1371

Making the stairs to the dollhouse

And so to all Hello!

Recently I happened important event in my life - my daughter was born.

And I decided to make it a real dollhouse.

The idea hatched about a month, then was bought tools and materials.

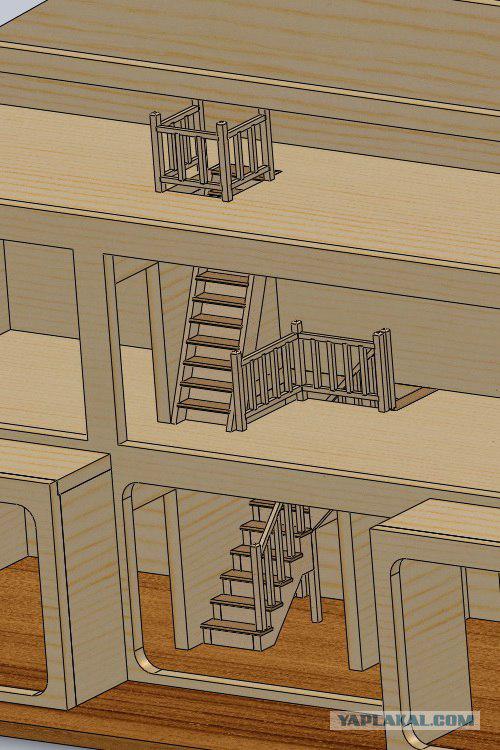

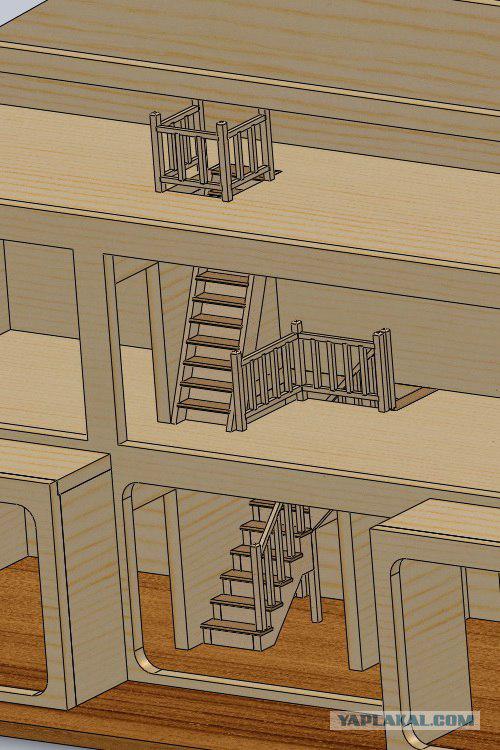

I killed a lot of time on 3D modeling, that all would have been in mm mm.

The very house is not yet made, and no final plan.

I'll show you how I did ladders and fences to the house.

It will be 39 pictures, please do not break and so went.

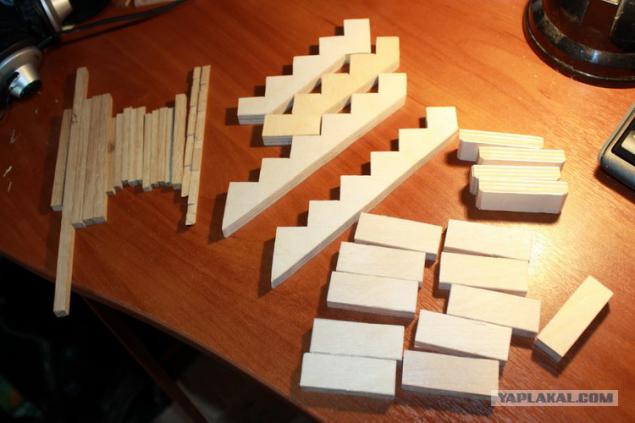

Items are divided into 3 parts:

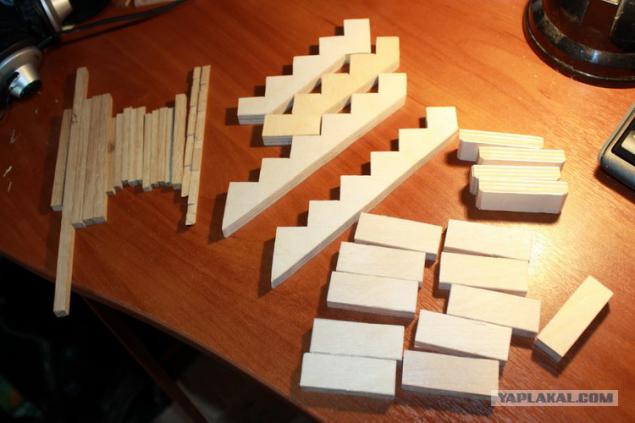

1) Standings + railing. 5 5 * and 7 * 7 mm.

In general, no longer stand to saw minitsirkulyarochki I like I do not know how. Jigsaws so smoothly impossible if doshkurivat then, it is for the week. Therefore, we proceed just take parketinu (280 * 70 * 15 Oak). And very quickly napilivaem tsirkulyarochnoy (Proxxon FET) rack. After manually by filing a jigsaw cut to the desired length, and as a jigsaw cut out the desired path for the connection.

03

04

05

06

07

08

09

10

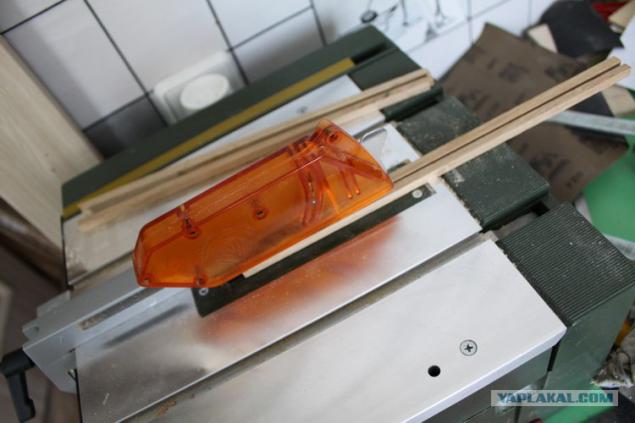

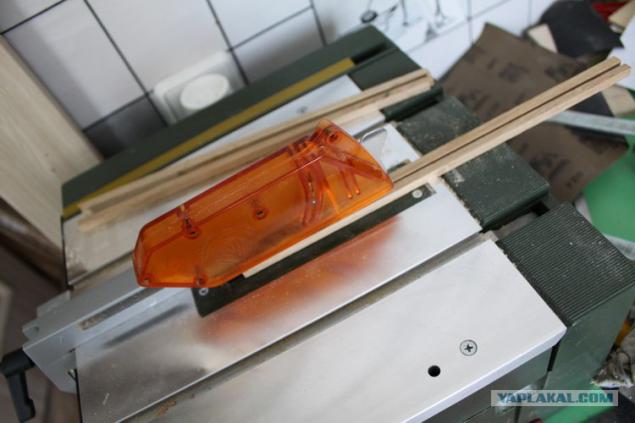

2) ribs. (width 5-8 mm).

Here it is best suited plywood, although the stairs to the attic, I took parketinu 5mm kindly fitted neighbor.

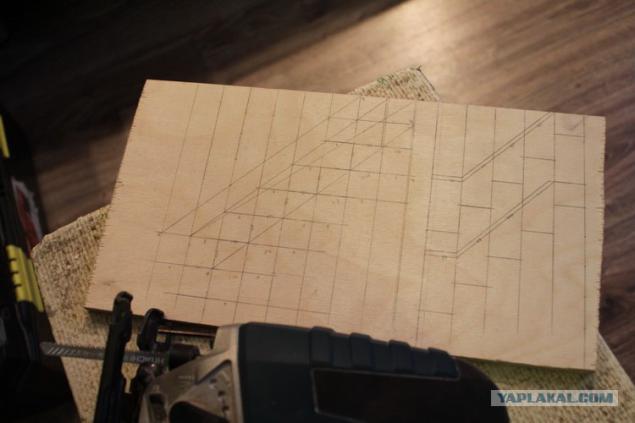

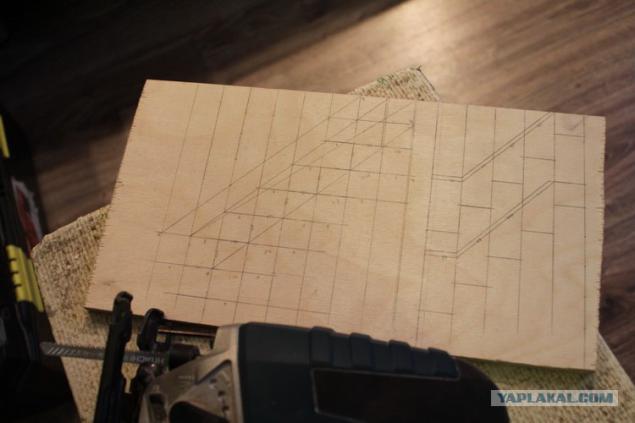

We are making the necessary drawings and Scrollsaw. Mostly sawed jigsaw, although in some places used minitsirkulyarku.

11

12

[13]

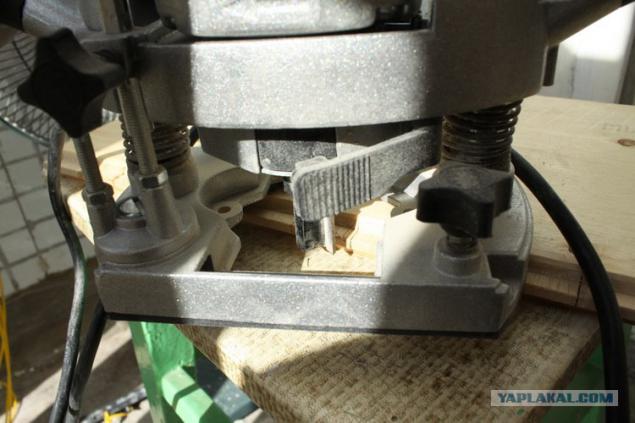

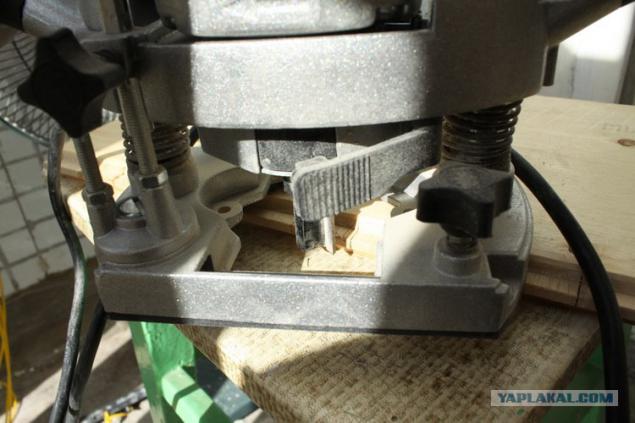

3) Steps. Here I used a cherry (3mm upper layer parquet). The most problem was - is to separate the top layer of cherries. He glued quality, and a second layer - Birch also quite durable and gnarly. As a result, one of the separated chisel (2 hours on a small slate). The second tried to cut down a router. Speed a little faster, but more ports lower part of the plate. Another idea came circular saw to make some cuts and chisel to break down, but it later. Once the correct plates are separated, and rascherchivaem napilivaem hand jigsaw necessary details.

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

Details are sawed, it's time to collect all this.

[22]

[23]

I decided to put on the glue bond + extra nails.

First, it was a completely crazy idea to use metal pins (staple), but in the end all the nails.

The analysis showed that if the nail right away (I have had only the d = 1.7) and the plywood strut (oak) crack. Then drill holes. I bought a Bosch drill for metal 1mm. The seller was very surprised that I'm going to drill metal drill wood, because it is intended for metal and wood in the presence of only a minimum of 3mm like.

The question of how the drill chuck to clamp 1mm HAMMER MD170A mini drills with collet at least 2.4mm? Here I go crazy specifically, 3-4 days of torment and answer more or less found.

Before drilling a center punch to make a mark, and after a bit hammered dobojnika drowned cap for easy sanding.

As a result, even with the pre-reamed holes in some places cracked plywood - a thin drill or nail large. In the future, I will use nails d = 1.2 or d = 1.4.

[24]

[25]

[26]

[27]

He began to glue all at the same time frame corner stairs, PPV all crawled off somewhere, gone, all the glue, all crooked. Disassembled, wiped from the glue and glue the edges began to turn. After all stuck together, I realized that as the assembly had to be glued to the nail and hammer it became uncomfortable. Okay, I break through. (evil was - sorry pictures did)

[28]

Sami steps simply glued to the finished frame.

[29]

[30]

[31]

Well, in the end sticking fences and railings.

[32]

[33]

[34]

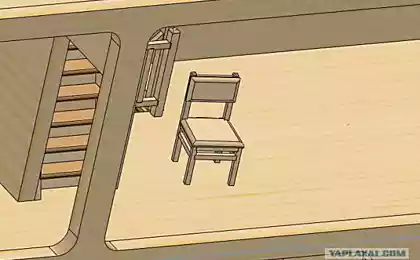

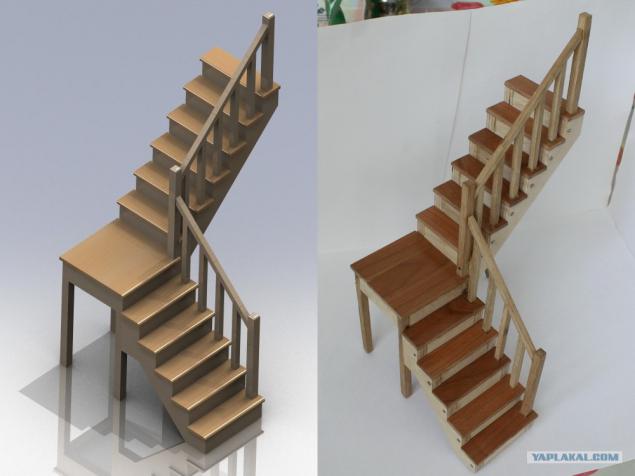

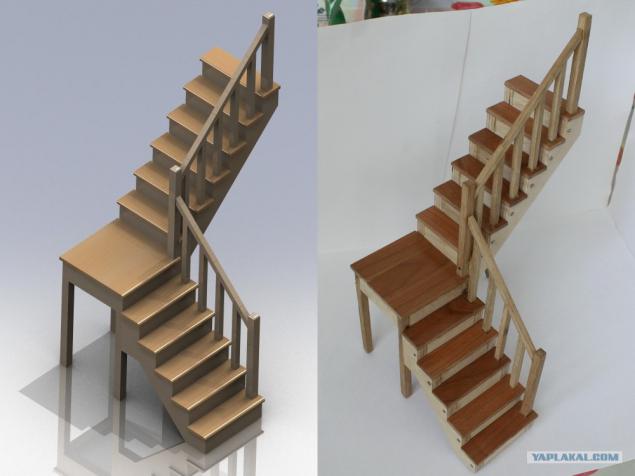

Finished products compare with the 3D plan

[35]

[36]

[37]

[38]

All together:

You're varnished and ready.

What I needed:

Minitsirkulyarka Proxxon FET (standard drive)

Jigsaw Bosch GST 75 BE (Special sawing of plywood)

Mini drills Hammer MD170A (+ 1mm drill and abrasive standard cylinder)

Hand mill ENKOR PME-850 / 8E (Hitachi cutter 16mm)

Rulers, triangles, caliper

Tisochki

Cramps in the range

Hand Soviet jigsaw (here by the way is nuance. If jigsaw Soviet and better today, something about the nail file is can not be said. Jig is very thick and very dull compared to the saws from Bahco. 140 rubles like 10 saws, superbly turned out)

Hammer, punch, dobojnik.

The knife, a chisel 2 (10 and 6 mm)

Files, nozhdachki.

Clay time carpenter. Nails 1.2mm

- What do I want to download the last.

In general, I'm a programmer and never dealt with anything like this.

Another 3 months ago I was a complete 0 to wood processing and simulation.

Yes, maybe you get a curve obliquely, but as it is. I think in the future will be more beautiful.

And ask everyone to visit me in a blog on the subject:

asv-miniatures.blogspot.com

All there waiting!

Good luck!

Source:

Recently I happened important event in my life - my daughter was born.

And I decided to make it a real dollhouse.

The idea hatched about a month, then was bought tools and materials.

I killed a lot of time on 3D modeling, that all would have been in mm mm.

The very house is not yet made, and no final plan.

I'll show you how I did ladders and fences to the house.

It will be 39 pictures, please do not break and so went.

Items are divided into 3 parts:

1) Standings + railing. 5 5 * and 7 * 7 mm.

In general, no longer stand to saw minitsirkulyarochki I like I do not know how. Jigsaws so smoothly impossible if doshkurivat then, it is for the week. Therefore, we proceed just take parketinu (280 * 70 * 15 Oak). And very quickly napilivaem tsirkulyarochnoy (Proxxon FET) rack. After manually by filing a jigsaw cut to the desired length, and as a jigsaw cut out the desired path for the connection.

03

04

05

06

07

08

09

10

2) ribs. (width 5-8 mm).

Here it is best suited plywood, although the stairs to the attic, I took parketinu 5mm kindly fitted neighbor.

We are making the necessary drawings and Scrollsaw. Mostly sawed jigsaw, although in some places used minitsirkulyarku.

11

12

[13]

3) Steps. Here I used a cherry (3mm upper layer parquet). The most problem was - is to separate the top layer of cherries. He glued quality, and a second layer - Birch also quite durable and gnarly. As a result, one of the separated chisel (2 hours on a small slate). The second tried to cut down a router. Speed a little faster, but more ports lower part of the plate. Another idea came circular saw to make some cuts and chisel to break down, but it later. Once the correct plates are separated, and rascherchivaem napilivaem hand jigsaw necessary details.

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

Details are sawed, it's time to collect all this.

[22]

[23]

I decided to put on the glue bond + extra nails.

First, it was a completely crazy idea to use metal pins (staple), but in the end all the nails.

The analysis showed that if the nail right away (I have had only the d = 1.7) and the plywood strut (oak) crack. Then drill holes. I bought a Bosch drill for metal 1mm. The seller was very surprised that I'm going to drill metal drill wood, because it is intended for metal and wood in the presence of only a minimum of 3mm like.

The question of how the drill chuck to clamp 1mm HAMMER MD170A mini drills with collet at least 2.4mm? Here I go crazy specifically, 3-4 days of torment and answer more or less found.

Before drilling a center punch to make a mark, and after a bit hammered dobojnika drowned cap for easy sanding.

As a result, even with the pre-reamed holes in some places cracked plywood - a thin drill or nail large. In the future, I will use nails d = 1.2 or d = 1.4.

[24]

[25]

[26]

[27]

He began to glue all at the same time frame corner stairs, PPV all crawled off somewhere, gone, all the glue, all crooked. Disassembled, wiped from the glue and glue the edges began to turn. After all stuck together, I realized that as the assembly had to be glued to the nail and hammer it became uncomfortable. Okay, I break through. (evil was - sorry pictures did)

[28]

Sami steps simply glued to the finished frame.

[29]

[30]

[31]

Well, in the end sticking fences and railings.

[32]

[33]

[34]

Finished products compare with the 3D plan

[35]

[36]

[37]

[38]

All together:

You're varnished and ready.

What I needed:

Minitsirkulyarka Proxxon FET (standard drive)

Jigsaw Bosch GST 75 BE (Special sawing of plywood)

Mini drills Hammer MD170A (+ 1mm drill and abrasive standard cylinder)

Hand mill ENKOR PME-850 / 8E (Hitachi cutter 16mm)

Rulers, triangles, caliper

Tisochki

Cramps in the range

Hand Soviet jigsaw (here by the way is nuance. If jigsaw Soviet and better today, something about the nail file is can not be said. Jig is very thick and very dull compared to the saws from Bahco. 140 rubles like 10 saws, superbly turned out)

Hammer, punch, dobojnik.

The knife, a chisel 2 (10 and 6 mm)

Files, nozhdachki.

Clay time carpenter. Nails 1.2mm

- What do I want to download the last.

In general, I'm a programmer and never dealt with anything like this.

Another 3 months ago I was a complete 0 to wood processing and simulation.

Yes, maybe you get a curve obliquely, but as it is. I think in the future will be more beautiful.

And ask everyone to visit me in a blog on the subject:

asv-miniatures.blogspot.com

All there waiting!

Good luck!

Source: