840

Rip motor from the boat.

Long hesitant to do another theme techno ... After we have a bunch of these technical topics, and they probably are not very interesting, because there are similar and the same type ...

But then as I remembered that many of the themes, like the same type, and none of it does not swear ... Therefore, I decided to take a picture on the little pictures, and in haste to ascribe to them a little letter, so as not to load the brains the good people useless information ...

is 17 pictures.

We will talk about some of the features in the repair of various boats in Norway. (Just a little)

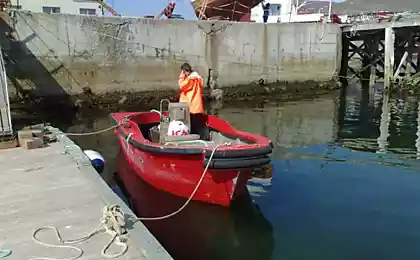

For example, this small fishing boat ...

In fact, I remember that the ship is allowed to call a military ship and sailing. However, in foreign languages, the people not to drive these grammatical vagaries of crockery and all these calls in one word - bot.

Typically, these small boats or the fishermen repairing the owners who catch fish with these boats. It concerns usually straightforward breakdowns and maintenance. But if there some complex troubleshooting, they have recourse to specialized repair shops (where I slowly mantulyu)

The main advantage of such an opportunity kontory- pull the boat ashore. It is impossible to remove the drive shaft of the propeller when the ship is in the water. If the ship is large, use a platform on wheels, sliding on the rails in the water. According to pull her boat on dry dock. If the ship is small, then use the elevating crane, which can lift 20 tonnes to a height of 80 meters, such as Liebherr ..). It usually occurs quickly (crane arrives faster than a tow truck for the car in the city.) But is it worth nedeshevo- (only vodile- the crane per hour drips pay about $ 160) ... Odnako- insurance pays for everything.

With that a ship (as in the picture at the beginning), something happened takoe- somehow he slid down the steep bank (such as unreliable put it) Once stranded, fell on its side and was absorbed by the sea water right at the half, that is, sinking all its left side.

I pulled it until the next day.

This ship is made of laminated glassfibre (like thick fiberglass) Therefore, sea water is not much damaged body and parts. However, the owners of the vessel were not sure that the motor and gearbox do not get water. It was therefore decided to pull decision- both. Motor have decided to change for a long time, but a box with hydraulic transmissions decided to check for corrosion inside. And at the same time to change the bearings and seals. I do not think it was necessary. However, in such cases, for all the insurance company pays.

The main thing that a technical expert to provide a report on the state of nodes. Therefore, it was decided to dismantle all stupid. And that change - decides insurance.

(Fear of their ships almost all owners. Regularly pay contributions in the case of major damage to get money for repairs. In addition, they pay for downtime, such as salary sailors.

By the way, I noticed that many medium-sized shipowners sometimes instigate any -nibud reconstruction projects that require major infusions of money the insurance. Convince the insurance company that, for example, a vessel is required reconstruction. In doing so, they manage vykruzhit with this repair yourself, for example, building materials for the house, paint and so on. N., Then slipping the insurance invoice).

Generally boats sometimes happens directly at the sink. This happens when a fault occurs at a permanent pumpout pump ... As a rule, this is followed by a level sensor. When you reach a certain level, the pump (powered on postoyanku) But if something did not work, the water flooded the vessel arriving. (Especially if there is looseness in the place of the output drive shaft of the screw ... and it happens often). People come to the pier (especially after the holidays) - and only sticks out from the water surface part. And it starts very gemorroyny work on the replacement of all ... sea water spoils everything except plastic and glass)

So, in my experience, one of the most difficult moments in the repair of major units on smaller vessels - a very small space for the engine and gearbox. It seems that a constructor is not suspected on probable repairs. Or, like the Hajj Nasreddin was sure that in 30 years, or the emir, or the donkey will die or be allowed to scrap the ship, or he just stupid sink somewhere very far away from the shore. And then you can not worry that someone will blame a bad design. As an example, I remember one such ship, whose engine and the transmission is in a small space - at the bottom of the front of the vessel, directly under the cabin, toilet and galley. Further, the drive shaft runs along in the bottom, through the vessel, and consisted of two short shafts. The entire total length of the drive shaft 12. The bearing was meters bearings and couplings were unavailable for either repair or for control. All this after assembly at the factory was tightly brewed aluminum sheet 8 mm ribs. This sheet is the bottom of a large tank of fish caught that are stored there for some time while fishing.

After a while, the welds at the bottom of lost tightness and whole fish slurry penetrated through into the cavity, where the shaft, bearings and couplings. Over time, this procedure spoiled. When we launched the bilge pump, the nauseating smell of the table around. Muddy gray mold slurry flowed into the sea and the wind helped to breathe a little bit.

From the water collapsed bearings, vibration - the clutch broke and eventually the screw does not rotate although motor running. Needed serious repair with the opening.

After pumping fish broth to help me with the Poles have sent two Bulgarians. (Norwegian and English, they did not know, with some able to explain in Russian, so we decided that would be most effective if I show them where and what to cut)

I drew a long rectangle marker along the bottom aluminum rezervuara- future opening through which it was necessary to get all this clap with rusty shaft and bearing damage, smelling of rotten fish.

Someone skazhet- fuck this work ... I did not choose her specifically. She chose me. It is of course, but on the one hand, it is necessary to think, did not seem in the sewers of Copan.

However, the company is a kind of ship repair. One passenger was in the repair of high-speed catamaran made entirely of aluminum ... There's a crack in the septic tank (that's where everything flows from tauleta). I have something else detached from the pair of flanges, and took the top hatch. But the welder had to climb right into this tank and brew inside the crack.

Because, again, no one suspected that the tank that suddenly need to change ... Pull it was not possible.

A lot of large units are mounted on the vessel during assembly. Then everything is tightly sealed. No turning back.

This motor boat was standing in a narrow doorway. It was impossible to remove the box. To lower bolt is impossible to pin down. Therefore, it was decided to shoot together. But the disconnect drive shaft from the transmission, too easy. Coupling at the bottom. We have to be in very uncomfortable positions. Often there is just hard to unscrew the bolt normal as pull down arms does not develop due effort. Constantly think - what the designer had mudaki- really sorry for the design was to make the opening even for 10-15 cm wider?

About the height of the engine compartment even obizhaemsya- barely manages to stand only on all fours, often hit his head on the ceiling ribs.

The most running tool - a stick with a magnet ... If awkward postures are frequent drop the keys in the muck under the motor oil ... You have to catch ...

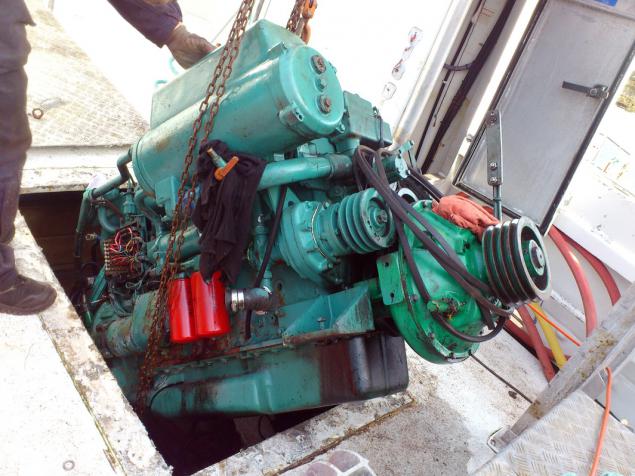

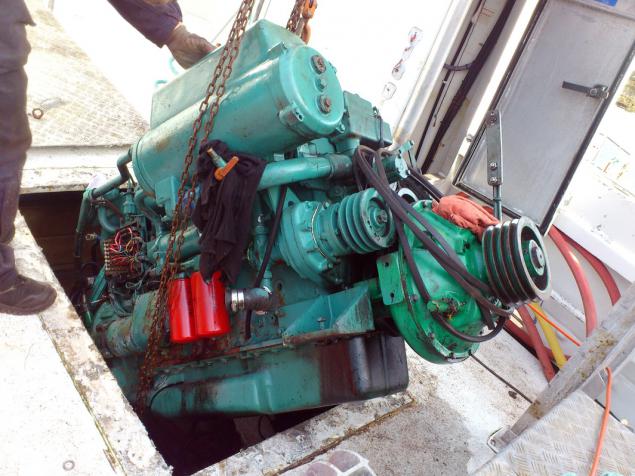

Well, finally we unscrewed the hatch in the ceiling and begin to pull out the motor.

Luke is much smaller, so the first ride up the front part of the motor up and take out the pan ...

That's kind of pulled up ... hanging

To promote the use small mobile crane.

It has been mentioned ...

On the one hand it looks decent.

But on the other hand, he began to corrode slightly.

starts to fall to the ground

View through the hatch at the empty space where the engine was ... at the bottom of the oil and coolant, which has flowed out of the engine when the disconnect hoses ...

Without engine it did not seem so crowded.

The motor on the feet was in the iron frame ... By mounting bolts from the bottom would never crawl ... scroll and bottom bolts were not secured ...

Here here Home Cities podstavochku under the motor. Visible is only wedges ...

the view from the other side ... there are traces of corrosion.

That's the way the table is visible from the boat propeller. The cover of the transmission. (Prokladochki new ... he cut out with scissors)

By the way, screw rejected ... ... go to the dump heavy and made of brass. (One blade -14 kg)

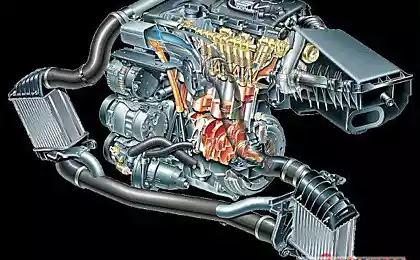

As I wrote above, it is necessary to disassemble the transmission control. That view of the body. Partially dismantled. Well washed

Secondary shaft. Gear charged.

That gear driven

Here gears and couplings forward and reverse.

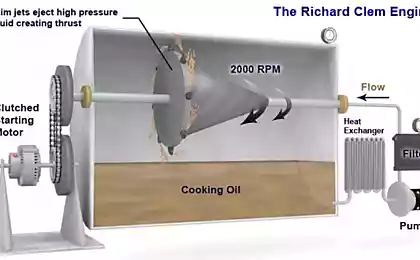

Hydraulic friction clutches. Oil high pressure presses the friction plates and clutch comes with a holder. (The same principle as in the automotive automatic transmission ... old hydraulic type.)

Depending on the direction in which fluid coupling directed pressure is either direct or reverse rotation of the output shaft.

These two Mandula alternately fed pressure shafts clutches. They made holes and feeding channels, which serves the oil in the holes at the ends of the rotating shaft seal (similar to piston rings) Rings are used for the separation of media pressure.

Actually repairing the boat is not finished.

Now everyone is waiting for, that decides the insurance.

Therefore, the topic I'll cover ...

If you were wondering, maybe, something I will add in the future.

Thank you for your attention.

this is all.

Source:

But then as I remembered that many of the themes, like the same type, and none of it does not swear ... Therefore, I decided to take a picture on the little pictures, and in haste to ascribe to them a little letter, so as not to load the brains the good people useless information ...

is 17 pictures.

We will talk about some of the features in the repair of various boats in Norway. (Just a little)

For example, this small fishing boat ...

In fact, I remember that the ship is allowed to call a military ship and sailing. However, in foreign languages, the people not to drive these grammatical vagaries of crockery and all these calls in one word - bot.

Typically, these small boats or the fishermen repairing the owners who catch fish with these boats. It concerns usually straightforward breakdowns and maintenance. But if there some complex troubleshooting, they have recourse to specialized repair shops (where I slowly mantulyu)

The main advantage of such an opportunity kontory- pull the boat ashore. It is impossible to remove the drive shaft of the propeller when the ship is in the water. If the ship is large, use a platform on wheels, sliding on the rails in the water. According to pull her boat on dry dock. If the ship is small, then use the elevating crane, which can lift 20 tonnes to a height of 80 meters, such as Liebherr ..). It usually occurs quickly (crane arrives faster than a tow truck for the car in the city.) But is it worth nedeshevo- (only vodile- the crane per hour drips pay about $ 160) ... Odnako- insurance pays for everything.

With that a ship (as in the picture at the beginning), something happened takoe- somehow he slid down the steep bank (such as unreliable put it) Once stranded, fell on its side and was absorbed by the sea water right at the half, that is, sinking all its left side.

I pulled it until the next day.

This ship is made of laminated glassfibre (like thick fiberglass) Therefore, sea water is not much damaged body and parts. However, the owners of the vessel were not sure that the motor and gearbox do not get water. It was therefore decided to pull decision- both. Motor have decided to change for a long time, but a box with hydraulic transmissions decided to check for corrosion inside. And at the same time to change the bearings and seals. I do not think it was necessary. However, in such cases, for all the insurance company pays.

The main thing that a technical expert to provide a report on the state of nodes. Therefore, it was decided to dismantle all stupid. And that change - decides insurance.

(Fear of their ships almost all owners. Regularly pay contributions in the case of major damage to get money for repairs. In addition, they pay for downtime, such as salary sailors.

By the way, I noticed that many medium-sized shipowners sometimes instigate any -nibud reconstruction projects that require major infusions of money the insurance. Convince the insurance company that, for example, a vessel is required reconstruction. In doing so, they manage vykruzhit with this repair yourself, for example, building materials for the house, paint and so on. N., Then slipping the insurance invoice).

Generally boats sometimes happens directly at the sink. This happens when a fault occurs at a permanent pumpout pump ... As a rule, this is followed by a level sensor. When you reach a certain level, the pump (powered on postoyanku) But if something did not work, the water flooded the vessel arriving. (Especially if there is looseness in the place of the output drive shaft of the screw ... and it happens often). People come to the pier (especially after the holidays) - and only sticks out from the water surface part. And it starts very gemorroyny work on the replacement of all ... sea water spoils everything except plastic and glass)

So, in my experience, one of the most difficult moments in the repair of major units on smaller vessels - a very small space for the engine and gearbox. It seems that a constructor is not suspected on probable repairs. Or, like the Hajj Nasreddin was sure that in 30 years, or the emir, or the donkey will die or be allowed to scrap the ship, or he just stupid sink somewhere very far away from the shore. And then you can not worry that someone will blame a bad design. As an example, I remember one such ship, whose engine and the transmission is in a small space - at the bottom of the front of the vessel, directly under the cabin, toilet and galley. Further, the drive shaft runs along in the bottom, through the vessel, and consisted of two short shafts. The entire total length of the drive shaft 12. The bearing was meters bearings and couplings were unavailable for either repair or for control. All this after assembly at the factory was tightly brewed aluminum sheet 8 mm ribs. This sheet is the bottom of a large tank of fish caught that are stored there for some time while fishing.

After a while, the welds at the bottom of lost tightness and whole fish slurry penetrated through into the cavity, where the shaft, bearings and couplings. Over time, this procedure spoiled. When we launched the bilge pump, the nauseating smell of the table around. Muddy gray mold slurry flowed into the sea and the wind helped to breathe a little bit.

From the water collapsed bearings, vibration - the clutch broke and eventually the screw does not rotate although motor running. Needed serious repair with the opening.

After pumping fish broth to help me with the Poles have sent two Bulgarians. (Norwegian and English, they did not know, with some able to explain in Russian, so we decided that would be most effective if I show them where and what to cut)

I drew a long rectangle marker along the bottom aluminum rezervuara- future opening through which it was necessary to get all this clap with rusty shaft and bearing damage, smelling of rotten fish.

Someone skazhet- fuck this work ... I did not choose her specifically. She chose me. It is of course, but on the one hand, it is necessary to think, did not seem in the sewers of Copan.

However, the company is a kind of ship repair. One passenger was in the repair of high-speed catamaran made entirely of aluminum ... There's a crack in the septic tank (that's where everything flows from tauleta). I have something else detached from the pair of flanges, and took the top hatch. But the welder had to climb right into this tank and brew inside the crack.

Because, again, no one suspected that the tank that suddenly need to change ... Pull it was not possible.

A lot of large units are mounted on the vessel during assembly. Then everything is tightly sealed. No turning back.

This motor boat was standing in a narrow doorway. It was impossible to remove the box. To lower bolt is impossible to pin down. Therefore, it was decided to shoot together. But the disconnect drive shaft from the transmission, too easy. Coupling at the bottom. We have to be in very uncomfortable positions. Often there is just hard to unscrew the bolt normal as pull down arms does not develop due effort. Constantly think - what the designer had mudaki- really sorry for the design was to make the opening even for 10-15 cm wider?

About the height of the engine compartment even obizhaemsya- barely manages to stand only on all fours, often hit his head on the ceiling ribs.

The most running tool - a stick with a magnet ... If awkward postures are frequent drop the keys in the muck under the motor oil ... You have to catch ...

Well, finally we unscrewed the hatch in the ceiling and begin to pull out the motor.

Luke is much smaller, so the first ride up the front part of the motor up and take out the pan ...

That's kind of pulled up ... hanging

To promote the use small mobile crane.

It has been mentioned ...

On the one hand it looks decent.

But on the other hand, he began to corrode slightly.

starts to fall to the ground

View through the hatch at the empty space where the engine was ... at the bottom of the oil and coolant, which has flowed out of the engine when the disconnect hoses ...

Without engine it did not seem so crowded.

The motor on the feet was in the iron frame ... By mounting bolts from the bottom would never crawl ... scroll and bottom bolts were not secured ...

Here here Home Cities podstavochku under the motor. Visible is only wedges ...

the view from the other side ... there are traces of corrosion.

That's the way the table is visible from the boat propeller. The cover of the transmission. (Prokladochki new ... he cut out with scissors)

By the way, screw rejected ... ... go to the dump heavy and made of brass. (One blade -14 kg)

As I wrote above, it is necessary to disassemble the transmission control. That view of the body. Partially dismantled. Well washed

Secondary shaft. Gear charged.

That gear driven

Here gears and couplings forward and reverse.

Hydraulic friction clutches. Oil high pressure presses the friction plates and clutch comes with a holder. (The same principle as in the automotive automatic transmission ... old hydraulic type.)

Depending on the direction in which fluid coupling directed pressure is either direct or reverse rotation of the output shaft.

These two Mandula alternately fed pressure shafts clutches. They made holes and feeding channels, which serves the oil in the holes at the ends of the rotating shaft seal (similar to piston rings) Rings are used for the separation of media pressure.

Actually repairing the boat is not finished.

Now everyone is waiting for, that decides the insurance.

Therefore, the topic I'll cover ...

If you were wondering, maybe, something I will add in the future.

Thank you for your attention.

this is all.

Source: