563

A day in the studio

The result I have a very productive den.Blago were available all the necessary materials and tools. I wanted to do something new. A little away from his style.

25 ph

Let's start.

We have available heat-treated steel strip 95X18 (hardness 58-59HRC). Draw a sketch on paper and cut out the pattern.

We transfer the pattern to the metal and hit the Bulgarian circuit.

Further Sander (Grinder) derive outline more precisely.

Thereafter conventional chamfer grinding wheels do near future cutting edge. This is to ensure that, in future breeding descents, the tool does not chafe against sharp edges.

On the plywood circle stretch the tape grit sandpaper P50 and preliminary conclusions slopes. And at the same time gently purifies the blade to the tip, because it is conceived as a drop-point.

Now back to The Grinder. and enter the flat slopes on both sides. Carefully follow the symmetry.

We get almost finished edge.

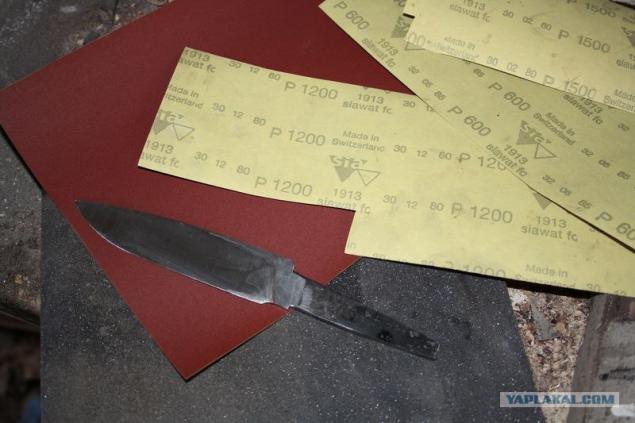

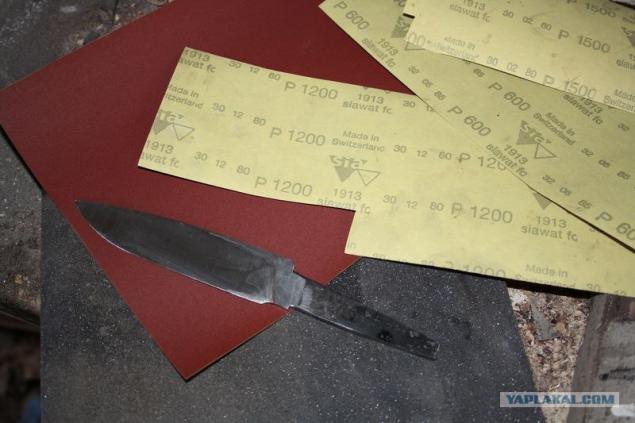

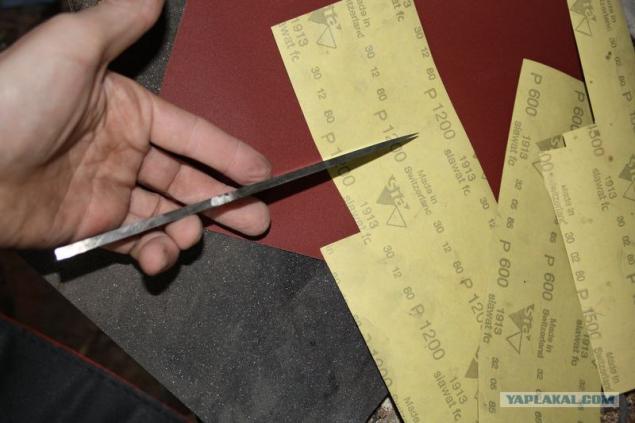

Changing the ribbon on a fine-grained and doshlifovyvaem wedge. After the tape 240grit obtain the product as close to ready. The basic allowance is removed. Now the tedious and time-consuming work - sanding by hand. Here are the raw material

View from above - the required drop:

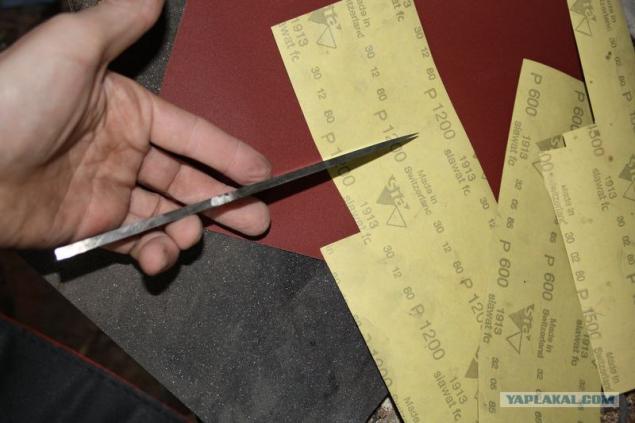

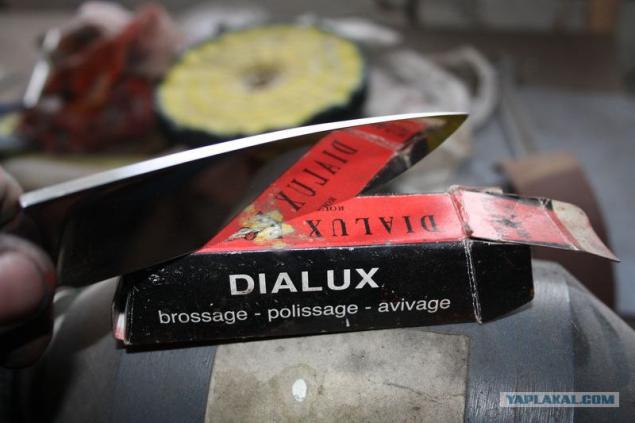

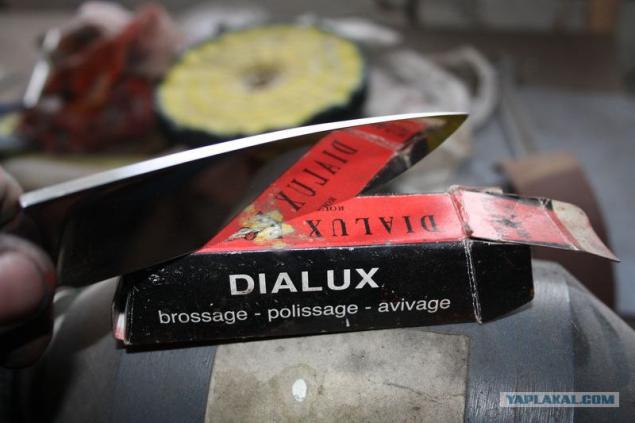

Hour wet elozanya of blade and I exhaled in the 2000 grit sandpaper. Now polishing. First diamond paste of 1 micron

Then, iron oxide and aluminum oxide. We get the shine (although because of the rush, I'm not happy with the result. Perepoliruyu later.

Take a piece of bronze

Zapilivaem bolster

Jumpers remove natfilem. He also customize the groove in bolster the size of the liner. We put on the shank and pour superglue

According to the plan, I want a couple of prostavochek. Cut them out of brass and electrical fiber (cardboard impregnated with special resin)

We put on hvastovik, lubricates superglue and clamped on both sides (have to adapt to it, but I prefer to take the two clutches.

While the glue is drying, prepare the handle is black. We will use a cross-section oak. I must say that brusochek unusual. It is impregnated with a polymer resin in a vacuum and thus requires no further processing of the protection from moisture. This is called stable wood.

Mark up on the bar and place in the drill shank groove. The main thing is not to break the bit of wood inside, otherwise then pull very hard.

Knead the polyester resin, fill the groove in the bar and insert to a shank. Hold to adjust. Then I took the bottle and drank pirrif piffka while waiting for the polymerization of the resin.

We transfer the pattern to the contours of the workpiece.

Processed on the grinder and get:

Drill Hole and glue in a tube. Note that in this case is expanded it will not turn out. Tree in end sections and can crack.

Treat the verge of a file.

Then grind sandpaper, consistently reducing the grain: P120, P240, P400, P600. Now you can polish. Circle rag, especially for wood, so as not to smear the hilt. Pasta white alumina.

After polishing, leather weave shnurochek 4 tail. He turns round, threaded hole in temlyachnoe. We have at the output here is:

On the other hand:

View from above:

All! You can komenty. Thank you for your attention and patience.

Source:

25 ph

Let's start.

We have available heat-treated steel strip 95X18 (hardness 58-59HRC). Draw a sketch on paper and cut out the pattern.

We transfer the pattern to the metal and hit the Bulgarian circuit.

Further Sander (Grinder) derive outline more precisely.

Thereafter conventional chamfer grinding wheels do near future cutting edge. This is to ensure that, in future breeding descents, the tool does not chafe against sharp edges.

On the plywood circle stretch the tape grit sandpaper P50 and preliminary conclusions slopes. And at the same time gently purifies the blade to the tip, because it is conceived as a drop-point.

Now back to The Grinder. and enter the flat slopes on both sides. Carefully follow the symmetry.

We get almost finished edge.

Changing the ribbon on a fine-grained and doshlifovyvaem wedge. After the tape 240grit obtain the product as close to ready. The basic allowance is removed. Now the tedious and time-consuming work - sanding by hand. Here are the raw material

View from above - the required drop:

Hour wet elozanya of blade and I exhaled in the 2000 grit sandpaper. Now polishing. First diamond paste of 1 micron

Then, iron oxide and aluminum oxide. We get the shine (although because of the rush, I'm not happy with the result. Perepoliruyu later.

Take a piece of bronze

Zapilivaem bolster

Jumpers remove natfilem. He also customize the groove in bolster the size of the liner. We put on the shank and pour superglue

According to the plan, I want a couple of prostavochek. Cut them out of brass and electrical fiber (cardboard impregnated with special resin)

We put on hvastovik, lubricates superglue and clamped on both sides (have to adapt to it, but I prefer to take the two clutches.

While the glue is drying, prepare the handle is black. We will use a cross-section oak. I must say that brusochek unusual. It is impregnated with a polymer resin in a vacuum and thus requires no further processing of the protection from moisture. This is called stable wood.

Mark up on the bar and place in the drill shank groove. The main thing is not to break the bit of wood inside, otherwise then pull very hard.

Knead the polyester resin, fill the groove in the bar and insert to a shank. Hold to adjust. Then I took the bottle and drank pirrif piffka while waiting for the polymerization of the resin.

We transfer the pattern to the contours of the workpiece.

Processed on the grinder and get:

Drill Hole and glue in a tube. Note that in this case is expanded it will not turn out. Tree in end sections and can crack.

Treat the verge of a file.

Then grind sandpaper, consistently reducing the grain: P120, P240, P400, P600. Now you can polish. Circle rag, especially for wood, so as not to smear the hilt. Pasta white alumina.

After polishing, leather weave shnurochek 4 tail. He turns round, threaded hole in temlyachnoe. We have at the output here is:

On the other hand:

View from above:

All! You can komenty. Thank you for your attention and patience.

Source: