632

How to make a door in his kitchen

From power tools: router, jig grinder.

On the local market at the huckster ordered material: two and three poperechki Stoev. It turned out a little expensive but need pine passed drying.

In the manufacture it took about 6 hours. Priced at about 2 TR including glass. It was cheaper to buy ready-made, but until then did the doors to the kitchen and the bathroom due to the non-standard size. And as the stand next door, it was decided to make them in the same style.

To start doing layout. For doors with direct markup poperechkami do nothing complicated, but for the diagonal ... So nothing smarter than I figured out how to put all on the floor.

11 photos and some text.

02. Mark up Stoev.

03. Make a notch at the spike poperechki. Cutter 12x70 mm. The groove depth must be 55 mm. Doing it for a few visits, each time pushing the cutter is 5-7 mm. The groove must be perfectly centered, so we put the limiter and pass on both sides. As a result, we get a groove ~ 13 mm but strictly in the middle.

04. saw off the excess from the poperechek

05. Again we take up the router, and do spike. The spike should enter into force with Stoev.

06. Frezeruem groove under a panel. The panels will be used as a shield made of pine, 12 mm thick.

07. Try on details. Everything is perfect has come, no differences.

08. round off the edges using a molding machine with a cutter bearing.

09. Collect, Poperechki put on a pair of glue and screws. Frezeruem under glass.

10. Shpaklyuem, grind and as one friend said: "There are no bad door, sometimes a little putty».

Sawdust was typed with a bag, except that flew into the ventilation.

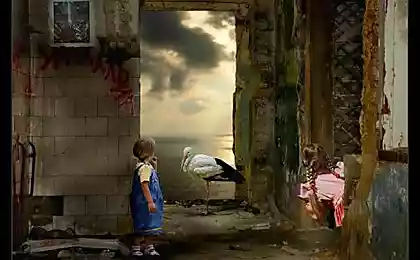

11. Here is the door to the bathroom.

That's all. You can criticize.

On the local market at the huckster ordered material: two and three poperechki Stoev. It turned out a little expensive but need pine passed drying.

In the manufacture it took about 6 hours. Priced at about 2 TR including glass. It was cheaper to buy ready-made, but until then did the doors to the kitchen and the bathroom due to the non-standard size. And as the stand next door, it was decided to make them in the same style.

To start doing layout. For doors with direct markup poperechkami do nothing complicated, but for the diagonal ... So nothing smarter than I figured out how to put all on the floor.

11 photos and some text.

02. Mark up Stoev.

03. Make a notch at the spike poperechki. Cutter 12x70 mm. The groove depth must be 55 mm. Doing it for a few visits, each time pushing the cutter is 5-7 mm. The groove must be perfectly centered, so we put the limiter and pass on both sides. As a result, we get a groove ~ 13 mm but strictly in the middle.

04. saw off the excess from the poperechek

05. Again we take up the router, and do spike. The spike should enter into force with Stoev.

06. Frezeruem groove under a panel. The panels will be used as a shield made of pine, 12 mm thick.

07. Try on details. Everything is perfect has come, no differences.

08. round off the edges using a molding machine with a cutter bearing.

09. Collect, Poperechki put on a pair of glue and screws. Frezeruem under glass.

10. Shpaklyuem, grind and as one friend said: "There are no bad door, sometimes a little putty».

Sawdust was typed with a bag, except that flew into the ventilation.

11. Here is the door to the bathroom.

That's all. You can criticize.