829

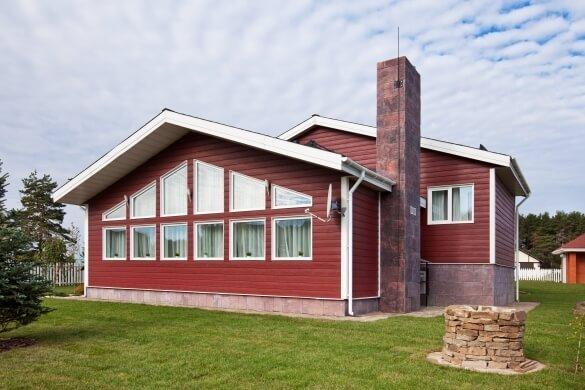

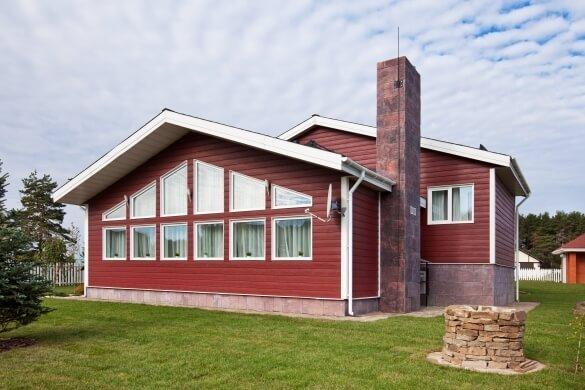

Siding KEDRAL- environmental friendliness, durability, resistance to external environmental sustainability

CEDRAL - universal covering material for interior and exterior use in private and commercial construction. Fiber cement siding of this collection comes in the form of boards. Its surface structure imitates the natural wood of valuable species such quality that distinguish it from the original visually practically impossible.

In addition to the aesthetic qualities of the material also has a high technical and operational characteristics - environmental friendliness, durability, resistance to adverse environmental conditions and mechanical damage, durability. In addition, fiber cement siding CEDRAL broadest scope - be operated in a temperature range of up to + -50⁰S 60⁰S. Installation can be carried out at any time of the year, prolonging the construction season for the entire year.

In view of raw material component has fiber cement siding CEDRAL increased mass, compared with a polymeric or metallic. However, the widespread belief that it is difficult to work with, and have necessarily to hire professionals - confusing, installation does not require special equipment and skill. Anyone with a minimal set of tools, clearly following the accompanying instructions, do the installation.

Fiber cement siding Cedral, made in Belgium, the company Eternit.

There are two types of boards - CEDRAL (Kedral) and CEDRAL Click (Click Kedral). In both cases, the board has a standard length - 3600 mm but different thickness and width in the first case - thickness 10 mm, width 190 mm, in the second - 12 mm, width 186 mm. Due to the dimensions of siding, cladding, even large areas carried out in a short time. The company also supplies a wide range of Eternit additional elements to the fiber cement siding Cedral, namely:. Internal and external corner profiles, starting and finishing planks, etc. The color scheme of additional elements correspond to colors of siding

.

The difference between CEDRAL (Kedral) and CEDRAL Click (Kedral Click) not only in the thickness and width, but also the methods of installation - KEDRAL typed on a wooden or metal sub-system overlap and fastened with screws or ershennye nails and KEDRAL Click - on a wooden or metal subsystem klyaymery, by tongue and groove connections.

Mount Technology lap siding KEDRAL

Both types of siding used as a finish coating material in ventilated façade systems, the minimum air gap - 20 mm. Depending on the characteristics of the building, installation of fiber cement siding is divided into several stages.

Substrate Preparation

Before installing the battens need to take care of the walls, which will spend more than a decade under the finish. Stone walls are cleaned of loose particles, large surface defects are eliminated, followed by treatment with a special primer deep penetration. The wooden walls are treated with antiseptic solution and covered with a protective membrane.

Installation of furring and insulation

Crate made of wooden beams, pre-impregnated with antiseptic solution, a width of 40 - 70 mm, the thickness of the insulation depends on the type, but not less than 20 mm. When choosing a timber paying special attention to the humidity - too wet when dry "lead", which will adversely affect the entire system. Orientation guide subsystem depends on the location of the boards on the facade - a vertical trim going horizontal battens and vice versa. Step crates maximum 600 mm. The type of hardware depends on the type and parameters of the base - this may be dowels, screws or screws of suitable diameter and length, fixed in increments of 800 mm. beam width of openings - 40 mm, in places of joining boards - not less than 70 mm

. The insulation material is placed between the joists crates, and the need to mount a specific method depends on its type. Most often it is mineral wool, fixed on a special plastic anchors with big hats, some heaters are mounted vraspor without additional fasteners.

Installation starting profiles and additional elements

To prevent pests (insects, rodents) under the lining, starting with one hundred strap around the perimeter of the building is fixed perforated ventilation profile. Further mounted starter profile, which allows you to set the angle of the first board. After installation, start-up and perforated profiles assembled corner elements - external and internal. Next on the subsystem (wooden bars) in places docking siding is attached a rubber band - EPDM tape, it will protect the wood from moisture and avoid rotting bar

. Mounting board CEDRAL

For fixing fiber cement boards are used to crate samozenkuyuschiesya branded stainless steel screws that do not require pre-drilling or ershennye nails. It is more convenient and faster to fix the screws of the board, using the screwdriver, as a function of rotational power control allows you to control the depth of immersion of the fastener. The assembly starts from the bottom up. The first board is installed on the start-profile, overlapping boards - 30 mm. Pay attention to the indentation from the edge of the board - not less than 20 mm in order to prevent damage to the siding. If the length of the wall in the range of 20 meters, the boards are assembled joint to joint, without gaps. If this value is exceeded, the deformation necessary clearance 5.3 mm every 20 meters.

Mount Technology siding KEDRAL Click

Preparation of the base.

Installation of furring and insulation (identical to all options, but the metal subsystem instead of wood can be used).

Installation starting profiles and additional elements.

Physical mechanical properties CEDRAL click are the same as in CEDRAL, differs only in the way of fastening the board. Boards CEDRAL click assembled joint to joint in the specially designed klyaymery. The assembly starts with a standard - from top to bottom, the first board is installed on the start-profile, top fixed klyaymerom on each block crates. The bottom of the following boards installed on klyaymery from the previous board, and the top again fixed clamps on bars. The entire building is coated on this algorithm. An exception is the finishing board fiber cement siding with slot connection: if it is a whole, clamps are used if it was necessary to cut - fixing screws on the mushroom hat, painted in the color of the board

.

The subtleties of working with fiber cement siding

CEDRAL boards lend themselves perfectly to any type of treatment - they can be sawed, drilled or milled. These manipulations do not require special equipment - suitable circular saw or "Bulgarian" with a special disc for cutting stone (Carbide powder-coated or tipped). Another option - use powerful electric jigsaw with the corresponding headset. When the work is required to use safety goggles and a respirator. To get an even cut and save the decorative board, is to follow a few recommendations.

Processed board shall be secured - otherwise obstruct the process of vibration and worsen outcome

. Fresh cut is handled fine sandpaper - cleaned the tiniest flaws

. Dust, resulting in cutting of material, carefully removed with a dry cloth made of microfiber.

All of these actions are standard mounting devices for any ventilated façade system. Siding KEDRAL not afraid of no rain, no frost and snow or summer heat - the facade of the years will delight its appearance and reliably protect the wall.

In addition to the aesthetic qualities of the material also has a high technical and operational characteristics - environmental friendliness, durability, resistance to adverse environmental conditions and mechanical damage, durability. In addition, fiber cement siding CEDRAL broadest scope - be operated in a temperature range of up to + -50⁰S 60⁰S. Installation can be carried out at any time of the year, prolonging the construction season for the entire year.

In view of raw material component has fiber cement siding CEDRAL increased mass, compared with a polymeric or metallic. However, the widespread belief that it is difficult to work with, and have necessarily to hire professionals - confusing, installation does not require special equipment and skill. Anyone with a minimal set of tools, clearly following the accompanying instructions, do the installation.

Fiber cement siding Cedral, made in Belgium, the company Eternit.

There are two types of boards - CEDRAL (Kedral) and CEDRAL Click (Click Kedral). In both cases, the board has a standard length - 3600 mm but different thickness and width in the first case - thickness 10 mm, width 190 mm, in the second - 12 mm, width 186 mm. Due to the dimensions of siding, cladding, even large areas carried out in a short time. The company also supplies a wide range of Eternit additional elements to the fiber cement siding Cedral, namely:. Internal and external corner profiles, starting and finishing planks, etc. The color scheme of additional elements correspond to colors of siding

.

The difference between CEDRAL (Kedral) and CEDRAL Click (Kedral Click) not only in the thickness and width, but also the methods of installation - KEDRAL typed on a wooden or metal sub-system overlap and fastened with screws or ershennye nails and KEDRAL Click - on a wooden or metal subsystem klyaymery, by tongue and groove connections.

Mount Technology lap siding KEDRAL

Both types of siding used as a finish coating material in ventilated façade systems, the minimum air gap - 20 mm. Depending on the characteristics of the building, installation of fiber cement siding is divided into several stages.

Substrate Preparation

Before installing the battens need to take care of the walls, which will spend more than a decade under the finish. Stone walls are cleaned of loose particles, large surface defects are eliminated, followed by treatment with a special primer deep penetration. The wooden walls are treated with antiseptic solution and covered with a protective membrane.

Installation of furring and insulation

Crate made of wooden beams, pre-impregnated with antiseptic solution, a width of 40 - 70 mm, the thickness of the insulation depends on the type, but not less than 20 mm. When choosing a timber paying special attention to the humidity - too wet when dry "lead", which will adversely affect the entire system. Orientation guide subsystem depends on the location of the boards on the facade - a vertical trim going horizontal battens and vice versa. Step crates maximum 600 mm. The type of hardware depends on the type and parameters of the base - this may be dowels, screws or screws of suitable diameter and length, fixed in increments of 800 mm. beam width of openings - 40 mm, in places of joining boards - not less than 70 mm

. The insulation material is placed between the joists crates, and the need to mount a specific method depends on its type. Most often it is mineral wool, fixed on a special plastic anchors with big hats, some heaters are mounted vraspor without additional fasteners.

Installation starting profiles and additional elements

To prevent pests (insects, rodents) under the lining, starting with one hundred strap around the perimeter of the building is fixed perforated ventilation profile. Further mounted starter profile, which allows you to set the angle of the first board. After installation, start-up and perforated profiles assembled corner elements - external and internal. Next on the subsystem (wooden bars) in places docking siding is attached a rubber band - EPDM tape, it will protect the wood from moisture and avoid rotting bar

. Mounting board CEDRAL

For fixing fiber cement boards are used to crate samozenkuyuschiesya branded stainless steel screws that do not require pre-drilling or ershennye nails. It is more convenient and faster to fix the screws of the board, using the screwdriver, as a function of rotational power control allows you to control the depth of immersion of the fastener. The assembly starts from the bottom up. The first board is installed on the start-profile, overlapping boards - 30 mm. Pay attention to the indentation from the edge of the board - not less than 20 mm in order to prevent damage to the siding. If the length of the wall in the range of 20 meters, the boards are assembled joint to joint, without gaps. If this value is exceeded, the deformation necessary clearance 5.3 mm every 20 meters.

Mount Technology siding KEDRAL Click

Preparation of the base.

Installation of furring and insulation (identical to all options, but the metal subsystem instead of wood can be used).

Installation starting profiles and additional elements.

Physical mechanical properties CEDRAL click are the same as in CEDRAL, differs only in the way of fastening the board. Boards CEDRAL click assembled joint to joint in the specially designed klyaymery. The assembly starts with a standard - from top to bottom, the first board is installed on the start-profile, top fixed klyaymerom on each block crates. The bottom of the following boards installed on klyaymery from the previous board, and the top again fixed clamps on bars. The entire building is coated on this algorithm. An exception is the finishing board fiber cement siding with slot connection: if it is a whole, clamps are used if it was necessary to cut - fixing screws on the mushroom hat, painted in the color of the board

.

The subtleties of working with fiber cement siding

CEDRAL boards lend themselves perfectly to any type of treatment - they can be sawed, drilled or milled. These manipulations do not require special equipment - suitable circular saw or "Bulgarian" with a special disc for cutting stone (Carbide powder-coated or tipped). Another option - use powerful electric jigsaw with the corresponding headset. When the work is required to use safety goggles and a respirator. To get an even cut and save the decorative board, is to follow a few recommendations.

Processed board shall be secured - otherwise obstruct the process of vibration and worsen outcome

. Fresh cut is handled fine sandpaper - cleaned the tiniest flaws

. Dust, resulting in cutting of material, carefully removed with a dry cloth made of microfiber.

All of these actions are standard mounting devices for any ventilated façade system. Siding KEDRAL not afraid of no rain, no frost and snow or summer heat - the facade of the years will delight its appearance and reliably protect the wall.