760

Features of installation of electric wiring in the premises of various building materials

Especially the installation of electrical wiring directly depend on the characteristics of the construction materials from which the building is constructed. And this is due to the fact that every building material has its own degree of fire risk. In this article we will look at this relationship, based on the current rules of device of electrical installations (7th edition of the SAE, updated 12.02.2016) and practical experience of our users.

Rules location of cable routesLocation of cable lines in the premises subject to certain rules:

The wiring is of the open type is laid directly on the surface of the walls. Wire either mounted on special insulators, or stacked in standard cable channels.

Selecting a transaction type when building a house should not be guided by their own preferences, after all, the basis should be taken solely Snips, GOSTs, PUE.Less questions from the "builders of self-taught", if the wiring is mounted on the walls of non-combustible construction materials. First, let's talk specifically about these cases.

The wiring along building structures of non-combustible materialsthe current rules of the SAE permit to use the premises wires and cables exclusively with copper conductors (section 7.1.34.).If the room has walls and ceilings of non-combustible materials (concrete, bricks, aerated concrete blocks, ceramic blocks, gypsum Board GWP, etc.), then it is advisable to mount the wiring is concealed. First, it is aesthetically pleasing, and secondly, it is safe in terms of accidental mechanical damage and, thirdly, the rules of the SAE (p. 7.1.37) it is allowed to mount the wiring is concealed in the walls of non-combustible materials.

In this case we are talking about a residential installation. In attics, basements (especially in an unheated) and indoor technical purposes, it is recommended to do the wiring of an open type.Rules electrical safety rules are as follows: if the building construction is of noncombustible materials, then it is allowed to lay zamonolichivajut irremovable wiring, using technological channels, grooves and voids. Thus as the conductors, it is sufficient to use insulated cables or wires in a protective sheath (e.g., cables VVG). In this case, the wiring is carried out without the use of metal pipes, corrugations and other protective elements.

If the draft is planned later wall plaster, shtroblenie walls under the wiring, as a rule, to resort is not necessary.

Of course, niche for switches and sockets will still have to create in the wall. But dust, and physical work in this case will be much less than if universally shtroblenie walls.

As for the power supply: it should be available at any self-respecting host. Because in the future she will definitely need. The scheme is necessary at least in order to repair the premises not to get a drill in the wire connected to electricity.

If you pave the wiring in the walls, which in the future is not planned to plaster, shtrobleniya in this case can not be avoided. Also stroebe walls have, if the overhaul is the replacement of old wiring and remove the old layer of plaster is not necessary.

Whether or not to create horizontal grooves? Is it possible stroebe bearing walls and concrete floors? Definitive answers to these questions among professional builders are there. Of course, from the point of view of the theory of strength of materials man-made furrows is able to significantly weaken the strength of building structures (like thin cut glass cutter weakens the strong glass). However, the rules of the SAE (p. 7.1.37) allow the laying of electrical networks in the furrows (in strobach) walls, partitions and ceilings. The main thing – do not overdo it with the grooves depth and width.

At the same time the maximum use of existing technological voids (e.g., slabs).

In strobach in steel sleeves, tray and technological channels allowed joint laying of wires and cables belonging to different lines (except vzaimodeistviyami conductors).The wiring along building structures made of combustible materials,a lot of questions concerning the rules of installation of electrical wiring, occurs in people who begin to electrify the premises of combustible building materials. We are basically talking about timber frame and wooden houses. The answers to most questions you can find everything in the same rules as the EMP.

Construction of houses made of combustible construction materials allows you to mount the wiring of both types (hidden and open). Which one to use depends on the preferences of the homeowner. As for protective elements, protecting the wiring from damage, and the building from fire caused by short circuit, their choice depends on the type of cable routing.

There are two ways of routing of open wiring in the premises:

Installation of retro-posting. The wiring in the cable channels. Installation of retro-wiringHow the design of retro-wiring conforms to the rules of the SAE – a moot point. These regulations create a transaction of this type is not even considered. However, let's try to understand this question.

In the case of retro-wiring, special twisted cable ("retro") is mounted directly on the wall, which is attached by means of small insulators. Given that the conductor has a coating of artificial silk impregnated with a non-flammable composition, it can be attributed to the class of wires, flame retardant. Therefore, installation of retro-posting on walls of combustible materials does not violate the rules of the SAE.

In accordance with the rules of the SAE distance from the conductor to the surface of combustible material must be at least 10 mm, which is ensured by the design of insulators for retro-wiring.

If the wire is much slack, the distance between the insulators can be reduced to 50 cm.

Mounting a retro-wiring, to consider one important caveat: most modern electronic equipment must be connected to the grounding circuit. For this reason, the composition of the posting, you should use a three-core cable (if there is no sale, then its advisable to make your own).

In places the passage of wiring through the wall or ceiling of combustible materials (e.g. wood) the cable (wire) should be laid in a metal pipe, with localization ability. The ends of the pipe should be sealed with non-combustible composition (for example, fire-resistant foam).The localization ability of the pipe is the quality to withstand short circuit in the wiring without burning out the walls of the pipe itself. In order that the pipe had that ability, its walls must be of a certain thickness:

Escutcheon when installed on a wall made of combustible materials must have fire-resistant lining (e.g., of asbestos or construction of a plaster solution) with a thickness of 10 mm. At the location of the wiring through combustible construction must be installed on the metal shell with localization ability.

Hidden wiring in the walls made of combustible materials,Particularly strip hidden wiring in the walls made of combustible materials (e.g. wood) are reduced to the fact that the wiring in the voids of these walls and partitions shall be run inside metal tubes, with localization ability (the rules of the SAE 7.1.38.).

The number one rule, and in relation to its implementation of any indulgences can not be. All other options (use plastic flutes, spiral wrap and other protective elements) should obviously be excluded, because from the point of view of fire safety, they are unacceptable.

When routing wires and cables on combustible structures (or inside them) in all cases, must be provided possibility of replacement of conductors.By the way, electrical wiring scattered on the floor, is the most convenient method of arrangement of the hidden wiring in the premises of flammable materials. Grooves to the outlets and switches in this case will be just down from the main roads.

When laying pipes and ducts for electrical wiring in the technological voids combustible constructions the ends of the pipes and ducts should be closed quickly remove non-combustible material (e.g., foam).

Order when mounting wiring replaceable in metal pipes, it was possible to create a sufficient number of turns, in the corners of the electric tracks, you must use distribution boxes. Access to these elements should always remain open.

The inner diameter of the pipe should be chosen so that laid cable inside it took no more than 40% of the total free space. This rule is valid for all safety items (cable-channels, corrugated trays, etc.).It should be noted that the creation of the hidden wiring in rooms with wooden walls – a laborious process. Because the channels for the wiring will have to equip their own forces. Space for pipes need to release through drilling, sampling, grooves and indent.

Vertical channels in the walls should be drilled at the installation log. Horizontal holes are done after the walls are ready. The cable was easier to stretch through pipes, in domestic clearance in advance to lay an auxiliary wire for stringing (conductor).

Routing the cable under the drywall, suspended ceilingsLaying of concealed wiring inside the frame walls, under sheathing of gypsum Board or plastic, as well as various types of ceilings is governed by the building rules SP 31-110-2003 (clause 14.15) and the rules of the SAE (p. 7.1.38.). In accordance with these regulations, the hidden wiring is allowed to be mounted in two ways:

If the walls, base walls or lining made of combustible materials, the conductors (e.g., marking VVG) should be placed in metal pipes, with localization capacity, or in closed boxes. If the building structure is made from noncombustible materials, then the wiring shall consist of wires (cables), flame retardant (e.g., VVGng), while it should be mechanical to protect non-combustible, non-metallic ducts or pipes (e.g. corrugated self-extinguishing pipe). In both cases, the transaction should be subject to recall.

If the wiring is mounted under the skin of the drywall and the support profile are almost closely adjacent to the wall, the wires it is advisable to lay in strobach done in the wall or in the plaster.

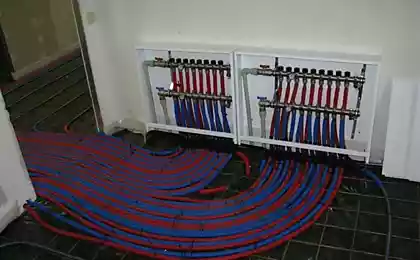

Paving the conductors under the ceilings, under plaster or plastic surfaces and inside frame walls, should be guided by General rules of electrical installations for combustible or non-combustible building construction (presented in the previous sections of the article).Wiring under the floorInstallation of electrical wiring under the floor – the perfect way to create a hidden cable wiring, without resorting to horizontal shtroblenie walls. Cable (main wire) in this case is brought directly to the locations of outlets, switches and junction boxes.

Way to create outdoor wiring depends on what material you plan to do the floors. In General, you should focus on the already known rules of the SAE.

If wiring is installed in the lower layers of the cement floor, then it is quite simple protective strip corrugations. Of course, inside the screed to lay a cable completely without corrugations, but replace the wiring, without resorting to the destruction of the floor surface, in this case will not work. By the way, the complexity of the repair and replacement of cables (wires) is the only significant drawback of outdoor wiring, and it should be taken into account when deciding on the type of electrical wiring.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.forumhouse.ru/articles/house/6712

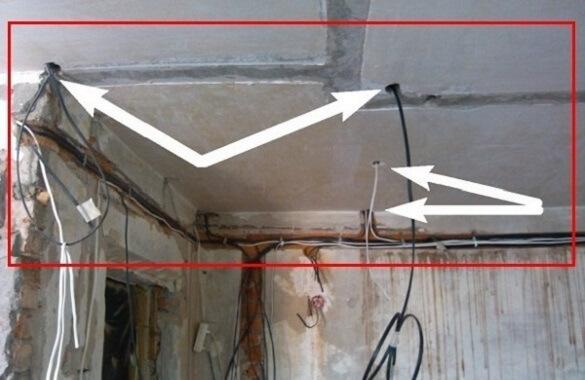

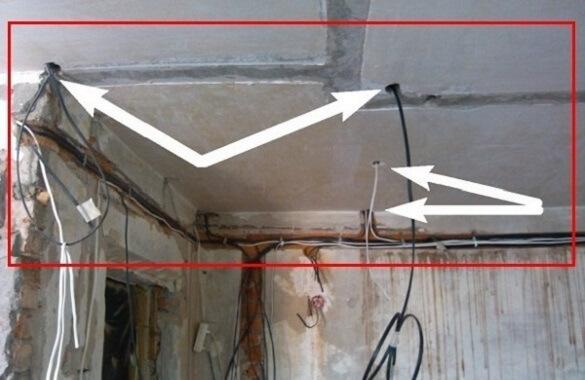

Rules location of cable routesLocation of cable lines in the premises subject to certain rules:

- wiring in the premises should be laid in accordance with a strictly horizontal or strictly vertical lines, in this case, rotation of the cable routing is only possible at 90° (the creation of various diagonals, related to saving of conductors is not permitted);

- the horizontal portions of the transaction should pass at a distance of 10...15 cm from the ceiling;

- the vertical portions of the transaction must defend from the door and window openings for a distance not less than 10 cm.

The wiring is of the open type is laid directly on the surface of the walls. Wire either mounted on special insulators, or stacked in standard cable channels.

Selecting a transaction type when building a house should not be guided by their own preferences, after all, the basis should be taken solely Snips, GOSTs, PUE.Less questions from the "builders of self-taught", if the wiring is mounted on the walls of non-combustible construction materials. First, let's talk specifically about these cases.

The wiring along building structures of non-combustible materialsthe current rules of the SAE permit to use the premises wires and cables exclusively with copper conductors (section 7.1.34.).If the room has walls and ceilings of non-combustible materials (concrete, bricks, aerated concrete blocks, ceramic blocks, gypsum Board GWP, etc.), then it is advisable to mount the wiring is concealed. First, it is aesthetically pleasing, and secondly, it is safe in terms of accidental mechanical damage and, thirdly, the rules of the SAE (p. 7.1.37) it is allowed to mount the wiring is concealed in the walls of non-combustible materials.

In this case we are talking about a residential installation. In attics, basements (especially in an unheated) and indoor technical purposes, it is recommended to do the wiring of an open type.Rules electrical safety rules are as follows: if the building construction is of noncombustible materials, then it is allowed to lay zamonolichivajut irremovable wiring, using technological channels, grooves and voids. Thus as the conductors, it is sufficient to use insulated cables or wires in a protective sheath (e.g., cables VVG). In this case, the wiring is carried out without the use of metal pipes, corrugations and other protective elements.

If the draft is planned later wall plaster, shtroblenie walls under the wiring, as a rule, to resort is not necessary.

Of course, niche for switches and sockets will still have to create in the wall. But dust, and physical work in this case will be much less than if universally shtroblenie walls.

As for the power supply: it should be available at any self-respecting host. Because in the future she will definitely need. The scheme is necessary at least in order to repair the premises not to get a drill in the wire connected to electricity.

If you pave the wiring in the walls, which in the future is not planned to plaster, shtrobleniya in this case can not be avoided. Also stroebe walls have, if the overhaul is the replacement of old wiring and remove the old layer of plaster is not necessary.

Whether or not to create horizontal grooves? Is it possible stroebe bearing walls and concrete floors? Definitive answers to these questions among professional builders are there. Of course, from the point of view of the theory of strength of materials man-made furrows is able to significantly weaken the strength of building structures (like thin cut glass cutter weakens the strong glass). However, the rules of the SAE (p. 7.1.37) allow the laying of electrical networks in the furrows (in strobach) walls, partitions and ceilings. The main thing – do not overdo it with the grooves depth and width.

At the same time the maximum use of existing technological voids (e.g., slabs).

In strobach in steel sleeves, tray and technological channels allowed joint laying of wires and cables belonging to different lines (except vzaimodeistviyami conductors).The wiring along building structures made of combustible materials,a lot of questions concerning the rules of installation of electrical wiring, occurs in people who begin to electrify the premises of combustible building materials. We are basically talking about timber frame and wooden houses. The answers to most questions you can find everything in the same rules as the EMP.

Construction of houses made of combustible construction materials allows you to mount the wiring of both types (hidden and open). Which one to use depends on the preferences of the homeowner. As for protective elements, protecting the wiring from damage, and the building from fire caused by short circuit, their choice depends on the type of cable routing.

There are two ways of routing of open wiring in the premises:

Installation of retro-posting. The wiring in the cable channels. Installation of retro-wiringHow the design of retro-wiring conforms to the rules of the SAE – a moot point. These regulations create a transaction of this type is not even considered. However, let's try to understand this question.

In the case of retro-wiring, special twisted cable ("retro") is mounted directly on the wall, which is attached by means of small insulators. Given that the conductor has a coating of artificial silk impregnated with a non-flammable composition, it can be attributed to the class of wires, flame retardant. Therefore, installation of retro-posting on walls of combustible materials does not violate the rules of the SAE.

In accordance with the rules of the SAE distance from the conductor to the surface of combustible material must be at least 10 mm, which is ensured by the design of insulators for retro-wiring.

If the wire is much slack, the distance between the insulators can be reduced to 50 cm.

Mounting a retro-wiring, to consider one important caveat: most modern electronic equipment must be connected to the grounding circuit. For this reason, the composition of the posting, you should use a three-core cable (if there is no sale, then its advisable to make your own).

In places the passage of wiring through the wall or ceiling of combustible materials (e.g. wood) the cable (wire) should be laid in a metal pipe, with localization ability. The ends of the pipe should be sealed with non-combustible composition (for example, fire-resistant foam).The localization ability of the pipe is the quality to withstand short circuit in the wiring without burning out the walls of the pipe itself. In order that the pipe had that ability, its walls must be of a certain thickness:

- for copper conductors cross section up to 2.5 mm2 wall thickness is not standardized;

- for copper conductors of 4 mm2 cross-section pipe must have a wall thickness not less than 2.8 mm;

- for copper conductors with cross-section 6-10 mm2 pipe must have a wall thickness not less than 3.2 mm.

Escutcheon when installed on a wall made of combustible materials must have fire-resistant lining (e.g., of asbestos or construction of a plaster solution) with a thickness of 10 mm. At the location of the wiring through combustible construction must be installed on the metal shell with localization ability.

Hidden wiring in the walls made of combustible materials,Particularly strip hidden wiring in the walls made of combustible materials (e.g. wood) are reduced to the fact that the wiring in the voids of these walls and partitions shall be run inside metal tubes, with localization ability (the rules of the SAE 7.1.38.).

The number one rule, and in relation to its implementation of any indulgences can not be. All other options (use plastic flutes, spiral wrap and other protective elements) should obviously be excluded, because from the point of view of fire safety, they are unacceptable.

When routing wires and cables on combustible structures (or inside them) in all cases, must be provided possibility of replacement of conductors.By the way, electrical wiring scattered on the floor, is the most convenient method of arrangement of the hidden wiring in the premises of flammable materials. Grooves to the outlets and switches in this case will be just down from the main roads.

When laying pipes and ducts for electrical wiring in the technological voids combustible constructions the ends of the pipes and ducts should be closed quickly remove non-combustible material (e.g., foam).

Order when mounting wiring replaceable in metal pipes, it was possible to create a sufficient number of turns, in the corners of the electric tracks, you must use distribution boxes. Access to these elements should always remain open.

The inner diameter of the pipe should be chosen so that laid cable inside it took no more than 40% of the total free space. This rule is valid for all safety items (cable-channels, corrugated trays, etc.).It should be noted that the creation of the hidden wiring in rooms with wooden walls – a laborious process. Because the channels for the wiring will have to equip their own forces. Space for pipes need to release through drilling, sampling, grooves and indent.

Vertical channels in the walls should be drilled at the installation log. Horizontal holes are done after the walls are ready. The cable was easier to stretch through pipes, in domestic clearance in advance to lay an auxiliary wire for stringing (conductor).

Routing the cable under the drywall, suspended ceilingsLaying of concealed wiring inside the frame walls, under sheathing of gypsum Board or plastic, as well as various types of ceilings is governed by the building rules SP 31-110-2003 (clause 14.15) and the rules of the SAE (p. 7.1.38.). In accordance with these regulations, the hidden wiring is allowed to be mounted in two ways:

If the walls, base walls or lining made of combustible materials, the conductors (e.g., marking VVG) should be placed in metal pipes, with localization capacity, or in closed boxes. If the building structure is made from noncombustible materials, then the wiring shall consist of wires (cables), flame retardant (e.g., VVGng), while it should be mechanical to protect non-combustible, non-metallic ducts or pipes (e.g. corrugated self-extinguishing pipe). In both cases, the transaction should be subject to recall.

If the wiring is mounted under the skin of the drywall and the support profile are almost closely adjacent to the wall, the wires it is advisable to lay in strobach done in the wall or in the plaster.

Paving the conductors under the ceilings, under plaster or plastic surfaces and inside frame walls, should be guided by General rules of electrical installations for combustible or non-combustible building construction (presented in the previous sections of the article).Wiring under the floorInstallation of electrical wiring under the floor – the perfect way to create a hidden cable wiring, without resorting to horizontal shtroblenie walls. Cable (main wire) in this case is brought directly to the locations of outlets, switches and junction boxes.

Way to create outdoor wiring depends on what material you plan to do the floors. In General, you should focus on the already known rules of the SAE.

If wiring is installed in the lower layers of the cement floor, then it is quite simple protective strip corrugations. Of course, inside the screed to lay a cable completely without corrugations, but replace the wiring, without resorting to the destruction of the floor surface, in this case will not work. By the way, the complexity of the repair and replacement of cables (wires) is the only significant drawback of outdoor wiring, and it should be taken into account when deciding on the type of electrical wiring.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.forumhouse.ru/articles/house/6712

"Learn to sit back!": recipe performance from the author of ReWork

Suburban oasis: how to build a summer shower on the site