1152

Looking at the sky

The fact that the Soviet Union was the first in space exploration, and today many people know. But it is much less known that we were among the first in other areas, as well space-related - astronomy. After all, for many years the world's largest telescope BTA (Big Telescope Azimuthal) belonged to the name of our country, and designed and built it was completely using domestic technology, demonstrating the leadership of the country in the field of optical instruments. What is the history of the creation of this unique research facility?

Resolution of the Council of Ministers on the establishment of reflecting telescope with a mirror diameter of 6 meters was taken March 25, 1960. Maintain a set of works on creation of the telescope was charged Leningrad Optical and Mechanical Association (LOMO) Lytkarino Optical Glass Factory, State Optical Institute, Vavilov, Gorky Machine Building Plant, and several other businesses. Chief designer of the telescope became Doctor of Technical Sciences Bagarat K. Ioannisiani. Draft tower telescope was designed in the Leningrad branch GIPRONII USSR Academy of Sciences.

10 ph via grey-croco

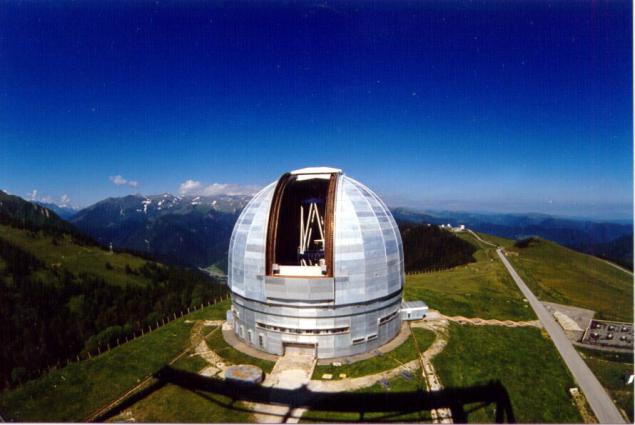

Originally produced siting of the telescope. After analyzing all the data area for the telescope BTA became a place at an altitude of 2100 meters near mountain Pastukhova, near the village Zelenchukskaya, which is located in Karachay-Cherkessia.

According to the project type was chosen azimuth telescope mount. Full outer diameter of the mirror was 6.05 meters with a thickness of 65 cm, uniform throughout the area.

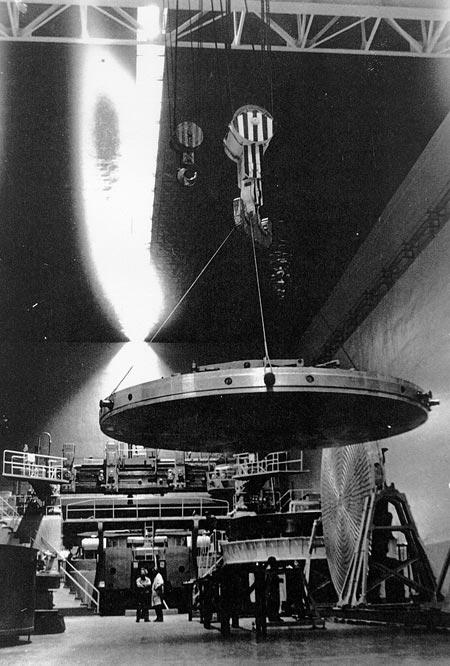

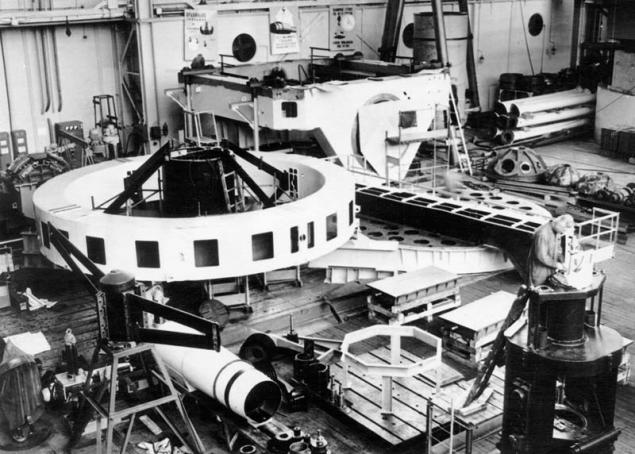

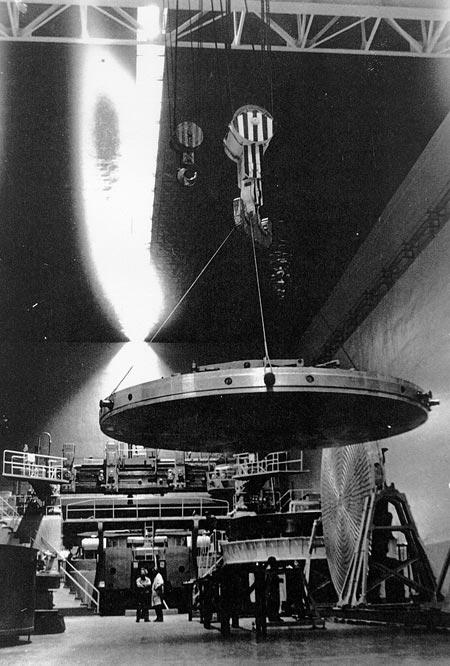

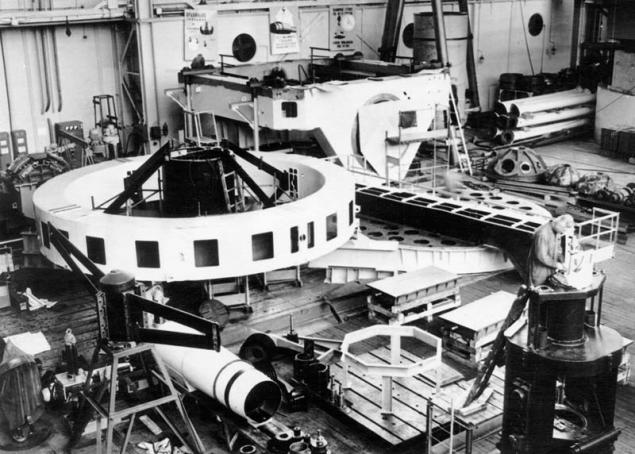

Assembling the design of the telescope performed indoors LOMO. Especially for this housing was built over 50 meters in height. Inside the case were established cranes with lifting capacity of 150 tons and 30. Before assembly, was made a special foundation. Assembly itself began in January 1966 and lasted more than two years, until September 1967.

Many of the nodes of the telescope are unique for their time, such as the main telescope spectrograph having a diameter of 2 meters, guiding system, which includes the telescope guide and comprehensive photo and television system, as well as specialized computers for controlling the operation of the system.

Remote control of BTA.

Assembly and factory testing of the telescope design was successfully completed May 7, 1968. To compensate for the absence of the primary mirror was installed concrete simulator.

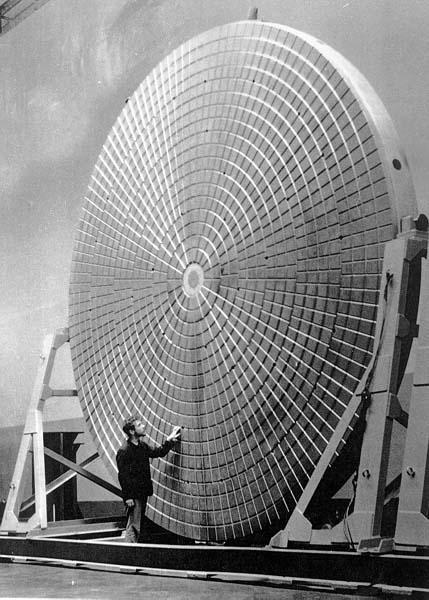

Even more important step was the construction of the telescope primary mirror cast. After all, this is the part which determines the optical quality of the telescope. Besides overcoming the obvious difficulties in creating a large mirror glass preform, before designers also had the task of the need to ensure high stability of the shape of the reflective surface of the mirror, as in the process of treatment and in a very difficult operating conditions at the observatory.

The main executor of the casting and processing mirrors became Lytkarino Optical Glass Factory, which was approved by the Government Resolution of 25 March 1960.

The task was difficult. Had cast a blank glass weighing 70 tons, to anneal it and pronounce the complex processing of all surfaces with 60 seats in the manufacture of blind holes on the back side of the center hole and others.

To perform this task at the plant was set up pilot production plant. The task of the workshop included the installation and debugging of equipment, improvement of industrial process technology and manufacturing billet mirrors.

Furnace for casting mirror was made in December, the 196Z organization "Teplomontazh", Moscow. The project was carried out of the furnace of the Leningrad organization "Giprosteklo».

Within three years, has been designed and built a special enclosure for preform manufacturing BTA. The main equipment of the shop was a unique structure, in some cases, not having any analogues.

November 20, 1964 was cast billet main mirror.

Billet mirrors BTA annealed for two years. The annealing process is ended December 5, 1966.

After finishing polishing and measurement products refraction workers GOI was concluded, the residual stresses in the workpiece is small, indicating a good executive mode of annealing and annealing furnaces.

The next step was the treatment of the workpiece in order to obtain a predetermined shape. The task was not easy, given the fact that by the time the accumulated experience handling large optical blanks was insignificant.

For workpiece mirror BTA decision was made on the application of the diamond tool.

The result produced by specialists LZOS research to develop optimum treatment conditions was developed and implemented technology for manufacturing industrial harvesting of the main mirror.

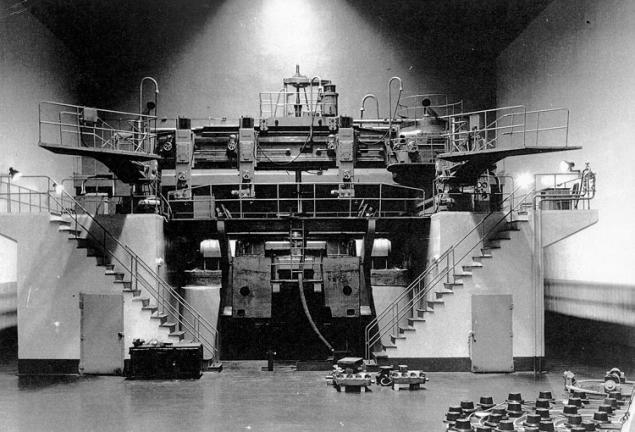

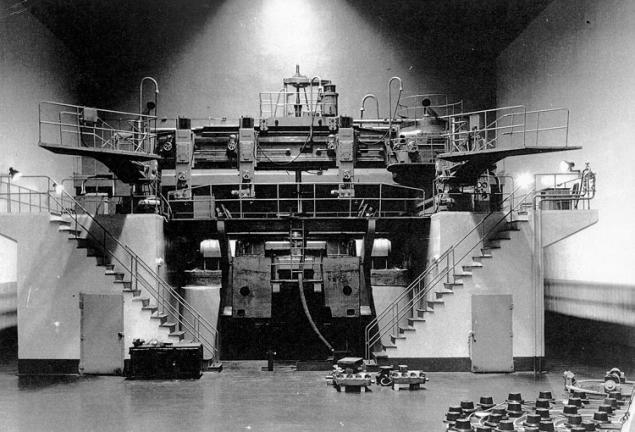

To handle mirror Kolomna Heavy Machine Tool Plant in 1963 created a special boring machine CG-158.

Machine CG-158.

For a given workpiece geometrical shape was designed and built complex of diamond tools.

Machining was carried out for nearly eighteen months. For stock removal weighing 28 tons was consumed 7,000 carats.

Acceptance of the workpiece for further precision machining front side was made September 4, 1968.

This treatment was carried out by experts in special LOMO thermostated enclosure on a unique grinder manufactured Kolomna Heavy Machine Tool Plant. The preform was installed in the processing mount.

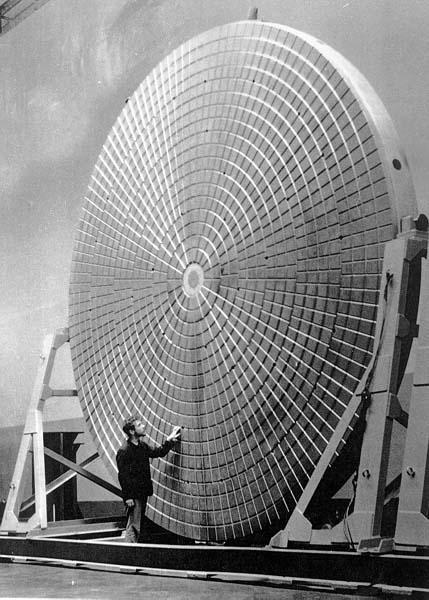

A tool for grinding.

The grinding process was completed in January 1969. The following operations become polished mirror surface. It was completed in July 1971. In the next two months, the surface quality was checked using several different methods.

And after all the parts of the telescope were ready, the next step was transported to an assembly plant.

Processing.

Although the design of the telescope has been delivered to the place before. Loading of the first batch of large parts began June 3, 1968. The very same transport took just over a year. General Duties of the carrier components of the telescope units, were assigned to Glavmosavtotransa.

Departure from the territory of LOMO.

Transportation mirror began June 30, 1974. After manufacturing the mirror was inhibited special protective film and mounted on a support in a special depreciation transport container with a high degree of thermal insulation. Inside the container installed accelerometers and temperature. Having in mind the exceptional value of mirror and considering that in case of its damage doubler can be made not earlier than 3 - 4 years of having a second workpiece were taken extraordinary precautions when transporting the mirror. In particular, the test flight was conducted with the simulator from May 12 to June 5, 1974.

Path valuable cargo began in Lytkarino. In southern Moscow river port with a special berth trailers were installed on a barge, secured and using a powerful tug set off, accompanied by a special team at a separate vessel through the channel Moscow - Volga, Volga Canal and Volga - Don to Rostov-on-Don.

In Rostov-on-Don trailers through a special berth went to the bank and continued to move, accompanied by cars and motorcycle traffic police on the roads of the North Caucasus to the observatory. August 21 cargo was safely delivered. The Board reviewed its safety, the container was closed and re-installed in a special warehouse. During the entire period of storage temperature of the mirror inside the container carefully monitored.

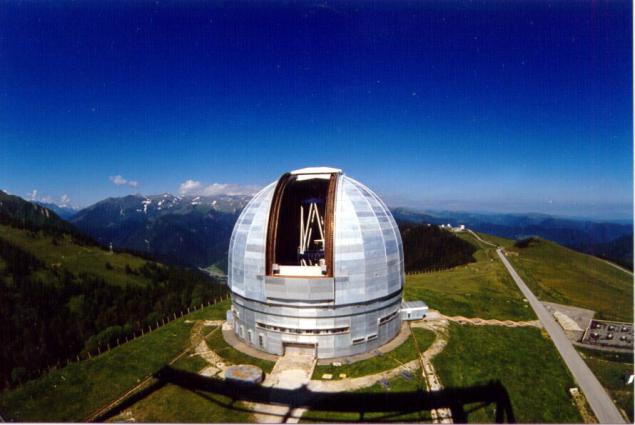

Construction of the observatory.

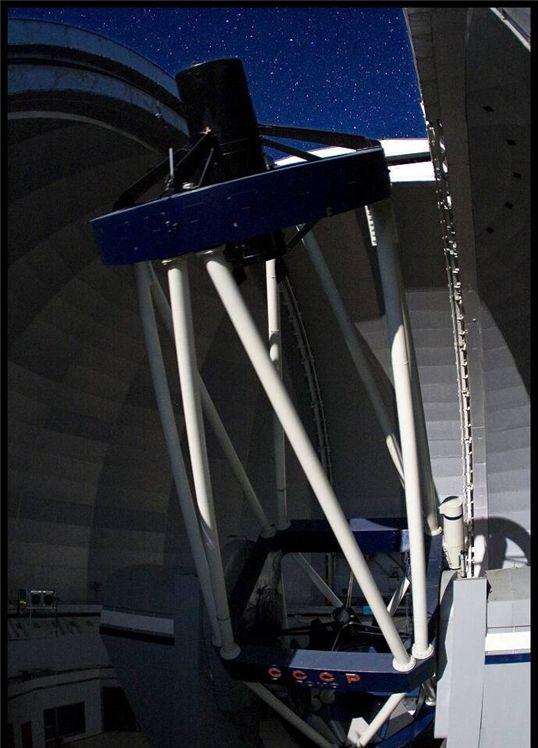

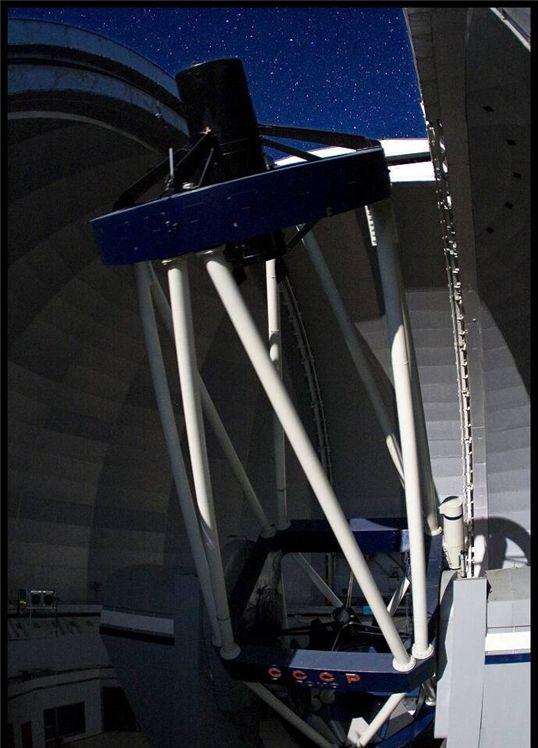

Construction of the Special Astrophysical Observatory began in 1967 on the project, the main architect and author of the draft DH Yenikeyeva on a plateau near the mountain Pastukhova. Tower Telescope had a height of 53 meters with a diameter of 45 meters. Major construction work was completed in 1971, and then began assembling the structure of the telescope. It was adopted by the State Commission commissioned 25 January 1972.

Construction of the tower.

The project envisaged the construction of the observatory not only building the observatory itself, but of power, water and power supply, houses for scientists mountain road length of 16 km, designed to transport bulky cargo, and a number of other objects.

The total area occupied by the scientific area of 50 hectares. On a platform located Tower BTA technical unit.

At kilometer away from research facilities were built hotel astronomer, house maintenance staff and other outbuildings.

Since aluminum reflective coating mirror optics telescopes require periodic updates, Gorky Machine Building Plant was designed and manufactured specifically unique vacuum system Voisin-6. Work began in March 1963, in 1968 it was completed fabrication and in 1970 launched its installation at the observatory. After installation and testing of the entire complex of equipment were identified and considered proposals for improving the individual elements of the installation.

It should be noted that the vacuum system for applying such diameter aluminum was formed first in the world.

Debugging of all major systems of the telescope was completed in mid-1974. All drives were tested telescope control systems, guidance and tracking, the basic accuracy of the mechanisms and systems. Work was carried out in collaboration with scientists from the Special Astrophysical Observatory.

August 21, 1974 the observatory was delivered to the primary mirror and its frame. In late September 1974 the mirror was unpacked, reopen, cleaned and placed in a frame.

During October, the default installation of unloading mechanisms, checking their work, and finally, the final assembly of the telescope tube.

The assembly process of BTA.

As a result of tests and examination of the results of monitoring of individual elements and systems of the telescope was transferred into test operation November 3, 1974.

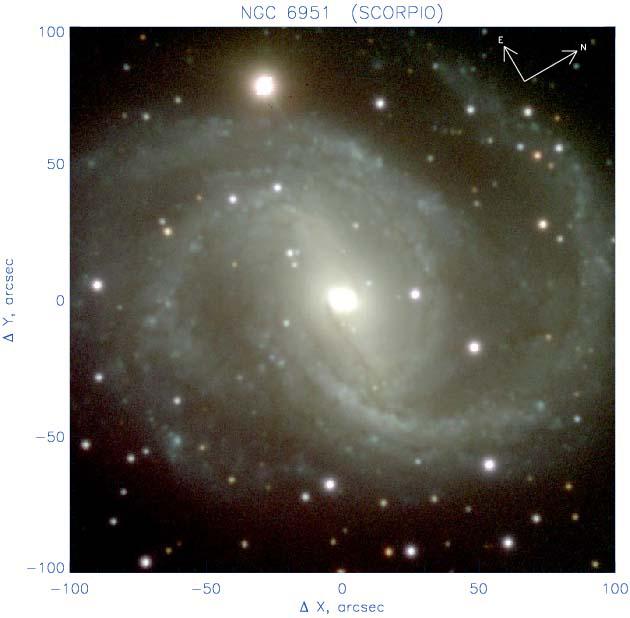

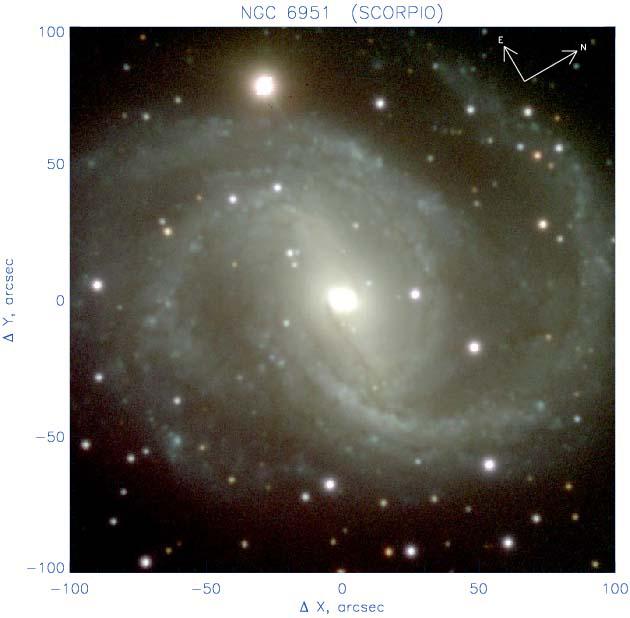

Trial operation of the telescope was carried out in the period from December 1974 until the spring of 1975. Studies have been made of the complex telescope during specific astronomical observations, training of operating personnel work independently on all complex systems and devices of the complex, as well as developing proposals for further improvement of the individual elements of the telescope.

Some characteristics of the BTA telescope.

Light diameter of the main mirror - 6000 mm.

The focal length of the primary focus without the corrector - 24000 mm.

The focal length of a lens with a fixed focal extension system - 349 400 mm.

The accuracy of the vertical axis of rotation of the telescope - about 2 ".

The accuracy of the automatic installation on specified coordinates - ± 10 ".

Accuracy of reference for the object of the telescope - 0, 2 diameter of the star image.

Mass of the primary mirror - 42 tons.

The mass of a motion of the telescope parts - about 650 tons.

The total mass of the telescope - about 850 tons.

The height of the telescope tube in the vertical position - 42 m.

December 30, 1975 was approved by an act of the State Interdepartmental Commission for acceptance into operation of the Big azimuth telescope.

So nearly three and a half decades ago, our country has once again forced to talk about themselves with respect and surprise the scientific world. And it is still the largest in Eurasia telescope remains today a monument of the time and the event. However, current rulers, the kingdom on the ruins of the empire, prefer to surprise the world with giant skyscrapers on the site of the destroyed historical monuments, the world's largest yachts nouveaux riches or a monument in honor of the Great Famine. Well, what time - such he and monuments.

Source: http: //

Resolution of the Council of Ministers on the establishment of reflecting telescope with a mirror diameter of 6 meters was taken March 25, 1960. Maintain a set of works on creation of the telescope was charged Leningrad Optical and Mechanical Association (LOMO) Lytkarino Optical Glass Factory, State Optical Institute, Vavilov, Gorky Machine Building Plant, and several other businesses. Chief designer of the telescope became Doctor of Technical Sciences Bagarat K. Ioannisiani. Draft tower telescope was designed in the Leningrad branch GIPRONII USSR Academy of Sciences.

10 ph via grey-croco

Originally produced siting of the telescope. After analyzing all the data area for the telescope BTA became a place at an altitude of 2100 meters near mountain Pastukhova, near the village Zelenchukskaya, which is located in Karachay-Cherkessia.

According to the project type was chosen azimuth telescope mount. Full outer diameter of the mirror was 6.05 meters with a thickness of 65 cm, uniform throughout the area.

Assembling the design of the telescope performed indoors LOMO. Especially for this housing was built over 50 meters in height. Inside the case were established cranes with lifting capacity of 150 tons and 30. Before assembly, was made a special foundation. Assembly itself began in January 1966 and lasted more than two years, until September 1967.

Many of the nodes of the telescope are unique for their time, such as the main telescope spectrograph having a diameter of 2 meters, guiding system, which includes the telescope guide and comprehensive photo and television system, as well as specialized computers for controlling the operation of the system.

Remote control of BTA.

Assembly and factory testing of the telescope design was successfully completed May 7, 1968. To compensate for the absence of the primary mirror was installed concrete simulator.

Even more important step was the construction of the telescope primary mirror cast. After all, this is the part which determines the optical quality of the telescope. Besides overcoming the obvious difficulties in creating a large mirror glass preform, before designers also had the task of the need to ensure high stability of the shape of the reflective surface of the mirror, as in the process of treatment and in a very difficult operating conditions at the observatory.

The main executor of the casting and processing mirrors became Lytkarino Optical Glass Factory, which was approved by the Government Resolution of 25 March 1960.

The task was difficult. Had cast a blank glass weighing 70 tons, to anneal it and pronounce the complex processing of all surfaces with 60 seats in the manufacture of blind holes on the back side of the center hole and others.

To perform this task at the plant was set up pilot production plant. The task of the workshop included the installation and debugging of equipment, improvement of industrial process technology and manufacturing billet mirrors.

Furnace for casting mirror was made in December, the 196Z organization "Teplomontazh", Moscow. The project was carried out of the furnace of the Leningrad organization "Giprosteklo».

Within three years, has been designed and built a special enclosure for preform manufacturing BTA. The main equipment of the shop was a unique structure, in some cases, not having any analogues.

November 20, 1964 was cast billet main mirror.

Billet mirrors BTA annealed for two years. The annealing process is ended December 5, 1966.

After finishing polishing and measurement products refraction workers GOI was concluded, the residual stresses in the workpiece is small, indicating a good executive mode of annealing and annealing furnaces.

The next step was the treatment of the workpiece in order to obtain a predetermined shape. The task was not easy, given the fact that by the time the accumulated experience handling large optical blanks was insignificant.

For workpiece mirror BTA decision was made on the application of the diamond tool.

The result produced by specialists LZOS research to develop optimum treatment conditions was developed and implemented technology for manufacturing industrial harvesting of the main mirror.

To handle mirror Kolomna Heavy Machine Tool Plant in 1963 created a special boring machine CG-158.

Machine CG-158.

For a given workpiece geometrical shape was designed and built complex of diamond tools.

Machining was carried out for nearly eighteen months. For stock removal weighing 28 tons was consumed 7,000 carats.

Acceptance of the workpiece for further precision machining front side was made September 4, 1968.

This treatment was carried out by experts in special LOMO thermostated enclosure on a unique grinder manufactured Kolomna Heavy Machine Tool Plant. The preform was installed in the processing mount.

A tool for grinding.

The grinding process was completed in January 1969. The following operations become polished mirror surface. It was completed in July 1971. In the next two months, the surface quality was checked using several different methods.

And after all the parts of the telescope were ready, the next step was transported to an assembly plant.

Processing.

Although the design of the telescope has been delivered to the place before. Loading of the first batch of large parts began June 3, 1968. The very same transport took just over a year. General Duties of the carrier components of the telescope units, were assigned to Glavmosavtotransa.

Departure from the territory of LOMO.

Transportation mirror began June 30, 1974. After manufacturing the mirror was inhibited special protective film and mounted on a support in a special depreciation transport container with a high degree of thermal insulation. Inside the container installed accelerometers and temperature. Having in mind the exceptional value of mirror and considering that in case of its damage doubler can be made not earlier than 3 - 4 years of having a second workpiece were taken extraordinary precautions when transporting the mirror. In particular, the test flight was conducted with the simulator from May 12 to June 5, 1974.

Path valuable cargo began in Lytkarino. In southern Moscow river port with a special berth trailers were installed on a barge, secured and using a powerful tug set off, accompanied by a special team at a separate vessel through the channel Moscow - Volga, Volga Canal and Volga - Don to Rostov-on-Don.

In Rostov-on-Don trailers through a special berth went to the bank and continued to move, accompanied by cars and motorcycle traffic police on the roads of the North Caucasus to the observatory. August 21 cargo was safely delivered. The Board reviewed its safety, the container was closed and re-installed in a special warehouse. During the entire period of storage temperature of the mirror inside the container carefully monitored.

Construction of the observatory.

Construction of the Special Astrophysical Observatory began in 1967 on the project, the main architect and author of the draft DH Yenikeyeva on a plateau near the mountain Pastukhova. Tower Telescope had a height of 53 meters with a diameter of 45 meters. Major construction work was completed in 1971, and then began assembling the structure of the telescope. It was adopted by the State Commission commissioned 25 January 1972.

Construction of the tower.

The project envisaged the construction of the observatory not only building the observatory itself, but of power, water and power supply, houses for scientists mountain road length of 16 km, designed to transport bulky cargo, and a number of other objects.

The total area occupied by the scientific area of 50 hectares. On a platform located Tower BTA technical unit.

At kilometer away from research facilities were built hotel astronomer, house maintenance staff and other outbuildings.

Since aluminum reflective coating mirror optics telescopes require periodic updates, Gorky Machine Building Plant was designed and manufactured specifically unique vacuum system Voisin-6. Work began in March 1963, in 1968 it was completed fabrication and in 1970 launched its installation at the observatory. After installation and testing of the entire complex of equipment were identified and considered proposals for improving the individual elements of the installation.

It should be noted that the vacuum system for applying such diameter aluminum was formed first in the world.

Debugging of all major systems of the telescope was completed in mid-1974. All drives were tested telescope control systems, guidance and tracking, the basic accuracy of the mechanisms and systems. Work was carried out in collaboration with scientists from the Special Astrophysical Observatory.

August 21, 1974 the observatory was delivered to the primary mirror and its frame. In late September 1974 the mirror was unpacked, reopen, cleaned and placed in a frame.

During October, the default installation of unloading mechanisms, checking their work, and finally, the final assembly of the telescope tube.

The assembly process of BTA.

As a result of tests and examination of the results of monitoring of individual elements and systems of the telescope was transferred into test operation November 3, 1974.

Trial operation of the telescope was carried out in the period from December 1974 until the spring of 1975. Studies have been made of the complex telescope during specific astronomical observations, training of operating personnel work independently on all complex systems and devices of the complex, as well as developing proposals for further improvement of the individual elements of the telescope.

Some characteristics of the BTA telescope.

Light diameter of the main mirror - 6000 mm.

The focal length of the primary focus without the corrector - 24000 mm.

The focal length of a lens with a fixed focal extension system - 349 400 mm.

The accuracy of the vertical axis of rotation of the telescope - about 2 ".

The accuracy of the automatic installation on specified coordinates - ± 10 ".

Accuracy of reference for the object of the telescope - 0, 2 diameter of the star image.

Mass of the primary mirror - 42 tons.

The mass of a motion of the telescope parts - about 650 tons.

The total mass of the telescope - about 850 tons.

The height of the telescope tube in the vertical position - 42 m.

December 30, 1975 was approved by an act of the State Interdepartmental Commission for acceptance into operation of the Big azimuth telescope.

So nearly three and a half decades ago, our country has once again forced to talk about themselves with respect and surprise the scientific world. And it is still the largest in Eurasia telescope remains today a monument of the time and the event. However, current rulers, the kingdom on the ruins of the empire, prefer to surprise the world with giant skyscrapers on the site of the destroyed historical monuments, the world's largest yachts nouveaux riches or a monument in honor of the Great Famine. Well, what time - such he and monuments.

Source: http: //