518

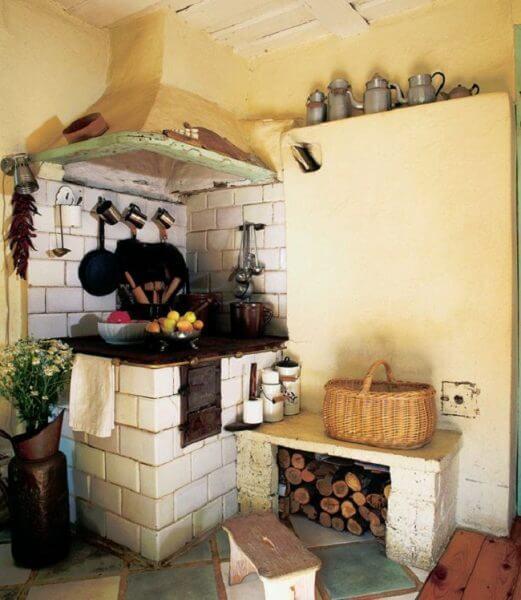

How to build a stove for a summer kitchen

Plates are often put directly on the floor or planted a wooden Board (provided that the floor is strong enough), but it is better to do the plates on the Foundation; in this case, the strength of the floor does not matter.

The heat transfer plates depends on their size and usually does not exceed 900 kcal/h.

To effectively use the heat released during the combustion of the fuel, stoves, often combined with heating pads.

Plates can be of different sizes, of different complexity, with different number of burners.

Simple boards have only the firebox (furnace), closed at the top by a cast-iron flooring cast iron or oven with hobs.

Plate of average complexity, in addition to the plate with the burner, often have the oven.

Complicated plate, as a rule, are equipped with an oven and a water-heating box.

In the simple plates of the hot gases generated by the burning fuel, should be sent under the flooring cast-iron or cast-iron stove, and then output to a pipe or a heating guard.

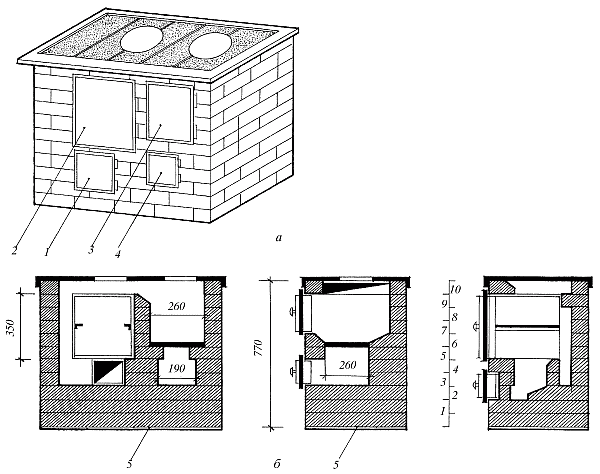

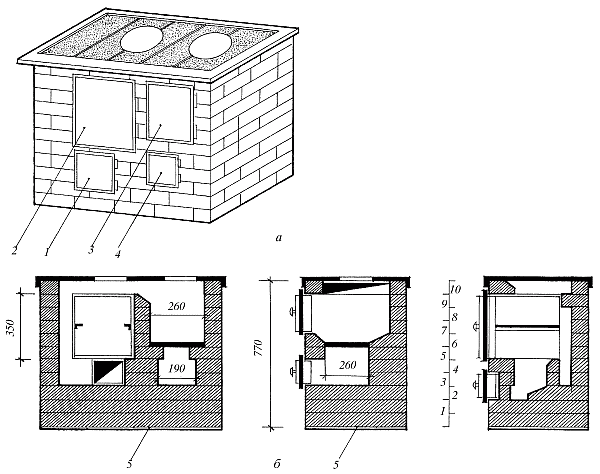

In Fig. shows a stove with an oven. It has options 1020х640х770 mm (length, width, height) and calculated under the pig-iron flooring (or five plates with plates) 530х900 mm.

If the flooring or of the plate have different size, it is necessary to correspondingly change the width and length of the plate. The channels are inside of it should remain the same.

This plate provides a heat loss of 600 kcal/h (with two furnaces in the day).

Fig.1 Cooking hob with an oven: a — appearance; b — plate in three sections; 1 — cleaning; 2 — oven; 3 — firebox; 4 — ash pit; 5 — felt, coated roofing steel

For brickwork will need the following materials:

Devices:

Also interesting: Eastern TANDOOR oven from bricks with their hands

Brick oven with his own hands —a step by step guide

The clutch plates should be carried out in strict accordance with the lining. The joints between the bricks are filled with a clay solution, keeping them the same width throughout the masonry. In the process of laying it is periodically necessary to check the verticality of the wall plate. For strength of masonry bricks in a row placed with the strict observance of bandaging of seams.

If the clutch is on the floor or planted a wooden Board, you first need to prepare the site:

On the floor (or on a wooden Board) placed two layers of sheet asbestos or sheet of felt, as should be soaked in a clay solution and covered them with a sheet of roofing steel, cut the size of the hearth.

Sheet nailed to the floor (the shield), and the extra, protruding beyond the edge of the felt or asbestos cut.

Steel sheet coated with a clay solution, and then spread on it the first row of bricks, also fastening them together with a clay solution. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: /users/4

The heat transfer plates depends on their size and usually does not exceed 900 kcal/h.

To effectively use the heat released during the combustion of the fuel, stoves, often combined with heating pads.

Plates can be of different sizes, of different complexity, with different number of burners.

Simple boards have only the firebox (furnace), closed at the top by a cast-iron flooring cast iron or oven with hobs.

Plate of average complexity, in addition to the plate with the burner, often have the oven.

Complicated plate, as a rule, are equipped with an oven and a water-heating box.

In the simple plates of the hot gases generated by the burning fuel, should be sent under the flooring cast-iron or cast-iron stove, and then output to a pipe or a heating guard.

In Fig. shows a stove with an oven. It has options 1020х640х770 mm (length, width, height) and calculated under the pig-iron flooring (or five plates with plates) 530х900 mm.

If the flooring or of the plate have different size, it is necessary to correspondingly change the width and length of the plate. The channels are inside of it should remain the same.

This plate provides a heat loss of 600 kcal/h (with two furnaces in the day).

Fig.1 Cooking hob with an oven: a — appearance; b — plate in three sections; 1 — cleaning; 2 — oven; 3 — firebox; 4 — ash pit; 5 — felt, coated roofing steel

For brickwork will need the following materials:

- 175 pieces of ordinary red brick;

- about 5 buckets of clay solution;

- 2 sheets of a roofing steel — 500х700 mm (predtopochnyj) and 1020х640 mm (under plate);

- 1 kg construction felt;

- 1.2 m steel tape (mm 25х15);

- 3,32 m steel area (30х30х4 mm) strapping.

Devices:

- 5 plates pig-iron flooring (530х180 mm each) plates;

- oven (350х350х450 mm);

- furnace door 250х210 mm;

- and ash-pit cleanout door (130х140 mm);

- smoke damper (damper) — 130x130 mm;

- grate (250х180 mm).

Also interesting: Eastern TANDOOR oven from bricks with their hands

Brick oven with his own hands —a step by step guide

The clutch plates should be carried out in strict accordance with the lining. The joints between the bricks are filled with a clay solution, keeping them the same width throughout the masonry. In the process of laying it is periodically necessary to check the verticality of the wall plate. For strength of masonry bricks in a row placed with the strict observance of bandaging of seams.

If the clutch is on the floor or planted a wooden Board, you first need to prepare the site:

On the floor (or on a wooden Board) placed two layers of sheet asbestos or sheet of felt, as should be soaked in a clay solution and covered them with a sheet of roofing steel, cut the size of the hearth.

Sheet nailed to the floor (the shield), and the extra, protruding beyond the edge of the felt or asbestos cut.

Steel sheet coated with a clay solution, and then spread on it the first row of bricks, also fastening them together with a clay solution. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: /users/4