1174

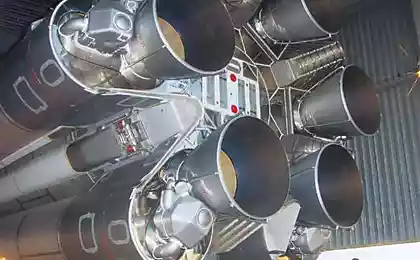

General Electric engineers printed the 3D-printer working model of the jet engine

Engine, measuring 20 by 30 centimeters and a rotation speed of 33 thousand revolutions per minute has been successfully tested in the division of GE Aviation. It is worth noting that this is the first jet engine, implemented exclusively via c 3D-printing technology.

To create the model, the engineers took several years. Most of the time taken to debug the additive printing technology and setting up the hardware. To do this, the engineers of the Center additive technology (Additive Development Center) used a special laser printer with powerful, melts the metal powder in a strictly defined order.

Self 3D-printing process takes no more time than in the case of conventional plastics. Therefore, in the next month plans to GA using this technology to begin mass production of fuel injectors for its new line of jet engines LEAP.

By the way, 3D-printing technology uses active and aircraft manufacturer Airbus, which uses in its new A350 more than 1,000 pieces of printed the 3D-printer.

P.S. More about the industrial, steel and chocolate 3D-Printing can be found on specialized conference in St. Petersburg.

Source: geektimes.ru/company/smile-expo/blog/250498/

The events of the trilogy "Back to the Future" could not happen

Flexible bricks? You will not believe!