1933

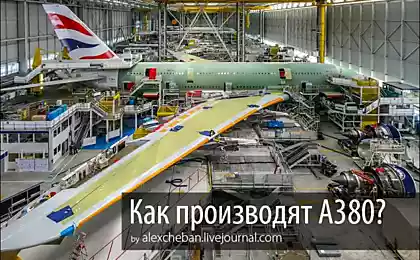

Super Jumbo (A380).

This post will be interesting to true connoisseurs airliners

Will be 44 photos + text.

Airbus A380-861 c engines GP7270.

At the end of the 90s the world's largest aircraft manufacturers, Boeing and Airbus, assessing the status and opportunities of the market of aircraft, were seriously taken aback by the question of creating an aircraft VLCT (Very Large Commercial Transport). It had to be, first of all, the aircraft with increased passenger capacity (about 600-800 seats).

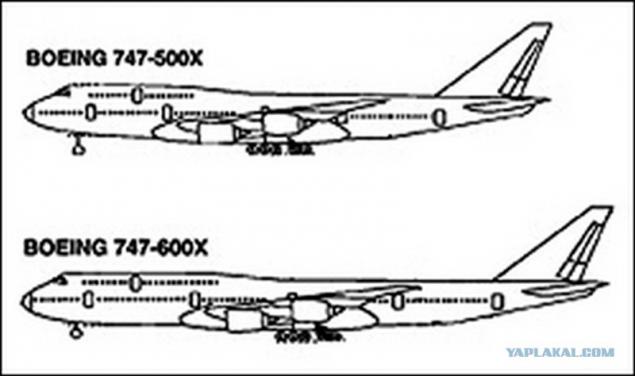

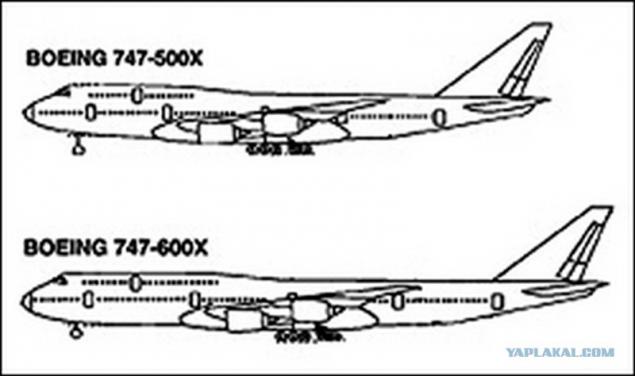

The program of the American aircraft manufacturers Boeing-wear name 747H. In this perspective, the planes were supposed 747-500H, -600H and 700x with enlarged "humpbacked" fuselage, larger than their predecessor Boeing-747-400.

Example layout Boeing 747-500X and 747-600X.

However, these plans were interrupted by the Asian financial crisis of 1997-2000. Then Boeing decided that the market outlook in the selected direction is too vague (especially the absence of prior demand by airlines), and the project was abandoned 747H.

Having lost the main opponent and, thus acquiring a certain freedom of action continued Airbus launched in June 1994. The work to create its own concept of aircraft VLCT.

At the same time with the aim of further increasing the competitiveness of the new project was embarked on a reduction in operating costs by 15-20% in comparison with the already in service aircraft rivals Boeing 747-400. Moreover, structurally it was chosen such variant arrangement which provided significantly larger passenger capacity, including in comparison to a Boeing 400-m.

The aircraft Boeing 747-400.

In December 2000, the program, while still bearing the name A3XX was launched. Its result was the world's largest passenger aircraft Airbus A380-800 (853 passengers in odnoklassovom version), now widely known in the world of wide-body double-deck aircraft, which later received a semi-official name of the Super Jumbo (Super Jumbo).

As the power plant at the new Airbus originally planned to use Trent 900 engine, it was at this time is in development in the British multinational corporation Rolls-Royce Group plc.

Rolls-Royce Trent - it is a whole family of turbofan engines, has received such a designation on the name of the river Trent, related to the number of main rivers of Great Britain. One of the options to transfer the name of the river drevnekeltskogo language means something like "rapidly flooded." A certain logic in comparison with a powerful jet engine visible.

It is interesting that the name Rolls-Royce had previously used in the creation of new types of engines. For example, it was the world's first turboprop Rolls-Royce RB.50 Trent, is being tested on a plane Gloster Meteor (in the version Gloster G.41A Meteor F.Mk.1 (EE227)).

The world's first turboprop Rolls-Royce RB.50 Trent (museum)

Posted in [mergetime] 1396979507 [/ mergetime]

Inet tupit, I try quicker. Gather F5, I do not have))

Gloster Meteor E227.

Later the same name found first turbofan engine Rolls-Royce, made to the same three-shaft design Rolls-Royce RB.203 Trent. It had a bypass ratio equal to three. It was the independent development on the basis of the engine Rolls-Royce Turbomeca Adour, which was a product of the interaction of firms Rolls-Royce and Turbomeca and is installed on military aircraft SEPECAT Jaguar and the Hawker Siddeley Hawk.

Fighter-bomber French Air Force Sepecat Jaguar.

This engine is meant to be a replacement of the existing family of bypass engines with a low bypass ratio Rolls-Royce Spey (RB.163 / 168 / 183Spey, incidentally, is also the name of the river), establishes both civil and military aircraft in the 60-ies. However, a series he did not go, but served as the basis for creating a new engine family Rolls-Royse RB211.

Rolls-Royse RB211 has become a massive commercial turbofan engine. It was created not easy, the company faced in the process with a variety of intractable technical problems. As a result, the cost projection turned out to be much more planned, and increased the final cost of the engine, and the project together with the company-designer were in crisis.

In January 1971, Rolls-Royse declared himself bankrupt. To keep afloat a national program L-1011 Tristar, for which only the engine and was intended RB211, UK government nationalized the company and allowed to continue working on the engine.

Liner L-1011 Tristar.

RB211 engines on the wing of the Boeing-747-300.

Posted in [mergetime] 1396979730 [/ mergetime]

Although the aircraft L-1011 Tristar could not compete, and its production was discontinued at the 250th copy RB211 engine like exploiting and airlines continue to operate on the aircraft Boeing 747/757/767 in their various versions. Suffice successful operation continues to this day, and the RB211 engine in the 1990s served as the basis for the creation of a new line of engines - Rolls-Royse Trent.

Since the beginning of widespread use of RB211 engine aircraft in commercial aviation division of Rolls-Royse (by then a company with governance) is becoming a major player in the aviation engine and ranks third after GE Aviation and Pratt & Whitney.

To maintain existing positions and further advance towards the conquest of market professionals engine Rolls-Royse went towards the creation of a new engine that meets modern requirements and suitable for almost any long-haul passenger airliner, or transport aircraft.

And to reduce costs (which are now tightly controlled by the government) to conduct research and development activities was based on already well-established concept of constructive engine RB211, made three-shaft design.

It was the beginning of the line engines Rolls-Royse Trent. The first engine in this family Trent 600 was intended to be installed on the aircraft McDonnell Douglas MD-11 for the British airline British Caledonian and Air Europe. However, the first company was acquired by British Airways, which canceled the order for the MD-11 and the second "safely" ceased to exist in the early '90s.

Trent 600 customers remained without and never came out of the rank demonstatsionnogo engine programs Trent. All the efforts of the company were directed to the development of the following modifications to the family - Trent 700 for the aircraft Airbus A330.

This engine was certified in January 1994 and became one of the options powerplant aircraft type A330-200 / 300. At the same time, in May 1996 it was reached matching engine standards ICAO ETOPS180.

Aircraft engines A330-200 c Trent-772B-60.

Modification of the Trent 800 (877, 895, 892) since May 1995 has been successfully used on planes Boeing-777-200 / 200ER / 300. In this segment, the engine Rolls-Royse occupies 41% of the market of engines. In order to improve traction performance was increased fan diameter: 2, 80 m to 2, 47 m from the Trent 700.

Engine Trent 800.

Plane Boeing-777 / 258ER with engines Trent 895.

Option Trent 500 of 2000 is set to Outbound passenger liner A340-500 (553), as well as modifications of the A340-600.

A340-642 aircraft with engines Trent 500.

In connection with the development of Boeing options V777h extended range Rolls-Royse developed an improved modification of the Trent 800, which received the name 8104 with the further development of its option in 8115 was calculated at the level of engine thrust to 100, 000 lbf with a further opportunity to address this significant threshold and increase its 110, 000 lbf.

This modification was used the last innovations in the field of commercial engine, in particular a fan sshirokohordnymi titanium blades with special saber-arrow-shaped profile (swept wide chord fan), which allows to get the most (at this stage) out of the fan in terms of operational efficiency, reduce weight and noise. The company Rolls-Royse has been a pioneer in these developments and deal with them since the 1970s.

However, Trent 8104 and was a demonstration model. Competition has done its job. Boeing has received from GE Aviation more than 500 million. $ In the development of the program 777h with the condition of exclusive use in its engines GE - GE90-110B and GE90-115B. It is clear that the issue was resolved in favor of General Electric.

But to make, of course, it was not in vain. Series Trent - it is now the most popular line of Rolls-Royce engines for commercial aircraft. All the latest development of the company were embodied in the latest versions of Trento - Rolls-RoyceTrent 900, Trent 1000 (for the Boeing 787 Dreamliner) and Trent XWB (for the new samoletaAirbus 350XWB). One of the most notable series engines was the Rolls-Royce Trent 900.

This engine from the beginning of the development of the A380 to become a major power plant of Airbus, especially strengthened its position since the beginning of the formation of massive orders for the plane. In March of 2000, Singapore Airlines and followed her in February 2001, the Australian airline Qantas th selected Trent 900 as the main engine for the aircraft ordered by them.

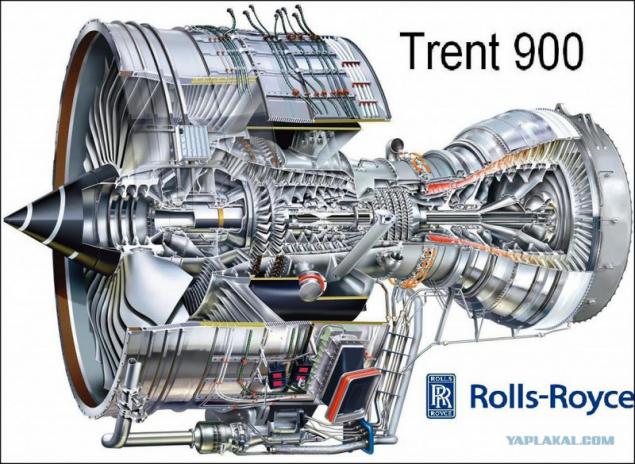

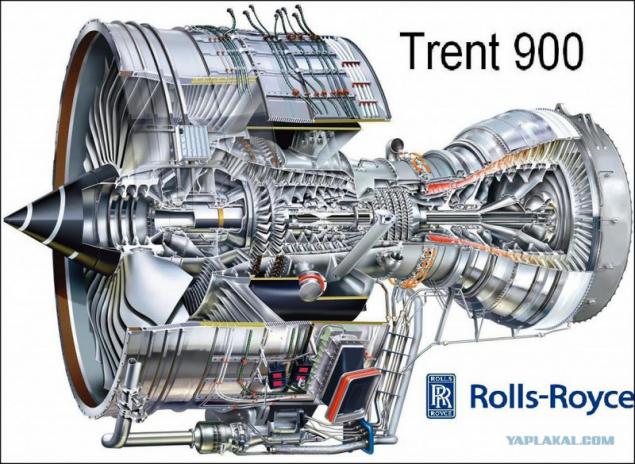

Engine Trent 900.

The decision to create Trent 900 specifically for the A380 was made in 1996. In May 2004, the engine was first tested in the air as a flying laboratory engines based on A340-300 aircraft. European certificate (EASA) was received in October of the same year, and in December 2006 was passed certification in the United States (FAA).

The test engine A340 with Trent 900.

A340 test aircraft with engines Trent 900.

Already in September 2007, the airline British Airways, say so by supporting local producers, decided on the choice of the Trent 900 for its A380 sets (there were 12 pieces). Thus at the end of 2009, the share of the motor in the motor park ordered and produced the A380 was 52%.

Like any CONTEMPORARY industrial products, particularly aircraft manufacturer, from Rolls-Royce have partners, risks and profits are shared among them according to their equity participation.

There are only six: Company Honeywell International, which manufactures pnevmositem; Italian company Avio SpA, the main of which is the prerogative of the box drive motor units; company Volvo Aero, involved in the production of the compressor housing; the company Goodrich Corporation - the fan housing and sensor systems; Italian company Industria de Turbo Propulsores SA, which manufactures low-pressure turbine; kompaniyaHamilton Sundstrand - instruments electronic engine control.

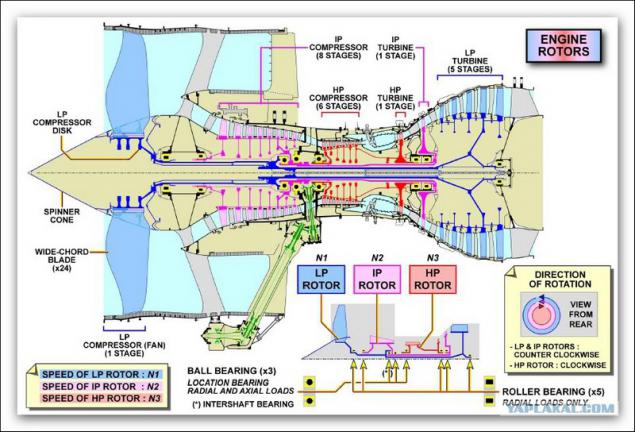

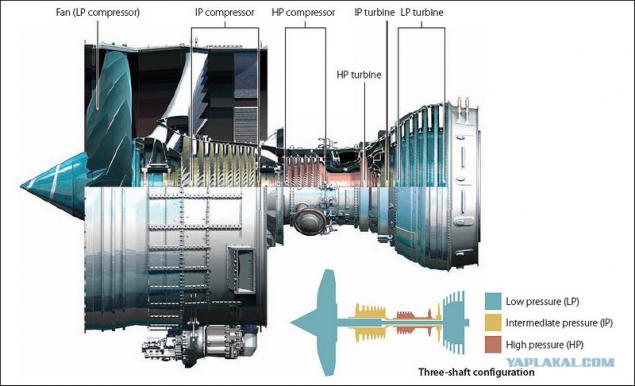

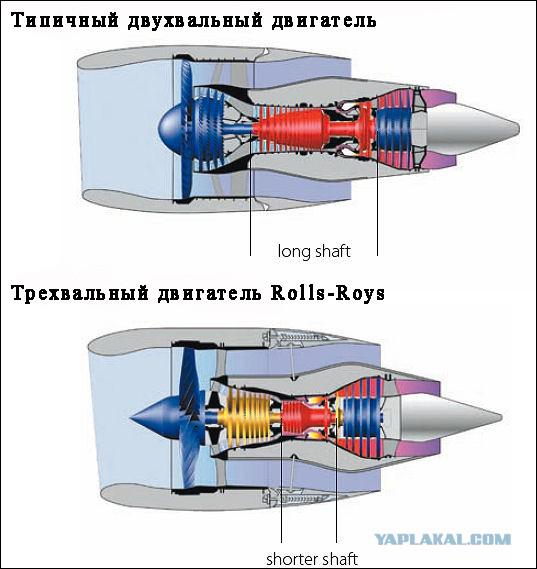

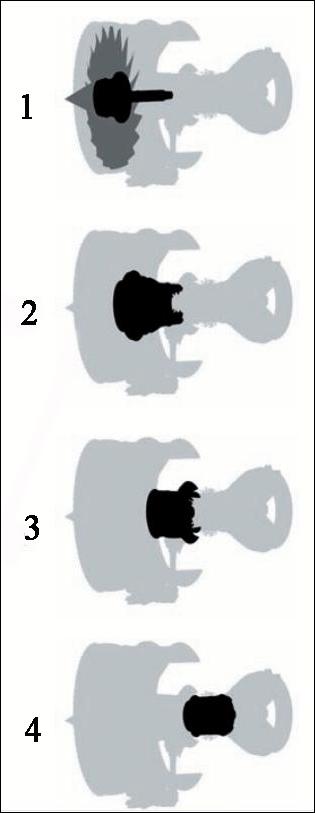

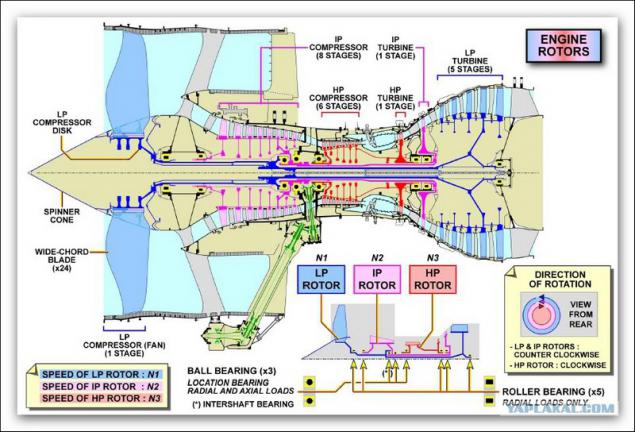

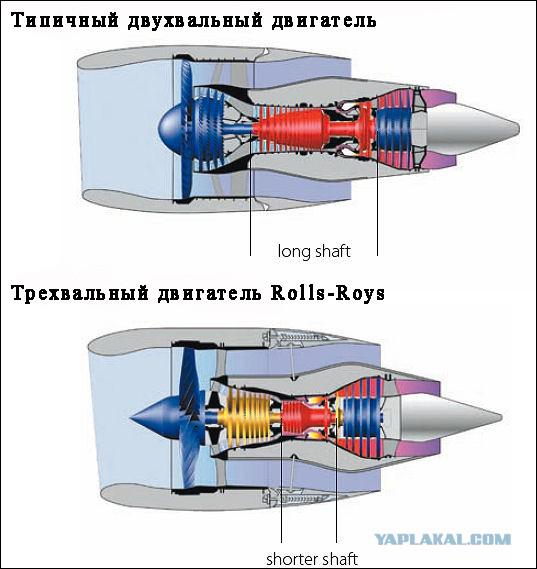

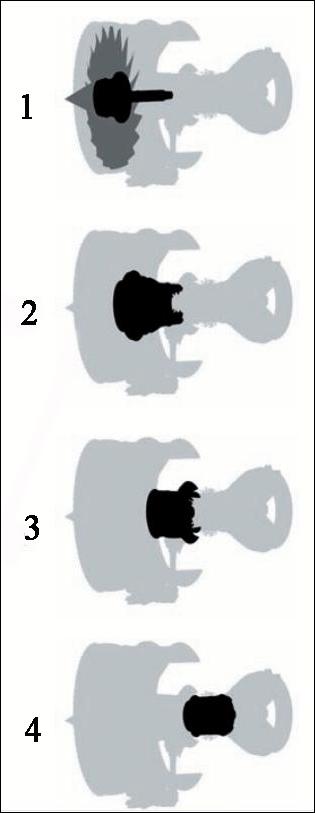

Trent 900 - three-shaft turbofan engine with a high bypass ratio (8, 7-8, 5). It is believed that the production and operation of the motor can be more difficult than the usual two-shaft TVRD, but in the process of this engine is stable and sustainable.

Driving engine Trent 900.

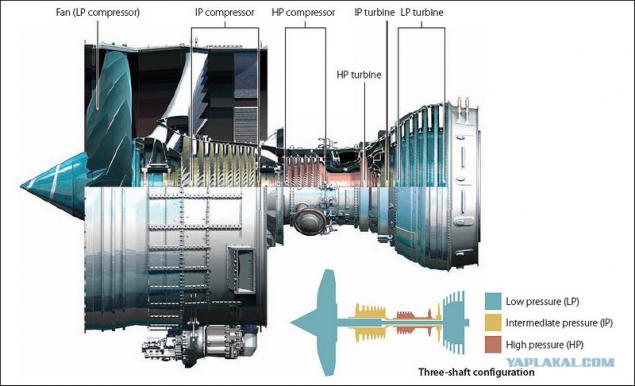

Three-shaft implies a gas generator with three independent from each other mechanically axle assembly. This gives some flexibility in design and allows to choose different combinations of source units to give different output settings for different engines, despite its apparent similarity of embodiment.

The configuration of three-shaft engine.

Besides shorter and therefore stiffer shafts in the three-shaft options allow more accurate flow rate to maintain optimal blade, thereby increasing the efficiency of the gas generator, the stock of its stable bessryvnoy work. Accordingly, reduced weight and dimensions of the engine.

Differences in the sizes of two- and three-shaft TVRD.

Therefore, Rolls-Royce uses three-shaft design in all commercial engines, with the result, a whole series of engines of the same circuit but in different sizes and traction characteristics.

The Trent 900 has inherited from its predecessor, a demonstration model of Trent 8104, a significant number of advanced technological solutions. In particular fan of large diameter (2, 95 m) with a wide-blades (24 pieces) special saber-arrow shaped. The blades are bent as if in the direction opposite to the rotation of the (very similar to the swept wing aircraft).

When the engine are moved at a circumferential speed of up to 1730 km / h, which is significantly higher than the speed of sound. Thanks to the specific configuration of the blades and the fan runs at those speeds effectively and low noise (one of the main parameters of the regulatory requirements for the operators of the A380), the more the flow rate at the inlet of the engine even at takeoff is relatively low. At the same time pull it higher than usual fan shape.

Fan engine Trent 900.

Its total weight of almost 15% lower than the mass of wide fan motors previous types. The main reason for this again in the blades of the fan. They are made of titanium alloy, hollow inside and are reinforced by printsipufermy Warren (Warren girder - lattice of equilateral triangles). This makes them strong, rigid and light at the same time.

Attempts to make the fan blades of composite materials on this engine failed. He could not stand the test of tests on birds from entering the fan.

Interestingly, the supplier of titanium for Rolls-Royce engines (as, indeed, for the majority of aviation equipment produced in the world) is a Russian corporation "VSMPO-Avisma".

Turbine blades are used as monolithic single crystal, and the hollow channels and holes for effective convection-film air cooling.

Thermally loaded components, such as elements of the combustion chamber and the nozzle of the turbine blades are protected by a special coating antitermalnym (thermal-barrier coating or TBC) significantly reduces the heat transfer.

When profiling gas path of the gas generator is taken as a basis for well-proven engine unit similar to Trent 500.

The main components of the engine:

Single-stage fan, eight-intermediate compressor, six-stage high-pressure compressor.

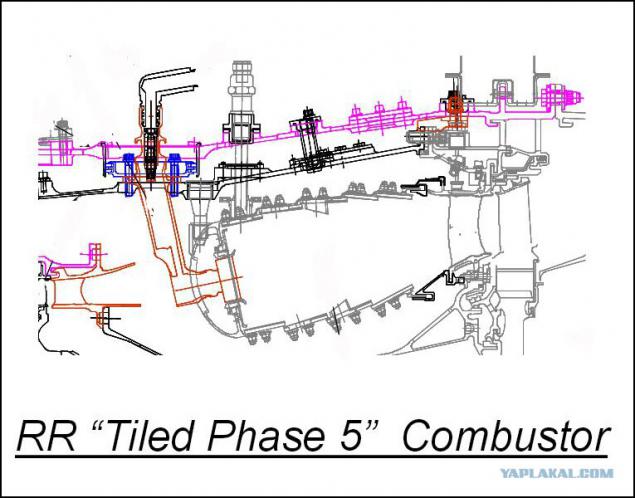

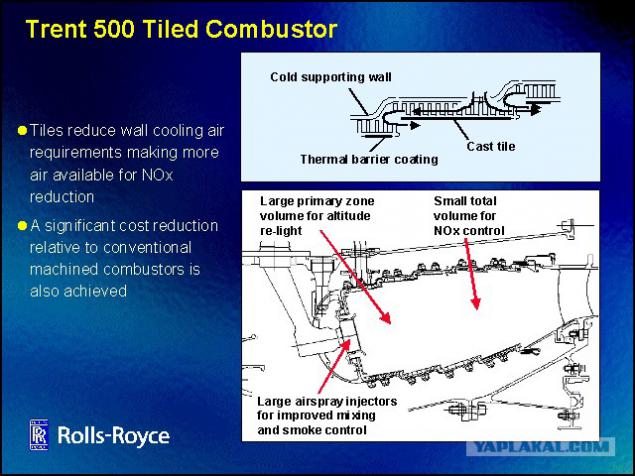

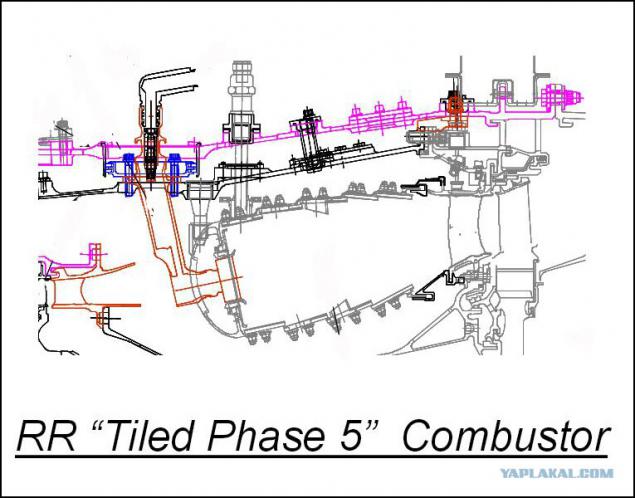

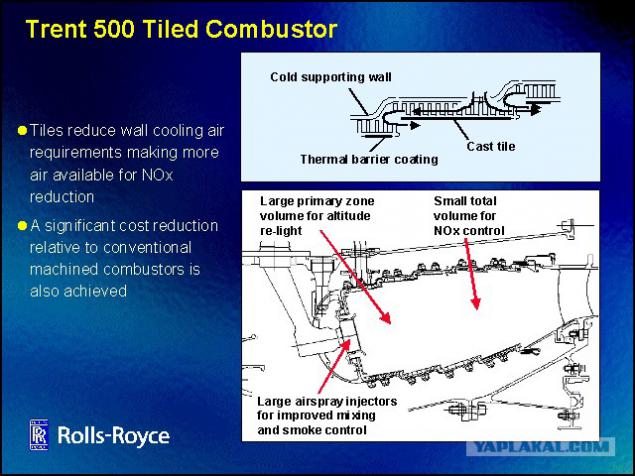

Annular combustor with 24 fuel nozzles (injectors), the so-called type «Tiled Rhase 5" (own name Rolls-Royse). This type of camera is used on engines Trent 500/800/900/1000. By the number of emissions complies with CAEP 8 with a large margin.

Combustion chamber type Phase 5.

Example of combustion chamber (for the Trent 500, the same stands on the Trent 900)

Such a combustion chamber has a certain type lamellar structure walls of the flame tube (tiled combustor), which allows a combination with antitermalnym coating (TBC) significantly improve their insulation and cooling zone of extremely high temperatures. In addition, it has a shorter combustion zone and along with high thermal efficiency has markedly reduced levels of NOx emissions.

Trent turbine 900 also consists of three independent parts. It is a single-stage high-pressure turbine, an intermediate single-stage turbine and a five-speed low-pressure turbine, the rotating fan.

Loading Trent 900 aircraft.

Besides the engine, as well as almost all modern TVRD has a modular design greatly facilitates (and cheaper) its production, operation and maintenance.

As advantage of the engine is presented not only by its modular design and the possibility of transporting assembled in the cargo hold of the transport plane Boeing-747.

The core modules of the design Trent 900.

Module 01. The rotor assembly low pressure compressor or fan. This rotor disk with a fan installed on it, rotates the low-pressure turbine. The disk slots are made on the principle of "dovetail", which set fan blades. The Trent series engines, the number ranges from 26 to 20. The minimum number (20) in the Trent 1000, at the Trent 900 - 24. The blades can be replaced without removing the engine from the aircraft.

Module 02. The intermediate compressor. The design of the disc and collected in a drum blades. In the latest model line Trent (XWB) in this module used blisks, but the 900-m they do not exist.

Module 03. The inner housing intermediate compressor. Located between the intermediate and high pressure compressor. Inside it are mounted bearings of the rotors. It has a hollow pillar, which are main oil and air lines, as well as the axis of the drive units.

04. Module assembly (system) pressure vessel. It consists of inner shells of high pressure compressor, combustor and high pressure turbine. On engines Trent 500/700/800 rotor system that rotates in the same direction as the other two rotor. Since Trent 900 engine rotation is reversed, which can significantly increase the efficiency of the turbine assembly as a whole.

Motor Modules Trent 900.

Module 05. The intermediate turbine.

That's all I wanted to say.

Source:

Will be 44 photos + text.

Airbus A380-861 c engines GP7270.

At the end of the 90s the world's largest aircraft manufacturers, Boeing and Airbus, assessing the status and opportunities of the market of aircraft, were seriously taken aback by the question of creating an aircraft VLCT (Very Large Commercial Transport). It had to be, first of all, the aircraft with increased passenger capacity (about 600-800 seats).

The program of the American aircraft manufacturers Boeing-wear name 747H. In this perspective, the planes were supposed 747-500H, -600H and 700x with enlarged "humpbacked" fuselage, larger than their predecessor Boeing-747-400.

Example layout Boeing 747-500X and 747-600X.

However, these plans were interrupted by the Asian financial crisis of 1997-2000. Then Boeing decided that the market outlook in the selected direction is too vague (especially the absence of prior demand by airlines), and the project was abandoned 747H.

Having lost the main opponent and, thus acquiring a certain freedom of action continued Airbus launched in June 1994. The work to create its own concept of aircraft VLCT.

At the same time with the aim of further increasing the competitiveness of the new project was embarked on a reduction in operating costs by 15-20% in comparison with the already in service aircraft rivals Boeing 747-400. Moreover, structurally it was chosen such variant arrangement which provided significantly larger passenger capacity, including in comparison to a Boeing 400-m.

The aircraft Boeing 747-400.

In December 2000, the program, while still bearing the name A3XX was launched. Its result was the world's largest passenger aircraft Airbus A380-800 (853 passengers in odnoklassovom version), now widely known in the world of wide-body double-deck aircraft, which later received a semi-official name of the Super Jumbo (Super Jumbo).

As the power plant at the new Airbus originally planned to use Trent 900 engine, it was at this time is in development in the British multinational corporation Rolls-Royce Group plc.

Rolls-Royce Trent - it is a whole family of turbofan engines, has received such a designation on the name of the river Trent, related to the number of main rivers of Great Britain. One of the options to transfer the name of the river drevnekeltskogo language means something like "rapidly flooded." A certain logic in comparison with a powerful jet engine visible.

It is interesting that the name Rolls-Royce had previously used in the creation of new types of engines. For example, it was the world's first turboprop Rolls-Royce RB.50 Trent, is being tested on a plane Gloster Meteor (in the version Gloster G.41A Meteor F.Mk.1 (EE227)).

The world's first turboprop Rolls-Royce RB.50 Trent (museum)

Posted in [mergetime] 1396979507 [/ mergetime]

Inet tupit, I try quicker. Gather F5, I do not have))

Gloster Meteor E227.

Later the same name found first turbofan engine Rolls-Royce, made to the same three-shaft design Rolls-Royce RB.203 Trent. It had a bypass ratio equal to three. It was the independent development on the basis of the engine Rolls-Royce Turbomeca Adour, which was a product of the interaction of firms Rolls-Royce and Turbomeca and is installed on military aircraft SEPECAT Jaguar and the Hawker Siddeley Hawk.

Fighter-bomber French Air Force Sepecat Jaguar.

This engine is meant to be a replacement of the existing family of bypass engines with a low bypass ratio Rolls-Royce Spey (RB.163 / 168 / 183Spey, incidentally, is also the name of the river), establishes both civil and military aircraft in the 60-ies. However, a series he did not go, but served as the basis for creating a new engine family Rolls-Royse RB211.

Rolls-Royse RB211 has become a massive commercial turbofan engine. It was created not easy, the company faced in the process with a variety of intractable technical problems. As a result, the cost projection turned out to be much more planned, and increased the final cost of the engine, and the project together with the company-designer were in crisis.

In January 1971, Rolls-Royse declared himself bankrupt. To keep afloat a national program L-1011 Tristar, for which only the engine and was intended RB211, UK government nationalized the company and allowed to continue working on the engine.

Liner L-1011 Tristar.

RB211 engines on the wing of the Boeing-747-300.

Posted in [mergetime] 1396979730 [/ mergetime]

Although the aircraft L-1011 Tristar could not compete, and its production was discontinued at the 250th copy RB211 engine like exploiting and airlines continue to operate on the aircraft Boeing 747/757/767 in their various versions. Suffice successful operation continues to this day, and the RB211 engine in the 1990s served as the basis for the creation of a new line of engines - Rolls-Royse Trent.

Since the beginning of widespread use of RB211 engine aircraft in commercial aviation division of Rolls-Royse (by then a company with governance) is becoming a major player in the aviation engine and ranks third after GE Aviation and Pratt & Whitney.

To maintain existing positions and further advance towards the conquest of market professionals engine Rolls-Royse went towards the creation of a new engine that meets modern requirements and suitable for almost any long-haul passenger airliner, or transport aircraft.

And to reduce costs (which are now tightly controlled by the government) to conduct research and development activities was based on already well-established concept of constructive engine RB211, made three-shaft design.

It was the beginning of the line engines Rolls-Royse Trent. The first engine in this family Trent 600 was intended to be installed on the aircraft McDonnell Douglas MD-11 for the British airline British Caledonian and Air Europe. However, the first company was acquired by British Airways, which canceled the order for the MD-11 and the second "safely" ceased to exist in the early '90s.

Trent 600 customers remained without and never came out of the rank demonstatsionnogo engine programs Trent. All the efforts of the company were directed to the development of the following modifications to the family - Trent 700 for the aircraft Airbus A330.

This engine was certified in January 1994 and became one of the options powerplant aircraft type A330-200 / 300. At the same time, in May 1996 it was reached matching engine standards ICAO ETOPS180.

Aircraft engines A330-200 c Trent-772B-60.

Modification of the Trent 800 (877, 895, 892) since May 1995 has been successfully used on planes Boeing-777-200 / 200ER / 300. In this segment, the engine Rolls-Royse occupies 41% of the market of engines. In order to improve traction performance was increased fan diameter: 2, 80 m to 2, 47 m from the Trent 700.

Engine Trent 800.

Plane Boeing-777 / 258ER with engines Trent 895.

Option Trent 500 of 2000 is set to Outbound passenger liner A340-500 (553), as well as modifications of the A340-600.

A340-642 aircraft with engines Trent 500.

In connection with the development of Boeing options V777h extended range Rolls-Royse developed an improved modification of the Trent 800, which received the name 8104 with the further development of its option in 8115 was calculated at the level of engine thrust to 100, 000 lbf with a further opportunity to address this significant threshold and increase its 110, 000 lbf.

This modification was used the last innovations in the field of commercial engine, in particular a fan sshirokohordnymi titanium blades with special saber-arrow-shaped profile (swept wide chord fan), which allows to get the most (at this stage) out of the fan in terms of operational efficiency, reduce weight and noise. The company Rolls-Royse has been a pioneer in these developments and deal with them since the 1970s.

However, Trent 8104 and was a demonstration model. Competition has done its job. Boeing has received from GE Aviation more than 500 million. $ In the development of the program 777h with the condition of exclusive use in its engines GE - GE90-110B and GE90-115B. It is clear that the issue was resolved in favor of General Electric.

But to make, of course, it was not in vain. Series Trent - it is now the most popular line of Rolls-Royce engines for commercial aircraft. All the latest development of the company were embodied in the latest versions of Trento - Rolls-RoyceTrent 900, Trent 1000 (for the Boeing 787 Dreamliner) and Trent XWB (for the new samoletaAirbus 350XWB). One of the most notable series engines was the Rolls-Royce Trent 900.

This engine from the beginning of the development of the A380 to become a major power plant of Airbus, especially strengthened its position since the beginning of the formation of massive orders for the plane. In March of 2000, Singapore Airlines and followed her in February 2001, the Australian airline Qantas th selected Trent 900 as the main engine for the aircraft ordered by them.

Engine Trent 900.

The decision to create Trent 900 specifically for the A380 was made in 1996. In May 2004, the engine was first tested in the air as a flying laboratory engines based on A340-300 aircraft. European certificate (EASA) was received in October of the same year, and in December 2006 was passed certification in the United States (FAA).

The test engine A340 with Trent 900.

A340 test aircraft with engines Trent 900.

Already in September 2007, the airline British Airways, say so by supporting local producers, decided on the choice of the Trent 900 for its A380 sets (there were 12 pieces). Thus at the end of 2009, the share of the motor in the motor park ordered and produced the A380 was 52%.

Like any CONTEMPORARY industrial products, particularly aircraft manufacturer, from Rolls-Royce have partners, risks and profits are shared among them according to their equity participation.

There are only six: Company Honeywell International, which manufactures pnevmositem; Italian company Avio SpA, the main of which is the prerogative of the box drive motor units; company Volvo Aero, involved in the production of the compressor housing; the company Goodrich Corporation - the fan housing and sensor systems; Italian company Industria de Turbo Propulsores SA, which manufactures low-pressure turbine; kompaniyaHamilton Sundstrand - instruments electronic engine control.

Trent 900 - three-shaft turbofan engine with a high bypass ratio (8, 7-8, 5). It is believed that the production and operation of the motor can be more difficult than the usual two-shaft TVRD, but in the process of this engine is stable and sustainable.

Driving engine Trent 900.

Three-shaft implies a gas generator with three independent from each other mechanically axle assembly. This gives some flexibility in design and allows to choose different combinations of source units to give different output settings for different engines, despite its apparent similarity of embodiment.

The configuration of three-shaft engine.

Besides shorter and therefore stiffer shafts in the three-shaft options allow more accurate flow rate to maintain optimal blade, thereby increasing the efficiency of the gas generator, the stock of its stable bessryvnoy work. Accordingly, reduced weight and dimensions of the engine.

Differences in the sizes of two- and three-shaft TVRD.

Therefore, Rolls-Royce uses three-shaft design in all commercial engines, with the result, a whole series of engines of the same circuit but in different sizes and traction characteristics.

The Trent 900 has inherited from its predecessor, a demonstration model of Trent 8104, a significant number of advanced technological solutions. In particular fan of large diameter (2, 95 m) with a wide-blades (24 pieces) special saber-arrow shaped. The blades are bent as if in the direction opposite to the rotation of the (very similar to the swept wing aircraft).

When the engine are moved at a circumferential speed of up to 1730 km / h, which is significantly higher than the speed of sound. Thanks to the specific configuration of the blades and the fan runs at those speeds effectively and low noise (one of the main parameters of the regulatory requirements for the operators of the A380), the more the flow rate at the inlet of the engine even at takeoff is relatively low. At the same time pull it higher than usual fan shape.

Fan engine Trent 900.

Its total weight of almost 15% lower than the mass of wide fan motors previous types. The main reason for this again in the blades of the fan. They are made of titanium alloy, hollow inside and are reinforced by printsipufermy Warren (Warren girder - lattice of equilateral triangles). This makes them strong, rigid and light at the same time.

Attempts to make the fan blades of composite materials on this engine failed. He could not stand the test of tests on birds from entering the fan.

Interestingly, the supplier of titanium for Rolls-Royce engines (as, indeed, for the majority of aviation equipment produced in the world) is a Russian corporation "VSMPO-Avisma".

Turbine blades are used as monolithic single crystal, and the hollow channels and holes for effective convection-film air cooling.

Thermally loaded components, such as elements of the combustion chamber and the nozzle of the turbine blades are protected by a special coating antitermalnym (thermal-barrier coating or TBC) significantly reduces the heat transfer.

When profiling gas path of the gas generator is taken as a basis for well-proven engine unit similar to Trent 500.

The main components of the engine:

Single-stage fan, eight-intermediate compressor, six-stage high-pressure compressor.

Annular combustor with 24 fuel nozzles (injectors), the so-called type «Tiled Rhase 5" (own name Rolls-Royse). This type of camera is used on engines Trent 500/800/900/1000. By the number of emissions complies with CAEP 8 with a large margin.

Combustion chamber type Phase 5.

Example of combustion chamber (for the Trent 500, the same stands on the Trent 900)

Such a combustion chamber has a certain type lamellar structure walls of the flame tube (tiled combustor), which allows a combination with antitermalnym coating (TBC) significantly improve their insulation and cooling zone of extremely high temperatures. In addition, it has a shorter combustion zone and along with high thermal efficiency has markedly reduced levels of NOx emissions.

Trent turbine 900 also consists of three independent parts. It is a single-stage high-pressure turbine, an intermediate single-stage turbine and a five-speed low-pressure turbine, the rotating fan.

Loading Trent 900 aircraft.

Besides the engine, as well as almost all modern TVRD has a modular design greatly facilitates (and cheaper) its production, operation and maintenance.

As advantage of the engine is presented not only by its modular design and the possibility of transporting assembled in the cargo hold of the transport plane Boeing-747.

The core modules of the design Trent 900.

Module 01. The rotor assembly low pressure compressor or fan. This rotor disk with a fan installed on it, rotates the low-pressure turbine. The disk slots are made on the principle of "dovetail", which set fan blades. The Trent series engines, the number ranges from 26 to 20. The minimum number (20) in the Trent 1000, at the Trent 900 - 24. The blades can be replaced without removing the engine from the aircraft.

Module 02. The intermediate compressor. The design of the disc and collected in a drum blades. In the latest model line Trent (XWB) in this module used blisks, but the 900-m they do not exist.

Module 03. The inner housing intermediate compressor. Located between the intermediate and high pressure compressor. Inside it are mounted bearings of the rotors. It has a hollow pillar, which are main oil and air lines, as well as the axis of the drive units.

04. Module assembly (system) pressure vessel. It consists of inner shells of high pressure compressor, combustor and high pressure turbine. On engines Trent 500/700/800 rotor system that rotates in the same direction as the other two rotor. Since Trent 900 engine rotation is reversed, which can significantly increase the efficiency of the turbine assembly as a whole.

Motor Modules Trent 900.

Module 05. The intermediate turbine.

That's all I wanted to say.

Source: