783

Japanese engineers invented bearings that require no lubrication

conventional bearings i>

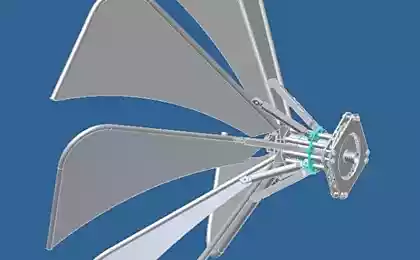

Japanese engineers from the company Coo Space figured out how to снизить friction roller bearings and eliminate the need to periodically lubricate them. They were able to exclude from the design of simple modifications of the separator through the outer ring of the bearing.

Rolling invented a long time ago. Mistakenly first experience of rolling elements to reduce friction attributed to the ancient Egyptians. In fact, the earliest instance of the bearing belongs to the Roman turntables, dating from 40 BC Leonardo Da Vinci (where the same without him) used them in his drawings of the helicopter about 1500. A first version of the bearings with cage suggested in the 17th century, Galileo.

Now bearings can be found in the vast majority of mechanisms. From movies and bike to bike from the car to the helicopter, from hard drives to the fans. The best way to reduce rotational friction is not invented - except for exotic, complex and expensive magnetic suspension.

Beads between the bearing rings generally used to reduce friction between moving parts. But if you use balls without separator, they will catch up and rub against each other, that on the contrary will lead to increased friction. A separator also contributes to the rolling resistance. As a result, any bearings require lubrication, and rare bearings without separators are limited in speed due to increased wear.

One Japanese inventors poured himself a strong green tea and thinking. If the only problem is that the balls rub against each other, is it possible to do so, that they have not met? It turned out - possible.

The operating principle of i>

If you make a recess in the outer ring, the balls, passing the dredging will slow down, and then - to accelerate. As a result of such a "ragged" rhythm is not catching the balls and do not rub against each other. And this structure does not require any separator or grease. They called it Autonomus Decentralized Bearing (autonomous decentralized bearings).

And circling and circling and circling i>

While the company successfully makes prototypes and has already received orders from all over the world for its miracle-bearings. Reduced friction on the order and eliminating the need for periodic maintenance will increase the efficiency and reduce the cost of future arrangements.

Source: geektimes.ru/post/250862/

Scientists have found that plankton produces 50% of all the oxygen on the planet

The main income of dentists