649

3d printing from first hand

On television and the Internet are now constantly talk about the new indispensable piece, 3d printing, which will be in a few years each. And scanning iPhones freshly printed products, we will be able to create copies of them at home.

I tell you the first-hand what it is.

So, yielding trends of new technologies, I decided to organize a small business, 3d printing as a service, and to me this was fated to herald the future.

And here he is currently a full black, lights blinking, beeping and lighting lures, wicked.

12 photos + text.

And let's printanem thread that battle stars, so try to say how cool you are, - I said. Son, whose eyes burned like two penny, happily introduced the initiative, folder grit and printani me a robot! Robot promised son will Grendizer.

In the meantime, he pulled out his zagashnika couple models, and flew the soul to heaven. Occupation will tell you fascinating, then calibrate the platform, the Kapton without bubbles Stick ... In general, comparable to the tinkering in the garage with the Russian classics. So on the first lot of tears were shed, and a lot of high-quality plastic, the US transferred empty.

Then, one day, no longer supplied plastic. Clogged head, I thought, and climbed to spin and broke the head. And it certainly was not at all in the head, and in my head, to be more precise, the intricacies of tuning and calibration, which are now in such typewriters are more than enough. So that the driver is "straight arm" should be supplied with the printer.

Popechalivshis and worn out enough with the extruder, after all, the process established. So, I now makerbota extruder with closed eyes gather and understand at the time as a Kalashnikov rifle.

This printer prints ABS and PLA plastic. Print quality 0, 35 - 0, 1 mm, the hollow model can print. The thickness of the layer and filling of model strongly influences the speed. While the essence, so the case, a model prepared for printing. And after dancing with a tambourine, getting the output is such a product.

ABS plastic. 0 Layer thickness 1 mm, cat hollow inside. Dinosaur with 15% coverage. Inside, he published something like a hundred, and so back, face and other horizontal parts were very good. Both models print took about 12 hours. The process of printing fascinates. It's like looking at another working man.

Experimenting further, in a short time has made a pig model for her son, run shaytanmashinu

Layer thickness porcine 0, 15 mm, 15% filling. ABS plastic. Print overhanging parts necessary to use support proper mustache in pigs - this is it.

Pig, I think, has gone perfectly.

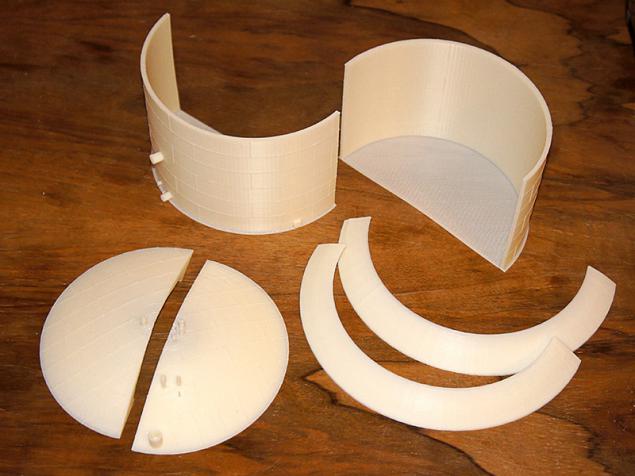

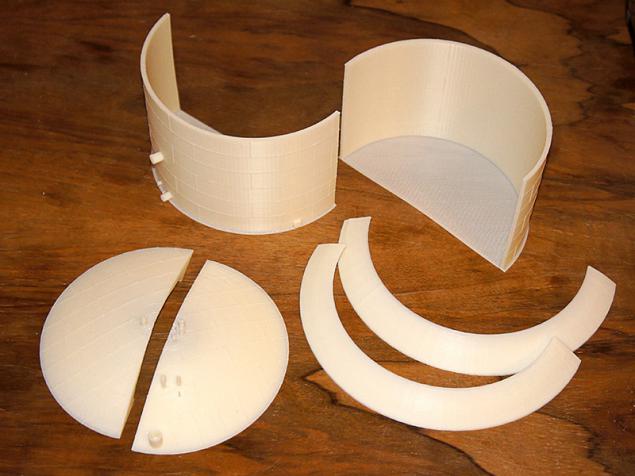

Then he received an order from the old frilensa. Need a reservoir model for NPH. There simply dancing with a tambourine is not done. The model is large, so it had to dissect and make a gluing of 6 parts, in addition to it there are enough small pipes, they had to be increased because they are not on the scale of thicker pins.

It revealed another problem - detachment models on the platform. Again connect the driver "straight arm", pull out the drum, and occasionally fighting the urge to throw out the infernal machine, the output of each detail. ABS plastic. The layer thickness of 0, 15 mm, 100% fill. On the wall and the cover it took 6 hours for each item. And a whole bunch of nerves.

In the future, if necessary, of course, have to handle the model solvent. To smooth wall. The print quality is good, but the texture of the paint still emerges.

Mug for my good friend, a talented designer. Layer 0, 1 mm, 100% coverage. PLA plastics.

Son asks the evil birds. First Ptah

He's a sidekick

I think the conflict is brewing

Next in line is the cup for pencils in the form of the King of pigs ... tonight will print

Posted in [mergetime] 1381471342 [/ mergetime]

Summarizing want to disappoint those who want to buy such a device, and do 3d printing by connecting it to a computer and pressing a couple of buttons. Perhaps these cars will be available to a wide range of users in a few years. When large corporations in this matter will start in earnest to develop the market. Now you are bound to jump up at night and run to his new pet to check, not otlipla whether the item from the table? And obstruction extruder? Or even how the accident occurred in the process. But in general, yes, technology is already on the verge of science fiction.

Author and source I

PS. If the topic is interesting, it will complement the new printed buns and share process works

tyts

Source:

I tell you the first-hand what it is.

So, yielding trends of new technologies, I decided to organize a small business, 3d printing as a service, and to me this was fated to herald the future.

And here he is currently a full black, lights blinking, beeping and lighting lures, wicked.

12 photos + text.

And let's printanem thread that battle stars, so try to say how cool you are, - I said. Son, whose eyes burned like two penny, happily introduced the initiative, folder grit and printani me a robot! Robot promised son will Grendizer.

In the meantime, he pulled out his zagashnika couple models, and flew the soul to heaven. Occupation will tell you fascinating, then calibrate the platform, the Kapton without bubbles Stick ... In general, comparable to the tinkering in the garage with the Russian classics. So on the first lot of tears were shed, and a lot of high-quality plastic, the US transferred empty.

Then, one day, no longer supplied plastic. Clogged head, I thought, and climbed to spin and broke the head. And it certainly was not at all in the head, and in my head, to be more precise, the intricacies of tuning and calibration, which are now in such typewriters are more than enough. So that the driver is "straight arm" should be supplied with the printer.

Popechalivshis and worn out enough with the extruder, after all, the process established. So, I now makerbota extruder with closed eyes gather and understand at the time as a Kalashnikov rifle.

This printer prints ABS and PLA plastic. Print quality 0, 35 - 0, 1 mm, the hollow model can print. The thickness of the layer and filling of model strongly influences the speed. While the essence, so the case, a model prepared for printing. And after dancing with a tambourine, getting the output is such a product.

ABS plastic. 0 Layer thickness 1 mm, cat hollow inside. Dinosaur with 15% coverage. Inside, he published something like a hundred, and so back, face and other horizontal parts were very good. Both models print took about 12 hours. The process of printing fascinates. It's like looking at another working man.

Experimenting further, in a short time has made a pig model for her son, run shaytanmashinu

Layer thickness porcine 0, 15 mm, 15% filling. ABS plastic. Print overhanging parts necessary to use support proper mustache in pigs - this is it.

Pig, I think, has gone perfectly.

Then he received an order from the old frilensa. Need a reservoir model for NPH. There simply dancing with a tambourine is not done. The model is large, so it had to dissect and make a gluing of 6 parts, in addition to it there are enough small pipes, they had to be increased because they are not on the scale of thicker pins.

It revealed another problem - detachment models on the platform. Again connect the driver "straight arm", pull out the drum, and occasionally fighting the urge to throw out the infernal machine, the output of each detail. ABS plastic. The layer thickness of 0, 15 mm, 100% fill. On the wall and the cover it took 6 hours for each item. And a whole bunch of nerves.

In the future, if necessary, of course, have to handle the model solvent. To smooth wall. The print quality is good, but the texture of the paint still emerges.

Mug for my good friend, a talented designer. Layer 0, 1 mm, 100% coverage. PLA plastics.

Son asks the evil birds. First Ptah

He's a sidekick

I think the conflict is brewing

Next in line is the cup for pencils in the form of the King of pigs ... tonight will print

Posted in [mergetime] 1381471342 [/ mergetime]

Summarizing want to disappoint those who want to buy such a device, and do 3d printing by connecting it to a computer and pressing a couple of buttons. Perhaps these cars will be available to a wide range of users in a few years. When large corporations in this matter will start in earnest to develop the market. Now you are bound to jump up at night and run to his new pet to check, not otlipla whether the item from the table? And obstruction extruder? Or even how the accident occurred in the process. But in general, yes, technology is already on the verge of science fiction.

Author and source I

PS. If the topic is interesting, it will complement the new printed buns and share process works

tyts

Source: