776

Heading for sell

Dream motorists go fast and spend little fuel performed by the exhaust gases.

At the turn of the century - present and past - technical progress in the automotive industry has slowed down markedly. Of course, the cars become smarter, they acquire the means of security and learn to build relationships with the environment. As for the engine, the engineers of the Motor no one demands the impossible - only more power and less fuel consumption. Individually, it's easy, but I want to get everything at once, and cheaper.

The last century

At the end of the XIX century, engineers are already thinking how to increase the capacity of the car and save on fuel. Engine power is greater, the greater the burn gasoline in a single cycle. You can add, for example, increasing the engine capacity. But you can not increase the volume and density, but at the same time increase the pressure, and thus, the piston will not be able myself to suck the fuel mixture, it is necessary somehow to deliver - for example, through the efforts of the heated exhaust.

Germans Gottlieb Daimler (Gottlieb Daimler, 1834-1900) and Rudolf Diesel (Rudolf Diesel, 1858-1913) experimented with the compressed fuel-air mixture and found that the increase in air pressure prior to mixing it with the fuel increases the combustion efficiency of the latter and thereby leads to an increase in engine power. But the patent for the first time the principle of turbo issued US Patent Office, and received his Swiss engineer Alfred Buchi (Alfred J. Büchi) in 1911. He was the first successfully implemented the pressurization of automotive engines using exhaust, while increasing engine power by 40%.

Petrol Ford EcoBoost engines feature direct fuel injection and turbocharging. The technology allows the three-liter V6 Ford cardinality indicators show the level of six-liter V8, and the fuel consumption is 15% less. Photo: Dillon Bryden / FORD

The first "testers" turbo steel trucks in 1938. The pioneers among the cars equipped with turbines were and Chevrolet Corvair Monza Oldsmobile Jetfire, released only to the US market in the years 1962-1963. Despite the obvious technical advantages of turbocharging for cars clearly manifested its main shortcomings, which will be discussed below. For a long time it was unclear how to deal with them.

Another significant event in the history of turbocharging occurred with the appearance of Mercedes-Benz 300 SD to 1977 - the first car equipped with a diesel turbo engine. Later, one of the "Germans" was followed by another - Volkswagen Turbodiesel.

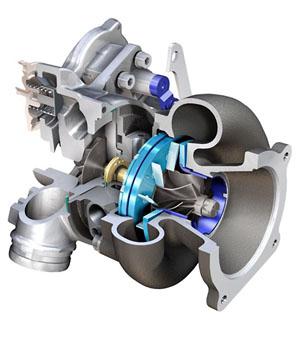

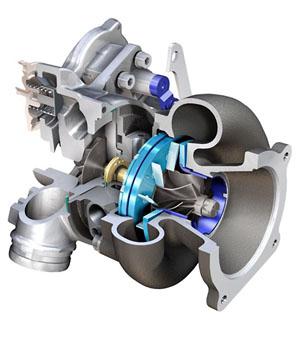

Basics sell

The method is based on the use of turbo power that has been used - exhaust. Leaving the engine, they fall to the turbine wheel, then transmits the energy of the compressor wheel, which compresses the air and pushes it into the engine. And to the air in the cylinders fit even more, use the intercooler - a kind of radiator that cools the incoming air, which again improves its density at the same pressure.

Despite the fact that the direct connection between the turbine and the engine crankshaft is not, system performance depends on the number of revolutions of the motor. The higher the engine speed, the greater the exhaust gas and the faster they move. Accordingly, the turbine spins more and more compressed air before it enters the engine cylinders.

Mercedes-Benz cars with an SD 300 turbo diesel 1977 release of the Germans created exclusively for export to the US and Canada - there just loved the big and powerful cars. Photo: Daimler AG

In turbo has disadvantages, the main of which, perhaps, - notable lag increase power by pressing the gas pedal. This effect is called "turboyamu" or "turbolagom". It is precisely because of the lack of direct communication between the turbine and the crankshaft. The driver presses on the gas, but the power of the engine rises only when the exhaust gas is sufficiently untwist turbine wheel. And then force him should unleash the compressor wheel. Generally, the delay in response to an increase in fuel supply is at any machine. But for a passenger - it is a critical component. In trucks with him can still be tolerated. Therefore, trucks, equipped with turbines, made in the 30th, and on the passenger pulled up to the 70s.

Turbocharged engines can reach up to 40% more power than without it. Naturally, the turbo are more and more economical. The already low efficiency of the internal combustion engine falls further from small engines due to the fact that the volume per unit area being over the outer surface and there is an additional heat dissipation. Therefore, the compact engines turbirovanie is particularly effective.

Changeable geometry

One of the first production cars, which managed to successfully cope with turboyamu became a Porsche 911 sports Turbo. In it there was a system with a variable geometry turbocharger (VTG, Variable Turbine Geometry). Her design feature is that special mobile guide "dispensed" exhaust pressure on the impeller, depending on the degree of pressing the gas pedal. Due to the turbine wheel begins to rotate more quickly before the amount rises and the speed of the exhaust gases.

In 2006, at the Geneva Motor Show, Porsche unveiled a new top model of the 911 series - Porsche Turbo 911. 480 horsepower at 6000 rev / min. This is approximately 60 forces greater than that of the preceding embodiment. Cars equipped with the supercharged engine with variable geometry. Illustration: Dr. Ing. h.c. F. Porsche AG

A special mechanism changes the angle of attack of the ten (exactly as their engine in Porsche) guides. This mode of the turbocharger is particularly relevant in the area of the low speed of the motor - the engine becomes more responsive and high-torque. When the engine enters a high rotational speed, "flaps" are located have a larger angle to the tangent line nearer to the radial direction. Now the gas flow which reaches the turbine impeller, "precipitates": firstly, increasing the flow area, and secondly, "wings" direct flow closer to the axis of the turbine, which reduces force on the blades.

As a rule, small-sized turbocharger increases engine torque at relatively low speeds, while large turbines - in the area of higher speeds. A system VGT allowed to stretch the horizontal "shelf" of torque from 1950 to 5000 rev / min, that is, make it an extremely high-torque over a very wide rpm range. And the moment the six-cylinder engine in volume 3 and 6 liters more than impressive - 620 N × m.

Turbocharged Direct Injection +

Such a tandem - turbocharger with direct injection - heavily used by Audi (technology TFSI) and Ford (EcoBoost). Compared with conventional naturally aspirated engine V6, four-cylinder Audi engine 2 0 TFSI with direct injection and turbocharging, which has the same dynamic performance, it consumes 10-15% less fuel.

By combining turbocharging and direct fuel injection, the engineers have increased capacity and improved dynamic performance while reducing fuel consumption. The technology of direct injection and turbocharging are perfectly combined because the evaporation of the fuel within the combustion chamber of the engine picks up heat from the intake air. This allows to increase the compression, greatly improving the efficiency of the engine, and solve another problem of turbocharged engines - increased tendency to knock at high levels of boost pressure.

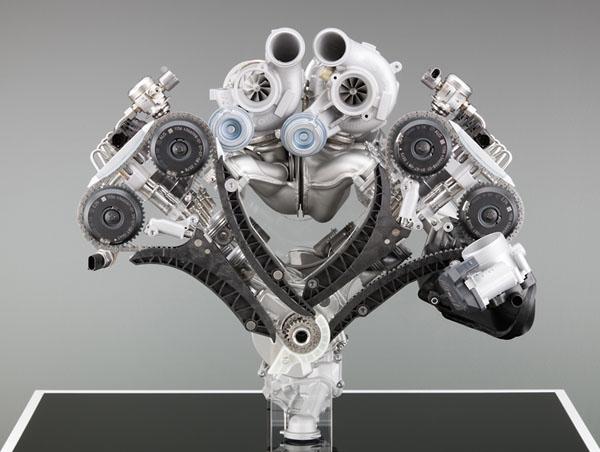

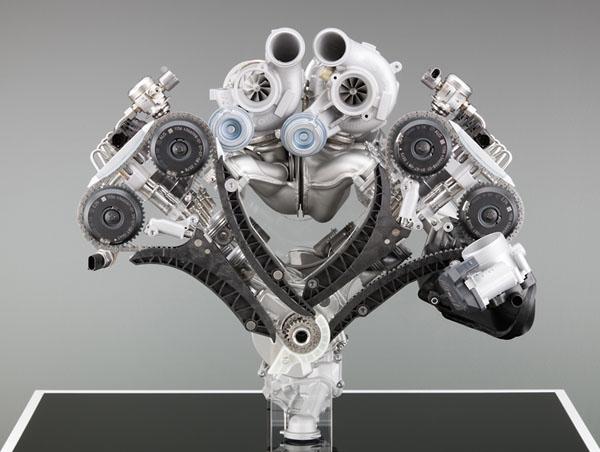

The engine TwinPower Turbo technology with double turbocharging Twin Scroll Twin Turbo and the BMW patented a common exhaust manifold special design. Both turbocharger with catalyst disposed in the V-shaped space between the rows of cylinders, which allows to place the inlet and outlet channels in such a manner that their length is reduced at the same time large cross-section. This considerably reduces the pressure loss on the side of the exhaust gases. Photo: BMW AG

Exhaust manifold with integrated turbocharger provides the high efficiency of the turbine by using energy of the exhaust gases. This at the same time manage to raise the ceiling and the power to improve the responsiveness of the engine, reduce fuel consumption and reduce emissions of harmful substances into the atmosphere.

Two are better than one

Effectively it helps fight turboyamu scheme with sequential supercharging, when low engine speeds the small turbocharger works, responsible for "saturation" thrust the low-speed and high-speed starts a second, bigger. In XX century, this kind of boost used in a Porsche 959, and so today are struggling with "turbo-pause" turbo diesel BMW and Land Rover, as well as gasoline engines Volkswagen, however, in their function of small turbines laid compressors or mechanical supercharger

This year, new turbochargers were announced by the companies BMW and Opel. They applied steam turbines of different size and capacity. One, a small turbine, has a quick response and allows the add power at low speed (1800 rev / min.). On medium speed (up to 3000 rev / min.) Connects the second, a large turbine that works alone at high speeds.

On-line engine often uses a single turbocharger with a double working apparatus. But more frequently the same pair of turbochargers in parallel serving individual groups of cylinders. This arrangement is typical of the V-turbo engine, where each block is a supercharger.

Supercharged future

There is a tradition in the automotive world - every year choose the best engine, created in the last 365 days. The last two years the Grand Prix in the competition goes to 1, 4-liter TSI Twincharger from Volkswagen. The relatively small volume of the engine is equipped with two compressors, which displays his power at the level of 2, 0-2, 4-liter naturally aspirated (ie, non-turbo or compressor) motors. A small volume of the engine 1, 4 TSI can produce from 140 to 170 hp

However, this is not the only "turboprizёr" Competition powertrains 2010. The different categories won five different supercharged engines produce VW, BMW and FIAT. Among the nominees of the atmospheric engines at times less than those which use compressors and turbochargers.

Nevertheless, some kind of a sensation was the recognition of the best motor of innovation, the Fiat 1.4 MultiAir Turbo, which are equipped with Alfa Romeo MiTo and Giulietta. He walked four, 5-liter V8 from the Ferrari 458 Italia and another compact turbine German auto giant Volkswagen: volume 1, 2 TSI. Ironically, the low-capacity engine (capacity varies from 86 to 105 hp) easily sets in motion a rather big Škoda Octavia and Yeti, as well as the Volkswagen Golf.

And the most compact engine-nominated supercharged to 1, 0-liter 85-strong unit of production Mitsubishi, mounted on the Smart Fortwo.

Perhaps it is a tandem "small turbo engine +" can be considered the most promising direction in the development of the European automotive industry. The small volume of the combustion chambers is difficult to spend a lot of fuel, but at the same time provides a turbo boost in power and torque, enough for a dynamic movement of middle-class sedans, crossovers and even small kompaktven. In addition, lower fuel consumption and reduced emissions responds to the atmosphere, which is particularly pleasing the Europeans, who have to pay higher charges for environmentally unfriendly cars.

Alexander Korobchenko here

The novelty of the Beijing Motor Show 2010 - the concept Ford Start. The car has received a one-liter three-cylinder economical EcoBoost engine with emissions below 100 g / km. Features of this engine are comparable to naturally aspirated 1, 6 liter "four". The unit is paired with a six-speed manual gearbox. Photo: Ford Motor Company

Source:

At the turn of the century - present and past - technical progress in the automotive industry has slowed down markedly. Of course, the cars become smarter, they acquire the means of security and learn to build relationships with the environment. As for the engine, the engineers of the Motor no one demands the impossible - only more power and less fuel consumption. Individually, it's easy, but I want to get everything at once, and cheaper.

The last century

At the end of the XIX century, engineers are already thinking how to increase the capacity of the car and save on fuel. Engine power is greater, the greater the burn gasoline in a single cycle. You can add, for example, increasing the engine capacity. But you can not increase the volume and density, but at the same time increase the pressure, and thus, the piston will not be able myself to suck the fuel mixture, it is necessary somehow to deliver - for example, through the efforts of the heated exhaust.

Germans Gottlieb Daimler (Gottlieb Daimler, 1834-1900) and Rudolf Diesel (Rudolf Diesel, 1858-1913) experimented with the compressed fuel-air mixture and found that the increase in air pressure prior to mixing it with the fuel increases the combustion efficiency of the latter and thereby leads to an increase in engine power. But the patent for the first time the principle of turbo issued US Patent Office, and received his Swiss engineer Alfred Buchi (Alfred J. Büchi) in 1911. He was the first successfully implemented the pressurization of automotive engines using exhaust, while increasing engine power by 40%.

Petrol Ford EcoBoost engines feature direct fuel injection and turbocharging. The technology allows the three-liter V6 Ford cardinality indicators show the level of six-liter V8, and the fuel consumption is 15% less. Photo: Dillon Bryden / FORD

The first "testers" turbo steel trucks in 1938. The pioneers among the cars equipped with turbines were and Chevrolet Corvair Monza Oldsmobile Jetfire, released only to the US market in the years 1962-1963. Despite the obvious technical advantages of turbocharging for cars clearly manifested its main shortcomings, which will be discussed below. For a long time it was unclear how to deal with them.

Another significant event in the history of turbocharging occurred with the appearance of Mercedes-Benz 300 SD to 1977 - the first car equipped with a diesel turbo engine. Later, one of the "Germans" was followed by another - Volkswagen Turbodiesel.

Basics sell

The method is based on the use of turbo power that has been used - exhaust. Leaving the engine, they fall to the turbine wheel, then transmits the energy of the compressor wheel, which compresses the air and pushes it into the engine. And to the air in the cylinders fit even more, use the intercooler - a kind of radiator that cools the incoming air, which again improves its density at the same pressure.

Despite the fact that the direct connection between the turbine and the engine crankshaft is not, system performance depends on the number of revolutions of the motor. The higher the engine speed, the greater the exhaust gas and the faster they move. Accordingly, the turbine spins more and more compressed air before it enters the engine cylinders.

Mercedes-Benz cars with an SD 300 turbo diesel 1977 release of the Germans created exclusively for export to the US and Canada - there just loved the big and powerful cars. Photo: Daimler AG

In turbo has disadvantages, the main of which, perhaps, - notable lag increase power by pressing the gas pedal. This effect is called "turboyamu" or "turbolagom". It is precisely because of the lack of direct communication between the turbine and the crankshaft. The driver presses on the gas, but the power of the engine rises only when the exhaust gas is sufficiently untwist turbine wheel. And then force him should unleash the compressor wheel. Generally, the delay in response to an increase in fuel supply is at any machine. But for a passenger - it is a critical component. In trucks with him can still be tolerated. Therefore, trucks, equipped with turbines, made in the 30th, and on the passenger pulled up to the 70s.

Turbocharged engines can reach up to 40% more power than without it. Naturally, the turbo are more and more economical. The already low efficiency of the internal combustion engine falls further from small engines due to the fact that the volume per unit area being over the outer surface and there is an additional heat dissipation. Therefore, the compact engines turbirovanie is particularly effective.

Changeable geometry

One of the first production cars, which managed to successfully cope with turboyamu became a Porsche 911 sports Turbo. In it there was a system with a variable geometry turbocharger (VTG, Variable Turbine Geometry). Her design feature is that special mobile guide "dispensed" exhaust pressure on the impeller, depending on the degree of pressing the gas pedal. Due to the turbine wheel begins to rotate more quickly before the amount rises and the speed of the exhaust gases.

In 2006, at the Geneva Motor Show, Porsche unveiled a new top model of the 911 series - Porsche Turbo 911. 480 horsepower at 6000 rev / min. This is approximately 60 forces greater than that of the preceding embodiment. Cars equipped with the supercharged engine with variable geometry. Illustration: Dr. Ing. h.c. F. Porsche AG

A special mechanism changes the angle of attack of the ten (exactly as their engine in Porsche) guides. This mode of the turbocharger is particularly relevant in the area of the low speed of the motor - the engine becomes more responsive and high-torque. When the engine enters a high rotational speed, "flaps" are located have a larger angle to the tangent line nearer to the radial direction. Now the gas flow which reaches the turbine impeller, "precipitates": firstly, increasing the flow area, and secondly, "wings" direct flow closer to the axis of the turbine, which reduces force on the blades.

As a rule, small-sized turbocharger increases engine torque at relatively low speeds, while large turbines - in the area of higher speeds. A system VGT allowed to stretch the horizontal "shelf" of torque from 1950 to 5000 rev / min, that is, make it an extremely high-torque over a very wide rpm range. And the moment the six-cylinder engine in volume 3 and 6 liters more than impressive - 620 N × m.

Turbocharged Direct Injection +

Such a tandem - turbocharger with direct injection - heavily used by Audi (technology TFSI) and Ford (EcoBoost). Compared with conventional naturally aspirated engine V6, four-cylinder Audi engine 2 0 TFSI with direct injection and turbocharging, which has the same dynamic performance, it consumes 10-15% less fuel.

By combining turbocharging and direct fuel injection, the engineers have increased capacity and improved dynamic performance while reducing fuel consumption. The technology of direct injection and turbocharging are perfectly combined because the evaporation of the fuel within the combustion chamber of the engine picks up heat from the intake air. This allows to increase the compression, greatly improving the efficiency of the engine, and solve another problem of turbocharged engines - increased tendency to knock at high levels of boost pressure.

The engine TwinPower Turbo technology with double turbocharging Twin Scroll Twin Turbo and the BMW patented a common exhaust manifold special design. Both turbocharger with catalyst disposed in the V-shaped space between the rows of cylinders, which allows to place the inlet and outlet channels in such a manner that their length is reduced at the same time large cross-section. This considerably reduces the pressure loss on the side of the exhaust gases. Photo: BMW AG

Exhaust manifold with integrated turbocharger provides the high efficiency of the turbine by using energy of the exhaust gases. This at the same time manage to raise the ceiling and the power to improve the responsiveness of the engine, reduce fuel consumption and reduce emissions of harmful substances into the atmosphere.

Two are better than one

Effectively it helps fight turboyamu scheme with sequential supercharging, when low engine speeds the small turbocharger works, responsible for "saturation" thrust the low-speed and high-speed starts a second, bigger. In XX century, this kind of boost used in a Porsche 959, and so today are struggling with "turbo-pause" turbo diesel BMW and Land Rover, as well as gasoline engines Volkswagen, however, in their function of small turbines laid compressors or mechanical supercharger

This year, new turbochargers were announced by the companies BMW and Opel. They applied steam turbines of different size and capacity. One, a small turbine, has a quick response and allows the add power at low speed (1800 rev / min.). On medium speed (up to 3000 rev / min.) Connects the second, a large turbine that works alone at high speeds.

On-line engine often uses a single turbocharger with a double working apparatus. But more frequently the same pair of turbochargers in parallel serving individual groups of cylinders. This arrangement is typical of the V-turbo engine, where each block is a supercharger.

Supercharged future

There is a tradition in the automotive world - every year choose the best engine, created in the last 365 days. The last two years the Grand Prix in the competition goes to 1, 4-liter TSI Twincharger from Volkswagen. The relatively small volume of the engine is equipped with two compressors, which displays his power at the level of 2, 0-2, 4-liter naturally aspirated (ie, non-turbo or compressor) motors. A small volume of the engine 1, 4 TSI can produce from 140 to 170 hp

However, this is not the only "turboprizёr" Competition powertrains 2010. The different categories won five different supercharged engines produce VW, BMW and FIAT. Among the nominees of the atmospheric engines at times less than those which use compressors and turbochargers.

Nevertheless, some kind of a sensation was the recognition of the best motor of innovation, the Fiat 1.4 MultiAir Turbo, which are equipped with Alfa Romeo MiTo and Giulietta. He walked four, 5-liter V8 from the Ferrari 458 Italia and another compact turbine German auto giant Volkswagen: volume 1, 2 TSI. Ironically, the low-capacity engine (capacity varies from 86 to 105 hp) easily sets in motion a rather big Škoda Octavia and Yeti, as well as the Volkswagen Golf.

And the most compact engine-nominated supercharged to 1, 0-liter 85-strong unit of production Mitsubishi, mounted on the Smart Fortwo.

Perhaps it is a tandem "small turbo engine +" can be considered the most promising direction in the development of the European automotive industry. The small volume of the combustion chambers is difficult to spend a lot of fuel, but at the same time provides a turbo boost in power and torque, enough for a dynamic movement of middle-class sedans, crossovers and even small kompaktven. In addition, lower fuel consumption and reduced emissions responds to the atmosphere, which is particularly pleasing the Europeans, who have to pay higher charges for environmentally unfriendly cars.

Alexander Korobchenko here

The novelty of the Beijing Motor Show 2010 - the concept Ford Start. The car has received a one-liter three-cylinder economical EcoBoost engine with emissions below 100 g / km. Features of this engine are comparable to naturally aspirated 1, 6 liter "four". The unit is paired with a six-speed manual gearbox. Photo: Ford Motor Company

Source: