861

Zapilivaem handle!

On the nose the New Year, it is necessary to take care of gifts for friends and relatives. So I decided to gash a couple of ballpoint pens for his friend and his wife. Gift made by their own hands - it is always doubly pleased.

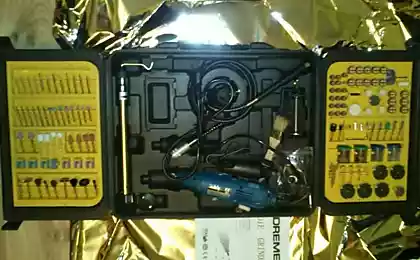

It all started with the fact that this fall I bought a lathe. Actually, I had planned to carve it legs for the table to the living room, but stumbled on kits for pens and decided to buy a try. Very pleased! Here is the set.

Will be 53 photos.

Now we take a couple of sticks of wood and zapilivaem! I took Wenge (Wenge) for him and Bloodwood (Blood Tree) for her.

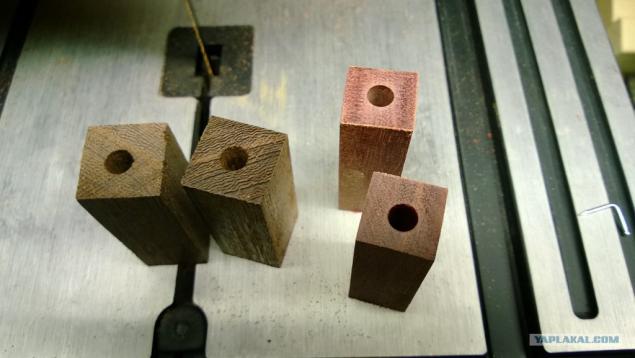

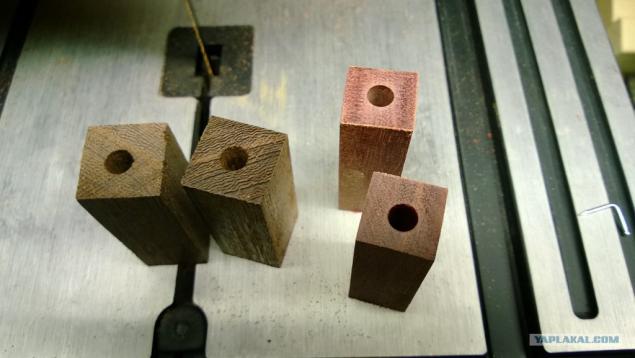

Drill a hole in the workpiece. Along.

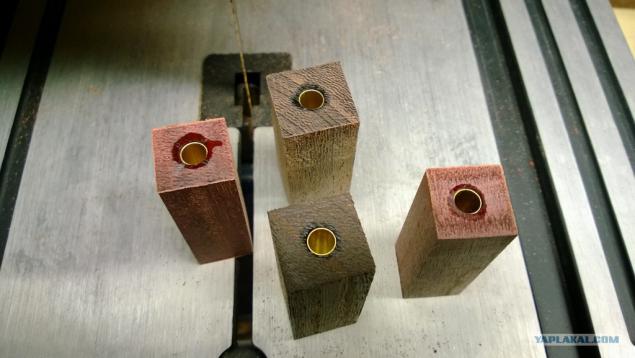

All 4 blanks are drilled.

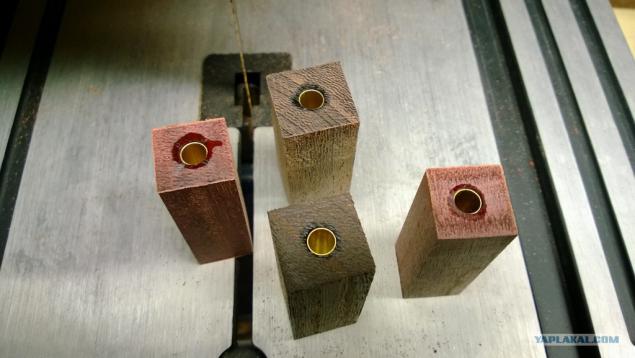

Now take a super glue and glue in the brass tube from the kit into pieces.

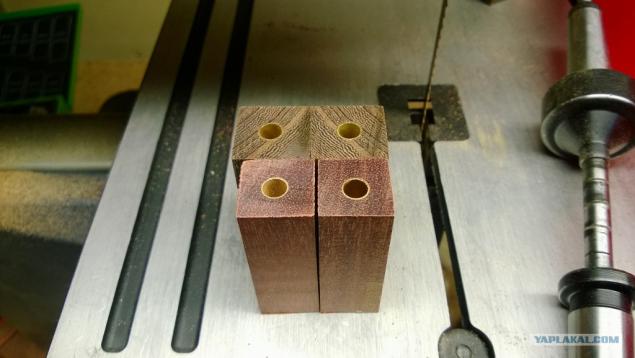

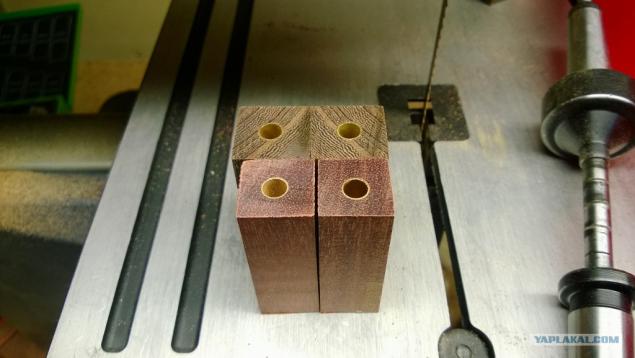

Next you need to sandpaper to grind off the ends so that they are flush with the tubes (saw off workpiece with a margin).

All are equal as the selection, with their uncle Chernomor:

Give the glue dry - drink tea. Go back and take the mandrel:

We put on the workpiece and the machine set. Uuuups. But the machine is not yet finished dish.

Remove the plate, remove the chips. Clean - the guarantee of health!

Finally, put the mandrel with blanks to the machine.

With a semicircular chisel grind coarsely

Wenge turned horrible tree for processing. Instead, the chip is removed virtually dust. Put a fan in order not to put light.

Billets acquired the form of cylinders

Now, with a small chisel (also semi-circular) attach to a shape close to the final.

Flat chisel attach final form.

Due to the fact that the chisel cut (you need very badly sharpened), the surface turns smooth as a baby ass and skins do not need.

The bottom line is that you need the edges to fit into one layer with metal rings. Then get a good grip. Why - it will become clear later. The hard work ... but it's better poshkurit. Smear wax grinding.

SKINS just 600 grain

The wax prevents dust to fly up in the air you can breathe easy. Cut the paper towel into many small pieces:

Time of rubber gloves! Why is that? Because that will cover all the same super glue!

How it's done? Turns the machine on the lowest speed, take a piece of towel, drip a few drops of super glue, quickly spend along the tree leaving a shiny trail, quickly throwing a towel until it is stuck to the glove. For everything - 5 seconds Fotorafirovat it once. But the gloves - a necessary thing, once still stuck:

Inflicting a few layers of super glue, grind to put the final layer. Now again take the wax and rub the handle

Polishing wax and all the same paper towel

Result

Remove from the machine. Super glue - elegant cover!

Now put the tree in the bloody machine

Specially made first on the left edge of the workpiece: after chisel gives a very smooth surface!

Gives form. This pen female - so make it thinner

The grooves on the edges - to burn. Take the steel wire

Turn the machine on the highest speed and the force of friction burn out, obtyagivaya wire around the preform. Due to the groove wire will not move out.

Result burning

Again wax polishing. His I cooked myself. For this we need to take equal parts of beeswax and mineral oil (such as Johnson's Baby) and cook them in a water bath. The oil penetrates into the wood, it adds shine and wax helps with sanding. The product I have put in a tube - very convenient!

Grind. No, I did not cut myself, it's the bloody dust of wood with a wax

Covering super glue ...

Whoops! While putting the layer on the workpiece and stayed stuck a towel to the handle. Again the skins ...

What a bloody rich color!

And here is the cemetery of gloves and pieces of towels. What to do? Beauty requires sacrifice!

That's what eventually happened ...

Now we collect! Take a clamp

And sawing for her tips here are from oak.

It's all in order not to buy a special press assembly handles. I do not have much money to spare ...

First pressed into the tip. Put the items in the "Press» ...

And compress clamp

Here you can see why it is important to grind off the workpiece flush with the metal rings. Then the diameter of the tree to be equal to the diameter of the tip and the handle will appear as one. Pressed into the mechanism (not yapovsky) ...

Check the position of the mechanism. The rod must be fully retracted in one position, and pushed into one another.

Pressed into the clip on the other end:

Dress up between the ring halves ...

Aligns the grain pattern of the tree and collect pen:

Completely analogously to collect second hand. Here they are together on the table:

Source:

It all started with the fact that this fall I bought a lathe. Actually, I had planned to carve it legs for the table to the living room, but stumbled on kits for pens and decided to buy a try. Very pleased! Here is the set.

Will be 53 photos.

Now we take a couple of sticks of wood and zapilivaem! I took Wenge (Wenge) for him and Bloodwood (Blood Tree) for her.

Drill a hole in the workpiece. Along.

All 4 blanks are drilled.

Now take a super glue and glue in the brass tube from the kit into pieces.

Next you need to sandpaper to grind off the ends so that they are flush with the tubes (saw off workpiece with a margin).

All are equal as the selection, with their uncle Chernomor:

Give the glue dry - drink tea. Go back and take the mandrel:

We put on the workpiece and the machine set. Uuuups. But the machine is not yet finished dish.

Remove the plate, remove the chips. Clean - the guarantee of health!

Finally, put the mandrel with blanks to the machine.

With a semicircular chisel grind coarsely

Wenge turned horrible tree for processing. Instead, the chip is removed virtually dust. Put a fan in order not to put light.

Billets acquired the form of cylinders

Now, with a small chisel (also semi-circular) attach to a shape close to the final.

Flat chisel attach final form.

Due to the fact that the chisel cut (you need very badly sharpened), the surface turns smooth as a baby ass and skins do not need.

The bottom line is that you need the edges to fit into one layer with metal rings. Then get a good grip. Why - it will become clear later. The hard work ... but it's better poshkurit. Smear wax grinding.

SKINS just 600 grain

The wax prevents dust to fly up in the air you can breathe easy. Cut the paper towel into many small pieces:

Time of rubber gloves! Why is that? Because that will cover all the same super glue!

How it's done? Turns the machine on the lowest speed, take a piece of towel, drip a few drops of super glue, quickly spend along the tree leaving a shiny trail, quickly throwing a towel until it is stuck to the glove. For everything - 5 seconds Fotorafirovat it once. But the gloves - a necessary thing, once still stuck:

Inflicting a few layers of super glue, grind to put the final layer. Now again take the wax and rub the handle

Polishing wax and all the same paper towel

Result

Remove from the machine. Super glue - elegant cover!

Now put the tree in the bloody machine

Specially made first on the left edge of the workpiece: after chisel gives a very smooth surface!

Gives form. This pen female - so make it thinner

The grooves on the edges - to burn. Take the steel wire

Turn the machine on the highest speed and the force of friction burn out, obtyagivaya wire around the preform. Due to the groove wire will not move out.

Result burning

Again wax polishing. His I cooked myself. For this we need to take equal parts of beeswax and mineral oil (such as Johnson's Baby) and cook them in a water bath. The oil penetrates into the wood, it adds shine and wax helps with sanding. The product I have put in a tube - very convenient!

Grind. No, I did not cut myself, it's the bloody dust of wood with a wax

Covering super glue ...

Whoops! While putting the layer on the workpiece and stayed stuck a towel to the handle. Again the skins ...

What a bloody rich color!

And here is the cemetery of gloves and pieces of towels. What to do? Beauty requires sacrifice!

That's what eventually happened ...

Now we collect! Take a clamp

And sawing for her tips here are from oak.

It's all in order not to buy a special press assembly handles. I do not have much money to spare ...

First pressed into the tip. Put the items in the "Press» ...

And compress clamp

Here you can see why it is important to grind off the workpiece flush with the metal rings. Then the diameter of the tree to be equal to the diameter of the tip and the handle will appear as one. Pressed into the mechanism (not yapovsky) ...

Check the position of the mechanism. The rod must be fully retracted in one position, and pushed into one another.

Pressed into the clip on the other end:

Dress up between the ring halves ...

Aligns the grain pattern of the tree and collect pen:

Completely analogously to collect second hand. Here they are together on the table:

Source: