3357

Dragon for MSI

Order h4>

Back in 2006 I did my first steps in modding, at least back in 2009, I went to a professional level. Behind his back thousands erased dust Coulter, spent liters of paint, a lot of completed projects. One is forced to think about it, what's next?

What prospects are there modding, what to do when the most interesting work is gradually turning into a routine?

It is with this in mind, I automatically pressed the inscription "Inbox" in guglopochte.

1 new message. I>

Subject « MSI Dragon PC » eloquently hinted that miss in the near future just is not necessary.

Project h4>

It seems to be working, IRTO every day. Someone phone, someone laptop, someone body and seemed to have all seen and wonder then nothing.

When you get an order from a major company - again become a greenhorn youngster and at least one night you can not sleep with excitement. Damn nice feeling when you are standing on the threshold of something complex, new, but such desired.

When the euphoria has passed, returned understanding of what needs to be done that will surpass everything I made earlier.

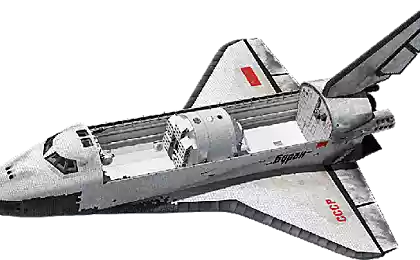

October 28, 2013 started the countdown of the project, codenamed «MSI Dragon PC». The body shall be made subject to a series of gaming accessories and manufactured with the expectation of participation in various activities. The next three weeks, we have tried to agree on the design.

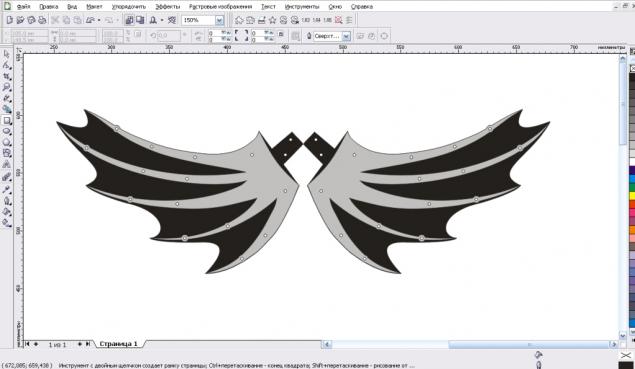

To develop a design for the body I usually spend one night. Worked - showed thrown, went further and so the circle. MSI desired body in the style of their new series of gaming accessories, to me, quite frankly, it seemed that all the components to build a dragon eerily banal, but to me a matter of fact, this is what was asked. Soon, a compromise was found - in the design, I decided to implicate them in addition to the dragon more corporate shield and in addition to the shield - sword. Unfortunately, when I come up, I was already mentally squeezed and, in truth, was ready to abandon the project because did not see solutions to the dilemma - how to do is not trivial and effectively. Besides, I can not stand to work on images of living creatures, I gravitate more to the technique and different mechanisms ...

To work through my last sentence for MSI I spent as much time, how much the average person has time to eat a standard hot dog.

Called the MSI and literally on the fingers described what I plan to do. I have absolutely nothing on hoping, I was - still.

MSI gave the nod.

In my studio there are a lot of necessary work tools and machine tools, the lack of some expensive units compensated savvy and contacts in the right places. We do not have one - 3D modeller who understands anything in modding.

All the projects I see in my head, but what I see does not see the customer. And MSI need something to show.

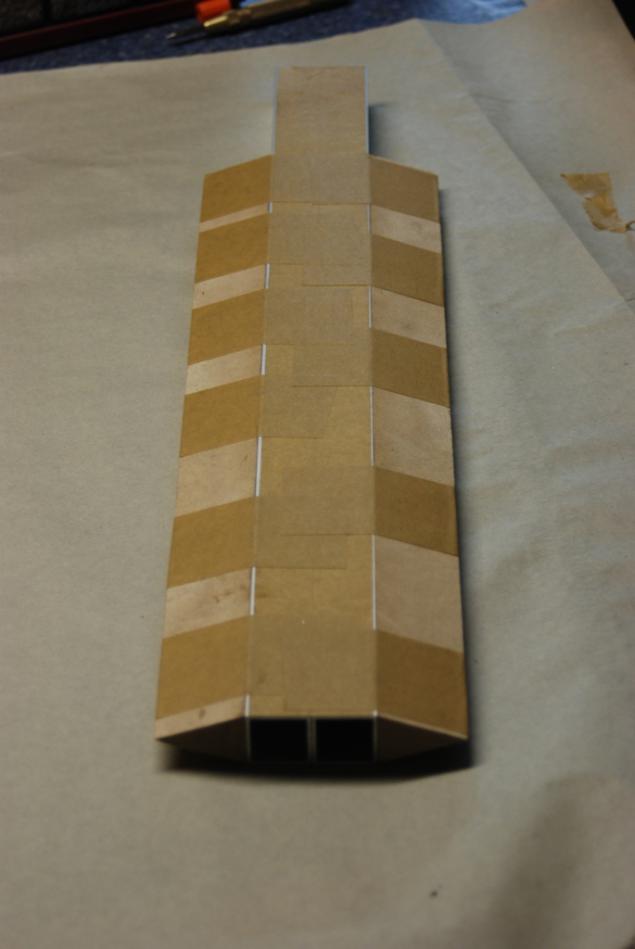

We went to a simple old-fashioned way - made a cardboard mock-up.

Layout has also been approved, and we started to work. Well begun ...

Not having an accurate model of the body in 3D, without the original drawings, and not having a fully developed concept, we realized that we did not meet deadlines.

Under the terms of the agreement with MSI we had to publish the progress of work in the form of a detailed vorkloga on one of the Ukrainian Internet resources. Terms of work, I called it, relying only on their own subjective feelings. I was wrong. How then would not weakly so wrong.

It was originally planned to finish the body for two weeks + -. That's how much time we spent just thinking through every detail that will make the project interesting, memorable and just cool. During the first two weeks of course we were doing something, but not very much, because was not entirely clear from what is better to do this or that detail.

The fact that two years earlier, MSI has already ordered one modder Kiev housing in the subject of their products, but disappointed with the result. Because housing, to put it mildly, was nontransportable - his weight was about 180 kg and poorly reflect the essence of the concept.

Our goal was to not screw up with the weight and design. Everything that is possible to do from lightweight materials. Well, the design should just scream about the company, which it commissioned. Remembered, imprinted in the memory.

The result was the thinking through the following concept of design and functional:

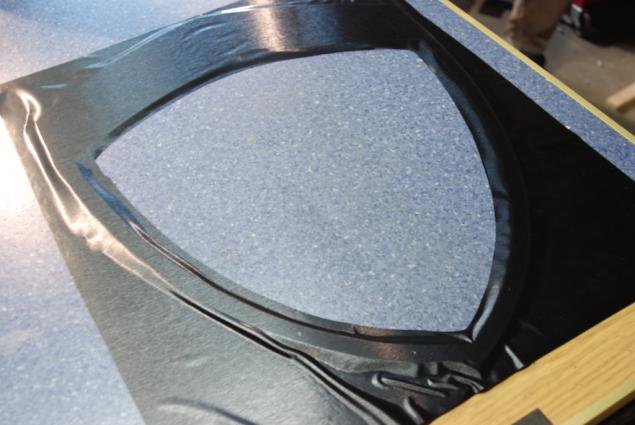

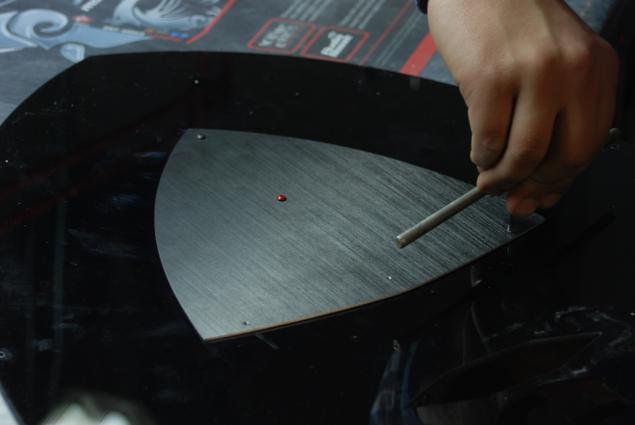

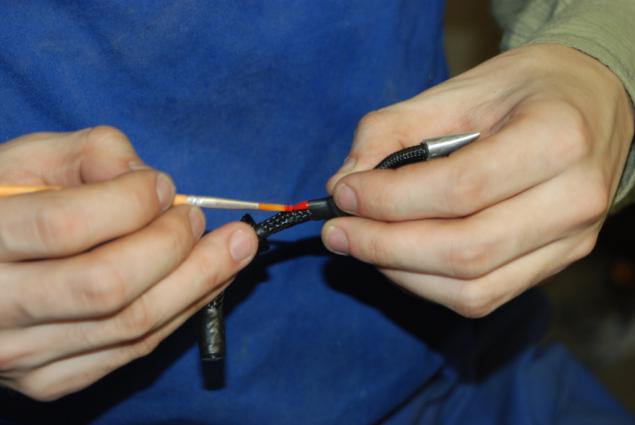

The body is designed as an open stand. The basis of the housing is a shield (one of the symbols of the line gaming accessories) in the shield vertically pierced with a sword. Dragon soars above the shield, holding in the paws of the motherboard with the graphics card. The highlight of the body is a system to enable it. Put in this case simply click - just stupid and boring. I thought that at any exhibition building should be "trick", which will simply attract people at the show, thanks to which everyone wants to be photographed with the case. Should be a "dialogue", a certain relationship between iron and man. I came up with the ring. Typically, such a ring. For subjects of swords, dragons and shields - it. The user wearing the ring, as if endowed with magical power to "revive" the computer. The computer will turn on only at the touch of a hand with a ring to the hilt of the sword! B>

Everyone wants to be photographed at the exhibition, clutching his sword hilt. And this, in turn, thousands of likes in instagrame, facebook and everywhere. Advertising in general is good.

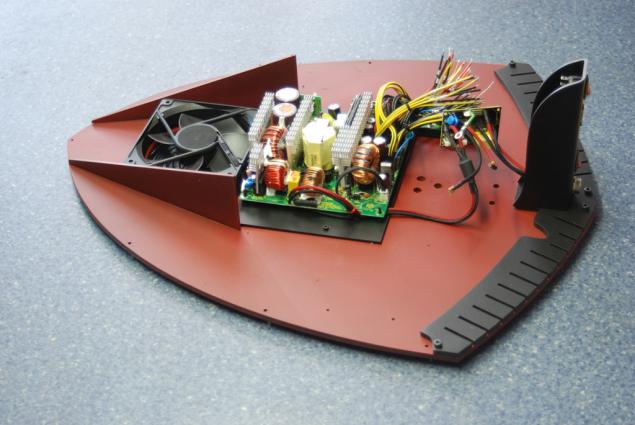

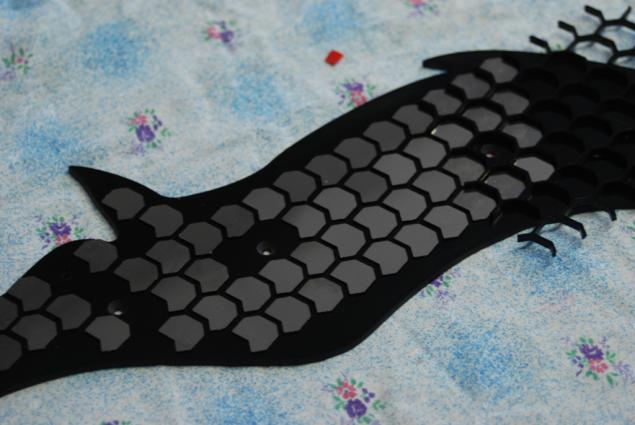

Initially, we wanted to make the shield and the dragon made of aluminum. Some parts of 3mm and 6mm from the other.

Prices of material is impressive, but the quality of aluminum while it was "through the floor", the number of deep scratches just defied account. Working with aluminum and more we refused because the company with which we usually cooperate in the field of waterjet cutting is closed and the number of competing companies for various reasons could not fulfill our order on the cutting of.

And the weight of aluminum needed for the body would be impressive. So we shifted to more affordable, better quality and lightweight material - acrylic sheet.

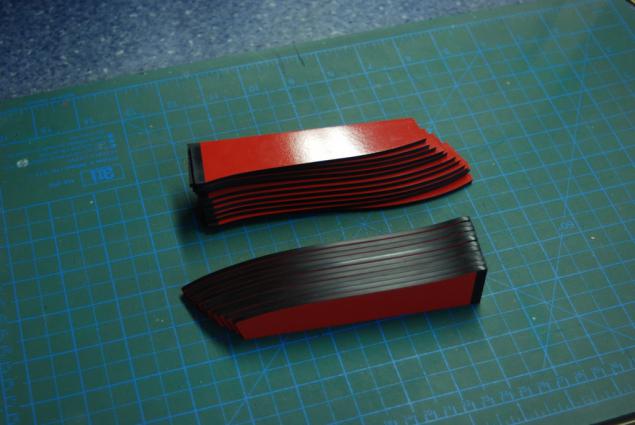

Made drawings, laser cut acrylic. Climbed another problem for the body of this size is too flexible acrylic, even two parts to put together 3mm bent.

Operational elements were invented structural reinforcement in key areas - aluminum plates, they will fit into the design and solve the problem of rigidity of some details.

A story about the case would not be complete without mentioning the main Fail - money.

The amount that I called MSI for the execution of this order, was not great, and in truth, was designed to pay 14 working days + materials. At the beginning of the project, I received an advance payment for materials.

By the end, I made a mistake and the terms and materials.

Prices of materials are not pleased, especially given the fact that a number of the key and not very cheap items we altered for different reasons at 2-3. Constantly needed something to buy more. Option was to simplify the design and construction in order to save money, but I did not consider it. If you do, so you do not regret about what has been done!

Money was gone very quickly, leading to a tightening of terms, because the money for the project had to earn doing other projects, as in the original plan is not taken into account ...

Therefore, the scheme of the project «MSI Dragon PC» looked like - we take another project, do we get the money from them deduct wages, taxes, rent, all that is left goes to «MSI Dragon PC».

Sadly it was - not a word.

Ask the rest of the money at once, or change the amount originally agreed I could not. Such were their conditions.