933

Notes on the protective glass

Hello, Habr. We often write about the second display in our smartphones, of introduced them about the advantages and unique experience. But any modern high-end smartphones, especially having two displays, today is unthinkable without reliable safety glass. In this sense, a kind of standard was the use of the company's products Corning, producing safety glass under the name Gorilla Glass. And if his presence in a good smartphone, tablet or laptop today, no surprise, then, and in the first YotaPhone, and preparing for an early launch in the sale YotaPhone 2 uses a unique bent glass Gorilla Glass, manufactured by special order.

The popularity and prevalence of the broadest Gorilla Glass almost made the name of this brand a household name. As a "pen", "thermos", "Jeep" and many other . But if this honor is usually awarded those companies that first brings to market products under its own brand, the popularity of Gorilla Glass is associated with excellent barrier properties of glass.

Long-term research on Corning allowed to develop technology of manufacturing glass, highly resistant to scratches and bumps and is more flexible.

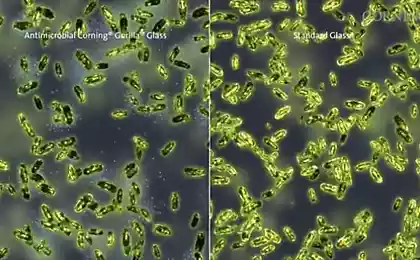

Process technology h4> The manufacturing process is as follows. The molten glass is poured into the trough mass, called "izotruba» (isopipe). Trough filled up until the molten mass begins to overflow evenly on both sides. Flowing around the chute, the two streams converge at its lowest point, where merge down, cooling down and forming a thin sheet of glass, with measurable in microns thick. At this stage it is not allowed no physical contact with the tools and equipment that are not formed on the surface defects.

After cooling, the glass sheets are cut from the slabs and subjected to chemical treatment. For this, they are placed in a bath filled with the molten salt at a temperature of 400 degrees Celsius. Starts flowing ion-exchange process, in which sodium ions in the surface layer of the glass are replaced by potassium ions. Because they are larger than the sodium ions, then the cooling of the surface layer is compressed, there arises compressive stress. Thanks to this glass acquires vysokotvёrduyu surface resistant to mechanical stress.

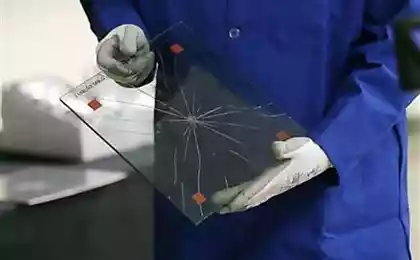

The curvature of the surface h4> YotaPhone was the first device that used a curved glass Gorilla Glass. In the first generation smartphone used glass Gorilla Glass 2 0 thick, 7mm, and in the second generation - Gorilla Glass 3. In this case, to protect the second display used specially manufactured for us Curved glass. Earlier we talked about the fact that the "standard" process technology Corning smelting involves only flat sheets of glass.

Bending glass preform is attached to the production company partner Biel Crystal. Corning from large sheets are prepared, followed by chemical etching to give anti-glare properties, the workpiece is cut, heated and give them the desired shape. At the end of the oleophobic coating is applied.

In turn, our production is applied to the sensor film. This is a fairly trivial task, given the curvature of the surface, but we managed to cope with the difficulties.

Thoughts about the future h4> For all its advantages Gorilla Glass, as well as any other safety glass, in one way or another reflects the surrounding area, especially light sources that can cause a nuisance when working with gadgets. This summer, published the results of experiments to create a glass with antireflection and superhydrophobic surface. Moreover, these studies were partially funded all the same company Corning.

The idea is the following: the glass surface of the mask is first applied to the polymer microparticles. Thereafter, the mixture was treated with hydrofluoric acid and sulfuric acid, which etches the surface through the holes formed after the deposition of the polymer mask. As a result, microscopic irregularities are formed from 1 to 100 microns in length and from tens to hundreds of nanometers high.

Further, the glass surface is deposited ultrathin (4-8 nm) layer of copper, which repeats microrelief formed as a result of etching. Further, the glass for 95 seconds, subjected to heating at a temperature of 750 degrees Celsius, whereby copper is collected in nanodroplets, randomly scattered on the glass surface asperities. The thicker a layer of copper was, the larger droplets are formed and the lower the number per unit area.

The glass is then subjected to реактивному ion etching , through which are formed on the surface of an average height nanoposts 50-200 nm and 100 nm in diameter. Thereafter, the metal layer is removed from the glass.

As a result of all these steps on a glass surface creates anti-reflection micro- and nano-relief.

The resulting glass has a much higher optical properties due to low reflectance. Also, it is possible to give a superhydrophobic property by applying a layer of silicon hydride fluoride.

In conjunction with the mechanical properties of Gorilla Glass woulda ideal glass for use in gadgets. But it is too early to speak about commercial use of the above process as required a lot of research. For example, while it is not clear how such a texture is resistant to mechanical stress as it is durable. Can she survive this?

How compatible is glass with a layer of touch touch screen? Do not worsen the heat exchange is texturing properties of glass? Remain many questions to answer which required a large amount of research and testing. In any case, the search for effective and reliable antireflection technology for protective glasses go in different directions.

Source: habrahabr.ru/company/yotadevices/blog/239883/

Another step in the direction of traffic safety from Volvo

Amazon opens in New York on the first physical store