394

Blade printed on a 3D printer supercar

3D printing technology is also used in the aerospace industry. Manufacturers can create lightweight but at the same time durable products in less time and is much cheaper compared to traditional production. Now, a startup from San Francisco called Divergent Microfactories decided to try to apply this technology in the automotive industry. As a result, the company debuted with a 3D-printed car, called the Blade, the first car made in this way.

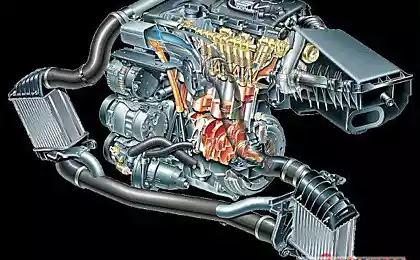

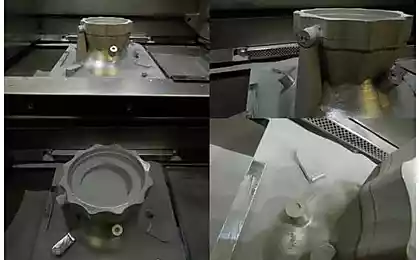

The base Blade is fully unique. Instead of doing the whole Divergent prints on a 3D printer aluminum nodes and elements from carbon fiber. Printed carbon fiber with aluminum elements are connected by nodes, resulting in a durable and lightweight skeleton of the car. According to various statements, this approach allows to reduce the weight of the chassis by as much as 90 percent, compared to traditional chassis of the car. This is achieved primarily through the use of carbon fiber and aluminum instead of steel. The total weight of the car is only 635 kg. This makes it one of the lightest supercars in the world. Engine power is "only" 700 HP. and it runs on liquefied gas and gasoline.

The company plans to release a limited batch of these cars to begin with. But we hope that auto sales will be successful, and in the future, such lighter vehicles will be distributed. At least it is worth to develop this direction, it would be interesting to print a car in your garage. Well, or it will at least reduce the production of cars. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: tehplaneta.ru/automotoavia/avtotekhnika/blade-napechatannyjj-na-3d-printere-superkar

The base Blade is fully unique. Instead of doing the whole Divergent prints on a 3D printer aluminum nodes and elements from carbon fiber. Printed carbon fiber with aluminum elements are connected by nodes, resulting in a durable and lightweight skeleton of the car. According to various statements, this approach allows to reduce the weight of the chassis by as much as 90 percent, compared to traditional chassis of the car. This is achieved primarily through the use of carbon fiber and aluminum instead of steel. The total weight of the car is only 635 kg. This makes it one of the lightest supercars in the world. Engine power is "only" 700 HP. and it runs on liquefied gas and gasoline.

The company plans to release a limited batch of these cars to begin with. But we hope that auto sales will be successful, and in the future, such lighter vehicles will be distributed. At least it is worth to develop this direction, it would be interesting to print a car in your garage. Well, or it will at least reduce the production of cars. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: tehplaneta.ru/automotoavia/avtotekhnika/blade-napechatannyjj-na-3d-printere-superkar