1390

Lytkarino Optical Glass Factory.

I went on a trip in Lytkarino Optical Glass Factory (LZOS).

I visited two years ago is true, but the photos are quite topical.

60 photos.

The factory is engaged in manufacturing of various optical glass and instruments out of it.

2. At the entrance we were met by two buses ...

3. And as usual Ilyich.

4. We leave the shop where brew glass.

The plant can brew about 300 grades of optical glass, of which 150 are cooked consistently and constantly in demand.

5. One of the furnaces.

6. From the oven pull out a vat of molten glass

7.

8. Read the "scum." Just like with the broth.

9.

10.

11.

12.

13. Glass comes to the warehouse, where it will be cool. Cool down can be very, very long time. Until a few weeks.

14. The men cut the finished glass is a simple metal sheet with handles.

15.

16. Once vat of glass put into place, it is covered "cap»

17. Self storage products.

18. Sometimes during the cooling that something can go wrong, and that's what happens.

19. Adowa roaster, which is brewed in another portion of the glass. A workshop by the way is not hot, degrees 25.

20.

21. The plant has its own power. Where with the help of gas-piston units produce electricity and heat for their own use. It turns out half the price than to take the city.

22.

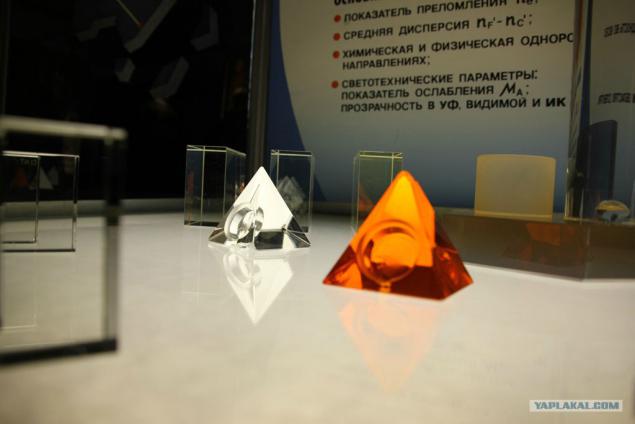

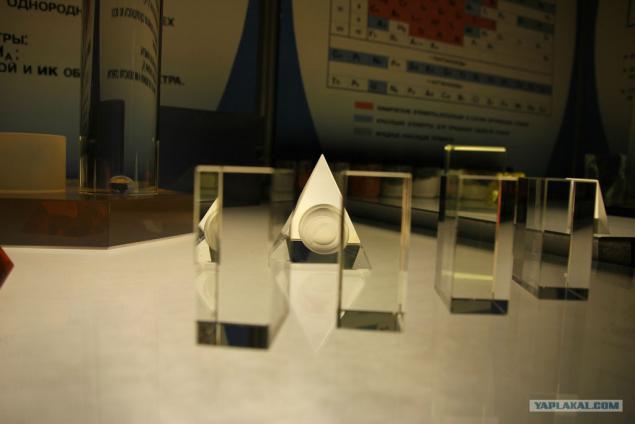

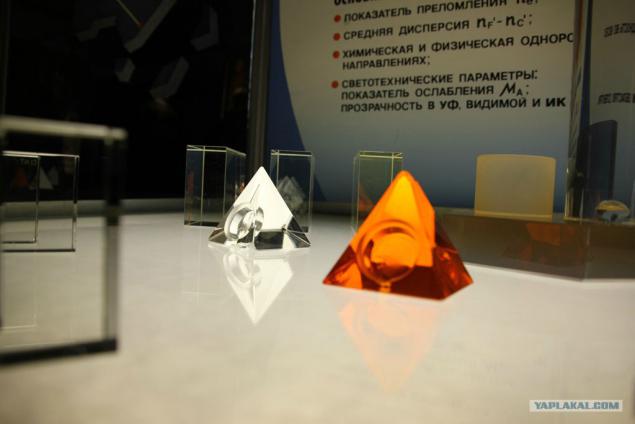

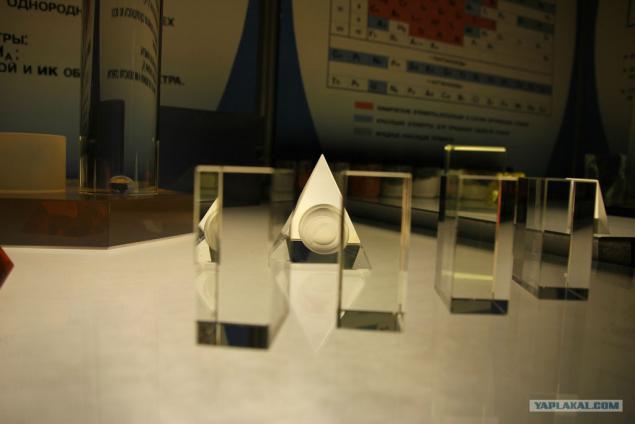

23. Next we went to the museum, which features products which is not a secret.

24.

25.

26.

27. In addition, the plant makes as night vision devices.

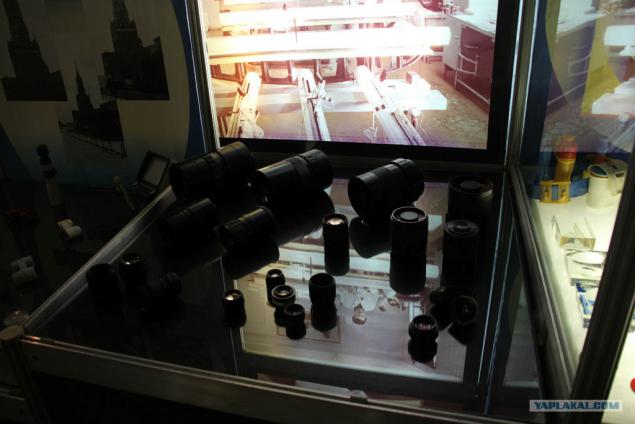

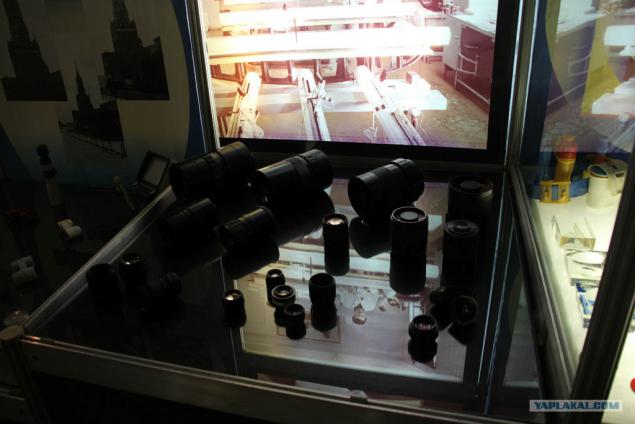

28. As well as lenses and lenses for spacecraft.

29. A more fiber optic systems.

30. Optical systems for the Army. Mounted on various armored vehicles.

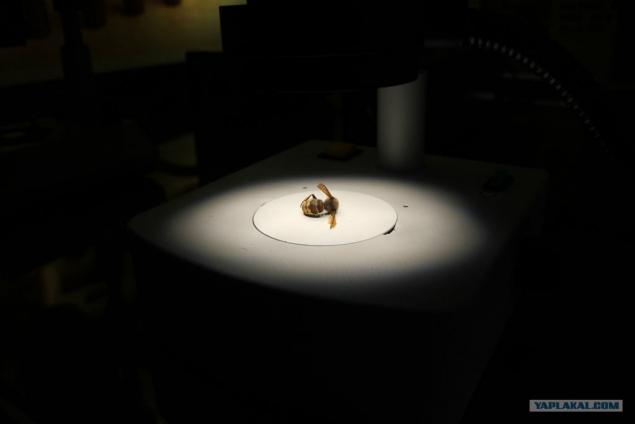

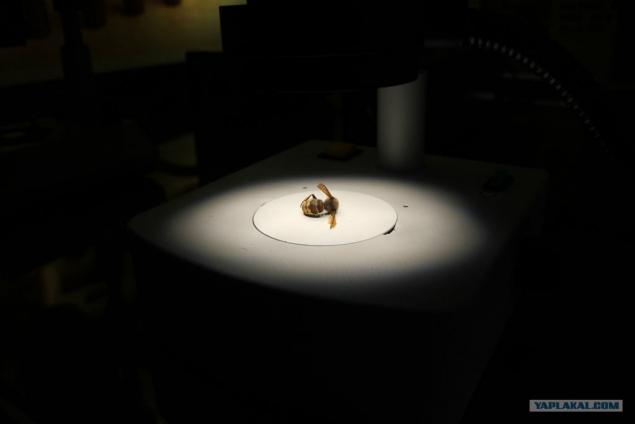

31. As well as the optics for microscopes. Through a microscope in a museum all we considered this pchёlku. They say there is a very long time.

32.

33

34. Various telescopes, binoculars, scopes.

35. Vision photography.

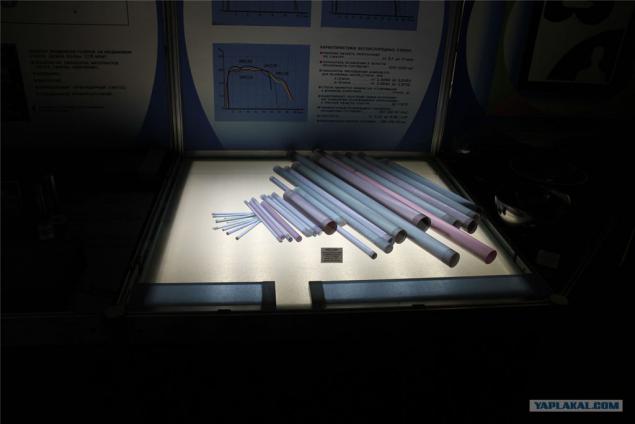

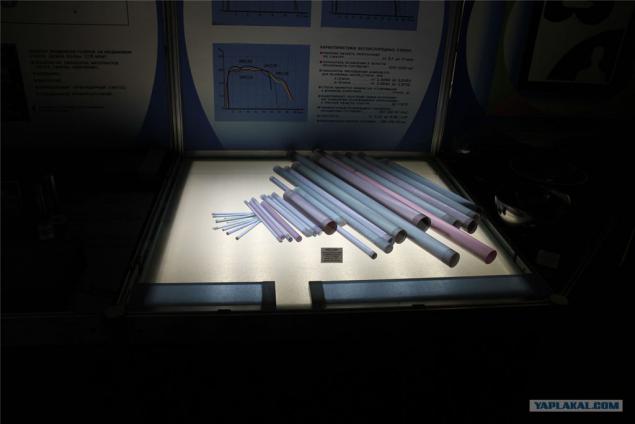

36. I do not know how to say, but these cylinders are used in different laser systems. Actually they are converted to light in the laser beam.

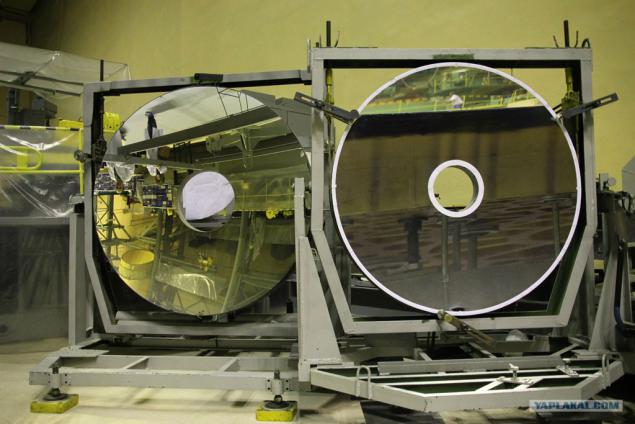

37. After the museum, we go to the most interesting shop. Shop optical systems.

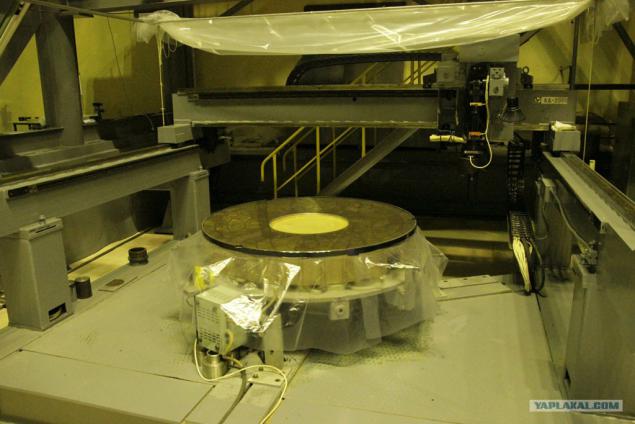

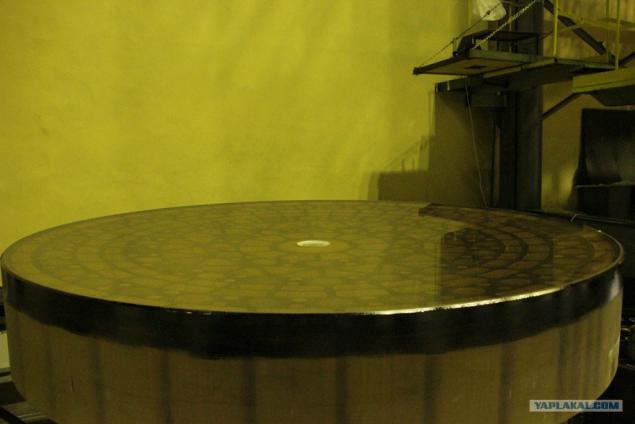

This workshop engaged in the production of optical space-related. Whether it's a mirror for ground or space telescopes, or lens optics for military satellites - all somehow done here, and then tested. The shop has a range of purity. During the visit there was treated with 6 meter ground-based telescope mirror. Then came the end of the second 4-month treatment phase of the mirror (the first was the removal 7 (sort of) millimeters of material from the surface of the mirror). So outsiders, even in overalls and shoe covers, but is allowed. By the way, I was among the last strangers who saw it in the mirror treatment. When the third stage, finishing mirror shop was closed, remove dust, and the entrance there was open only for professionals in special costumes.

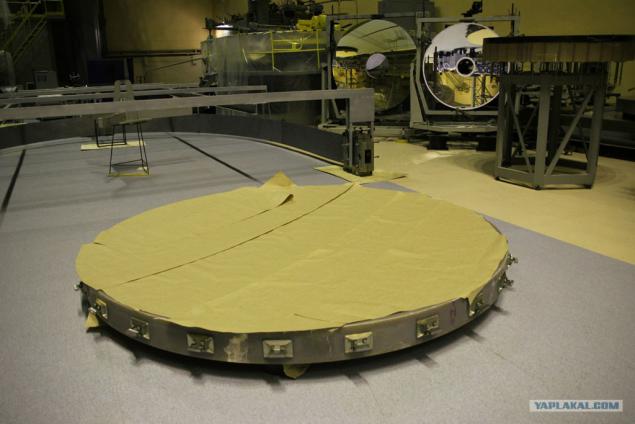

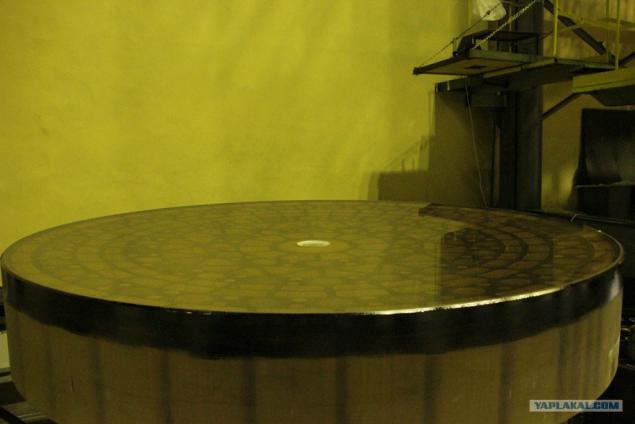

38. The mirror telescope is almost ready.

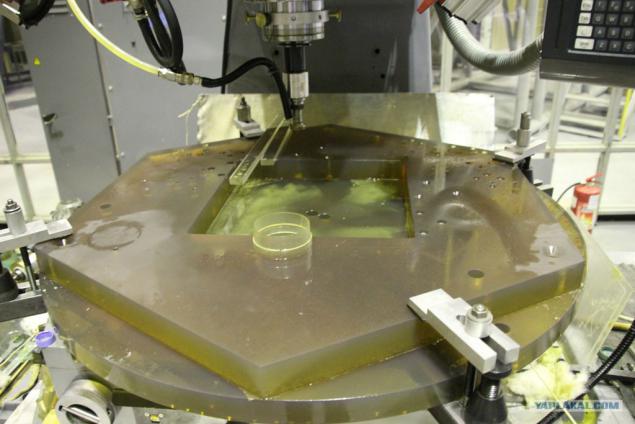

39. Mirror on treatment.

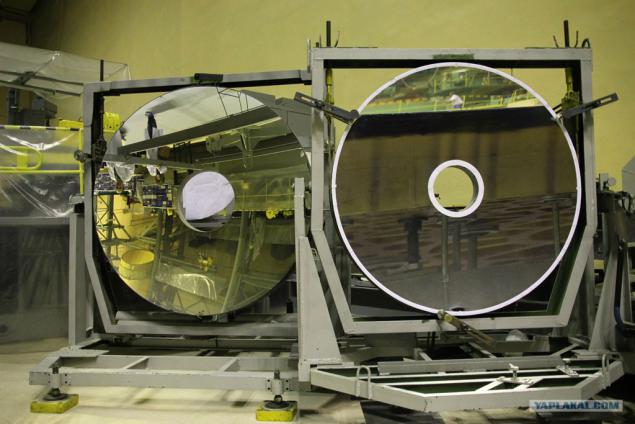

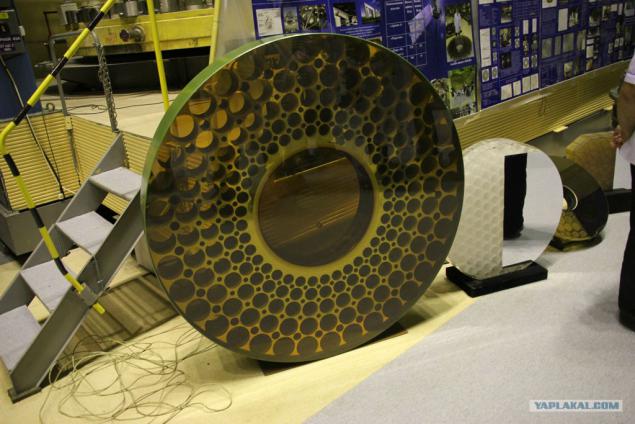

40. Optics for space telescopes.

41. Optics for space telescopes.

42. Optics for space telescopes.

43. Another mirror.

44.

45. By the way at the plant was done for the mirror and the famous space telescope Hubble

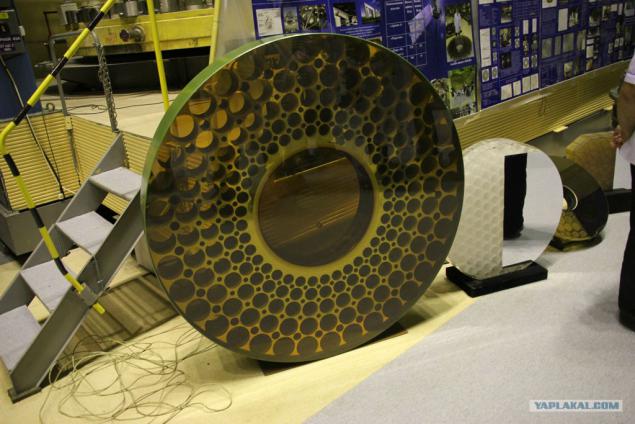

46. The hexagonal part for a huge ground-based telescope mirror.

Europeans staged a competition for the construction of a huge mirror telescope. We participated in the competition in addition to two more Lytkarintsev plant foreignness. Since the whole mirror can only do a certain limited size, it was decided to do just such a mirror of hexagons. Lytkarino able to more accurately handle these hexagons all.

47.

48. Little people.

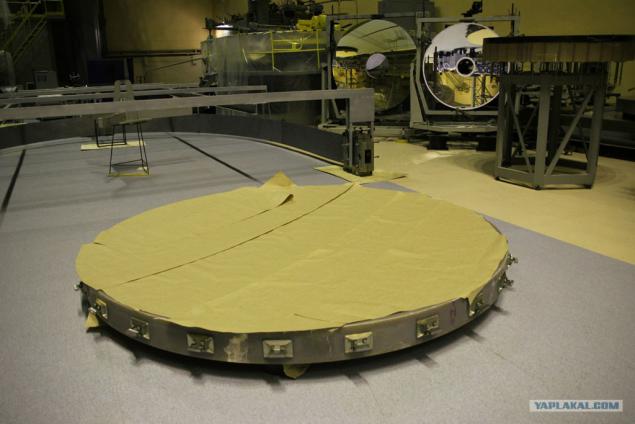

49. In addition to mirrors in the shop and had a lot of pieces of different sizes. I do not remember the exact name, but the essence of this device is that if the mirror is sent into space, it is there anyway to change its shape, with respect to that which was on the ground, and its characteristics change. In general, it would not have happened and there is this mechanism. On it she is put a mirror, and he gives it form, which will be under the conditions of use.

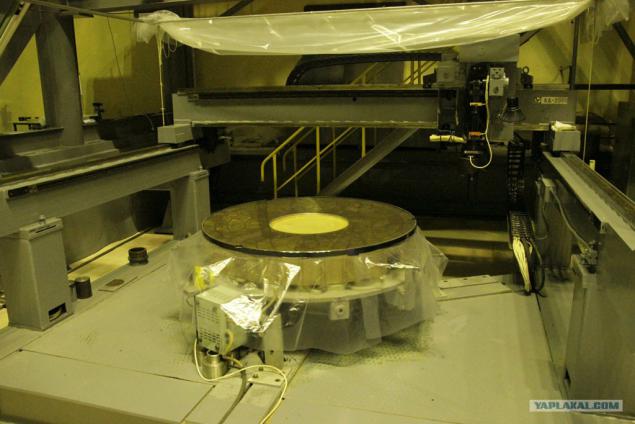

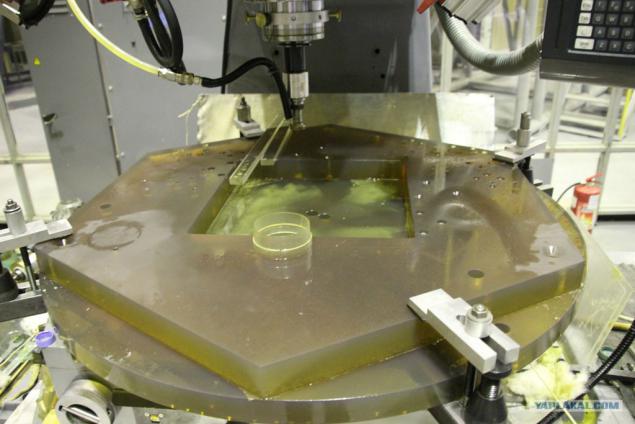

50. Table processing a huge six-meter mirror.

I visited two years ago is true, but the photos are quite topical.

60 photos.

The factory is engaged in manufacturing of various optical glass and instruments out of it.

2. At the entrance we were met by two buses ...

3. And as usual Ilyich.

4. We leave the shop where brew glass.

The plant can brew about 300 grades of optical glass, of which 150 are cooked consistently and constantly in demand.

5. One of the furnaces.

6. From the oven pull out a vat of molten glass

7.

8. Read the "scum." Just like with the broth.

9.

10.

11.

12.

13. Glass comes to the warehouse, where it will be cool. Cool down can be very, very long time. Until a few weeks.

14. The men cut the finished glass is a simple metal sheet with handles.

15.

16. Once vat of glass put into place, it is covered "cap»

17. Self storage products.

18. Sometimes during the cooling that something can go wrong, and that's what happens.

19. Adowa roaster, which is brewed in another portion of the glass. A workshop by the way is not hot, degrees 25.

20.

21. The plant has its own power. Where with the help of gas-piston units produce electricity and heat for their own use. It turns out half the price than to take the city.

22.

23. Next we went to the museum, which features products which is not a secret.

24.

25.

26.

27. In addition, the plant makes as night vision devices.

28. As well as lenses and lenses for spacecraft.

29. A more fiber optic systems.

30. Optical systems for the Army. Mounted on various armored vehicles.

31. As well as the optics for microscopes. Through a microscope in a museum all we considered this pchёlku. They say there is a very long time.

32.

33

34. Various telescopes, binoculars, scopes.

35. Vision photography.

36. I do not know how to say, but these cylinders are used in different laser systems. Actually they are converted to light in the laser beam.

37. After the museum, we go to the most interesting shop. Shop optical systems.

This workshop engaged in the production of optical space-related. Whether it's a mirror for ground or space telescopes, or lens optics for military satellites - all somehow done here, and then tested. The shop has a range of purity. During the visit there was treated with 6 meter ground-based telescope mirror. Then came the end of the second 4-month treatment phase of the mirror (the first was the removal 7 (sort of) millimeters of material from the surface of the mirror). So outsiders, even in overalls and shoe covers, but is allowed. By the way, I was among the last strangers who saw it in the mirror treatment. When the third stage, finishing mirror shop was closed, remove dust, and the entrance there was open only for professionals in special costumes.

38. The mirror telescope is almost ready.

39. Mirror on treatment.

40. Optics for space telescopes.

41. Optics for space telescopes.

42. Optics for space telescopes.

43. Another mirror.

44.

45. By the way at the plant was done for the mirror and the famous space telescope Hubble

46. The hexagonal part for a huge ground-based telescope mirror.

Europeans staged a competition for the construction of a huge mirror telescope. We participated in the competition in addition to two more Lytkarintsev plant foreignness. Since the whole mirror can only do a certain limited size, it was decided to do just such a mirror of hexagons. Lytkarino able to more accurately handle these hexagons all.

47.

48. Little people.

49. In addition to mirrors in the shop and had a lot of pieces of different sizes. I do not remember the exact name, but the essence of this device is that if the mirror is sent into space, it is there anyway to change its shape, with respect to that which was on the ground, and its characteristics change. In general, it would not have happened and there is this mechanism. On it she is put a mirror, and he gives it form, which will be under the conditions of use.

50. Table processing a huge six-meter mirror.