1126

Wankel engine

Continuing the theme of simple mechanisms that were a mystery interesting article about the famous inventor Felix Wankel Henry and his engine

9 ph via ibigdan

Steam engines and internal combustion engines have one common disadvantage - the reciprocating motion of the piston to be converted into rotational movement of wheels. Hence known low efficiency and high wear of machine elements. Many desirable to construct the internal combustion engine so that all movable parts in it only rotate - as is the case in electric motors. However, the task was not easy, successfully solving it was only self-taught mechanic, who for all his life and did not get a higher education, or even working specialty.

Felix Heinrich Wankel (Felix Heinrich Wankel, 1902-1988) was born August 13, 1902 in the small German town of Lahr. During World War I killed my father, Felix, because of what the future inventor had to quit school and go to work as an apprentice seller in a bookshop at the publishing house. Through this work Wankel addicted to reading books, which he taught himself technical disciplines, mechanics and automotive.

There is a legend that the solution came seventeen Felix in a dream. True or not - is unknown. But it is clear that Felix had a very extraordinary abilities and mechanics "nezamylennym" view of things. He understood how the four cycle of conventional internal combustion engine (injection, compression, combustion, exhaust) can be carried out in rotation.

Pretty soon I came to the first Wankel engine design, and in 1924 he organized a small workshop, which also serves as a makeshift "laboratory". Here Felix and began to carry out the first serious studies in the field of rotary-piston internal combustion engine.

Since 1921, the Wankel has been an active member of the Nazi Party. He advocated the ideals of the party, was the founder of the military Vsegermanskogo yungfyurerom youth associations and various organizations. In 1932 he left the party, accusing one of his former colleagues in the political corruption. However, over the counter charges he himself had to spend in prison for six months. Freed from prison thanks to the intercession of Wilhelm Keppler (Wilhelm Keppler), he continued to work on the engine. In 1934 he created the first prototype and received a patent. He designed new valves and combustion chambers for your motor, it has created a number of different options developed a classification of the different kinematic schemes rotary piston machines.

In 1936, a prototype of the Wankel engine are interested in BMW - Felix got the money and its own laboratory in Lindau to develop advanced aero engines.

However, until the defeat of Nazi Germany, no Wankel engine in the series did not go. Perhaps, bringing to mind the design and creation of mass production required too much time.

After the war, the laboratory was closed, the equipment exported to France, but Felix remained without work (affected former membership in the National Socialist Party). But soon Wankel still got a design engineer in the company NSU Motorenwerke AG, which is one of the oldest manufacturers of motorcycles and cars.

In 1957, the joint efforts of Felix Wankel and NSU leading engineer Frёde Walter (Walter Froede) rotary-piston engine was first installed on the vehicle NSU Prinz. The initial design was far from perfect: even to replace the spark needed to dismantle almost all the "engine", the reliability is poor, but about the economy at this stage of development and did say it was a sin. As a result, a series of tests still went to the car with a traditional internal combustion engine. Nevertheless, the first rotary-piston engine DKM-54 proved its fundamental performance, opened areas for further refinement and has shown tremendous potential "rotornikov».

Thus, a new type of internal combustion engine finally got his start in life. In the future, it is waiting for a lot more enhancements and improvements. But the prospects of rotary-piston engine are so attractive that engineers nothing could stop in bringing structure to operational excellence.

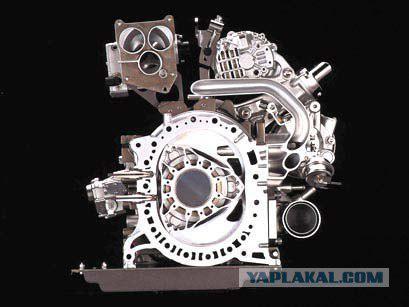

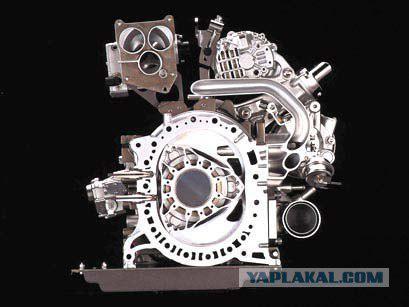

Constructivism

Before analyzing the advantages and disadvantages of the rotary-piston internal combustion engine is still a closer look at their design.

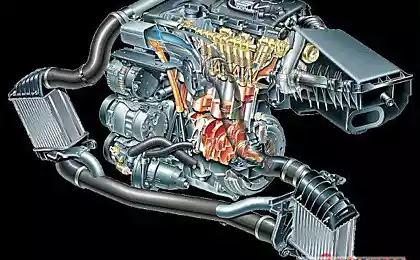

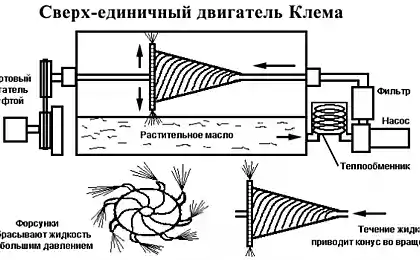

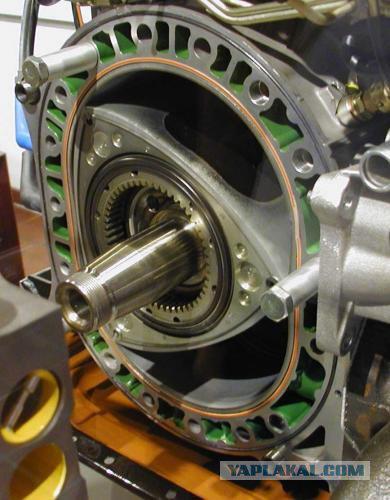

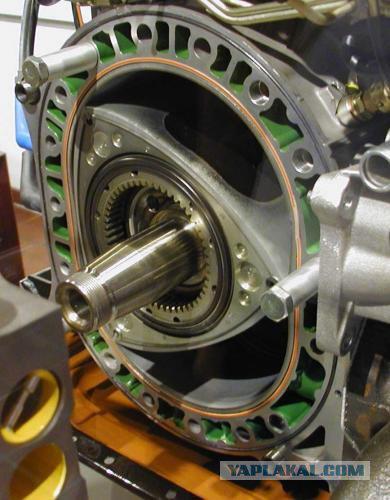

In the center of the rotor done a round hole, inside covered with teeth like gears. In this hole is inserted a rotary shaft of smaller diameter, and with teeth, which provides no slippage between it and the rotor. Diameter ratio of the hole and shaft are chosen so that the top of the triangle moving along the same closed curve, which is called "epitrochoid" - art as an engineer Wankel was that, to first understand that this is possible, and then everything accurately calculate. As a result, the piston having the shape of a triangle Reuleaux, cuts in the chamber, repeat the form found Wankel curve, three chambers of variable volume and position.

The design of the rotary-piston internal combustion engine allows for any four-cycle without any special timing. Due to this fact, "rotornik" is much easier to conventional four stroke piston engine, in which an average of almost a thousand more than the details.

Sealing of the working chamber of the rotary-piston engine is provided and axial sealing plate is pressed against the "cylinder" ribbon spring and centrifugal forces and gas pressure.

Another technical feature of it - a high "productivity." For one complete revolution of the rotor (ie, for a series of "injection, compression, ignition, exhaust"), the output shaft makes three complete revolutions. In a conventional reciprocating engine such results can only be achieved by using a six-cylinder engine.

Vankelmaniya

After the first successful demonstration of a rotary internal combustion engine in 1957, the largest auto giants began to show increased interest in the development. First license to drive, gets an informal name "Wankel" Corporation bought Curtiss-Wright, a year later, Daimler-Benz, MAN, Friedrich Krupp and Mazda. In just a very short period of time the license for the new technology acquired about a hundred companies worldwide, including such monsters as the Rolls-Royce, Porsche, BMW and Ford.

This interest in the "Wankel" as major players in the automotive market due to its great potential and significant advantages - in rotary-piston engine with 40% fewer parts, it is easier to repair and manufacture.

Moreover, the "Wankel" nearly twice as smaller and lighter than conventional reciprocating internal combustion engine, which in turn improves the car's handling, facilitates the optimal location of transmission and allows you to make a more spacious and comfortable interior.

Rotary-piston engine produces high power at relatively modest fuel consumption. For example, the modern "Wankel" volume of only 1300 cc develops a power of 220 hp and a turbocharged - all 350. Another example - a miniature motor OSMG 1400 weighing 335 g (working volume 5 cm³) has an output of 1, 27 L .from. In fact, this crumb is 27% stronger than a horse.

Another important advantage - a low level of noise and vibration. The rotary-piston engine is perfectly balanced mechanically, besides the mass of moving parts (and their number), there is much less so "Wankel" is much quieter and does not vibrate.

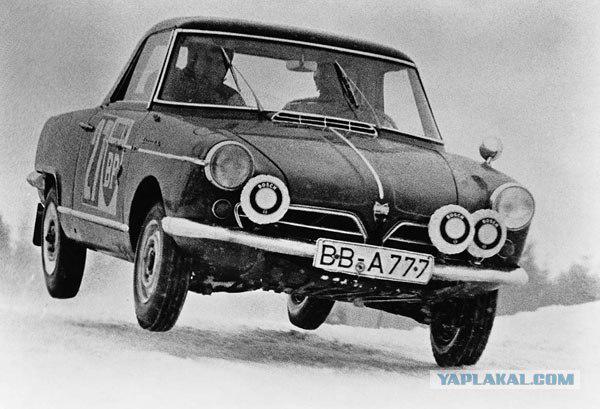

And finally, the rotary-piston engine has excellent dynamic characteristics. In low gear possible without much load on the engine to disperse the car to 100 km / h at high engine speeds. Besides, the construction of the "Wankel" due to lack of mechanism for converting reciprocating motion to rotary motion, capable of withstanding tremendous momentum than the traditional internal combustion engine. When released in 1964, followed by the legendary NSU Spyder model NSU Ro 80 (in the world there is still a lot of clubs, the owners of these cars), Citroen M35 (1970), Mercedes C-111 (1969), Corvette XP (1973). But the only mass producer was the Japanese Mazda, are available with 1967 times of 2-3 new models with RAP. Rotary engines are put on a boat, snowmobiles and light aircraft. End of euphoria came in 1973, at the height of the oil crisis. And then it emerged the main disadvantage of rotary engines - uneconomical. With the exception of Mazda, all automakers turned Rotary programs, and the Japanese company sales in America declined from 104,960 units sold in 1973 to 61192 - in 1974.

Fly in the ointment

Along with indisputable advantages, "Wankel" and also had a number of very serious drawbacks. Firstly, durability. One of the first prototypes of rotary piston engines on tests worn out in just two hours. Next, a more successful DKM-54 has survived a hundred hours, but this is for the normal operation of the car still was not enough. The main problem lay in the uneven wear of the inner surface of the chamber. It appeared during operation the transverse grooves, which received the name saying "mark of the devil».

In the Mazda after acquiring the license for "Wankel" was established a department dedicated to the improvement of rotary-piston engine. Pretty soon it became clear that during the rotation of the triangular rotor, plugs in his tops begin to vibrate, resulting in and formed "mark of the devil».

Currently, the problem of reliability and durability finally decided by applying high wear resistant coating including a ceramic.

Another serious problem - the increased exhaust emissions "Wankel". Compared with the conventional piston engine "rotornik" emits less nitrogen oxides, but more hydrocarbons due to incomplete combustion of fuel. Pretty soon the engineers Mazda, believed in a bright future, "Wankel" found a simple and effective solution to this problem. They have created a so-called thermal reactor in which residues of hydrocarbons in the exhaust gases just "afterburning". The first car to implement such a scheme, was the Mazda R100, also called the Familia Presto Rotary, released in 1968. This machine is one of the few immediately passed very stringent environmental requirements put forward by the United States in 1970 for imported cars.

Next issue rotary piston engines partially stems from the previous one. This efficiency. Fuel standard "Wankel 'due to incomplete combustion of the mixture is substantially higher than that of a standard engine. Once again, Mazda engineers set to work. With a whole range of measures, including the processing of thermal reactor and the carburetor, the addition of a heat exchanger in the exhaust system, the development of the catalytic converter and the introduction of a new ignition system, the company has reduced fuel consumption by 40%. As a result, the undoubted success in 1978 was released on a sports car Mazda RX-7.

It is worth noting that at this time of worldwide machine rotary-piston engine and Mazda just released ... AvtoVAZ.

It was during the disastrous 1974 the Soviet government in the Volga Automobile Plant produces special design bureau of the RAP (RAP CSC) - the socialist economy is unpredictable. The Tolyatti, work began on the construction of plants for the mass production of "Wankel". Since the WHA was originally planned as a mere copier of Western technology (particularly fiatovskih), factory specialists, it was decided to reproduce the engine Mazda, completely throwing all ten-year achievements of domestic engine-building institutions.

Soviet officials for a long time negotiating with Felix Wankel for the purchase of licenses, some of which were directly in Moscow. Money, however, did not find, so take advantage of some proprietary technologies failed. In 1976 he earned a first-section the Volga VAZ-311 engine 65 hp, five years spent on fine-tuning the design, and then was released on a pilot batch of 50 pieces of rotary "of ones" VAZ-21018, instantly dispersed among workers VAZ. Immediately it became clear that the engine only looks like a Japanese - crumble, he became a very Soviet-style. Management of the plant was forced to six months to replace all the standard-piston engines, to reduce by half the staff of CSC RAP and suspend the construction of shops. Salvation domestic rotary engine came from the security services: they are not very interested in fuel economy and engine life, but strong - the dynamic characteristics. Immediately two engines VAZ-311 was made two-piece DUR 120 hp, which was established to "spetsedinichku" - VAZ-21019. It is this model became known informally as "Arkan", we must countless tales of police, "Cossacks", catching heaped "Mercedes" and many guards - orders and medals. Until the 90s outwardly unassuming "Arkan" is really easy to catch up with all the cars. In addition to the VAZ-21019 AvtoVAZ also produced small batch of cars VAZ-2105, -2107, -2108, -2109, -21099. The maximum speed of the rotor "eight" is about 210 km / h, and it accelerates up to a hundred in just 8 seconds.

Revived on special order SKB raps began to make engines for the water and racing, where cars with rotary engines have become so often win prizes that sports officials have been forced to ban the use of RAP.

In 1987, the head of the SDB died RAP Boris Pospelov, and at the general meeting has been chosen Vladimir Shnyakin - the man who came in from the aviation and automotive disliked ground transportation. The main focus is the creation of SDB RPD engines for aircraft.

This was the first strategic mistake: aircraft have produced considerably fewer cars, and lives with factory engines sold.

The second mistake was the orientation to keep the production car raps on the low-power engines of VAZ-1185 42 hp for "Oka", although more voracious, but more dynamic rotary engines and asks for the most high-speed domestic cars - for example, "eight". Those Japanese set "Wankel" only on the sports models. As a result, the Russian roads were only a few rotary minicars "Oka". In 1998 he was finally drafted the civilian version of the twin-cylinder rotary 1, 3-liter engine VAZ-415, which were installed on the VAZ-2105, 2107, 2108 and 2109.

So why all the leading car manufacturers has not changed on "Wankel"? The fact that for the production of rotary-piston engines is required, first, perfected technology with a variety of the most diverse nuances and not every company is willing to go the way of the same Mazda, simultaneously stepping on numerous "rake". And secondly, we need a special high-precision machine tools, can grind the surface, described this as a tricky curve epitrochoid.

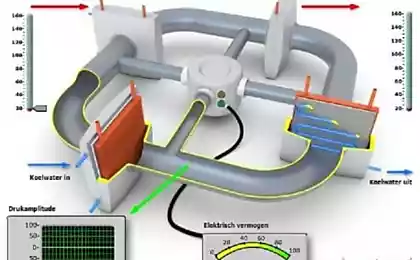

Currently, only Mazda is engaged in serious research in the field of rotary-piston engine, gradually improving their design, and most of the pitfalls in this area has already been passed. For modern machines surface described epitrochoid are not a problem (like not a problem far more complex curves), new structural materials allow to increase the service life of the rotary-piston engine, and its cost now is lower than the standard internal combustion engine due to the smaller number of employed parts. Compared with engines precursor able to reduce oil consumption by 50%, gasoline 40% and to increase the emission of harmful oxides to rules corresponding to Euro IV. Two-cylinder engine «Renesis» volume of 1, 3 liters produces 250 liters capacity. from. and occupies much less space in the engine compartment. Next model engine Renesis 16X 2 has a smaller volume, but more power, less heat. Cars RX series consume from 7 to 14 liters per 100 km, depending on the driving mode, and oils from 0 to 4 l 0 l 1000 6 km.

Mark Mazda automobiles with letters in the name of the RE can use as a fuel as gasoline and hydrogen. It was the second wave of growth in attention to the RPD engine from developers. The engine can successfully use hydrogen as it is less susceptible to knocking than a conventional motor using a reciprocating motion of the piston.

Source:

9 ph via ibigdan

Steam engines and internal combustion engines have one common disadvantage - the reciprocating motion of the piston to be converted into rotational movement of wheels. Hence known low efficiency and high wear of machine elements. Many desirable to construct the internal combustion engine so that all movable parts in it only rotate - as is the case in electric motors. However, the task was not easy, successfully solving it was only self-taught mechanic, who for all his life and did not get a higher education, or even working specialty.

Felix Heinrich Wankel (Felix Heinrich Wankel, 1902-1988) was born August 13, 1902 in the small German town of Lahr. During World War I killed my father, Felix, because of what the future inventor had to quit school and go to work as an apprentice seller in a bookshop at the publishing house. Through this work Wankel addicted to reading books, which he taught himself technical disciplines, mechanics and automotive.

There is a legend that the solution came seventeen Felix in a dream. True or not - is unknown. But it is clear that Felix had a very extraordinary abilities and mechanics "nezamylennym" view of things. He understood how the four cycle of conventional internal combustion engine (injection, compression, combustion, exhaust) can be carried out in rotation.

Pretty soon I came to the first Wankel engine design, and in 1924 he organized a small workshop, which also serves as a makeshift "laboratory". Here Felix and began to carry out the first serious studies in the field of rotary-piston internal combustion engine.

Since 1921, the Wankel has been an active member of the Nazi Party. He advocated the ideals of the party, was the founder of the military Vsegermanskogo yungfyurerom youth associations and various organizations. In 1932 he left the party, accusing one of his former colleagues in the political corruption. However, over the counter charges he himself had to spend in prison for six months. Freed from prison thanks to the intercession of Wilhelm Keppler (Wilhelm Keppler), he continued to work on the engine. In 1934 he created the first prototype and received a patent. He designed new valves and combustion chambers for your motor, it has created a number of different options developed a classification of the different kinematic schemes rotary piston machines.

In 1936, a prototype of the Wankel engine are interested in BMW - Felix got the money and its own laboratory in Lindau to develop advanced aero engines.

However, until the defeat of Nazi Germany, no Wankel engine in the series did not go. Perhaps, bringing to mind the design and creation of mass production required too much time.

After the war, the laboratory was closed, the equipment exported to France, but Felix remained without work (affected former membership in the National Socialist Party). But soon Wankel still got a design engineer in the company NSU Motorenwerke AG, which is one of the oldest manufacturers of motorcycles and cars.

In 1957, the joint efforts of Felix Wankel and NSU leading engineer Frёde Walter (Walter Froede) rotary-piston engine was first installed on the vehicle NSU Prinz. The initial design was far from perfect: even to replace the spark needed to dismantle almost all the "engine", the reliability is poor, but about the economy at this stage of development and did say it was a sin. As a result, a series of tests still went to the car with a traditional internal combustion engine. Nevertheless, the first rotary-piston engine DKM-54 proved its fundamental performance, opened areas for further refinement and has shown tremendous potential "rotornikov».

Thus, a new type of internal combustion engine finally got his start in life. In the future, it is waiting for a lot more enhancements and improvements. But the prospects of rotary-piston engine are so attractive that engineers nothing could stop in bringing structure to operational excellence.

Constructivism

Before analyzing the advantages and disadvantages of the rotary-piston internal combustion engine is still a closer look at their design.

In the center of the rotor done a round hole, inside covered with teeth like gears. In this hole is inserted a rotary shaft of smaller diameter, and with teeth, which provides no slippage between it and the rotor. Diameter ratio of the hole and shaft are chosen so that the top of the triangle moving along the same closed curve, which is called "epitrochoid" - art as an engineer Wankel was that, to first understand that this is possible, and then everything accurately calculate. As a result, the piston having the shape of a triangle Reuleaux, cuts in the chamber, repeat the form found Wankel curve, three chambers of variable volume and position.

The design of the rotary-piston internal combustion engine allows for any four-cycle without any special timing. Due to this fact, "rotornik" is much easier to conventional four stroke piston engine, in which an average of almost a thousand more than the details.

Sealing of the working chamber of the rotary-piston engine is provided and axial sealing plate is pressed against the "cylinder" ribbon spring and centrifugal forces and gas pressure.

Another technical feature of it - a high "productivity." For one complete revolution of the rotor (ie, for a series of "injection, compression, ignition, exhaust"), the output shaft makes three complete revolutions. In a conventional reciprocating engine such results can only be achieved by using a six-cylinder engine.

Vankelmaniya

After the first successful demonstration of a rotary internal combustion engine in 1957, the largest auto giants began to show increased interest in the development. First license to drive, gets an informal name "Wankel" Corporation bought Curtiss-Wright, a year later, Daimler-Benz, MAN, Friedrich Krupp and Mazda. In just a very short period of time the license for the new technology acquired about a hundred companies worldwide, including such monsters as the Rolls-Royce, Porsche, BMW and Ford.

This interest in the "Wankel" as major players in the automotive market due to its great potential and significant advantages - in rotary-piston engine with 40% fewer parts, it is easier to repair and manufacture.

Moreover, the "Wankel" nearly twice as smaller and lighter than conventional reciprocating internal combustion engine, which in turn improves the car's handling, facilitates the optimal location of transmission and allows you to make a more spacious and comfortable interior.

Rotary-piston engine produces high power at relatively modest fuel consumption. For example, the modern "Wankel" volume of only 1300 cc develops a power of 220 hp and a turbocharged - all 350. Another example - a miniature motor OSMG 1400 weighing 335 g (working volume 5 cm³) has an output of 1, 27 L .from. In fact, this crumb is 27% stronger than a horse.

Another important advantage - a low level of noise and vibration. The rotary-piston engine is perfectly balanced mechanically, besides the mass of moving parts (and their number), there is much less so "Wankel" is much quieter and does not vibrate.

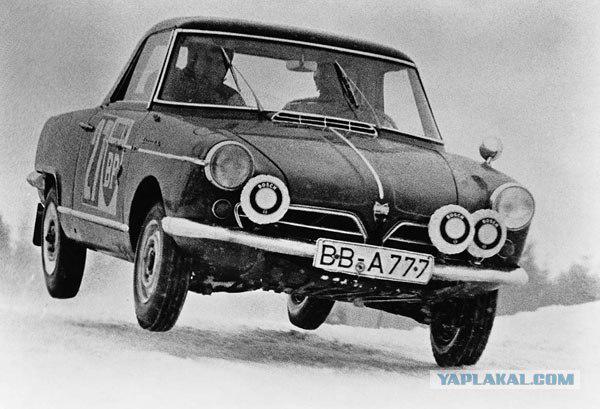

And finally, the rotary-piston engine has excellent dynamic characteristics. In low gear possible without much load on the engine to disperse the car to 100 km / h at high engine speeds. Besides, the construction of the "Wankel" due to lack of mechanism for converting reciprocating motion to rotary motion, capable of withstanding tremendous momentum than the traditional internal combustion engine. When released in 1964, followed by the legendary NSU Spyder model NSU Ro 80 (in the world there is still a lot of clubs, the owners of these cars), Citroen M35 (1970), Mercedes C-111 (1969), Corvette XP (1973). But the only mass producer was the Japanese Mazda, are available with 1967 times of 2-3 new models with RAP. Rotary engines are put on a boat, snowmobiles and light aircraft. End of euphoria came in 1973, at the height of the oil crisis. And then it emerged the main disadvantage of rotary engines - uneconomical. With the exception of Mazda, all automakers turned Rotary programs, and the Japanese company sales in America declined from 104,960 units sold in 1973 to 61192 - in 1974.

Fly in the ointment

Along with indisputable advantages, "Wankel" and also had a number of very serious drawbacks. Firstly, durability. One of the first prototypes of rotary piston engines on tests worn out in just two hours. Next, a more successful DKM-54 has survived a hundred hours, but this is for the normal operation of the car still was not enough. The main problem lay in the uneven wear of the inner surface of the chamber. It appeared during operation the transverse grooves, which received the name saying "mark of the devil».

In the Mazda after acquiring the license for "Wankel" was established a department dedicated to the improvement of rotary-piston engine. Pretty soon it became clear that during the rotation of the triangular rotor, plugs in his tops begin to vibrate, resulting in and formed "mark of the devil».

Currently, the problem of reliability and durability finally decided by applying high wear resistant coating including a ceramic.

Another serious problem - the increased exhaust emissions "Wankel". Compared with the conventional piston engine "rotornik" emits less nitrogen oxides, but more hydrocarbons due to incomplete combustion of fuel. Pretty soon the engineers Mazda, believed in a bright future, "Wankel" found a simple and effective solution to this problem. They have created a so-called thermal reactor in which residues of hydrocarbons in the exhaust gases just "afterburning". The first car to implement such a scheme, was the Mazda R100, also called the Familia Presto Rotary, released in 1968. This machine is one of the few immediately passed very stringent environmental requirements put forward by the United States in 1970 for imported cars.

Next issue rotary piston engines partially stems from the previous one. This efficiency. Fuel standard "Wankel 'due to incomplete combustion of the mixture is substantially higher than that of a standard engine. Once again, Mazda engineers set to work. With a whole range of measures, including the processing of thermal reactor and the carburetor, the addition of a heat exchanger in the exhaust system, the development of the catalytic converter and the introduction of a new ignition system, the company has reduced fuel consumption by 40%. As a result, the undoubted success in 1978 was released on a sports car Mazda RX-7.

It is worth noting that at this time of worldwide machine rotary-piston engine and Mazda just released ... AvtoVAZ.

It was during the disastrous 1974 the Soviet government in the Volga Automobile Plant produces special design bureau of the RAP (RAP CSC) - the socialist economy is unpredictable. The Tolyatti, work began on the construction of plants for the mass production of "Wankel". Since the WHA was originally planned as a mere copier of Western technology (particularly fiatovskih), factory specialists, it was decided to reproduce the engine Mazda, completely throwing all ten-year achievements of domestic engine-building institutions.

Soviet officials for a long time negotiating with Felix Wankel for the purchase of licenses, some of which were directly in Moscow. Money, however, did not find, so take advantage of some proprietary technologies failed. In 1976 he earned a first-section the Volga VAZ-311 engine 65 hp, five years spent on fine-tuning the design, and then was released on a pilot batch of 50 pieces of rotary "of ones" VAZ-21018, instantly dispersed among workers VAZ. Immediately it became clear that the engine only looks like a Japanese - crumble, he became a very Soviet-style. Management of the plant was forced to six months to replace all the standard-piston engines, to reduce by half the staff of CSC RAP and suspend the construction of shops. Salvation domestic rotary engine came from the security services: they are not very interested in fuel economy and engine life, but strong - the dynamic characteristics. Immediately two engines VAZ-311 was made two-piece DUR 120 hp, which was established to "spetsedinichku" - VAZ-21019. It is this model became known informally as "Arkan", we must countless tales of police, "Cossacks", catching heaped "Mercedes" and many guards - orders and medals. Until the 90s outwardly unassuming "Arkan" is really easy to catch up with all the cars. In addition to the VAZ-21019 AvtoVAZ also produced small batch of cars VAZ-2105, -2107, -2108, -2109, -21099. The maximum speed of the rotor "eight" is about 210 km / h, and it accelerates up to a hundred in just 8 seconds.

Revived on special order SKB raps began to make engines for the water and racing, where cars with rotary engines have become so often win prizes that sports officials have been forced to ban the use of RAP.

In 1987, the head of the SDB died RAP Boris Pospelov, and at the general meeting has been chosen Vladimir Shnyakin - the man who came in from the aviation and automotive disliked ground transportation. The main focus is the creation of SDB RPD engines for aircraft.

This was the first strategic mistake: aircraft have produced considerably fewer cars, and lives with factory engines sold.

The second mistake was the orientation to keep the production car raps on the low-power engines of VAZ-1185 42 hp for "Oka", although more voracious, but more dynamic rotary engines and asks for the most high-speed domestic cars - for example, "eight". Those Japanese set "Wankel" only on the sports models. As a result, the Russian roads were only a few rotary minicars "Oka". In 1998 he was finally drafted the civilian version of the twin-cylinder rotary 1, 3-liter engine VAZ-415, which were installed on the VAZ-2105, 2107, 2108 and 2109.

So why all the leading car manufacturers has not changed on "Wankel"? The fact that for the production of rotary-piston engines is required, first, perfected technology with a variety of the most diverse nuances and not every company is willing to go the way of the same Mazda, simultaneously stepping on numerous "rake". And secondly, we need a special high-precision machine tools, can grind the surface, described this as a tricky curve epitrochoid.

Currently, only Mazda is engaged in serious research in the field of rotary-piston engine, gradually improving their design, and most of the pitfalls in this area has already been passed. For modern machines surface described epitrochoid are not a problem (like not a problem far more complex curves), new structural materials allow to increase the service life of the rotary-piston engine, and its cost now is lower than the standard internal combustion engine due to the smaller number of employed parts. Compared with engines precursor able to reduce oil consumption by 50%, gasoline 40% and to increase the emission of harmful oxides to rules corresponding to Euro IV. Two-cylinder engine «Renesis» volume of 1, 3 liters produces 250 liters capacity. from. and occupies much less space in the engine compartment. Next model engine Renesis 16X 2 has a smaller volume, but more power, less heat. Cars RX series consume from 7 to 14 liters per 100 km, depending on the driving mode, and oils from 0 to 4 l 0 l 1000 6 km.

Mark Mazda automobiles with letters in the name of the RE can use as a fuel as gasoline and hydrogen. It was the second wave of growth in attention to the RPD engine from developers. The engine can successfully use hydrogen as it is less susceptible to knocking than a conventional motor using a reciprocating motion of the piston.

Source: