1115

Wooden mouse. Project History

Have you ever wondered how things are, how far they go from idea to realization, as just a simple thing? How easy is it to do a comb? A computer mouse? A wooden computer mouse from solid mahogany bar with LCD small screen, with its own e-stuffing and manufactured and braided cable for her? I think you will be interested in my way that I went for 2, 5 years creating my mouse.

60+ pictures + text

Design, engineering, simulation

As I was designing a complete zero, then I went to the case as a complete ignoramus. Bought clay and began to sculpt his dreams mouse.

First, I'm blind mouse that is ideal for me to work on the desktop. She pictures a large dark gray. Then I'm blind mouse that would fit me for the role of mobile (small dark gray). And then I took the children to steal a piece of clay to work, and colleagues have fashioned a mouse, claims the title of "people." She lay perfectly in your hand for most of the male population of our team (pictured colored). And what? Turned banal and dull form, we day and night to pull his arms to the skies. Apparently, among the three standard mouse, any user will find themselves comfortable. The triumph of the ideal?

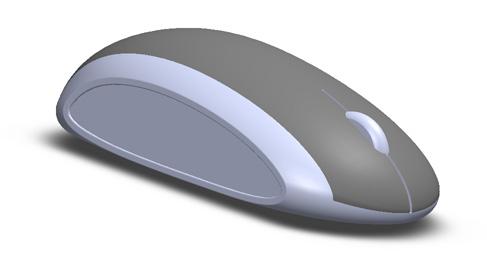

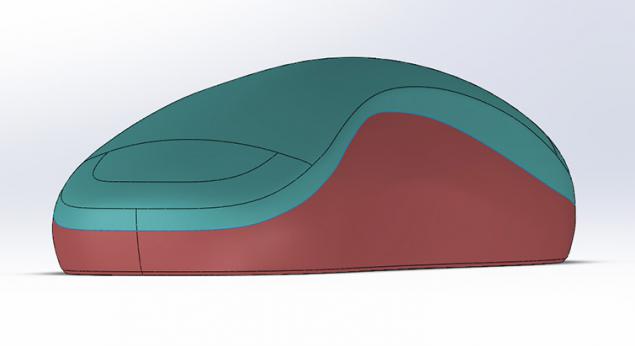

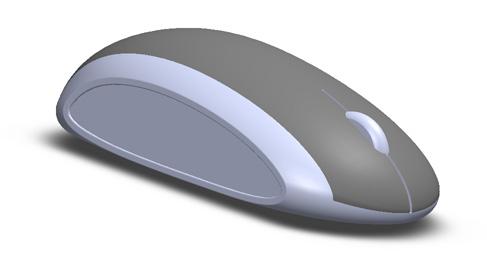

As a result, the computer mouse has been modeled, which, from my point of view, claimed to be the graceful and beautiful.

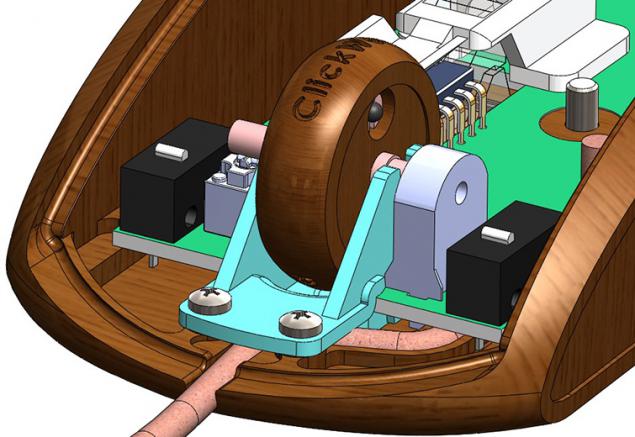

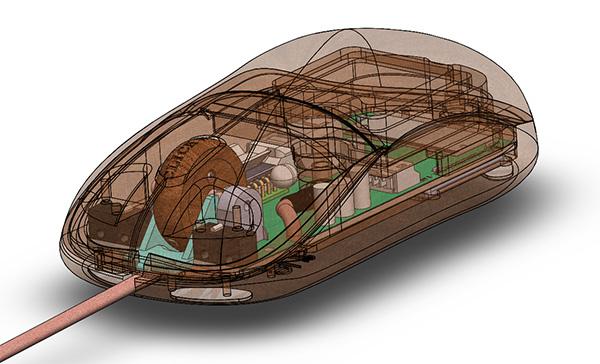

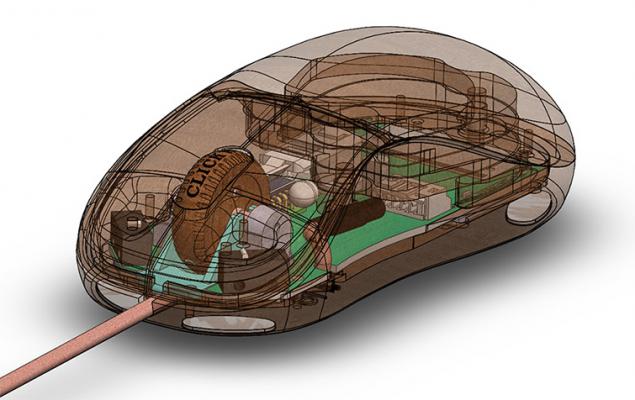

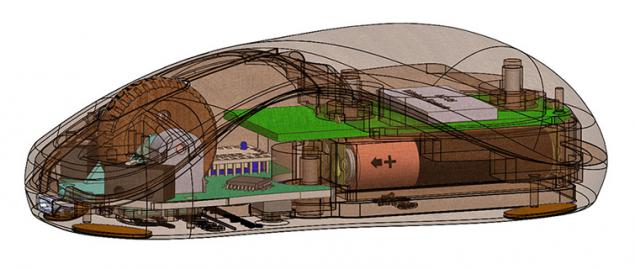

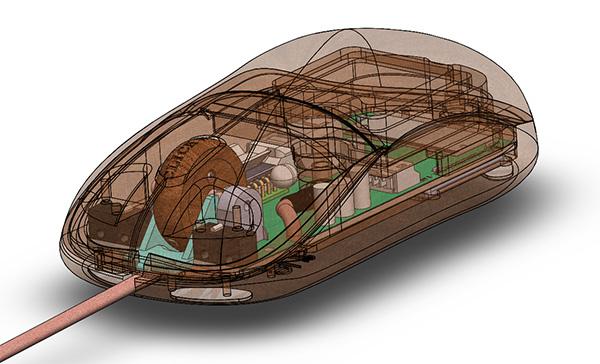

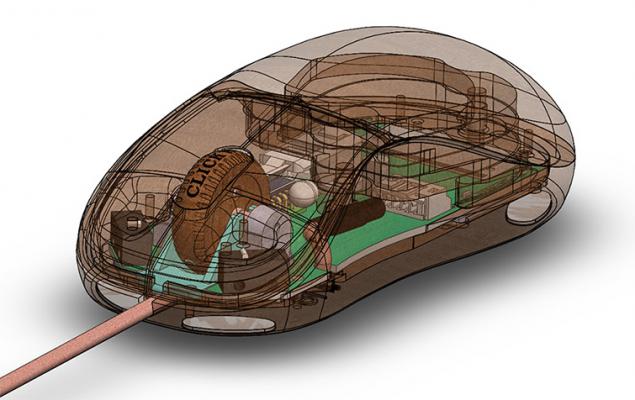

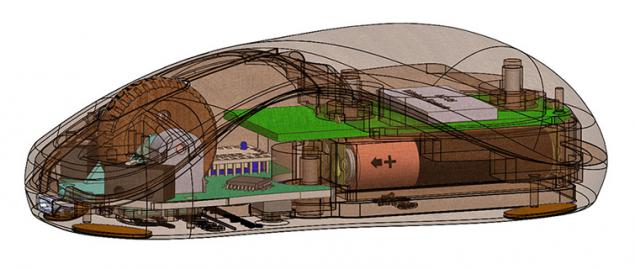

At that time, she loved me madly. And, without thinking twice, I shared a computer model to detail. There were thought fasteners and interfacing with electronic stuffing. It sounds simple, but in fact were spent hundreds of hours of painstaking work.

Thereafter, the parts were grown on 3D-machine to check the collection.

Material - polyamide. In his hand he is sitting well, like a glove. All parts fit together, the assembly process also took place without any problems.

The next step - cutting the tree. Acquired probably a dozen different species of mahogany, but started with Sapele wood, other breeds are waiting in the wings.

...

Live, the design is not liked. The vertical gap between the buttons and the body looked bad and slovenly. Visible technology "sore" when working with wood - wood chips and withdrawal. And the main thing - the keys are not bent, there was a click.

Long thought of the design. Something embarrassing, and there was no sense of satisfaction. Then I realized - mouse lacks solidity. I decided to go back to the original version of the mouse, which I modeled in the beginning, but at the professional level and the use of clay sculpture. In one mouse is made of two different designs. It is convenient for comparison and decision.

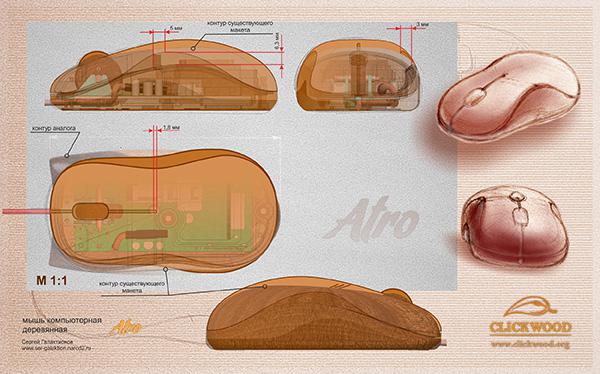

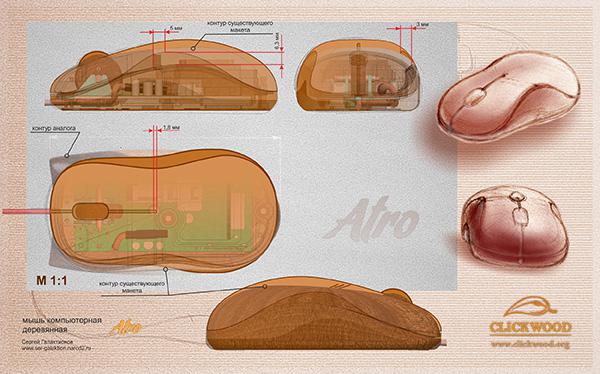

After receiving the final version has been made 3D scanning and transfer surfaces in SolidWorks.

The second model to be not much more successful than the first. Button is not pressed, and fix it in the current model was not possible. Marriage patterns were laid at the DNA level. We need a more integrated approach with simultaneous control and design and technology. Otherwise, nothing happens. Whether or technological excellence, and good design, but not all at once. These characteristics are sitting on opposite sides of the swing. So I throw out all the trash and start over again. Sketch design-modeling testing, cultivation and so on, but with the process control of critical parameters on the one hand, and design on the other. We are looking for a middle ground.

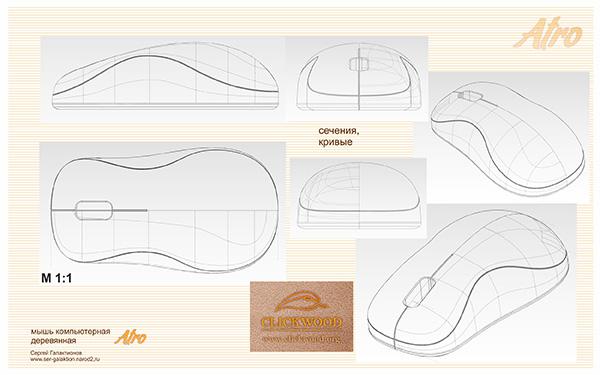

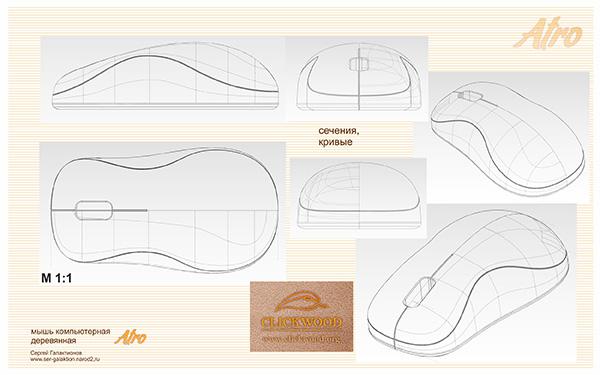

The third model is made in the framework of classical product design cycle. He began with a sketch.

Draw the outline.

Finally, the approved design.

Plasticine layout.

3D scanner, receiving surface.

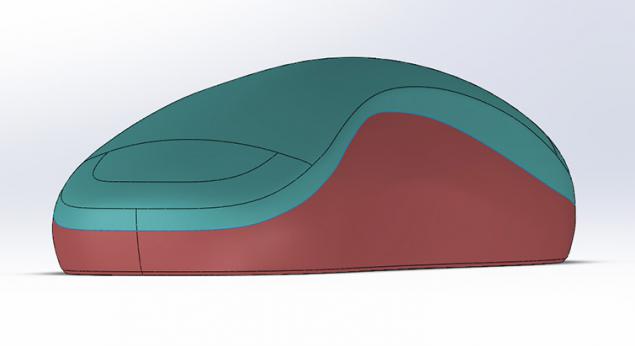

The computer model.

Then began the process of fine-tuning the body. The machine CNC to cut the body, test, modify, and then again to cut. As a result, workable only get a tenth version of the housing. The biggest challenge was to make a comfortable keystroke. As a result, in some areas the thickness of the wood decreased to 0, 7 mm! In the process of refining the body I took a year.

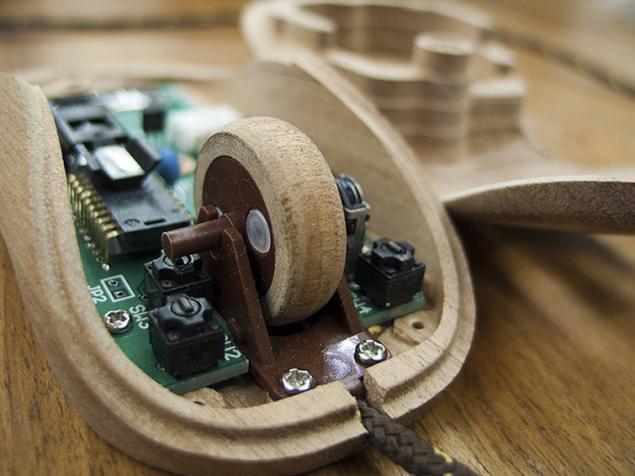

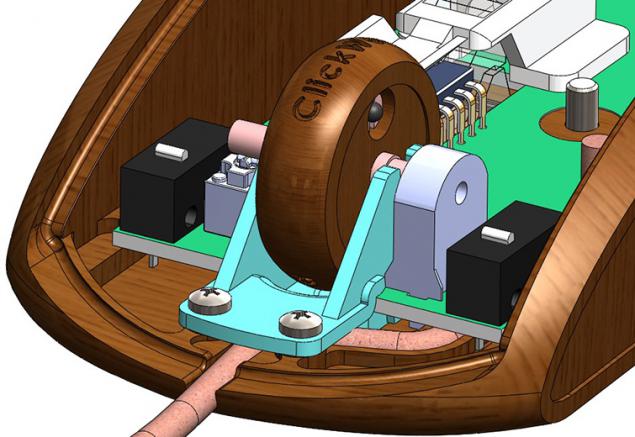

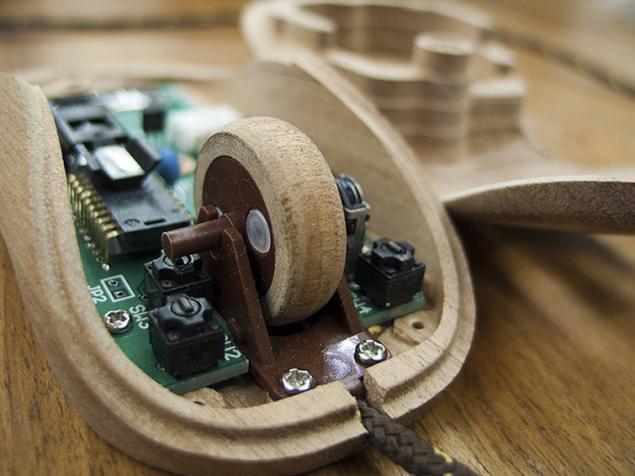

Wood were also made by the wheel and jack.

At the wheel, I paid a laser engraved with the brand Clickwood.

On the approach of the eleventh version of the body, where I made small changes. I also began to develop a wireless version of the mouse. Wireless modules based on technology bluetooth, Optosensor - Laser. AAA Batteries, 2 pieces, with the possibility of replacement. When recharging the mouse will continue to work. All the elements are very tight, with the arrangement had to be pretty smash his head. As a container for batteries is a cavity specially carved in the wooden body of the mouse.

Wooden parts

Working with wood begins with the selection of the wood. Boards should be the correct geometry, have a minimum of knots and defects, and have the necessary humidity.

Initially the board is dried at home. A minimum of six months.

After the board is cut into bars of a small size, which finally dried for several weeks at the place of further processing. At all stages, the humidity is controlled by a special device. If we neglect the drying process, the tree loses its geometric stability, and production and operation of the mouse becomes impossible.

Prepared bars CNC machined using a specially developed program.

From the beginning of creation until the final details and the details of the mouse assembly is rigidly fixed on a metal snap to any of the stages of the item has not changed its shape and geometric dimensions.

...

The treatment of the upper part of the mouse has to do with a jeweler's precision as its profile is designed for soft clicks and in some places very thin. I control the pressing force grammometrom. In normal mice, it varies from 50 to 75 HS. I try to win 50 HS.

With the tree in my project linked the greatest difficulties. Moreover, it is the most significant part of the cost, and the share of marriage here is very high. Wood - anisotropic material. It may lead, can get vices be chipped, or simply an error in topcoat technology can lead to that housing the mouse is sent to the trash. I confess that I'm processing technology is still improving and is not fully convinced that he had found the right. For the statistics: in the first batch of ten housings to the finished product came only three. Therefore, part of the process chain associated with the tree, is critical to the cost and quality of the finished product. Above it is a permanent job.

In the future, I plan to work with the bone. In particular, it has engaged in the creation of the wheel bone.

The electronic part

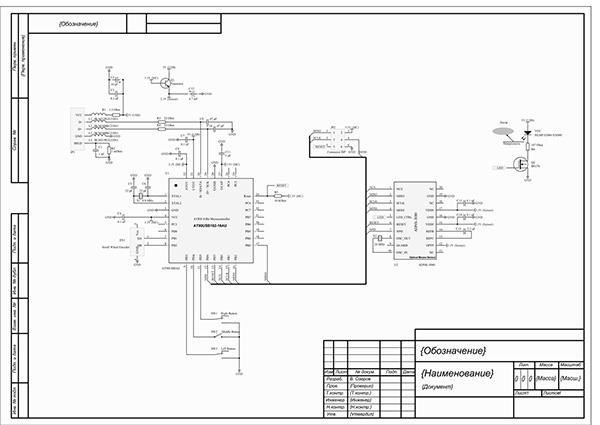

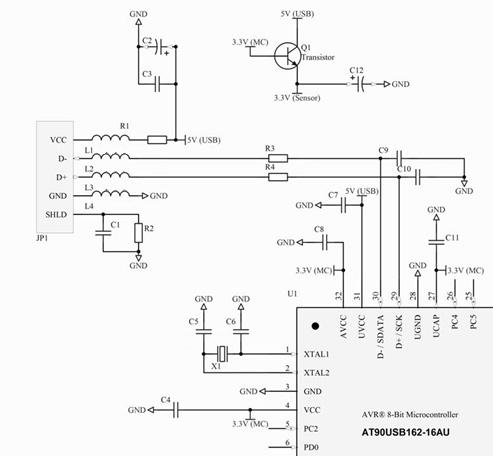

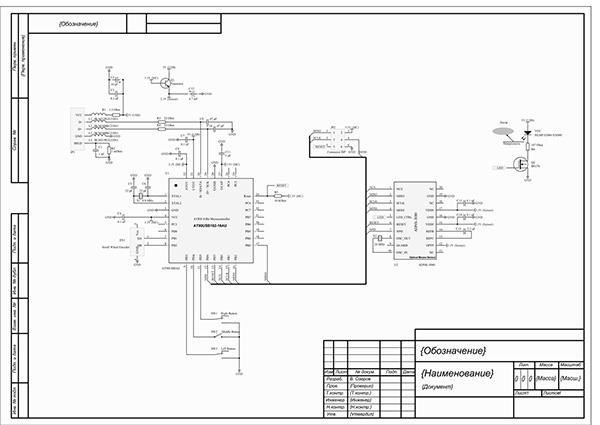

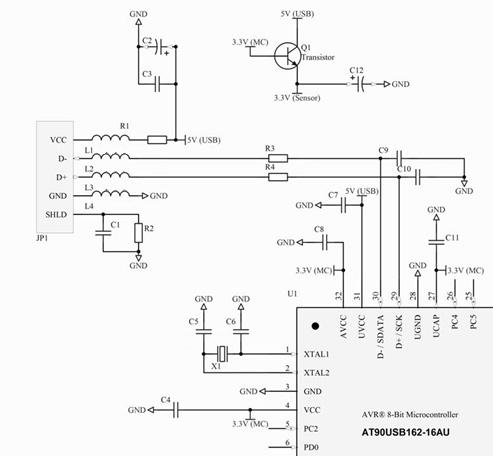

The first scheme mouse I developed independently. As the sensor took a top optical sensor ADNS-3090 the company Avago, brains became controller of the company Atmel, the remaining components of brand companies like Murata, Yageo, Geyer, Omron and Molex.

Particular attention is paid to quality nutrition mouse, then, in my opinion, his perfectionism reached absolute

The first working breadboard.

skip prototypes, will not delay the post

The black finish, final.

There have also been experimenting with different buttons. I always tried to pick out among other quiet mouse. Well, I just do it myself, I decided to conduct an experiment and make a mouse and test it in the work. To do this, click the left and right "Mikrikov" replaced the soft and quiet, to use for the center button (notice that the center button clicks are always quieter?). It created a special version of the board, and which are mounted three equal "mikrika."

Mouse was a couple of weeks in my operation, and I share the conclusion: in my case, no clicks - it's not comfortable. Wood absorbs some click, and it seems that the tight wooden keys, and you have to press harder. It's hard to describe the feeling, but the closest analogy - as if a finger is the mouse button from soft, to crumb, wood, and for sure it is necessary to click further squeezed. The experiment can be considered successful, because to get a clear result of what should be the response of mouse click - a clear, resonant, uniquely interpreted.

I picked up and bought mouse game gold-plated connectors. As usual in China. I do not know about "good contact", but in harmony with the tree perfectly.

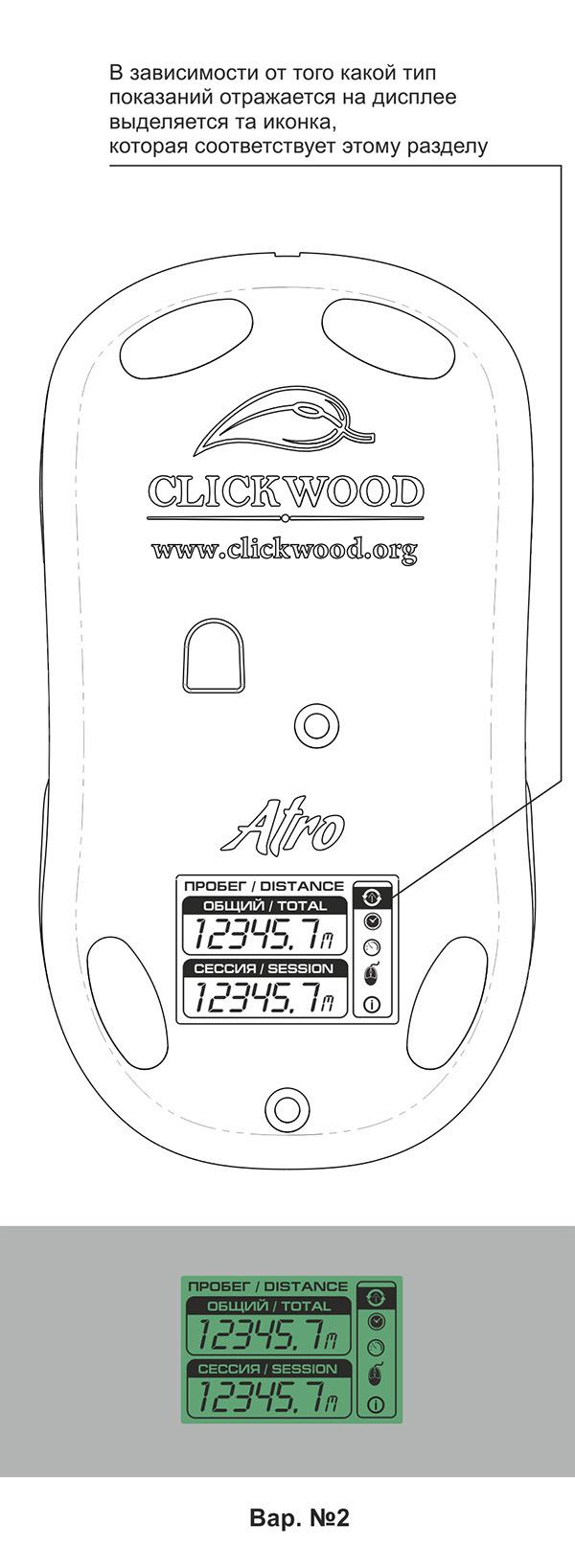

Small screen, flashing

Inspired by the idea to place the mouse in the display, he began his search among hundreds of suppliers. The requirements were simple: strict dimensional limits and the possibility of at least a symbolic display of at least eight familiarity. While picking up, I learned almost all displays. They vary by type: character and graphics, technology: TAB, COG, TFT, OLED, LCD, E-Paper and others. Each type or technology has a lot more varieties, sizes, colors, lights, and so forth. In general, it was what to delve.

Break half of the internet, I found out that I needed a size produces only one company in the whole world. All other options are clearly greater in size. And even I found the display hardly placed inside the mouse. Alternatively considered custom display that I could make for my needs, but it is a very expensive option for me (about a hundred thousand rubles). For the first model is quite suitable graphic display with a resolution of 128 x 64 pixels, which I chose.

In order to understand how to really look and combined with my mouse display, I had to be ordered from the manufacturer all kinds of display. What do these species? The model name consists of alphanumeric combinations unpronounceable type FP12P629AU12. All of them are composed of various blocks and clearly explained in the specification. For example, the sample can be collected from the blocks FP.12.P.629A.U12, where encrypted type, size, voltage controller, operating temperature range and other information about the model. And the last block of the most cunning. It can be several tens of values, each of which is a particular combination of characteristics such as availability and highlight color, background color, character color, a range of degrees, from which information is read clearly. That's just the parameters were interesting to me.

As a result, "try" I ordered 18 of various modifications. Manufacturer agreed, but said that the minimum order - 5 displays for each modification. I had nowhere to go and I had to accept, knowing that 90% will go into the garbage. And in one of the cloudy days express delivery service brought me home a huge box in which you can live homeless medium build. In the box there were 18 smaller boxes, each of which is freely placed 5 displeychike securely fixed for long-distance trips in cold Russia. Concomitant package was so much that the mother-enough to hide a few beds for winter.

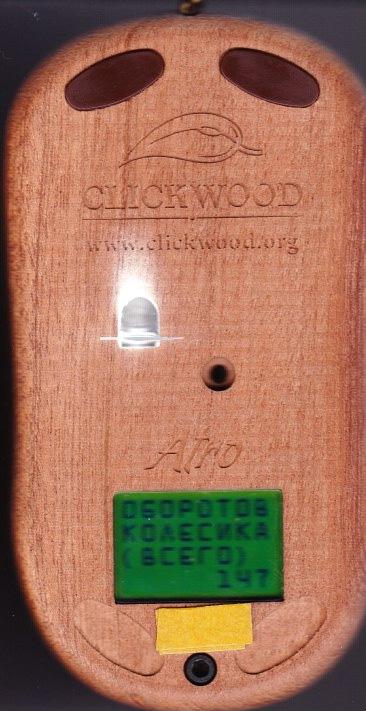

Finally, after thorough testing on a specially assembled stand fit for the series turned out to be two displays. They differ only background: gray and yellow-green. It is their and I will offer to complete mouse. By default, I plan to put the yellow-green, but it will be available two versions: the display with a gray background and the mouse does not display.

But the main intrigue was the kind of information can be displayed on a screen? I was offered different ideas: the ambient temperature, an indication of the arrival of letters, something else is not very original.

My train of thought was going the other way. To begin with, there are two significant limitations on display operational information: the presence of a user in front of the huge and high quality source of any information (monitor) and the need to turn the mouse for more information. In addition, the screen is small, low resolution, LED interferes with normal reading. Therefore, the conclusion I turned one: the information should be just entertaining, applied value that tends to zero, but WOW! -effect To be a killer.

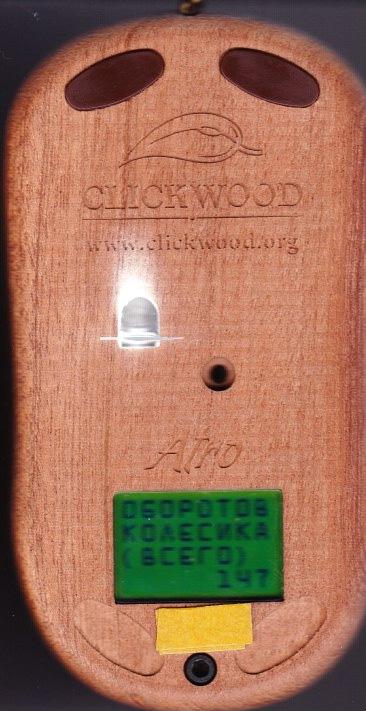

What kind of information can be of such a nature from ordinary complexity of the device? Its a bit: run, time use, speed of movement, number of clicks and scroll wheel. From the latter option, I decided to give up, because I thought he was uninteresting. The remaining attributes are session binding (recent use of a mouse from the time the power supply is turned, that connect to the computer or turn on the computer itself) and to the entire lifetime of the mouse. For example, the user can click at any time to find out how many times he hit the left mouse button or mouse as it ran in meters per day or from the time of its purchase. The information is absolutely useless, but especially curious will understand how much he tormented mouse. If there are other interesting ideas, they will be to implement the new firmware.

Also added a summary of the mouse (model number and click Firmware, the month of manufacture) and the small screen setting. It will be possible to select a language and a system of measures (English or Metric). To store all this information had to be added to the diagram flash-memory persistence.

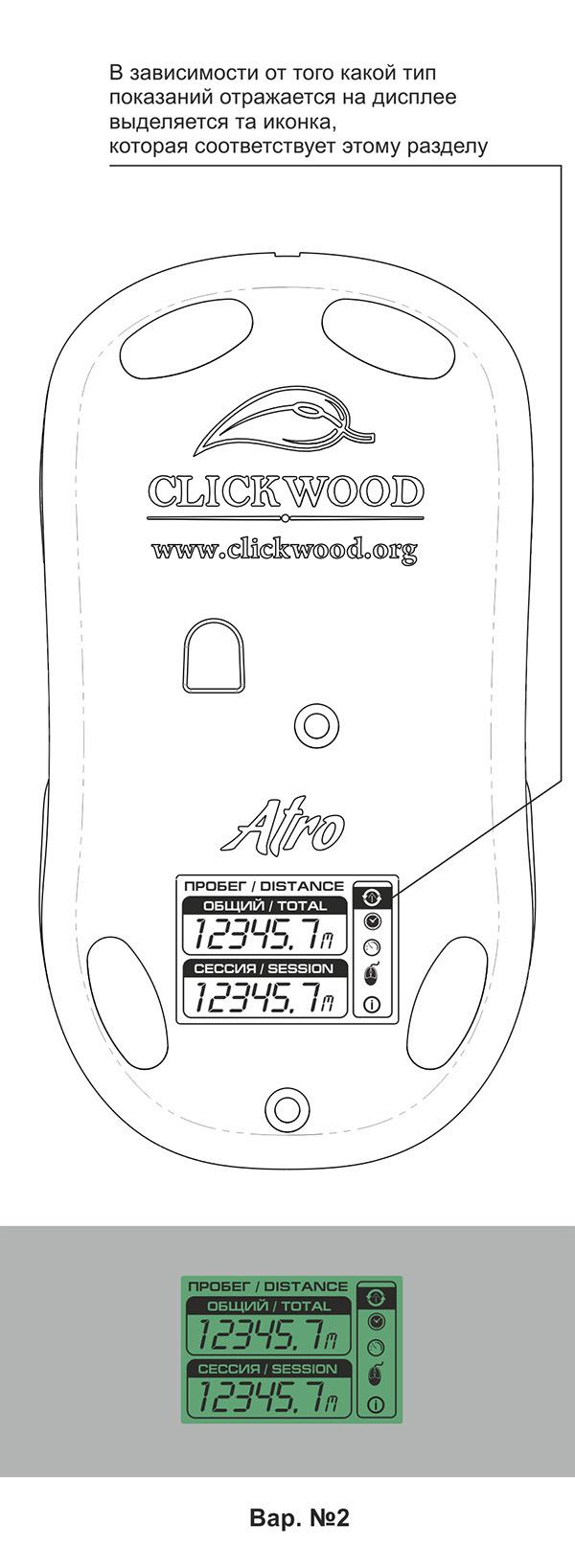

To put this amount of information, I had to break all the screens. Each screen displays one type of information, and displays the settings for the session and for all time. A total of six screens, which are changed with the mouse wheel.

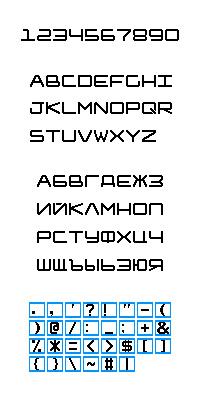

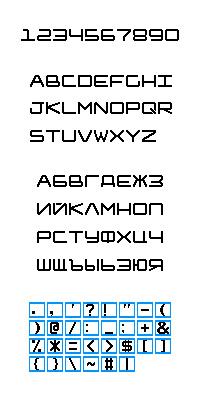

The first version was implemented in clear text key, which even developed several options for font.

I did firmware to evaluate how text looks created using a mouse on a screen font. Terrible looks, what to say.

It is now obvious that need graphics on a screen rather than a set of character information. So I attracted to the work of the designer, and together we have prepared three variants of graphical performance, as a result of the most successful has been recognized as the second option.

Of course, such a design require higher resolution, so it had to be adapted.

But that's not the end of history. Once picked up the small screen for the mouse, I made an order for the test batch maketok. In the end, came the small screen, but for some reason the number of findings which differ from what is stated in the specification (datasheet). At the request of the manufacturer came the answer, that, well, okay, it's a small modification, and it does not affect performance. Meanwhile, the missing two conductors responsible for the brightness of the display graphics.

It was all very suspicious. And just as the water looked. Altered payment under the modified screen is soldered, and then it turned out that the screen is very dim. As if the batteries run down device. And it turned out after a long and painstaking work on the search and selection of the small screen, the purchase of a trial lot of modifications and testing. Time, money, and so on.

But the story turned out to be a good ending. After correspondence with the Chinese, it became clear that the small screen can now adjust its contrast directly from the firmware. Podlechites firmware, and everything was just great show!

All displayed as planned: mileage, speed, number of clicks and stuff.

Later firmware also repeatedly changed: there was a setting to change the language. Two languages on the same screen is bad - deteriorates readability, the English-language user Cyrillic abracadabra will only irritate, and may in the future need to support other languages. The difficulties began when I tried to align the mouse run. It seems that there is a complex: the optical sensor transmits an increment of two coordinates, which is necessary to bring the system up and add on module to the current value. That's the whole run.

But as it turned out, not so simple. Two people with mice, which are set to the same sensor can get dramatically different results! The fact is that the resolution of the sensor (sensitivity) is very strongly dependent on the surface on which rides a mouse. The best result is obtained when the mouse rolls on the white paper. Slightly worse than wood and fabric. In the laminate, and the film really bad. Claimed passport sensitivity is achieved only in ideal from the point of view of the sensor surfaces.

For the end user it does not matter. He connects the mouse and by trial and error in the operating system exposes a comfortable speed of movement of the cursor. The system remembers this ratio and uses it to increase or decrease the value of the increment of coordinates movement.

But it is quite another thing, if your intention is to read these parameters directly from the mouse. The mouse on the same surface will show the result of one meter run, on the other - and a half. Speed will "lie." And with that something must be done.

Presented?

I'm in shock. Wow!

Source:

60+ pictures + text

Design, engineering, simulation

As I was designing a complete zero, then I went to the case as a complete ignoramus. Bought clay and began to sculpt his dreams mouse.

First, I'm blind mouse that is ideal for me to work on the desktop. She pictures a large dark gray. Then I'm blind mouse that would fit me for the role of mobile (small dark gray). And then I took the children to steal a piece of clay to work, and colleagues have fashioned a mouse, claims the title of "people." She lay perfectly in your hand for most of the male population of our team (pictured colored). And what? Turned banal and dull form, we day and night to pull his arms to the skies. Apparently, among the three standard mouse, any user will find themselves comfortable. The triumph of the ideal?

As a result, the computer mouse has been modeled, which, from my point of view, claimed to be the graceful and beautiful.

At that time, she loved me madly. And, without thinking twice, I shared a computer model to detail. There were thought fasteners and interfacing with electronic stuffing. It sounds simple, but in fact were spent hundreds of hours of painstaking work.

Thereafter, the parts were grown on 3D-machine to check the collection.

Material - polyamide. In his hand he is sitting well, like a glove. All parts fit together, the assembly process also took place without any problems.

The next step - cutting the tree. Acquired probably a dozen different species of mahogany, but started with Sapele wood, other breeds are waiting in the wings.

...

Live, the design is not liked. The vertical gap between the buttons and the body looked bad and slovenly. Visible technology "sore" when working with wood - wood chips and withdrawal. And the main thing - the keys are not bent, there was a click.

Long thought of the design. Something embarrassing, and there was no sense of satisfaction. Then I realized - mouse lacks solidity. I decided to go back to the original version of the mouse, which I modeled in the beginning, but at the professional level and the use of clay sculpture. In one mouse is made of two different designs. It is convenient for comparison and decision.

After receiving the final version has been made 3D scanning and transfer surfaces in SolidWorks.

The second model to be not much more successful than the first. Button is not pressed, and fix it in the current model was not possible. Marriage patterns were laid at the DNA level. We need a more integrated approach with simultaneous control and design and technology. Otherwise, nothing happens. Whether or technological excellence, and good design, but not all at once. These characteristics are sitting on opposite sides of the swing. So I throw out all the trash and start over again. Sketch design-modeling testing, cultivation and so on, but with the process control of critical parameters on the one hand, and design on the other. We are looking for a middle ground.

The third model is made in the framework of classical product design cycle. He began with a sketch.

Draw the outline.

Finally, the approved design.

Plasticine layout.

3D scanner, receiving surface.

The computer model.

Then began the process of fine-tuning the body. The machine CNC to cut the body, test, modify, and then again to cut. As a result, workable only get a tenth version of the housing. The biggest challenge was to make a comfortable keystroke. As a result, in some areas the thickness of the wood decreased to 0, 7 mm! In the process of refining the body I took a year.

Wood were also made by the wheel and jack.

At the wheel, I paid a laser engraved with the brand Clickwood.

On the approach of the eleventh version of the body, where I made small changes. I also began to develop a wireless version of the mouse. Wireless modules based on technology bluetooth, Optosensor - Laser. AAA Batteries, 2 pieces, with the possibility of replacement. When recharging the mouse will continue to work. All the elements are very tight, with the arrangement had to be pretty smash his head. As a container for batteries is a cavity specially carved in the wooden body of the mouse.

Wooden parts

Working with wood begins with the selection of the wood. Boards should be the correct geometry, have a minimum of knots and defects, and have the necessary humidity.

Initially the board is dried at home. A minimum of six months.

After the board is cut into bars of a small size, which finally dried for several weeks at the place of further processing. At all stages, the humidity is controlled by a special device. If we neglect the drying process, the tree loses its geometric stability, and production and operation of the mouse becomes impossible.

Prepared bars CNC machined using a specially developed program.

From the beginning of creation until the final details and the details of the mouse assembly is rigidly fixed on a metal snap to any of the stages of the item has not changed its shape and geometric dimensions.

...

The treatment of the upper part of the mouse has to do with a jeweler's precision as its profile is designed for soft clicks and in some places very thin. I control the pressing force grammometrom. In normal mice, it varies from 50 to 75 HS. I try to win 50 HS.

With the tree in my project linked the greatest difficulties. Moreover, it is the most significant part of the cost, and the share of marriage here is very high. Wood - anisotropic material. It may lead, can get vices be chipped, or simply an error in topcoat technology can lead to that housing the mouse is sent to the trash. I confess that I'm processing technology is still improving and is not fully convinced that he had found the right. For the statistics: in the first batch of ten housings to the finished product came only three. Therefore, part of the process chain associated with the tree, is critical to the cost and quality of the finished product. Above it is a permanent job.

In the future, I plan to work with the bone. In particular, it has engaged in the creation of the wheel bone.

The electronic part

The first scheme mouse I developed independently. As the sensor took a top optical sensor ADNS-3090 the company Avago, brains became controller of the company Atmel, the remaining components of brand companies like Murata, Yageo, Geyer, Omron and Molex.

Particular attention is paid to quality nutrition mouse, then, in my opinion, his perfectionism reached absolute

The first working breadboard.

skip prototypes, will not delay the post

The black finish, final.

There have also been experimenting with different buttons. I always tried to pick out among other quiet mouse. Well, I just do it myself, I decided to conduct an experiment and make a mouse and test it in the work. To do this, click the left and right "Mikrikov" replaced the soft and quiet, to use for the center button (notice that the center button clicks are always quieter?). It created a special version of the board, and which are mounted three equal "mikrika."

Mouse was a couple of weeks in my operation, and I share the conclusion: in my case, no clicks - it's not comfortable. Wood absorbs some click, and it seems that the tight wooden keys, and you have to press harder. It's hard to describe the feeling, but the closest analogy - as if a finger is the mouse button from soft, to crumb, wood, and for sure it is necessary to click further squeezed. The experiment can be considered successful, because to get a clear result of what should be the response of mouse click - a clear, resonant, uniquely interpreted.

I picked up and bought mouse game gold-plated connectors. As usual in China. I do not know about "good contact", but in harmony with the tree perfectly.

Small screen, flashing

Inspired by the idea to place the mouse in the display, he began his search among hundreds of suppliers. The requirements were simple: strict dimensional limits and the possibility of at least a symbolic display of at least eight familiarity. While picking up, I learned almost all displays. They vary by type: character and graphics, technology: TAB, COG, TFT, OLED, LCD, E-Paper and others. Each type or technology has a lot more varieties, sizes, colors, lights, and so forth. In general, it was what to delve.

Break half of the internet, I found out that I needed a size produces only one company in the whole world. All other options are clearly greater in size. And even I found the display hardly placed inside the mouse. Alternatively considered custom display that I could make for my needs, but it is a very expensive option for me (about a hundred thousand rubles). For the first model is quite suitable graphic display with a resolution of 128 x 64 pixels, which I chose.

In order to understand how to really look and combined with my mouse display, I had to be ordered from the manufacturer all kinds of display. What do these species? The model name consists of alphanumeric combinations unpronounceable type FP12P629AU12. All of them are composed of various blocks and clearly explained in the specification. For example, the sample can be collected from the blocks FP.12.P.629A.U12, where encrypted type, size, voltage controller, operating temperature range and other information about the model. And the last block of the most cunning. It can be several tens of values, each of which is a particular combination of characteristics such as availability and highlight color, background color, character color, a range of degrees, from which information is read clearly. That's just the parameters were interesting to me.

As a result, "try" I ordered 18 of various modifications. Manufacturer agreed, but said that the minimum order - 5 displays for each modification. I had nowhere to go and I had to accept, knowing that 90% will go into the garbage. And in one of the cloudy days express delivery service brought me home a huge box in which you can live homeless medium build. In the box there were 18 smaller boxes, each of which is freely placed 5 displeychike securely fixed for long-distance trips in cold Russia. Concomitant package was so much that the mother-enough to hide a few beds for winter.

Finally, after thorough testing on a specially assembled stand fit for the series turned out to be two displays. They differ only background: gray and yellow-green. It is their and I will offer to complete mouse. By default, I plan to put the yellow-green, but it will be available two versions: the display with a gray background and the mouse does not display.

But the main intrigue was the kind of information can be displayed on a screen? I was offered different ideas: the ambient temperature, an indication of the arrival of letters, something else is not very original.

My train of thought was going the other way. To begin with, there are two significant limitations on display operational information: the presence of a user in front of the huge and high quality source of any information (monitor) and the need to turn the mouse for more information. In addition, the screen is small, low resolution, LED interferes with normal reading. Therefore, the conclusion I turned one: the information should be just entertaining, applied value that tends to zero, but WOW! -effect To be a killer.

What kind of information can be of such a nature from ordinary complexity of the device? Its a bit: run, time use, speed of movement, number of clicks and scroll wheel. From the latter option, I decided to give up, because I thought he was uninteresting. The remaining attributes are session binding (recent use of a mouse from the time the power supply is turned, that connect to the computer or turn on the computer itself) and to the entire lifetime of the mouse. For example, the user can click at any time to find out how many times he hit the left mouse button or mouse as it ran in meters per day or from the time of its purchase. The information is absolutely useless, but especially curious will understand how much he tormented mouse. If there are other interesting ideas, they will be to implement the new firmware.

Also added a summary of the mouse (model number and click Firmware, the month of manufacture) and the small screen setting. It will be possible to select a language and a system of measures (English or Metric). To store all this information had to be added to the diagram flash-memory persistence.

To put this amount of information, I had to break all the screens. Each screen displays one type of information, and displays the settings for the session and for all time. A total of six screens, which are changed with the mouse wheel.

The first version was implemented in clear text key, which even developed several options for font.

I did firmware to evaluate how text looks created using a mouse on a screen font. Terrible looks, what to say.

It is now obvious that need graphics on a screen rather than a set of character information. So I attracted to the work of the designer, and together we have prepared three variants of graphical performance, as a result of the most successful has been recognized as the second option.

Of course, such a design require higher resolution, so it had to be adapted.

But that's not the end of history. Once picked up the small screen for the mouse, I made an order for the test batch maketok. In the end, came the small screen, but for some reason the number of findings which differ from what is stated in the specification (datasheet). At the request of the manufacturer came the answer, that, well, okay, it's a small modification, and it does not affect performance. Meanwhile, the missing two conductors responsible for the brightness of the display graphics.

It was all very suspicious. And just as the water looked. Altered payment under the modified screen is soldered, and then it turned out that the screen is very dim. As if the batteries run down device. And it turned out after a long and painstaking work on the search and selection of the small screen, the purchase of a trial lot of modifications and testing. Time, money, and so on.

But the story turned out to be a good ending. After correspondence with the Chinese, it became clear that the small screen can now adjust its contrast directly from the firmware. Podlechites firmware, and everything was just great show!

All displayed as planned: mileage, speed, number of clicks and stuff.

Later firmware also repeatedly changed: there was a setting to change the language. Two languages on the same screen is bad - deteriorates readability, the English-language user Cyrillic abracadabra will only irritate, and may in the future need to support other languages. The difficulties began when I tried to align the mouse run. It seems that there is a complex: the optical sensor transmits an increment of two coordinates, which is necessary to bring the system up and add on module to the current value. That's the whole run.

But as it turned out, not so simple. Two people with mice, which are set to the same sensor can get dramatically different results! The fact is that the resolution of the sensor (sensitivity) is very strongly dependent on the surface on which rides a mouse. The best result is obtained when the mouse rolls on the white paper. Slightly worse than wood and fabric. In the laminate, and the film really bad. Claimed passport sensitivity is achieved only in ideal from the point of view of the sensor surfaces.

For the end user it does not matter. He connects the mouse and by trial and error in the operating system exposes a comfortable speed of movement of the cursor. The system remembers this ratio and uses it to increase or decrease the value of the increment of coordinates movement.

But it is quite another thing, if your intention is to read these parameters directly from the mouse. The mouse on the same surface will show the result of one meter run, on the other - and a half. Speed will "lie." And with that something must be done.

Presented?

I'm in shock. Wow!

Source: