723

Energy-saving glass

The problem of keeping warm is especially important for those who decorated his house glass facade. Double glazing in this case gives little effect. The fact that approximately 1/3 of the heat loss occurs through the glass by convection and conduction, and by setting the glazing, this problem can be solved. But the rest of the heat loss (2/3) occur because regular glass passed long heat waves, which give us the heaters. To delay in the building thermal radiation, invented the so-called energy-saving glass. Their use in the construction of town houses, subject to the availability of modern heating and ventilation systems, can be very profitable.

The principle of energy-saving glass

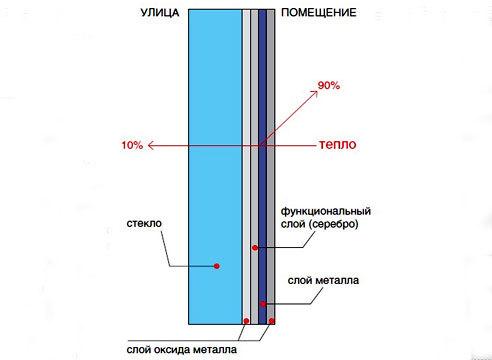

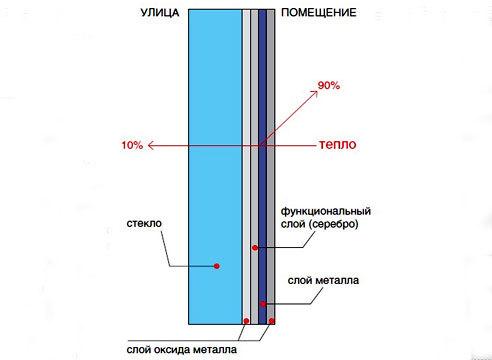

What are glass different from the usual? On one side of the energy-saving glass coated with a special, imperceptible to the eye surface. This kind of filter does not provide the long-wave heat radiation (infrared waves) go outside. It reflects them back into the room. Glass having such properties, also called heat-selective, low-emission. With the first definition of all clear without further ado. The second is connected with the physical concept as the emissivity of the surface or emission. So, the issue of energy-saving glass is much less simple, therefore it is called low emissivity. With the term "selective" is even easier, because it is glass transmits waves of light and heat selectively ranges.

energy-saving glass production secrets

For the production of conventional sheet glass used two ways: vertical (by pulling) and horizontal (metal melt). Last produces so-called float glass, which has excellent optical properties and high light transmission capacity. It is used for the production of energy-saving glass. On the polished surface of float glass is sprayed coating of non-ferrous metals (mainly silver), or their oxides. Due to the electrical conductivity and interference phenomena such glass gains the ability to reflect heat waves in the infrared range and thus reduce heat losses in the room. Energy-saving glass has a metal coating thickness of a few tens of nanometers. It is no different from ordinary glass, and is completely transparent to our eyes. Use energy-saving glass in the composition of glass as full tightness is required for their operation.

In areas with hot climates recommend the use of low-emission glass blackout. They have a low degree of transmittance of sunlight, protecting the room from the heat of summer, which they bring. Such a solar control glass can be of different colors:. Bronze, gray, green, pink

Energy-saving glass: a cover select

Currently, two types of coatings for energy-saving glass: soft (Double Low-E), the so-called I-glass and solid (Low-E), or K-glass

. In the production of energy-saving glass with hard coating (K-glass), a thin layer of metal oxide is sprayed onto the still hot surface of float glass. This coating is particularly durable, so it is called hard. K-glass, greatly reducing heat loss, improves the thermal insulation space, reducing the cost of its heating. Externally, it is no different from the usual and has a high light transmission. K-glass in the pane facing low-emissivity coating in the direction of the room.

Energy-saving glass with a soft coating (I-glass) produced by more sophisticated technology. It has superior characteristics as compared with K-glass, more in particular a light transmission capability and low coefficient of emissivity. Experts estimate that the average size of the window of a country house, equipped with double-glazed glass with an I-save in the heating season as much heat energy as it gives 300 kg of fuel oil or diesel fuel. It should be borne in mind that the I-glass is easily scratched (low abrasion resistance). However, due to the fact that its energy-saving coating is always located inside the glass, on the exploitation of this flaw does not affect.

Energy-saving glass: manufacturers

Energy efficient windows are widely used in many countries. The technology of their production is complex and requires highly skilled manufacturers, so in the world there are only a few companies producing such glass in large volumes. Among them are the Pilkington (UK), PPG (USA), Saint Gobam (France). In Russia, until recently, the bulk of the high-quality imported glass. When completed in the Klin district, Moscow region a new production complex Glaverbelrossiyane were able to use in the glazing of their homes and offices of domestic energy-saving glass.

Energy-saving glass: benefits

If we compare the single-chamber glazed windows with low-E glass with a conventional two-chamber, he:

30-40% superior to the energy-saving properties and has better light transmission;

glass with the same thickness (4 mm), it is lighter, and thus reduces the load on the accessories and the window casement lifetime increases;

has approximately the same price;

safer. For the manufacture of energy efficient windows used only tempered glass obtained by chemical or heat treatment. Compared with conventional tempered glass 5-10 times stronger resists shocks and temperature changes. If it breaks it disintegrates into tiny safe fragments having blunt edges. Low-E glass is hardened before applying the thermal barrier coating.

The principle of energy-saving glass

What are glass different from the usual? On one side of the energy-saving glass coated with a special, imperceptible to the eye surface. This kind of filter does not provide the long-wave heat radiation (infrared waves) go outside. It reflects them back into the room. Glass having such properties, also called heat-selective, low-emission. With the first definition of all clear without further ado. The second is connected with the physical concept as the emissivity of the surface or emission. So, the issue of energy-saving glass is much less simple, therefore it is called low emissivity. With the term "selective" is even easier, because it is glass transmits waves of light and heat selectively ranges.

energy-saving glass production secrets

For the production of conventional sheet glass used two ways: vertical (by pulling) and horizontal (metal melt). Last produces so-called float glass, which has excellent optical properties and high light transmission capacity. It is used for the production of energy-saving glass. On the polished surface of float glass is sprayed coating of non-ferrous metals (mainly silver), or their oxides. Due to the electrical conductivity and interference phenomena such glass gains the ability to reflect heat waves in the infrared range and thus reduce heat losses in the room. Energy-saving glass has a metal coating thickness of a few tens of nanometers. It is no different from ordinary glass, and is completely transparent to our eyes. Use energy-saving glass in the composition of glass as full tightness is required for their operation.

In areas with hot climates recommend the use of low-emission glass blackout. They have a low degree of transmittance of sunlight, protecting the room from the heat of summer, which they bring. Such a solar control glass can be of different colors:. Bronze, gray, green, pink

Energy-saving glass: a cover select

Currently, two types of coatings for energy-saving glass: soft (Double Low-E), the so-called I-glass and solid (Low-E), or K-glass

. In the production of energy-saving glass with hard coating (K-glass), a thin layer of metal oxide is sprayed onto the still hot surface of float glass. This coating is particularly durable, so it is called hard. K-glass, greatly reducing heat loss, improves the thermal insulation space, reducing the cost of its heating. Externally, it is no different from the usual and has a high light transmission. K-glass in the pane facing low-emissivity coating in the direction of the room.

Energy-saving glass with a soft coating (I-glass) produced by more sophisticated technology. It has superior characteristics as compared with K-glass, more in particular a light transmission capability and low coefficient of emissivity. Experts estimate that the average size of the window of a country house, equipped with double-glazed glass with an I-save in the heating season as much heat energy as it gives 300 kg of fuel oil or diesel fuel. It should be borne in mind that the I-glass is easily scratched (low abrasion resistance). However, due to the fact that its energy-saving coating is always located inside the glass, on the exploitation of this flaw does not affect.

Energy-saving glass: manufacturers

Energy efficient windows are widely used in many countries. The technology of their production is complex and requires highly skilled manufacturers, so in the world there are only a few companies producing such glass in large volumes. Among them are the Pilkington (UK), PPG (USA), Saint Gobam (France). In Russia, until recently, the bulk of the high-quality imported glass. When completed in the Klin district, Moscow region a new production complex Glaverbelrossiyane were able to use in the glazing of their homes and offices of domestic energy-saving glass.

Energy-saving glass: benefits

If we compare the single-chamber glazed windows with low-E glass with a conventional two-chamber, he:

30-40% superior to the energy-saving properties and has better light transmission;

glass with the same thickness (4 mm), it is lighter, and thus reduces the load on the accessories and the window casement lifetime increases;

has approximately the same price;

safer. For the manufacture of energy efficient windows used only tempered glass obtained by chemical or heat treatment. Compared with conventional tempered glass 5-10 times stronger resists shocks and temperature changes. If it breaks it disintegrates into tiny safe fragments having blunt edges. Low-E glass is hardened before applying the thermal barrier coating.

Surprising Six-Year History of the Defender of the Motherland - Sergei Aleshkova

35+ fun photos, who broke your brain