986

3D-printer from teen

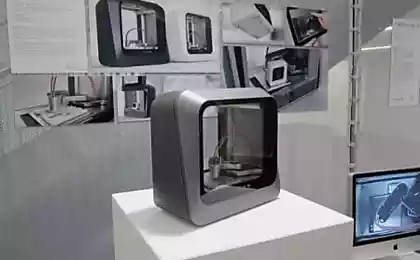

VolgoBot - it's 3D-printer, which will soon be put into production in the line of home appliances for 3D-printing. Everything would be fine if the author of this development has not been ... 15-year-old schoolboy! At work the young genius take a look at the continuation of the post!

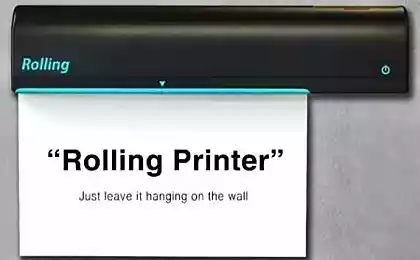

VolgoBot based on the achievements of the popular project RepRap, but is an original design. "I use technology Fused deposition modeling (FDM), when the plastic is fed in the form of rods in the thermal head, there is melted and applied in layers on the desktop, gradually forming part. In my printer thermal head moves horizontally, XY axis using a clever positioning mechanism called H-Bot, simply put, is when the design is only one belt. Desk, in turn, goes on the vertical axis Z, gradually sinking during printing ", - says Mikhail. As the print media, he plans to use any appropriate technology requirements: melt at temperatures up to 300 degrees, allocate a minimum of harmful substances not clog the thermal head. For example, it is ABS plastic, PLA, Neylon, Polywood (wood imitation).

Title VolgoBot chosen in honor of the city on the Volga, where Michael lives. Now in the assembly stage is VolgoBot №0. His mission - to print the items to VolgoBot №1 and give life to the next 3D-printers. "I'm almost finished assembly can only Teflon tube for feeding rod into the thermal head, which" races "in the mail. While engaged in setting and calibration electronics mechanics ", - says Mikhail.

Before you begin to develop your own 3D-printer, Michael studied the structure of existing models. To gain experience he modeled in KOMPAS-3D printer Prusa Mendel i2 (developer Josef Prusa).

Michael knew many CAD-systems, but believes that his choice is KOMPAS-3D: «It is much more convenient for me and dearer." His familiarity with the system, he began with a training version of KOMPAS-3D LT, and now enjoys a full-featured KOMPAS-3D Home.

From here

VolgoBot based on the achievements of the popular project RepRap, but is an original design. "I use technology Fused deposition modeling (FDM), when the plastic is fed in the form of rods in the thermal head, there is melted and applied in layers on the desktop, gradually forming part. In my printer thermal head moves horizontally, XY axis using a clever positioning mechanism called H-Bot, simply put, is when the design is only one belt. Desk, in turn, goes on the vertical axis Z, gradually sinking during printing ", - says Mikhail. As the print media, he plans to use any appropriate technology requirements: melt at temperatures up to 300 degrees, allocate a minimum of harmful substances not clog the thermal head. For example, it is ABS plastic, PLA, Neylon, Polywood (wood imitation).

Title VolgoBot chosen in honor of the city on the Volga, where Michael lives. Now in the assembly stage is VolgoBot №0. His mission - to print the items to VolgoBot №1 and give life to the next 3D-printers. "I'm almost finished assembly can only Teflon tube for feeding rod into the thermal head, which" races "in the mail. While engaged in setting and calibration electronics mechanics ", - says Mikhail.

Before you begin to develop your own 3D-printer, Michael studied the structure of existing models. To gain experience he modeled in KOMPAS-3D printer Prusa Mendel i2 (developer Josef Prusa).

Michael knew many CAD-systems, but believes that his choice is KOMPAS-3D: «It is much more convenient for me and dearer." His familiarity with the system, he began with a training version of KOMPAS-3D LT, and now enjoys a full-featured KOMPAS-3D Home.

From here