751

Features cover composites

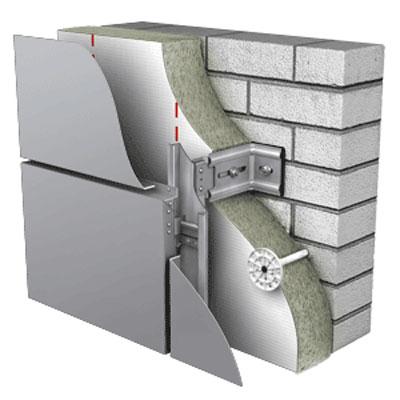

Composite aluminum panels appreciate both good strength properties and beautiful appearance. This is largely due to the polymer coating, which imparts special properties and increases the scope of application.

Types of coverage h2>

Currently manufacturers are using two main types of coatings, each having its own advantages.

- Polyester is created on the basis of polyester, which allows you to have a good lightfastness and to achieve a high gloss effect. In addition to protection against corrosion and the adverse effects of PE-coating does not interfere with a good flex panels to create different shapes. These properties are important in the creation of interior decoration or advertising designs.

- For the facades are usually installed composites PVDF-coated. It is based polivinildenftorid and acrylic. It can greatly improve strength as well as resistance to ultraviolet light or mechanical damage. This was possible thanks to the fluorocarbon compound that forms during production grip on the macromolecular level, which provides a special strength and durability.

Technology painting h2>

The technological process of painting is now fully automated, making it possible to improve the quality and to make great, attractive composite panels.

- The first phase of aluminum roll unwinds and subjected to a thorough cleaning of the existing grease and dirt.

- special etching acids in a special chamber eliminates the oxide accumulated during shipment and storage. Then roll well dry.

- Painting takes place in complete isolation, to exclude the smallest particles of dirt or dust, as this will affect the quality.

- The coating will have not one, but several layers because in the beginning you should apply primer and then the color pigment to create the desired shade of color and texture.

- Clear lacquer, for application over these layers, good protection from the influence of the environment.

- For the spray is also used oxide films made by the method of electrochemical anodization. They not only safeguard against scratches, but also give a metallic tint, imitating bronze, silver, brass or gold.

- laminated cover will be necessary to simulate wood or natural stone that is important for the realization of the architectural project. This warranty period is not less than twenty years. http: / /www.ask-h.ru/ . However, installation of ventilated facades, preference is given to coating with polivinildenftoridom because it is better to withstand the load, and the negative effects of a long service life.