1568

Brilliant Engine Clem that do not require fuel and running "by itself"

Richard Clem worked in the field of heavy engineering in Dallas. He worked with the equipment, spraying and pumped liquid asphalt. Clem noticed that the asphalt pump continues to run for some period of time (30 minutes) after the power was turned off. This discovery led to the development of the motor. As a result of transformations of the real power output of the engine, whose weight was 200 pounds, reached 350 horsepower. According to eyewitnesses, Clem often went to his car, which was built this engine, on the Central highway in Dallas. He claimed that the machine requires no fuel, you only need to change the oil every 150,000 miles.

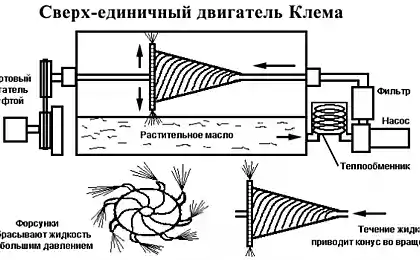

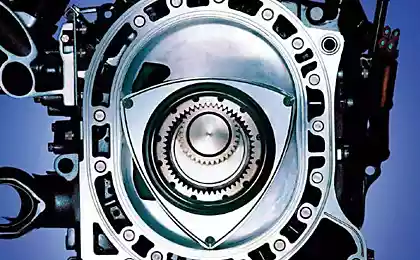

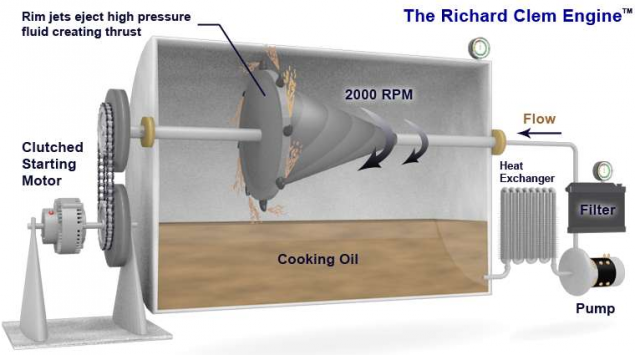

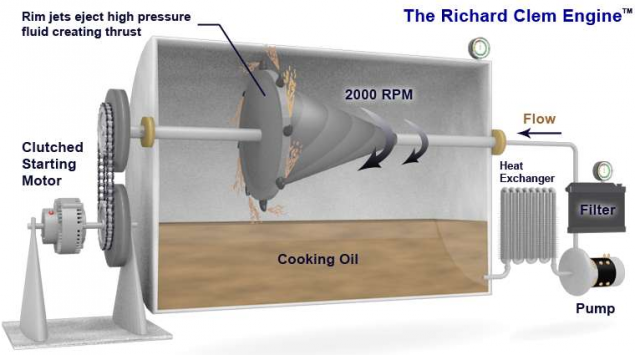

The motor has only one moving part: the rotor is conical, vertically arranged on the hollow shaft. In the cone-cut spiral grooves, passing around it along the entire length, and feeding the peripheral nozzles, which are located at the base of the cone. The liquid passes through the spiral grooves, vypuskaetsya of nozzles and causes the cone to rotate. Reaching a certain speed, the cone becomes independent of the starter pump and began to work independently. At operating speeds from 1800 to 2300 rpm the fluid heated up to 300 F, there is a need for a heat exchanger. As a result, used vegetable oil, as at a temperature of 300 F water boils and conventional engine oil breaks down.

The only other power source was a 12+volt battery. Clem never applied for a patent, as the design of its motor was developed based on previously patented asphalt pump. Fifteen companies rejected his invention before a large coal company offered him financial support and has signed contracts for the sale of the motor. Shortly after the documents were signed, Richard Clem died of a heart attack.

The design of the Clem engine

Inside the motor is a cone mounted on a horizontal axis. The shaft on which the reinforced cone that is empty inside and goes into the spiral hollow channels inside the cone. They wrap around the cone and end at the base of the nozzles (injectors).

The liquid is fed into the Central axis under pressure of 300-500 pounds per square inch, passes through the spiral channels and vypuskaetsya through nozzles, which causes the cone to rotate. The greater the fluid pressure, the faster the rotation of the cone.With further increase in speed, the liquid is heated, which requires a heat exchanger and filter. At a certain speed, the cone begins self-rotation, independent from the engine. The rotation speed of the shaft reaches 1800-2300 rpm.What happened with the invention of Clem?

Once the inventor had a heart attack and his papers were seized, his son drove one operating engine on a farm near Dallas. There he filled it with concrete at a depth of 10 feet, and the engine continued to operate at this depth for several years.The motor was tested by Bendix Corporation. The test consisted of attaching the engine to the dynamometer to measure the power on the shaft.The measurements showed that the engine is steadily producing 350 horsepower for 9 days so impressed the engineers at Bendix. They came to the conclusion that the source that could generate all the energy in a closed system for such a long time, can only be nuclear.The engine design does not contain non-traditional items, with the exception of the cone with spiral channels and the hollow shaft.An example implementation of the Clem engine

The motor (the red rectangle) is rotating "carousel" of Signer in the center of which is the knee, immersed in liquid. Due to the forced rotation of the water from the bottom rises to the "turntable", and then centrifugal forces moves toward the nozzles on the distal ends of the tubes and ejected "back", "pushing" so the rotation of turntables. This model as the Clem engine and engine Schauberger, Schauberger although there are additional troubles.

And immediately the question of how such a system can get more energy than you will have to spend on promotion wheel Signer? So, we promote our "turntable". To spin up a flywheel, you have to spend a certain amount of energy E=(I*w^2)/2 where I is the moment of inertia of turntables, w – rotation speed (Rev/s). This formula is well known. But after promotion to the frequency reference costs for the rotation is needed only to overcome friction. And this is significantly less than the original cost. So, our "spinner" is spinning...

Let us now consider the energy balance of a unit volume of fluid V when you move it in a closed cycle ABCD during rotation of turntables. It is clear that for sections AB and CD are subjected to the force of gravity. Up – costs down – their return. In the end, in the amount of zero. When driving the liquid volume along the segment DA no differential pressure, and the speed is almost zero, since any pressure gradient is aligned with gravity, the way Nature works. Work in this area is also equal to zero.

But in the BC area due to the rotation creates a pressure differential, if the center of the turntables, the pressure will take equal to zero, at the periphery of the pressure is already equal to P, which is directly proportional to the square of the radius of turntables. As you know the product V*P – is the work of centrifugal forces on an elementary volume of water. Means that in this area "spinner" is filled with energy simply because it is the design, and it rotates. And, on each revolution of energy becomes more and more. And since our motor after the promotion, "vane" spends energy only to overcome friction, such portion of energy will increase the speed of rotation of turntables, or you can reduce the power of the motor while maintaining speed, or increase the load, which is equivalent to the increase in friction.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

https://my.mail.ru/video/embed/884741148189392973

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

published

Source: xn----dtbbgbt6ann0jm3a.xn--p1ai/klema.html

The motor has only one moving part: the rotor is conical, vertically arranged on the hollow shaft. In the cone-cut spiral grooves, passing around it along the entire length, and feeding the peripheral nozzles, which are located at the base of the cone. The liquid passes through the spiral grooves, vypuskaetsya of nozzles and causes the cone to rotate. Reaching a certain speed, the cone becomes independent of the starter pump and began to work independently. At operating speeds from 1800 to 2300 rpm the fluid heated up to 300 F, there is a need for a heat exchanger. As a result, used vegetable oil, as at a temperature of 300 F water boils and conventional engine oil breaks down.

The only other power source was a 12+volt battery. Clem never applied for a patent, as the design of its motor was developed based on previously patented asphalt pump. Fifteen companies rejected his invention before a large coal company offered him financial support and has signed contracts for the sale of the motor. Shortly after the documents were signed, Richard Clem died of a heart attack.

The design of the Clem engine

Inside the motor is a cone mounted on a horizontal axis. The shaft on which the reinforced cone that is empty inside and goes into the spiral hollow channels inside the cone. They wrap around the cone and end at the base of the nozzles (injectors).

The liquid is fed into the Central axis under pressure of 300-500 pounds per square inch, passes through the spiral channels and vypuskaetsya through nozzles, which causes the cone to rotate. The greater the fluid pressure, the faster the rotation of the cone.With further increase in speed, the liquid is heated, which requires a heat exchanger and filter. At a certain speed, the cone begins self-rotation, independent from the engine. The rotation speed of the shaft reaches 1800-2300 rpm.What happened with the invention of Clem?

Once the inventor had a heart attack and his papers were seized, his son drove one operating engine on a farm near Dallas. There he filled it with concrete at a depth of 10 feet, and the engine continued to operate at this depth for several years.The motor was tested by Bendix Corporation. The test consisted of attaching the engine to the dynamometer to measure the power on the shaft.The measurements showed that the engine is steadily producing 350 horsepower for 9 days so impressed the engineers at Bendix. They came to the conclusion that the source that could generate all the energy in a closed system for such a long time, can only be nuclear.The engine design does not contain non-traditional items, with the exception of the cone with spiral channels and the hollow shaft.An example implementation of the Clem engine

The motor (the red rectangle) is rotating "carousel" of Signer in the center of which is the knee, immersed in liquid. Due to the forced rotation of the water from the bottom rises to the "turntable", and then centrifugal forces moves toward the nozzles on the distal ends of the tubes and ejected "back", "pushing" so the rotation of turntables. This model as the Clem engine and engine Schauberger, Schauberger although there are additional troubles.

And immediately the question of how such a system can get more energy than you will have to spend on promotion wheel Signer? So, we promote our "turntable". To spin up a flywheel, you have to spend a certain amount of energy E=(I*w^2)/2 where I is the moment of inertia of turntables, w – rotation speed (Rev/s). This formula is well known. But after promotion to the frequency reference costs for the rotation is needed only to overcome friction. And this is significantly less than the original cost. So, our "spinner" is spinning...

Let us now consider the energy balance of a unit volume of fluid V when you move it in a closed cycle ABCD during rotation of turntables. It is clear that for sections AB and CD are subjected to the force of gravity. Up – costs down – their return. In the end, in the amount of zero. When driving the liquid volume along the segment DA no differential pressure, and the speed is almost zero, since any pressure gradient is aligned with gravity, the way Nature works. Work in this area is also equal to zero.

But in the BC area due to the rotation creates a pressure differential, if the center of the turntables, the pressure will take equal to zero, at the periphery of the pressure is already equal to P, which is directly proportional to the square of the radius of turntables. As you know the product V*P – is the work of centrifugal forces on an elementary volume of water. Means that in this area "spinner" is filled with energy simply because it is the design, and it rotates. And, on each revolution of energy becomes more and more. And since our motor after the promotion, "vane" spends energy only to overcome friction, such portion of energy will increase the speed of rotation of turntables, or you can reduce the power of the motor while maintaining speed, or increase the load, which is equivalent to the increase in friction.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

https://my.mail.ru/video/embed/884741148189392973

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

published

Source: xn----dtbbgbt6ann0jm3a.xn--p1ai/klema.html

Liz Burbo: body Shape store the information about the psychological trauma

"KamAZ" with the beginnings of artificial intelligence will enter production in 2017