1538

The story of one opening

In the second year at college, when we were told "the history of science," I remember hearing about a student who forgot to turn off the pot and make a discovery, or a famous scientist who has received an apple on his head, and thought it was a fairy tale, and in modern science this does not happen. Basically, if you look at publications in top physics journals, it is clear that all of them - the result of a long hard digging in one direction. Novoselov with game even got nobelevku not for the discovery, as such, but for the "systematic study of the properties." But, nevertheless, the opening in the modern science still happen, and I want to tell you about one of them being his co-author.

From the beginning - a small excursion into the field of physics and nanotechnology, bark I do - this is the micro- and nano-tribology. By itself, tribology - the science of very advanced age, which is engaged in friction and wear. It would seem that in this area is already known - poured more lubricant, and no friction. And study here, from a scientific point of view, nothing special. But with the development of miniaturization, tribology has received tripled breath. Because the methods of the macrocosm (pour a bucket of oil) on the micro level do not work - and not because it all just drown, you can also butter and added drop-wise?

The problem is that reducing the size of the moving parts, the contribution of the surface. And all kinds of surface effects, which are negligible at the macro level, at the micro-level, begin to dominate. In particular, surface tension. Therefore, while reducing components after a certain limit, it is impossible to use a lubricant. And on the stage appears dry friction. For example, the coefficient of dry friction of silicon on silicon (the most common material for MEMS) reaches 0.7. Ie 70% of the capacity of the engine will go on just what would turn the rotor. Must somehow deal with it. The obvious way - to put on some components of strong em> cover with low friction. Since this is a micro-components, and the thickness of the coating should be very small - usually talking about tens of nanometers, but there are also ultra-thin coating with a thickness of 1-2 nm. In principle, there are a fair number of coatings which may be used to reduce friction and wear - soft metals, organic molecules swiveling graphene and diamond film. Many materials, but they all have certain disadvantages, and any universal not yet invented.

From this list, perhaps, the diamond film (Diamond-like coatings, DLC) are best known. Especially because they can equally well be used as micro- and macro-level. So, Hyundai is currently using DLC coating surface valve engines fitted in top models of cars. Plan to use the DLC in the HDD to reinforce the landing surface hydrodynamic bearings. You can find hundreds of other uses DLC in real life, including the coating on the cutting edge of the blade for shaving. In most cases, the DLC coating using magnetron sputtering - a well-known method and the exhaust. But, as always, there are nuances. The most important - all this is very expensive. There are purely technical problems, such as high levels of internal stress, sensitivity to humidity, etc. Therefore, attempts to make the DLC cheaper and better yet, do not stop.

Together with colleagues from my alma mater, we have been developing for several years one can say an alternative technology - application of diamond films by ion beam, which is used as the material is not atomic carbon, and the molecules of fullerene C 60 sub>. Fullerene is ionized, accelerated to 5 keV and thrashes on the substrate. In this case the molecules are broken and formed from the debris of amorphous structure with interesting properties. Details can be found in this article . This method has its advantages, in particular, our films are not afraid of moisture, and of the use of ion beam allows to coat objects of arbitrary shape that is somewhat difficult in the case of magnetron sputtering. The disadvantage of our films - quite a high level of residual stresses. The film tends to expand to occupy a larger volume than it has. This leads to unpleasant consequences - if you put a thin film on a substrate - substrate can be bent. If the substrate is thicker, and the adhesion between the film and the substrate is not good enough - the film just exfoliate.

We had the idea to dilute the solid mass DLC with something soft that would compensate for the internal stresses. And since, as a base material used, fullerene, and it was added. It was found that if in parallel with the ion beam on the substrate to direct molecular beam, the result is a nano-composite in which the fullerene molecules are surrounded by a solid amorphous carbon. As expected, the level of stress in this film was significantly less. Generally speaking, we have not found any stress. Of course, the film hardness also decreased - if the film deposited from the ion beam characteristic values of 50-60 GPa, the nano-composite showed 25-30 GPa. But it's still quite a lot - for example, the hardness of single-crystal silicon ~ 10 GPa. Ur problem is solved. Here, in the process of measuring the hardness, and crept discovery, which I mentioned at the outset.

But before we get to the point, you need to make another retreat. Tell about how to measure the hardness of the films. In principle, the method is the same - take a tared diamond pyramid, and pressed into the surface with a certain force. The softer the material, the deeper going pyramid. I measure the size of the print - get hardness. All this is easy when you have to try on the hardness of the rail. And it becomes difficult, when it comes to films with a thickness of 100 nm. For this purpose, we developed a method наноиндентирования (Nanoindentation, depth sensing indentation). The bottom line is that we gradually increase the load on the pyramid (the indenter) and simultaneously fix the depth of penetration. Commonly used linear law of loading and unloading. Well need a special pyramid. In our case, this triangular pyramid with a tip diameter of 100 nm.

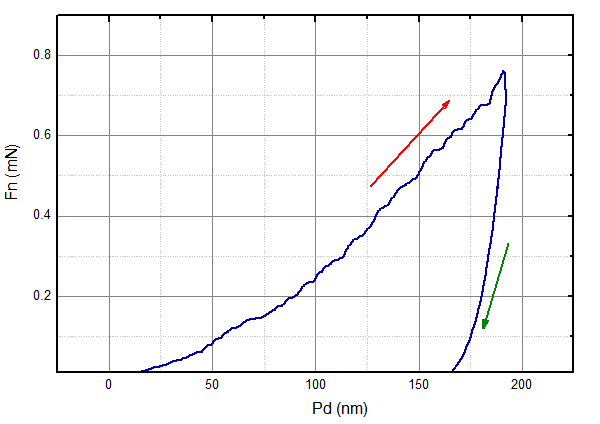

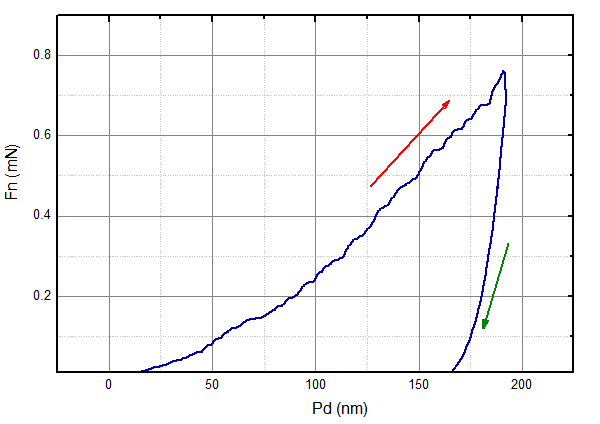

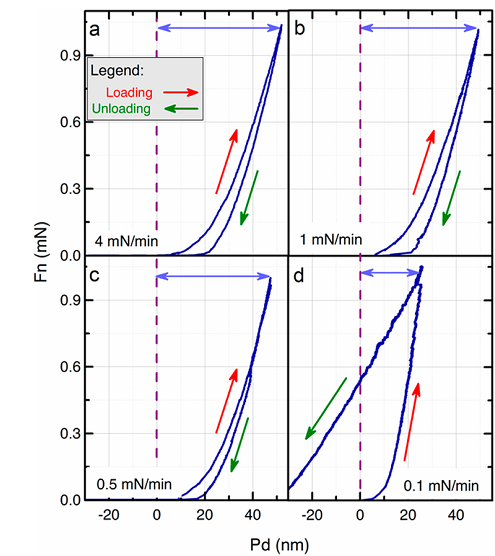

As a result of "controlled piercing", for example, soft fullerene films obtained is such a curve:

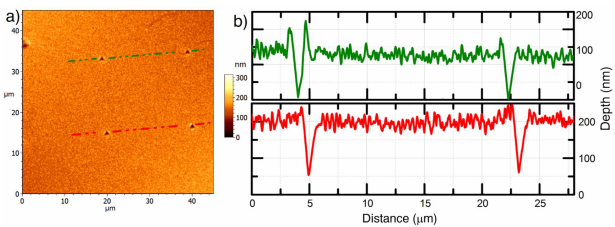

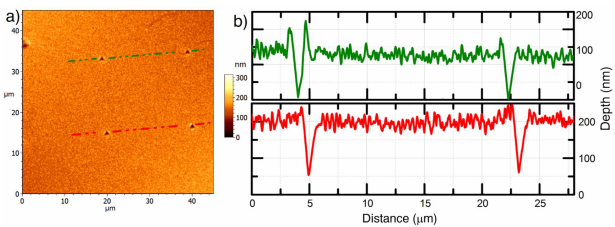

Here the axis X - is the depth of penetration of the indenter (in nanometers), Y - force applied to the indenter. The red arrow indicates the direction of the load, the green - unloading. The depth of penetration depends on the hardness. The softer the material, the indenter penetrates deeper with the same load. Thus the elasticity (Young's modulus) can be calculated from the slope of the load curve. Loading and unloading curves do not coincide as a result of plastic deformation at the contact point. If you explore the imprint using the atomic force microscope, you will get this following picture:

Left - top view, right - section along the red and green lines. It is clearly seen that the indenter - still triangular pyramid :). In the case of elastic materials such as rubber, load curve will coincide with the unloading curve, because in this case there is only elastic deformation up to a certain limit, of course, well fingerprint on the surface will not. The case where the unloading curve will lie higher than the load curve, in principle, not possible.

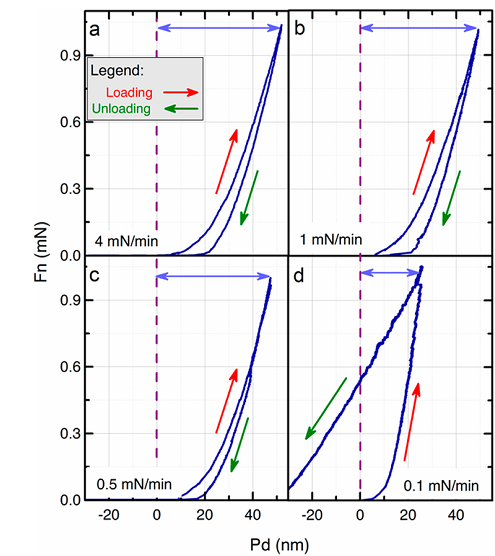

Well, one day, this "impossible" and the curve was recorded experimentally (Figure d):

At first I just thought it was some kind of glitch in the instrument. Then checked again. Reproduced. Do not believe it. Then he began to understand. As it turned out, this phenomenon is characteristic of nano-composites consisting of a mixture of fullerene molecules and solid amorphous carbon. Depending on the speed with which loading and unloading is performed during a test, the curve changes shape. When we push fast - get the typical pattern for a solid film (a). Davim slow - get 'what can not be. " Obviously, at low speed punching in the film there is some additional driving force that pushes back the indenter. But what?

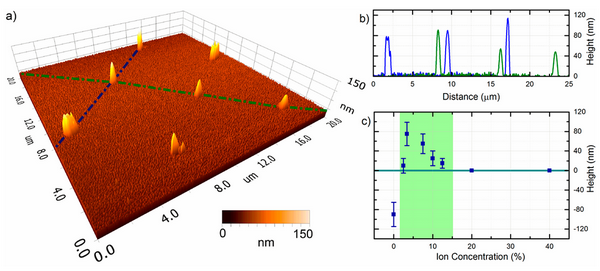

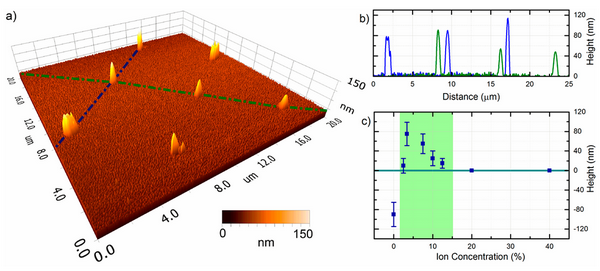

Detailed analysis shows that in the case of "anomalous" indentation instead indentation formed hill height of several tens of nanometers (a, b):

Detailed analysis showed that the height of the "hills" depends on the ratio of the ionic and molecular beams during manufacture ©.

It is obvious that under load the material to swell, which leads to the expulsion of the indenter and forming hills instead prints. So at the expense of what? With the combined ion and molecular beam polymerization occurs fullerene molecules. In the normal state they are linked by weak van der Waals forces. However, if they are properly "kick" that between two neighboring molecules form a much stronger covalent bonds. These two types of communication besides strength differ in length. The covalent bond is shorter and polymerized molecules are packed more densely. At the "puncture" polymer complexes at the site of contact deform and break covalent bonds. As a result of closely packed molecules tend to move away from each other, which leads to an increase in the volume and filling the indentation forming a hill. Why this effect is observed only at low indentation? We believe that the yield depolymerized molecules to the surface - a process of diffusion, and with rapid indentation of them simply do not have time.

In addition to "self-healing" of the surface, such nano-composite films show another interesting feature - dynamic hardness. The film is very strong in the case of shock, with relatively soft and supple in the case of load constant or slowly increasing. Why do it - we have not figured out yet in the air rush thoughts like "nano-vests for nano-robots." Any ideas?

A more detailed description can be found in this article (Eng.). She's on the sci-hub: http://pubs.acs.org.sci-hub.org/doi/abs/10.1021/nl500321g.

______________________

Text prepared in blog editor from © SoftCoder.ru h6>

From the beginning - a small excursion into the field of physics and nanotechnology, bark I do - this is the micro- and nano-tribology. By itself, tribology - the science of very advanced age, which is engaged in friction and wear. It would seem that in this area is already known - poured more lubricant, and no friction. And study here, from a scientific point of view, nothing special. But with the development of miniaturization, tribology has received tripled breath. Because the methods of the macrocosm (pour a bucket of oil) on the micro level do not work - and not because it all just drown, you can also butter and added drop-wise?

The problem is that reducing the size of the moving parts, the contribution of the surface. And all kinds of surface effects, which are negligible at the macro level, at the micro-level, begin to dominate. In particular, surface tension. Therefore, while reducing components after a certain limit, it is impossible to use a lubricant. And on the stage appears dry friction. For example, the coefficient of dry friction of silicon on silicon (the most common material for MEMS) reaches 0.7. Ie 70% of the capacity of the engine will go on just what would turn the rotor. Must somehow deal with it. The obvious way - to put on some components of strong em> cover with low friction. Since this is a micro-components, and the thickness of the coating should be very small - usually talking about tens of nanometers, but there are also ultra-thin coating with a thickness of 1-2 nm. In principle, there are a fair number of coatings which may be used to reduce friction and wear - soft metals, organic molecules swiveling graphene and diamond film. Many materials, but they all have certain disadvantages, and any universal not yet invented.

From this list, perhaps, the diamond film (Diamond-like coatings, DLC) are best known. Especially because they can equally well be used as micro- and macro-level. So, Hyundai is currently using DLC coating surface valve engines fitted in top models of cars. Plan to use the DLC in the HDD to reinforce the landing surface hydrodynamic bearings. You can find hundreds of other uses DLC in real life, including the coating on the cutting edge of the blade for shaving. In most cases, the DLC coating using magnetron sputtering - a well-known method and the exhaust. But, as always, there are nuances. The most important - all this is very expensive. There are purely technical problems, such as high levels of internal stress, sensitivity to humidity, etc. Therefore, attempts to make the DLC cheaper and better yet, do not stop.

Together with colleagues from my alma mater, we have been developing for several years one can say an alternative technology - application of diamond films by ion beam, which is used as the material is not atomic carbon, and the molecules of fullerene C 60 sub>. Fullerene is ionized, accelerated to 5 keV and thrashes on the substrate. In this case the molecules are broken and formed from the debris of amorphous structure with interesting properties. Details can be found in this article . This method has its advantages, in particular, our films are not afraid of moisture, and of the use of ion beam allows to coat objects of arbitrary shape that is somewhat difficult in the case of magnetron sputtering. The disadvantage of our films - quite a high level of residual stresses. The film tends to expand to occupy a larger volume than it has. This leads to unpleasant consequences - if you put a thin film on a substrate - substrate can be bent. If the substrate is thicker, and the adhesion between the film and the substrate is not good enough - the film just exfoliate.

We had the idea to dilute the solid mass DLC with something soft that would compensate for the internal stresses. And since, as a base material used, fullerene, and it was added. It was found that if in parallel with the ion beam on the substrate to direct molecular beam, the result is a nano-composite in which the fullerene molecules are surrounded by a solid amorphous carbon. As expected, the level of stress in this film was significantly less. Generally speaking, we have not found any stress. Of course, the film hardness also decreased - if the film deposited from the ion beam characteristic values of 50-60 GPa, the nano-composite showed 25-30 GPa. But it's still quite a lot - for example, the hardness of single-crystal silicon ~ 10 GPa. Ur problem is solved. Here, in the process of measuring the hardness, and crept discovery, which I mentioned at the outset.

But before we get to the point, you need to make another retreat. Tell about how to measure the hardness of the films. In principle, the method is the same - take a tared diamond pyramid, and pressed into the surface with a certain force. The softer the material, the deeper going pyramid. I measure the size of the print - get hardness. All this is easy when you have to try on the hardness of the rail. And it becomes difficult, when it comes to films with a thickness of 100 nm. For this purpose, we developed a method наноиндентирования (Nanoindentation, depth sensing indentation). The bottom line is that we gradually increase the load on the pyramid (the indenter) and simultaneously fix the depth of penetration. Commonly used linear law of loading and unloading. Well need a special pyramid. In our case, this triangular pyramid with a tip diameter of 100 nm.

As a result of "controlled piercing", for example, soft fullerene films obtained is such a curve:

Here the axis X - is the depth of penetration of the indenter (in nanometers), Y - force applied to the indenter. The red arrow indicates the direction of the load, the green - unloading. The depth of penetration depends on the hardness. The softer the material, the indenter penetrates deeper with the same load. Thus the elasticity (Young's modulus) can be calculated from the slope of the load curve. Loading and unloading curves do not coincide as a result of plastic deformation at the contact point. If you explore the imprint using the atomic force microscope, you will get this following picture:

Left - top view, right - section along the red and green lines. It is clearly seen that the indenter - still triangular pyramid :). In the case of elastic materials such as rubber, load curve will coincide with the unloading curve, because in this case there is only elastic deformation up to a certain limit, of course, well fingerprint on the surface will not. The case where the unloading curve will lie higher than the load curve, in principle, not possible.

Well, one day, this "impossible" and the curve was recorded experimentally (Figure d):

At first I just thought it was some kind of glitch in the instrument. Then checked again. Reproduced. Do not believe it. Then he began to understand. As it turned out, this phenomenon is characteristic of nano-composites consisting of a mixture of fullerene molecules and solid amorphous carbon. Depending on the speed with which loading and unloading is performed during a test, the curve changes shape. When we push fast - get the typical pattern for a solid film (a). Davim slow - get 'what can not be. " Obviously, at low speed punching in the film there is some additional driving force that pushes back the indenter. But what?

Detailed analysis shows that in the case of "anomalous" indentation instead indentation formed hill height of several tens of nanometers (a, b):

Detailed analysis showed that the height of the "hills" depends on the ratio of the ionic and molecular beams during manufacture ©.

It is obvious that under load the material to swell, which leads to the expulsion of the indenter and forming hills instead prints. So at the expense of what? With the combined ion and molecular beam polymerization occurs fullerene molecules. In the normal state they are linked by weak van der Waals forces. However, if they are properly "kick" that between two neighboring molecules form a much stronger covalent bonds. These two types of communication besides strength differ in length. The covalent bond is shorter and polymerized molecules are packed more densely. At the "puncture" polymer complexes at the site of contact deform and break covalent bonds. As a result of closely packed molecules tend to move away from each other, which leads to an increase in the volume and filling the indentation forming a hill. Why this effect is observed only at low indentation? We believe that the yield depolymerized molecules to the surface - a process of diffusion, and with rapid indentation of them simply do not have time.

In addition to "self-healing" of the surface, such nano-composite films show another interesting feature - dynamic hardness. The film is very strong in the case of shock, with relatively soft and supple in the case of load constant or slowly increasing. Why do it - we have not figured out yet in the air rush thoughts like "nano-vests for nano-robots." Any ideas?

A more detailed description can be found in this article (Eng.). She's on the sci-hub: http://pubs.acs.org.sci-hub.org/doi/abs/10.1021/nl500321g.

______________________