Over the past four years, the market has changed dramatically. Greatly increased the quality of displays, increased duration of battery life. Against the background of the use of OEM-manufacturers are very similar platforms, the choice of materials for their devices become more and more important. Almost all the manufacturers have faced the need for drastic change of the materials used: while the market is becoming saturated, less and less buyers change their mobile devices. And producers have to invent various moves to stimulate demand. Often it comes down to a more careful selection of materials for use in exterior device.

However, such efforts often go to waste. Just a lot of people are of little concern to the material body, especially when used with a cover. For example, there is a perception that aluminum is heavier, less reliable affects the communication quality as compared to polycarbonate. Some refer to too much heat with heavy use. In this case, aluminum is more expensive, as claimed by some manufacturers. And if you use glass, it is obvious to everyone that the fall of this gadget will not survive. And then the question arises: why manufacturers still use different materials impractical?

It can not be answered unequivocally. In choosing the material necessary to take into account the many different requirements. And there is no single, best option. For most parts, the choice is limited to three materials: plastic, glass and metal.

Plastic h4>

Among the huge variety of plastics, polycarbonate is most commonly used when creating mobile devices. It is resistant to shock, relatively well keeps heat and incredibly flexible. Polycarbonate is almost not an obstacle for radio wave propagation. And because the price competition in the mobile market is enhanced polycarbonate lower cost compared to metal and glass will become more compelling advantage.

But this material has disadvantages. Polycarbonate has a low thermal conductivity, i.e. how it actually works thermal insulator. And this leads to a decrease in the clock frequency of the central and graphics processors to prevent them from overheating. In this case, metal housing (aluminum and magnesium) conduct heat well and act as a heat sink. A similar situation is observed when comparing the polycarbonate glass. For comparison, the thermal conductivity of aluminum is 205 W / m * K, magnesium - 156, a monolayer of glass - 0, 8, and polycarbonate - 0, 22. In other words, all other things being equal apparatus polycarbonate housings do have slower compared with counterparts in metal and glass enclosures.

But that's not all. I mentioned the high flexibility of polycarbonate. And it becomes a big disadvantage for smartphones, which are trying to make as thin as possible and more compact. Metal and glass provide a much greater mechanical stiffness in bending. After all, smartphones, even the back cover performs various functions: in particular, it is often mounted antenna to support all kinds of communications standards. Bent on the load cap can affect quite fragile antenna contacts, which are often very small. Up to a certain point they will survive, but then just contact broken. As an example, lead modification Tegra 3 smartphone HTC One X. It pursued defect: Wi often lose -Fi and Bluetooth due to the destruction of antenna contacts. To solve the problem the manufacturer had further strengthened the lid to keep it from curling external loads.

Metal h4>

Many lauded as supermaterial metal housings for mobile devices. However, people are often limited to appearance and tactile sensations. Of course, with respect to the subject we are talking about aluminum. Magnesium is also frequently used, but generally for the manufacture of the frame.

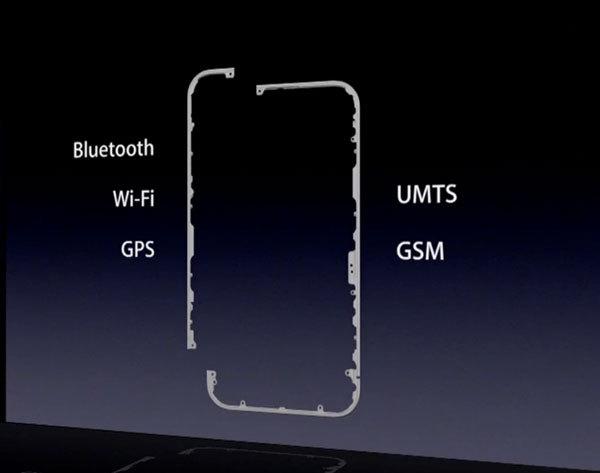

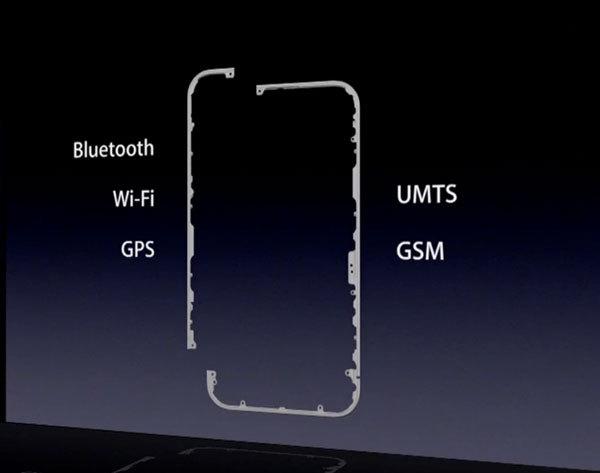

In aluminum alloys has its advantages. First of all, this is a high rigidity. With this gadget insides protected in the event of impact better than polycarbonate housing. However, with all-aluminum housing appropriate to do an external antenna to improve the signal characteristics.

Aluminum alloys are also better resist scratches than polycarbonate. But gadgets aluminum is rarely used without anodizing. It is of three types, and only one of them has a high resistance to damage. In other cases, anodized can not say the same and quickly covered with scratches. Also one of the major advantages of aluminum is its high thermal conductivity, which allows not to save on clock speeds.

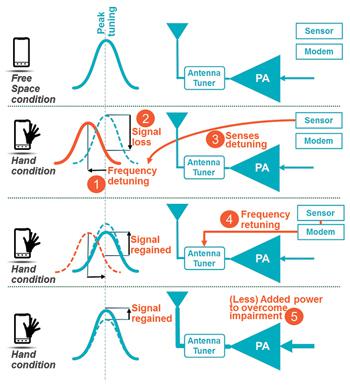

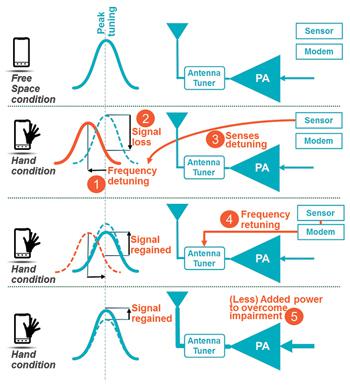

But as with any other material, aluminum is not ideal for the manufacture of mobile devices. Upon cancellation of the external antenna has to make plastic / glass radiotransparent "window". This means that the device will be less izotropichnym when receiving the signal. Even if part of the aluminum body to turn to an external antenna, human hand touches it will make noise. Also in this case it is much more difficult to provide compatibility with different frequencies.

If you use several different antennas and tuners for the sake of creating a fully metal body remains the disadvantage of a noticeable difference in the reception signal. And, this difference depends on the current frequency.

In addition to problems with the signal, aluminum has a lower resistance to plastic deformation. Although the insides are better protected, but the appearance quickly deteriorates due to the small vmyatinok. But polycarbonate with good chances survive the fall without damage. Aluminum is also much more expensive, but still requires more time and energy to process, resulting in a decent share of the price of the finished product. Finally, excellent thermal conductivity of aluminum is poured into the hot surface of the device is too high computational load. Also in the cold to keep polycarbonate shell in hand much nicer than aluminum.

Magnesium is lighter than aluminum due to the much lower density. In this case, magnesium less effect on the passage of the radio signal, having a number of advantages of aluminum compared with glass and polycarbonate: high thermal conductivity, relatively high hardness and somewhat better resistance to scratches. By all indications it appears that the aluminum magnesium better.

However, from the supply of magnesium body on the conveyor keeps us highly flammable magnesium in oxygen, because of what the cast has to be carried out in a vacuum chamber. Moreover, no surface treatment of magnesium corrodes rapidly, rendering it a better choice in making the body, although it is often used when creating the frame of the product.

Glass h4>

This is the hardest and tsarapinoustoychivy of all three materials under consideration. But also the most fragile, prone to fragmentation. Therefore, the glass moves only plastic deformation. Aluminosilicate glass, better known under the name Gorilla Glass, is used to make buildings more often. It is the thermal conductivity between the aluminum and polycarbonate. Glass distorts little radio that allows you to use an internal antenna. However, the main drawback - the fragility and insecurity for people in the event of failure. Besides glass imposes great restrictions on the shape of the body potential. Therefore, these devices are usually small in size, and the proportion of glass in the total volume of the material body are trying to do less.

Conclusion h4> Of course, engineers are trying to circumvent the innate shortcomings of all these materials. In the case of polycarbonate enclosures use a magnesium frame, which removes heat at the glass display, which acts as a heat sink. The wall thickness, and various types of plastics, metal and glass can substantially mitigate inherent disadvantages. For example, the addition of ABS to a polycarbonate significantly improves the toughness of the material. Ballistic film on the glass reduces the risk of injury, the person in the case of partition. And advances in antennostroenii nullify the shielding effect of any metal.

But the question still remains - why it is so important is the choice of material? The answer lies in industrial design. We are constantly in touch smartphones and tablets, keep them in their hands. Most of the time we look at the display, but constantly have tactile contact with the device. And the way it looks, how to touch, how it forms, all this is very important. Always better when the device is good in the hand, it's nice to the touch, beautiful. Unwanted items spoil the appearance. Good design is obvious and visible. Only when we are faced with bad design, we begin to notice good. Technology can mitigate the shortcomings of materials, but there is nothing to fix bad design.

The second reason why the choice of materials received much attention, are such important parameters for mobile devices, such as weight and dimensions. For example, polycarbonate housing often have to do with thicker walls to provide the necessary rigidity of the structure.

While all this sounds subjective, but when the market reaches saturation point, the choice of materials and industrial design will be critical factors. However, they are of steel.

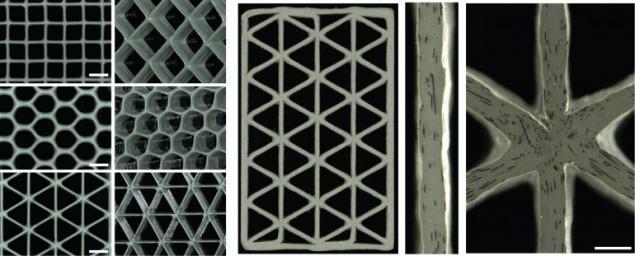

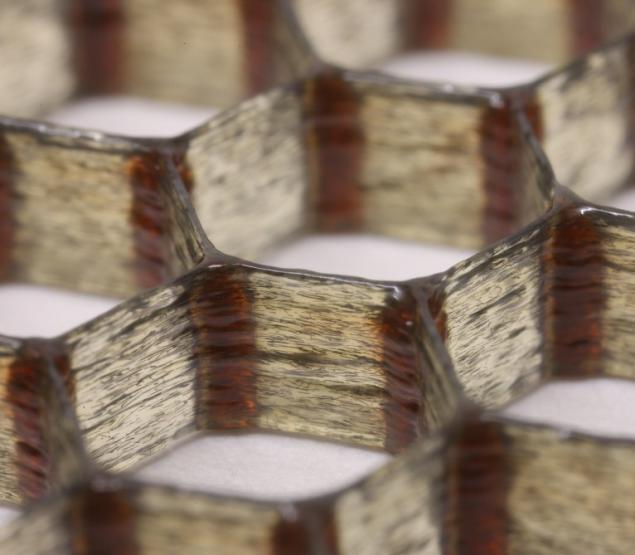

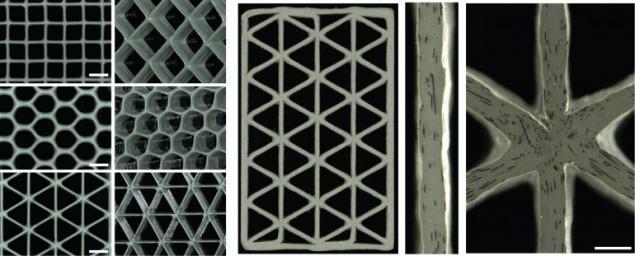

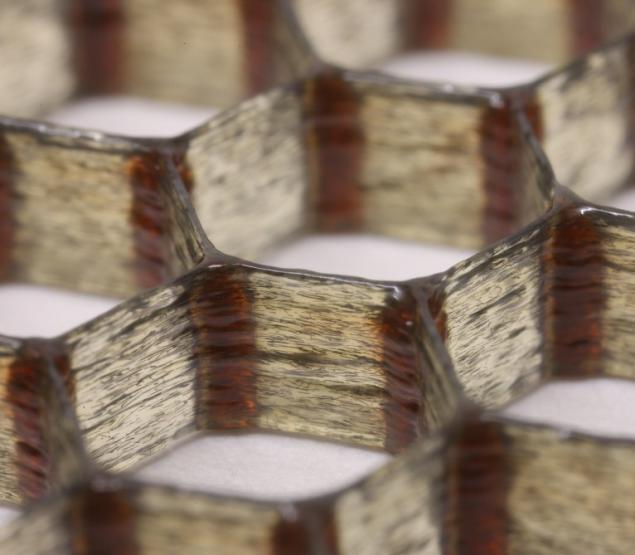

However, the situation may change in relation to the development of new materials and technologies. In particular, the three-dimensional printing industry can help create a new hull. Imagine a smartphone with very thin walls, easy, but if made of steel. This is quite possible in the future with the help of 3D-printing of composite materials. For example, in the form of honeycomb panels of resins having a very high mechanical stiffness:

A similar principle applies when creating intercontinental missiles and space, in which a very thin outer shell acts as a support structure frame.

Further miniaturization will require the creation of flexible gadgets. In particular, producers for several years been experimenting with the manufacture of such displays. As the protective glass and the material of the housing can be used very flexible, thin glass, for example, Willow Glass. It was developed by Corning, a manufacturer of Gorilla Glass.

Another candidate materials for buildings gadgets is graphite. However, this is a special material, which all say that there are millions of applications, describe its wonderful properties, but that's usually it ends. It is not known whether will be able to establish industrial production of graphene at an affordable price. Yet all its splendor does not go beyond laboratories.

Also, there can be mentioned a material called Liquidmetal. He has a unique amorphous structure, so it is also called "metallosteklom." By its strength and elasticity comparable with titanium, corrosion resistant. He can be given a complex shape without deteriorating strength properties. Therefore, many tipped him as the "material of the future" for making gadgets.

Source: habrahabr.ru/company/asus/blog/229801/