4125

History of composite materials

The composite material - a heterogeneous solid material from two or more components with a clear difference between them. The simplest example - the usual plywood. But there is much more interesting technologies and materials used in aircraft, automotive and other fields. Read more - by habrakatom.

Ancient explorers h4>

The era of plastics h4> It would not be advanced composites, if scientists invented plastic. Prior to this the only source of adhesive and binders were natural resins which are derived from animals or plants. And at the beginning of the XX century have developed vinyl, polystyrene, polyester and phenol - these materials are greater than the previously used.

Early innovations in composite materials: Second World h4> Many inventions in this field were invented during the war. As the Mongols created their composite bow and the Second World War reinforced polymers allowed to migrate from the laboratory to the real world.

The adaptation of composites h4> In general, by the end of the war a small niche was filled composite industry. And now faced a difficult task: how to proceed with military orders for products for peaceful purposes.

Space and aviation h4> aluminum and other metals in the manufacture of aircraft parts replaced with composites of low density, thus reducing the weight of the aircraft. This in turn saves fuel. So in civil aviation are now widely used composites.

Weapons h4> Of course, the composite materials used in the creation of weapons. For example, an intercontinental ballistic missile "Topol-M": 90% of it consists of composites, including engine design and a head portion.

Modern polymer composite materials h4> The most interesting group composites - are polymers. It's not plywood and straw in brick, and in the production of complex materials, including inodgda work even at the nano (10 -9 degrees).

How to use carbon fabric? H4>

Nanotechnology h4> Sami polymer composites are hardly nanotehnoologichnymi if nanotechnology is defined as "a set of engineering methods and techniques used in the study, design and production of materials, devices and systems, including targeted monitoring and control structure, chemical composition and reacting the individual components of the nanoscale elements (with dimensions of the order of 100 nm or less), which lead to an improvement either in additional operating and / or consumer characteristics and properties of the products obtained ».

Medicine h4> Of course, the military initially develop very often turn into products peacetime, and are used including in medicine. Diqing

Conclusion h4> ancient techniques that helped make bricks and bows stronger, combined with modern materials gives invaluable advantages in different areas. Among these areas - aviation and automotive, aerospace, medicine, including dentistry and prosthetics, and construction. Even something as simple as reinforcement in concrete structures, has now become more technological, made of fiberglass and carbon fiber. Seals at the dentist, as I wrote above, also apply to composite materials. Composite materials have become part of our lives, sometimes completely invisible to us.

Ancient explorers h4>

Two or more heterogeneous material is used together to create a new unique material or improve the performance of one of them. The first use of this method applies to 1500 BC, when Egypt and Mesopotamia began to use clay and straw for the structure of buildings. Also straw introduced into the composition to enhance ceramic products and boats.

Bricks, which used scrapping, called "adobe". Approximately so they did the Egyptians:

Next milestone - it's 1200 BC. Mongols tried: they created the first composite bow. Using materials such as wood, bone and animal glue. Mongolian bow is usually made of several layers of wood, basically it was a birch, which are glued together using animal glue. Horny pads are located on the inner side of the bow, fixed conductors.

The era of plastics h4> It would not be advanced composites, if scientists invented plastic. Prior to this the only source of adhesive and binders were natural resins which are derived from animals or plants. And at the beginning of the XX century have developed vinyl, polystyrene, polyester and phenol - these materials are greater than the previously used.

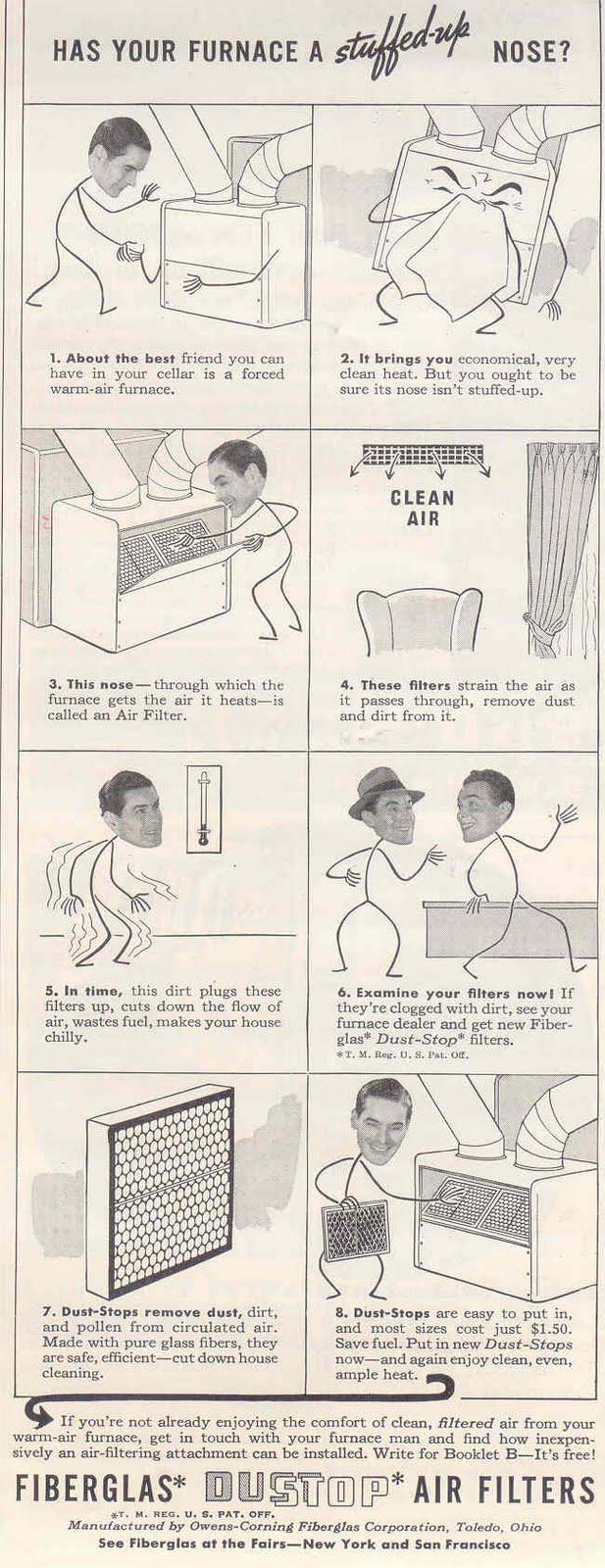

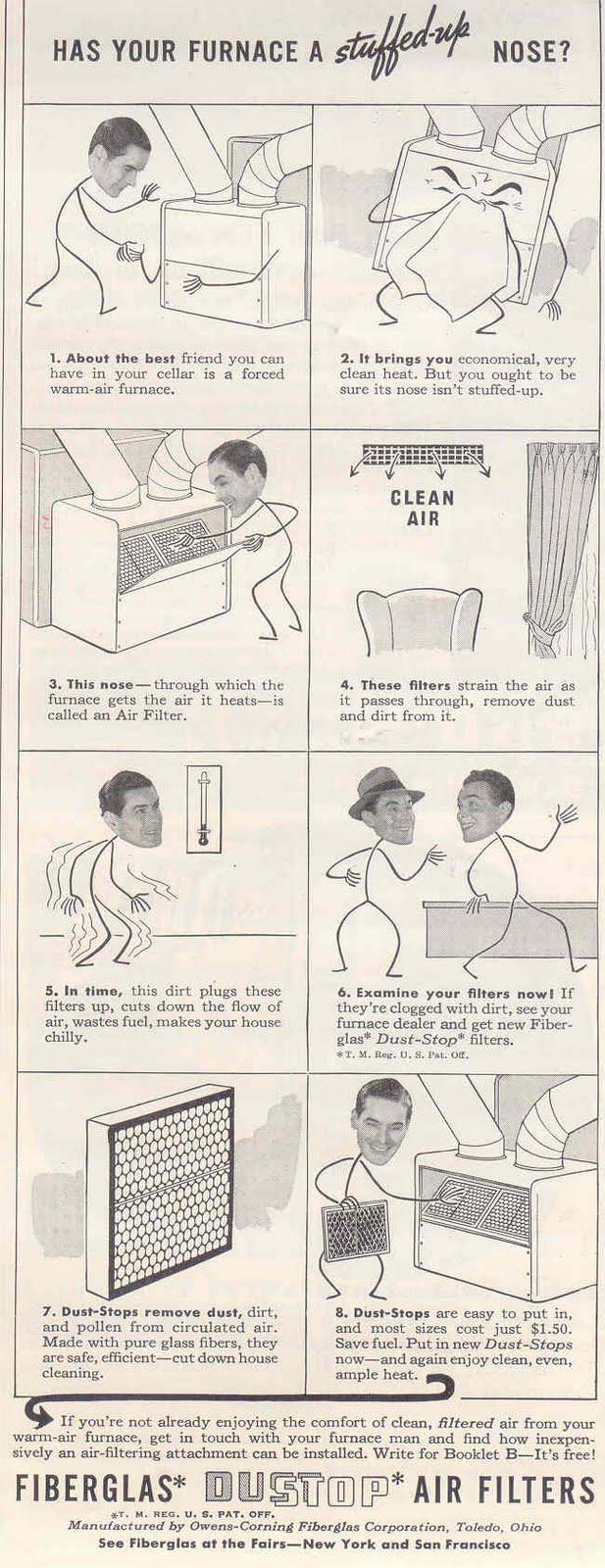

But plastics were not able to provide sufficient strength. You had better reinforcement, and in 1935 the firm Owens / Corning Fiberglass presented. In combination with plastic polymer fiber is extremely strong and at the same time very light structure. This is the beginning of reinforced plastics industry.

The first advertisement of the product Fiberglass refers to 1939. This advertisement air filter of this company.

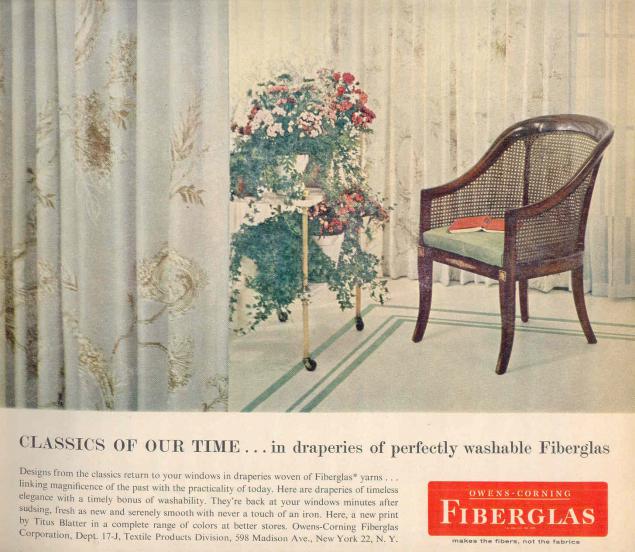

In 1957 the company advertised the curtains of fiberglass with a print.

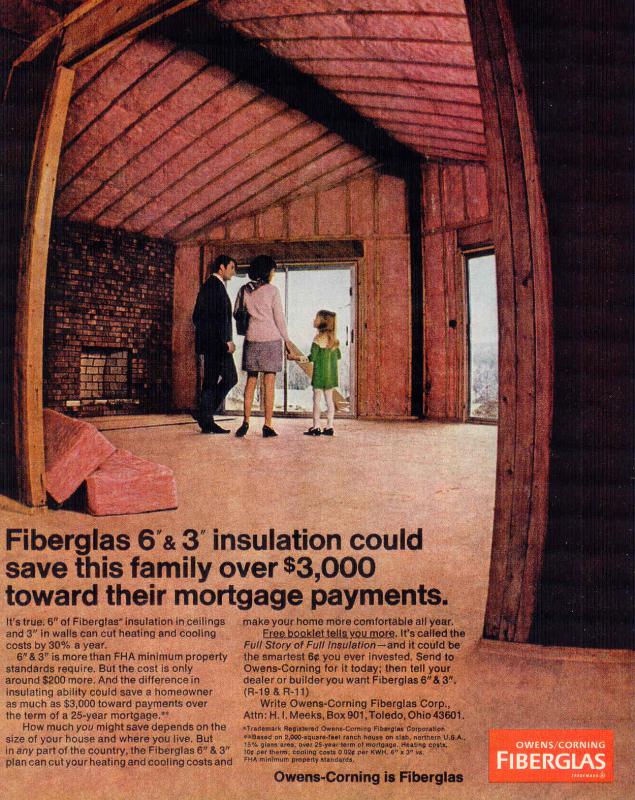

Still something of 1970 - the panel of fiberglass for insulation during construction.

Early innovations in composite materials: Second World h4> Many inventions in this field were invented during the war. As the Mongols created their composite bow and the Second World War reinforced polymers allowed to migrate from the laboratory to the real world.

Alternative materials that reduce the weight of the final product were needed in military aircraft. Very quickly, the engineers realized the benefits of composites in terms of their weight and strength.

Also, engineers have learned about the advantages of such a composite of fiberglass, as radiopronitsaemost. And they began to apply the "fairing" that protect the radios from external factors, including wind.

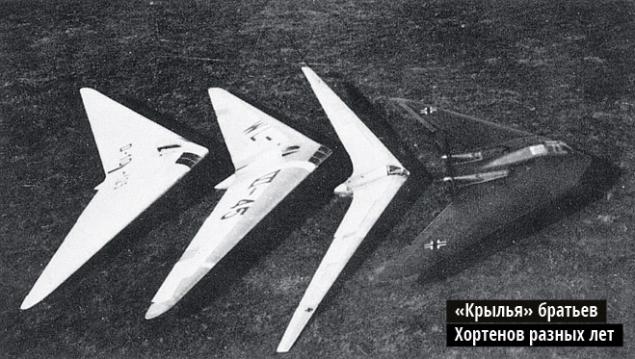

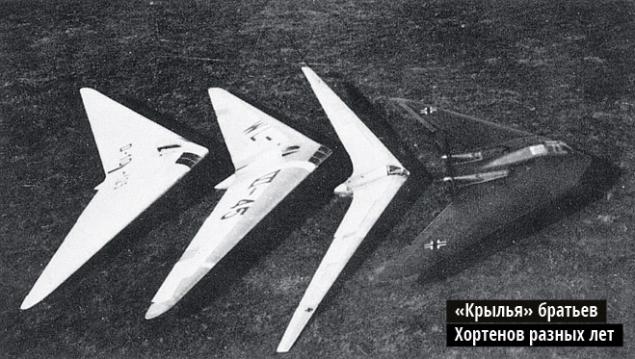

During the war, Germany was trying to develop stealth aircraft, long before the US Stealth. Then it was necessary to use a composite material in the body, where between layers of plywood was to light balsa filler - a tree growing in South America. But in 1944, this material was not reachable for the Germans, so I had to use ersatz composite "formholts": between layers 1 and 5 mm plywood was a mixture of resin-impregnated porous sawdust and coal.

The adaptation of composites h4> In general, by the end of the war a small niche was filled composite industry. And now faced a difficult task: how to proceed with military orders for products for peaceful purposes.

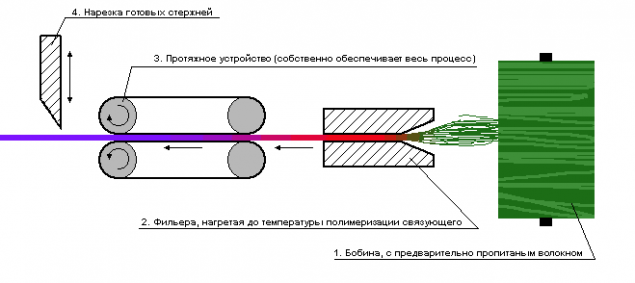

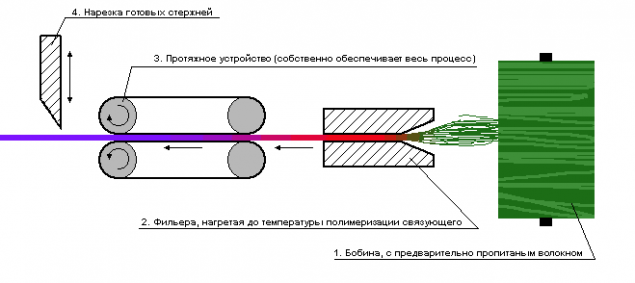

Among the obvious choices were the boats. The first boat with a composite hull was presented in 1946. Around the same time to make a surfboard fiberglass. And there was a method of "drawing" - "pultrusion" used in the manufacture of polymer composite materials.

For example, the circuit dry pultrusion. The method greatly simplifies production.

Cars - another important area for polymer composites.

In 1954 in the USA on sale there first sports car, which KORUS made of fiberglass: Kaiser-Darrin. This machine was accelerated to 60 miles per hour in 15 seconds 1. A maximum speed - a little less than 100 miles per hour, which is about 160 km / h.

These characteristics become dostizhymymi when the engine 90 horsepower thanks largely to the low weight avtomobyali, about 2,200 pounds, or 997 kg.

In the 1970s, the materials become even better and harder. The company DuPont, namely one group running Stephanie Kwolek, developed aramid fibers, known to us as Kevlar. Now it is a well-known material used in bulletproof vests. Kevlar is five times stronger than steel. Developed this material for reinforcing tires, and he is now being used for these purposes. Also, they are reinforced with copper and fiber optic cables.

Car Tire Wrangler with Kevlar.

Kevlar sleeve with dock for iPhone.

Unmanned aircraft Kevlar is also used. For example, for extra protection UAV RQ-11 Raven.

Space and aviation h4> aluminum and other metals in the manufacture of aircraft parts replaced with composites of low density, thus reducing the weight of the aircraft. This in turn saves fuel. So in civil aviation are now widely used composites.

In the Boeing 787 DreamLiner of composite materials based on carbon made 50% of the elements of the fuselage. Thus, the aircraft lighter and stronger than conventional liner with aluminum fuselage.

Engine Genx from General Electric also has a composite material, of which the shell, the turbine blades and nozzles that inject fuel into the combustion chamber.

Weapons h4> Of course, the composite materials used in the creation of weapons. For example, an intercontinental ballistic missile "Topol-M": 90% of it consists of composites, including engine design and a head portion.

Replacement rifle Christensen Arms, made of carbon fiber. The rifle is based on the bolt group Remington-700.

Carabiner Carbon Custom R-93 with interchangeable barrels.

Butts for rifles, made of composite materials. Presented at the "open innovation" in the past year, the Russian manufacturer of HC «Composite».

Modern polymer composite materials h4> The most interesting group composites - are polymers. It's not plywood and straw in brick, and in the production of complex materials, including inodgda work even at the nano (10 -9 degrees).

A bit of theory at this time. Reinforcement is used:

Carbon fabric (carbon);

Aramid fabric (Kevlar);

Hybrid fabric (carbon + Kevlar);

Unidirectional hybrid fabrics;

Fiberglass;

Multiaxial fabrics;

Carbon tape;

Prepregs.

How to use carbon fabric? H4>

For the manufacture of carboxylic parts used as a carbon fiber with randomly spaced and fills the entire volume of the material yarns and fabrics (Carbon Fabric). The most common types of such tangles like Plain, Twill, Satin.

Tissue density or specific mass, expressed in g / m2, in addition to the type of weaving is dependent on the thickness of the fiber, which is determined by the amount uglenitey. This characteristic of multiple thousands. Thus, the abbreviation 1K means a thousand strands of the fiber.

Often we hear from kids to area motorists that they are "pasted in carbon cars." Here we are, in fact, is often not on polymer composites, and an ordinary decorative films made under the carbon. Hicacos advantages such a film does not: the weight of items does not become less in strength, too, she will not win. So it is - just the pursuit of fashion and a desire to make their own cars like racing cars from Need For Speed.

In the construction of buildings and roads, for the reinforcement of concrete tanks and reservoirs used carbon fiber and fiberglass rebar, inert to all aggressive media, has high durability and life expectancy of 75 years.

Reinforce the construction and thereafter can be performed with an external part, using carbon tape impregnated with a two component epoxy formulation. Picture better, unfortunately, did not find.

Asphalt can be reinforced by adding fibers to it. Remembered straw and clay in the beginning of the post?

Nanotechnology h4> Sami polymer composites are hardly nanotehnoologichnymi if nanotechnology is defined as "a set of engineering methods and techniques used in the study, design and production of materials, devices and systems, including targeted monitoring and control structure, chemical composition and reacting the individual components of the nanoscale elements (with dimensions of the order of 100 nm or less), which lead to an improvement either in additional operating and / or consumer characteristics and properties of the products obtained ».

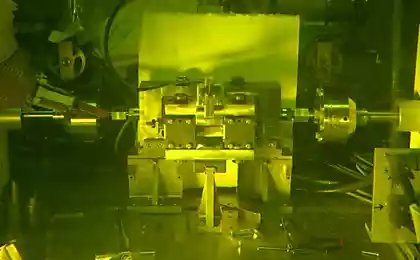

But recently entered the market polymeric resins that act as a binder, which, based on the production process, it is covered by the definition of nanotechnology.

Medicine h4> Of course, the military initially develop very often turn into products peacetime, and are used including in medicine. Diqing

Of course, initially military technologies often converted into products peacetime and used including medicine.

We begin, of course, with dentistry. Fillings you put? With high probability were composites. Just when you are ready to install the physician mix components, and then set in place and then keeps a few minutes ultraviolet lamp. This light-curing seal.

There are seals and chemical curing. For example, the glass ionomer cement powder and liquid in which the powder - alyumoftorsilikatnoe glass with fluorine and liquid - an aqueous solution of polyacrylic acid.

Composite fibers are used in the manufacture of orthoses. Brace - a special tool designed for unloading, fixing, or correction of activation functions of the joint or limb. Here are Cortez, bandages, shoes, and other products.

Needless to say, dentures are made from composite materials. In the case of specimens for the runners it is necessary, as this flexibility and the strength of other materials are unable to provide.

Conclusion h4> ancient techniques that helped make bricks and bows stronger, combined with modern materials gives invaluable advantages in different areas. Among these areas - aviation and automotive, aerospace, medicine, including dentistry and prosthetics, and construction. Even something as simple as reinforcement in concrete structures, has now become more technological, made of fiberglass and carbon fiber. Seals at the dentist, as I wrote above, also apply to composite materials. Composite materials have become part of our lives, sometimes completely invisible to us.

The use of this method is possible even at home. I mentioned in one of the past publications , I plan to make a new fashion for your quadrocopter. Once attain this success - write.

Source: geektimes.ru/post/240596/

Top notes of children

The FBI has asked the US Congress to legally reduce protection iOS and Android devices