783

Super optics.

Part 1

via livejournal

2. Then enter the lens at the vacuum station. Here reign of nanotechnology specialists, and this is no joke.

3. In this apparatus in a vacuum state for the lens is deposited magnesium fluoride to obtain the desired reflectivity.

4.No before this lens rubbing alcohol.

5.Opyat visual inspection.

6. Then, they are inserted into the frame.

7.And mounted on a sphere.

8.Za once can be processed in the vacuum apparatus a plurality of lenses of different diameters.

9.Na these devices exhibited the necessary parameters.

10. And welcome to the best, the new world). This operation is the called the "enlightenment".

11.

12.After the bombing of magnesium fluoride lens surface, they fall at the final stage. Here the lens again inspect for quality.

13.Kromki lenses varnished before being sent to the assembly.

14. Excess rubbing alcohol.

15.Some lenses glued together, this is what I previously knew.

16.

17.

18.A here you can see the entire palette of lenses manufactured at the plant. The lenses are made only for domestic production, for optical sights and thermal imagers. This concludes our tour of the workshops where such are made familiar to us, but really unusual items came to an end, but not in a hurry to close the window, then we will see how to make the other parts and is assembled.

19.Posle two-hour walking around the shops where they make lenses and listening to a very interesting story about this process, we moved on to Olga, a security guard who was waiting all this time we again went with us to the other part of the private, secure facilities. We were met by the director of the production, which held forth the workshops, which produces almost all of the details for the final product of the enterprise.

In one of the rooms I saw this piece of fabric with familiar characters and asked in surprise: "MTR - really special operations forces (Belarusian paratroopers)"? To which I replied smiling, it's a symbol of student construction teams MSTU. Bauman)).

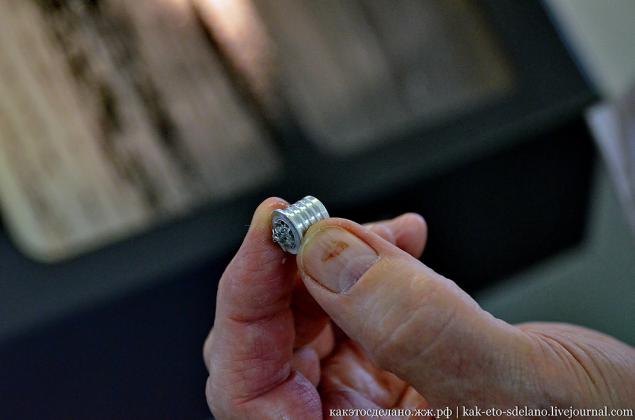

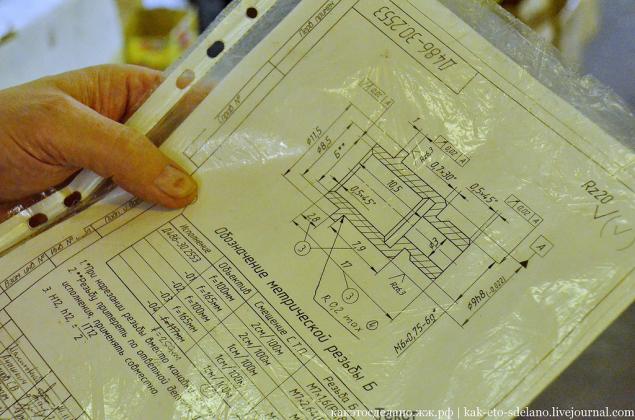

20.Zdes make drawings with all the options for future harvesting.

21. All necessary parameters are set at the CNC. Here most of the modern machines.

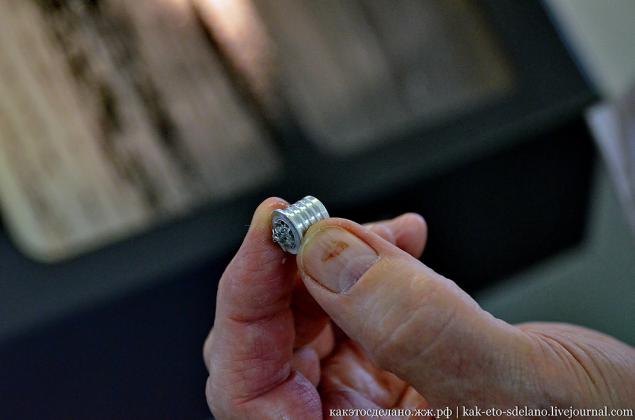

22. It is very simple - Whack, Whack, bam ...

23.I bagatelle ready!

24.Na fact, these machines do a pretty sophisticated operation.

25.Na this workpiece already have holes and thread.

26.Na simpler machines are made less complex elements to the metal part of the sight.

27.K example here are:

28.Ili such.

29.Eti parts made on CNC machines. Already on Form guessed profile products.

30.

31.Zatem all parts fall into the control department.

32.Zdes is sampled parts from each batch and inspected for compliance.

33.

34.Esche creation of CNC machines.

35.Etot worker develops a thread that details were well adjusted to each other.

36. In this workshop stamped plastic parts.

37.Vse done using molds.

38.Vot this part

39.Sdelana this mold.

40.Sklad literally clogged pipes all diameters and sizes.

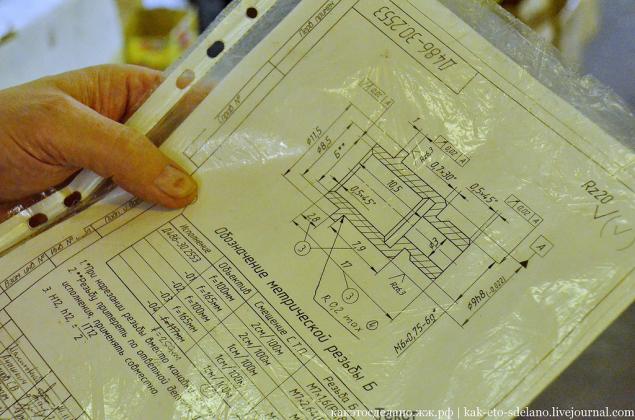

41.Obschy view of the shop.

42.Metallicheskie parts after machining sent to the gasoline bath to remove traces of lubricating oil.

43.A then their waiting ultrasonic bath to wash away all the smallest particles.

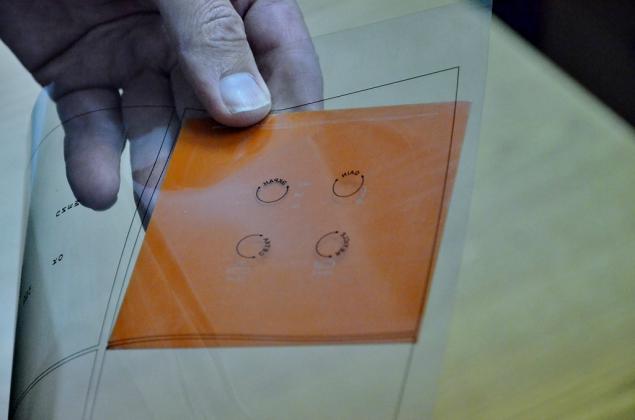

44.Po this pattern in the workpiece machined bolt holes. It is inserted through the holes and billet drilled holes.

45.Zdes a rack with templates.

46.Posle all procedures of the external parts are painted with black paint.

47.

48.Etot device makes laser engraving on the details.

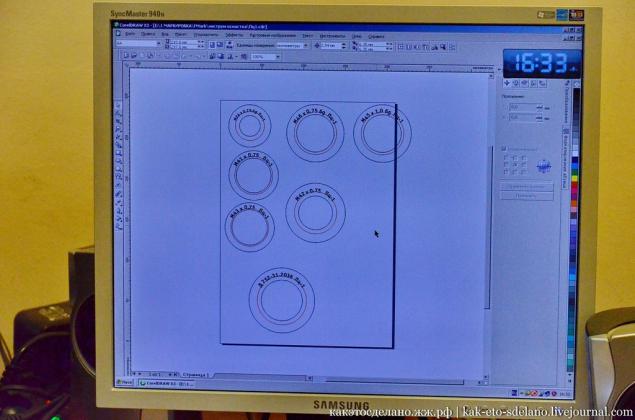

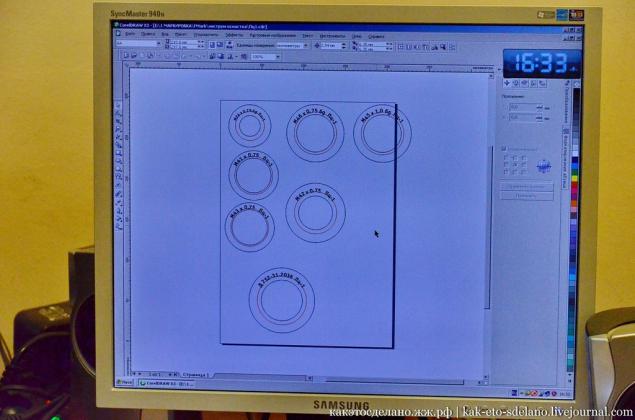

49. So it looks from the outside.

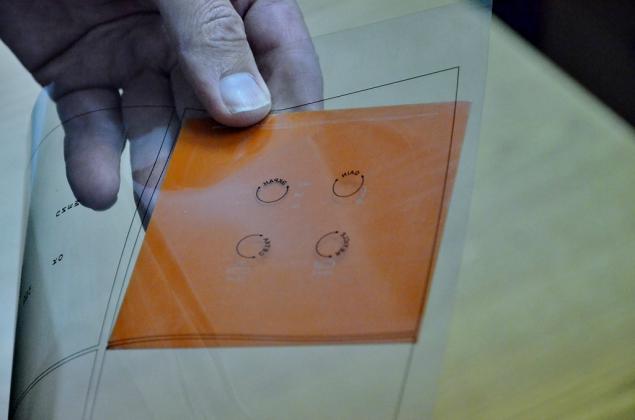

50.

51.Zdes made silkscreen - printing or drawing on the item.

52.Na computer designed stencil.

53.Podobny this.

54.Na stock company all items neatly sorted into box.

55.Na each box information stored here often. You can just envy at how carefully and comfortably all this is done, it is not necessary to run the enterprise to find the right part or screw-bolt. I have such an organization at home.

56. Go ahead. Here again, the lenses are wiped with a cotton swab with alcohol and placed in parts of the sight of the future.

57.

58.Na each stage of strict quality control, no speck of dust should not get inside the product.

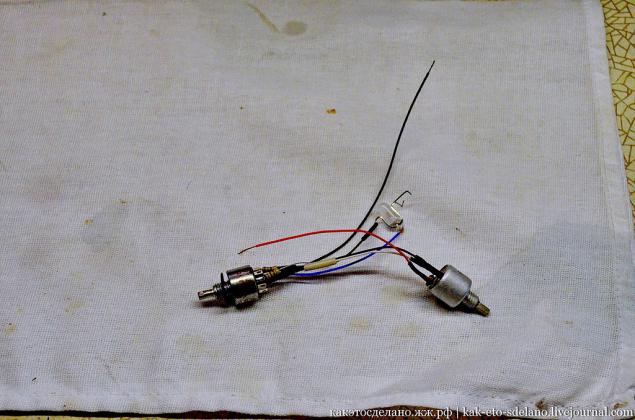

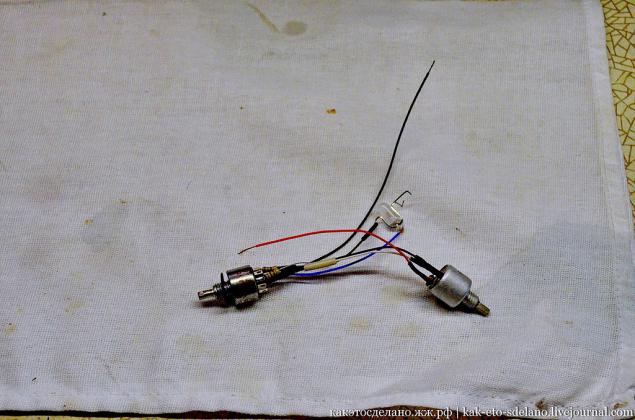

59.Nasha tour lasted for the fourth hour and by the time we went into the office, staff time, which were collected by electronic stuffing sights over, because unfortunately there was no one to ask about the details of production at this stage.

60.Hotya think here and so everything is clear - the wires are soldered to the various chips and other electronic gizmos.

61. Virtually all parts in the optical sight of domestic production. Is that the screws do not.

62.

63.V office floor above is a final product assembly.

64.

65.Elektronny bush.

66.

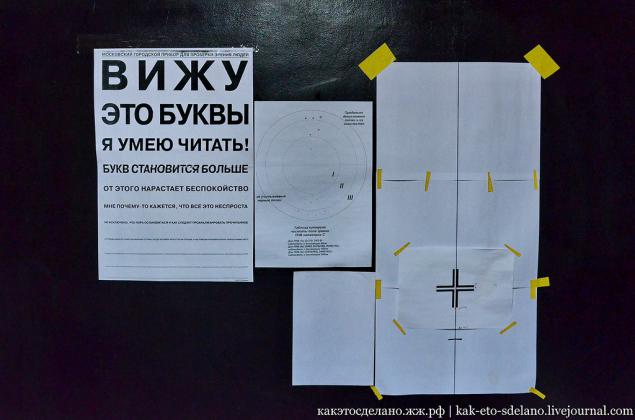

67.Posle how the telescope is assembled, it is calibrated with the help of this tool here.

68.Cherez riflescope

69.Na this rack stores the same parts of the optical sight, can not remember exactly what, but as you can see the dimensions they differ slightly. The fact that the parts can be to some microns more or less, and there is a choice, you can fit exactly to the size of the desired slot / thread, in the future do not unscrew or came loose.

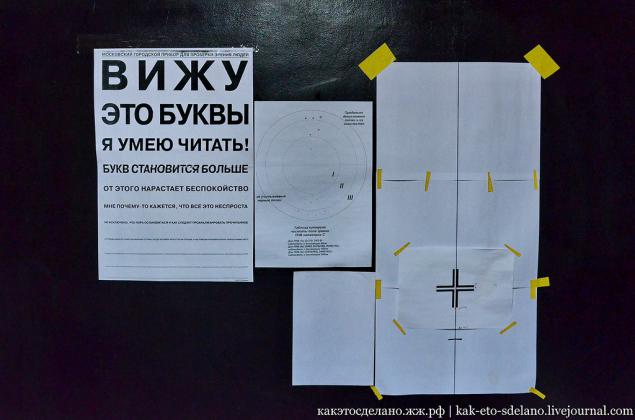

71.Esche instrument for calibration run. Note the poster on it shows just the sight of this production.

72.

73.Uzhe finished products.

74.A copy of the largest optical sight, made in a single copy to verify the ability to build such an enterprise.

75.Nu is our tour came to an end, check your vision goodbye.

Thanks to the head of the press service of the plant "Daedalus" Olga Egorova, for the opportunity to see the interesting production.

That's all. Thank you all.

via livejournal

2. Then enter the lens at the vacuum station. Here reign of nanotechnology specialists, and this is no joke.

3. In this apparatus in a vacuum state for the lens is deposited magnesium fluoride to obtain the desired reflectivity.

4.No before this lens rubbing alcohol.

5.Opyat visual inspection.

6. Then, they are inserted into the frame.

7.And mounted on a sphere.

8.Za once can be processed in the vacuum apparatus a plurality of lenses of different diameters.

9.Na these devices exhibited the necessary parameters.

10. And welcome to the best, the new world). This operation is the called the "enlightenment".

11.

12.After the bombing of magnesium fluoride lens surface, they fall at the final stage. Here the lens again inspect for quality.

13.Kromki lenses varnished before being sent to the assembly.

14. Excess rubbing alcohol.

15.Some lenses glued together, this is what I previously knew.

16.

17.

18.A here you can see the entire palette of lenses manufactured at the plant. The lenses are made only for domestic production, for optical sights and thermal imagers. This concludes our tour of the workshops where such are made familiar to us, but really unusual items came to an end, but not in a hurry to close the window, then we will see how to make the other parts and is assembled.

19.Posle two-hour walking around the shops where they make lenses and listening to a very interesting story about this process, we moved on to Olga, a security guard who was waiting all this time we again went with us to the other part of the private, secure facilities. We were met by the director of the production, which held forth the workshops, which produces almost all of the details for the final product of the enterprise.

In one of the rooms I saw this piece of fabric with familiar characters and asked in surprise: "MTR - really special operations forces (Belarusian paratroopers)"? To which I replied smiling, it's a symbol of student construction teams MSTU. Bauman)).

20.Zdes make drawings with all the options for future harvesting.

21. All necessary parameters are set at the CNC. Here most of the modern machines.

22. It is very simple - Whack, Whack, bam ...

23.I bagatelle ready!

24.Na fact, these machines do a pretty sophisticated operation.

25.Na this workpiece already have holes and thread.

26.Na simpler machines are made less complex elements to the metal part of the sight.

27.K example here are:

28.Ili such.

29.Eti parts made on CNC machines. Already on Form guessed profile products.

30.

31.Zatem all parts fall into the control department.

32.Zdes is sampled parts from each batch and inspected for compliance.

33.

34.Esche creation of CNC machines.

35.Etot worker develops a thread that details were well adjusted to each other.

36. In this workshop stamped plastic parts.

37.Vse done using molds.

38.Vot this part

39.Sdelana this mold.

40.Sklad literally clogged pipes all diameters and sizes.

41.Obschy view of the shop.

42.Metallicheskie parts after machining sent to the gasoline bath to remove traces of lubricating oil.

43.A then their waiting ultrasonic bath to wash away all the smallest particles.

44.Po this pattern in the workpiece machined bolt holes. It is inserted through the holes and billet drilled holes.

45.Zdes a rack with templates.

46.Posle all procedures of the external parts are painted with black paint.

47.

48.Etot device makes laser engraving on the details.

49. So it looks from the outside.

50.

51.Zdes made silkscreen - printing or drawing on the item.

52.Na computer designed stencil.

53.Podobny this.

54.Na stock company all items neatly sorted into box.

55.Na each box information stored here often. You can just envy at how carefully and comfortably all this is done, it is not necessary to run the enterprise to find the right part or screw-bolt. I have such an organization at home.

56. Go ahead. Here again, the lenses are wiped with a cotton swab with alcohol and placed in parts of the sight of the future.

57.

58.Na each stage of strict quality control, no speck of dust should not get inside the product.

59.Nasha tour lasted for the fourth hour and by the time we went into the office, staff time, which were collected by electronic stuffing sights over, because unfortunately there was no one to ask about the details of production at this stage.

60.Hotya think here and so everything is clear - the wires are soldered to the various chips and other electronic gizmos.

61. Virtually all parts in the optical sight of domestic production. Is that the screws do not.

62.

63.V office floor above is a final product assembly.

64.

65.Elektronny bush.

66.

67.Posle how the telescope is assembled, it is calibrated with the help of this tool here.

68.Cherez riflescope

69.Na this rack stores the same parts of the optical sight, can not remember exactly what, but as you can see the dimensions they differ slightly. The fact that the parts can be to some microns more or less, and there is a choice, you can fit exactly to the size of the desired slot / thread, in the future do not unscrew or came loose.

71.Esche instrument for calibration run. Note the poster on it shows just the sight of this production.

72.

73.Uzhe finished products.

74.A copy of the largest optical sight, made in a single copy to verify the ability to build such an enterprise.

75.Nu is our tour came to an end, check your vision goodbye.

Thanks to the head of the press service of the plant "Daedalus" Olga Egorova, for the opportunity to see the interesting production.

That's all. Thank you all.

Charles de Gaulle and Paris itself.

NASA astronomers have discovered coming from the constellation Perseus pulsed signals.