offspring:

51. Then go to the granary to make the mixture of feed (a kind of "buffet") for our mini chicken farm. The grain from rodents protects our cat Ginger, he likes to hunt here:

52. That's our bird's courtyard, there are two kinds of chickens, guinea fowl, turkeys and ducks:

53. Getting meal:

54. Ducks are separate, because sitting on the nest will soon forward to the first litter:

55. Duck nest not stand:

56. We also have here are beauties here:

57. This incubator him in late March we laid an egg, chicken and turkey. Every day you need to monitor the temperature and humidity, turn-off slope of the incubator, the eggs overturned:

58. Last in line, as the patient, - Fedor. This red-eared sliders, he was 15 years old. It likes fresh fish and eggs.

59. After feeding of their pets, finally, dinner themselves:

60.Poslednyaya.

After dinner, do homework together.

So, in the household chores, and the evening passed ... soon all the costs of their rooms to rest. Tomorrow - a new day and new business!

Source: