1652

As I walked to the store or a chair with his hands

It was necessary for the new year to make a gift, go to the store, he saw there a chair, very much.

p.s. 35 photos will be

Author © mazai

forum.woodtools.ru/index.php?topic=30204.0

The price of this happiness was 12,000 rubles.

I decided to do it myself.

Work completely elementary and no difficulty is not here. Maybe someone will be interested.

Material alder, oak and elm. Natural color of the wood. Cladding - parquet lacquer Marshall PROTEX semi. Brushing, with intermediate grinding.

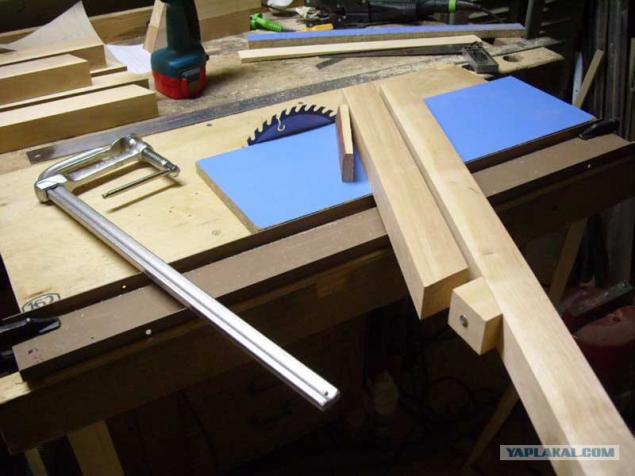

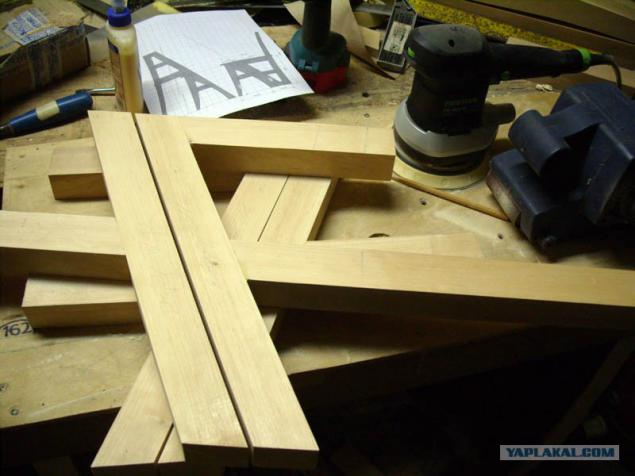

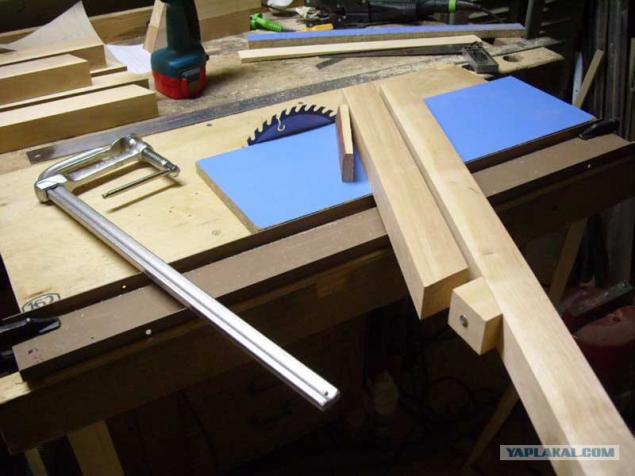

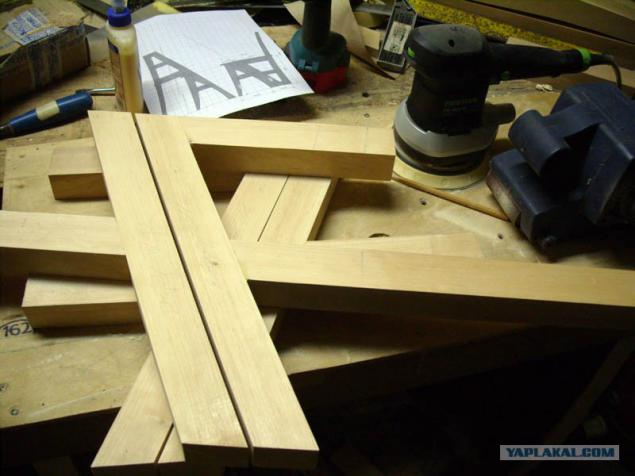

The process of making primitive. Of the tools used marking gauge, hand circular saw, router, belt and orbital sander, jig saw, band saw little, some hand tools.

Due to lack of space workshop had to use makeshift devices. That's the way looked manufacturing process.

Zapilivanie angles and connection details in an oblique spike

05

06

07

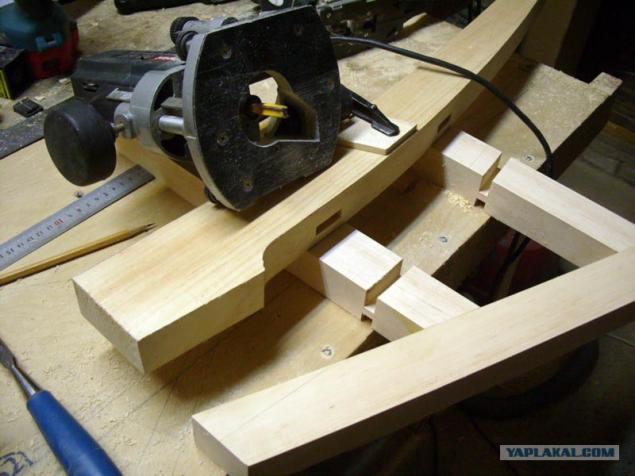

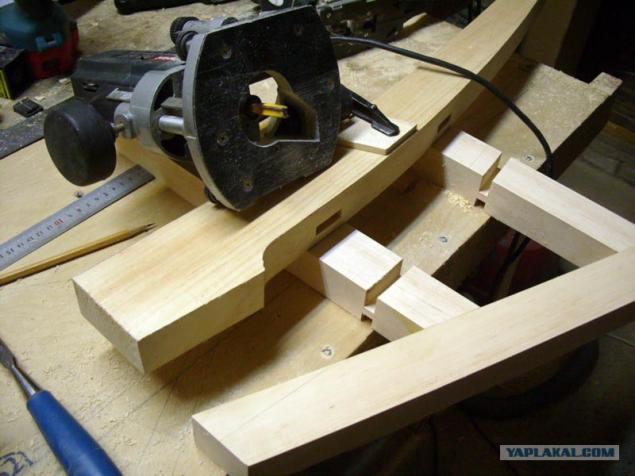

Production of compound curved parts and the individual elements along the curved profile.

09

10

11

And parts were connected at an acute angle

13

14

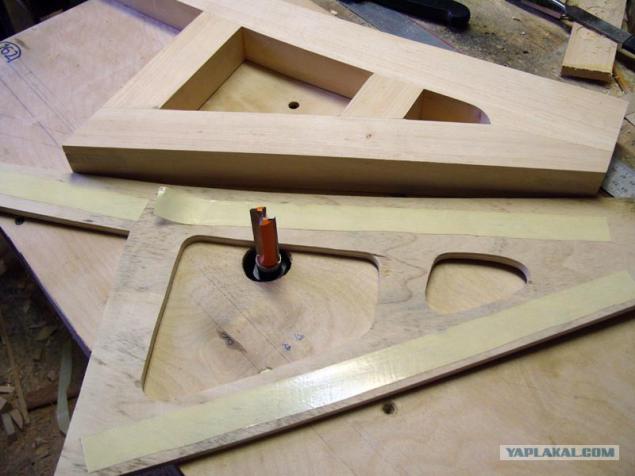

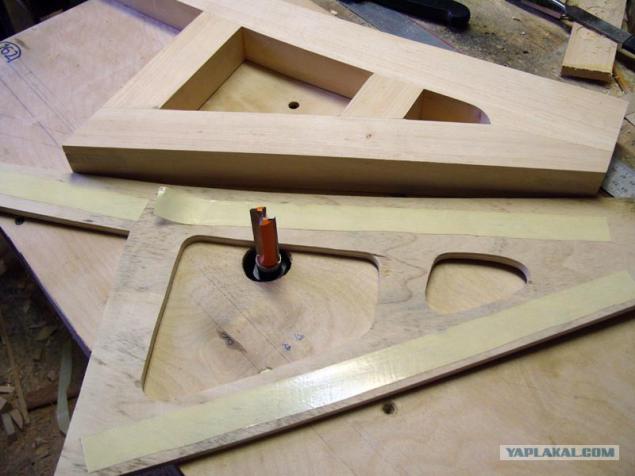

The contours of the details have been run-in templates

15

16

17

18

Next is the milling chamfers, slots under the stairs, steps and produced themselves were assembled

19

20

21

22

23

24

Sleepers were sawed back on the bandsaw, connected manually. The back is inserted in the dowel (3 on each side).

25

26

The whole structure is fixed in the folded state of the brass hook 3mm (homemade)

27

Outcome assembly

28

29

30

31

32

33

34

Source:

p.s. 35 photos will be

Author © mazai

forum.woodtools.ru/index.php?topic=30204.0

The price of this happiness was 12,000 rubles.

I decided to do it myself.

Work completely elementary and no difficulty is not here. Maybe someone will be interested.

Material alder, oak and elm. Natural color of the wood. Cladding - parquet lacquer Marshall PROTEX semi. Brushing, with intermediate grinding.

The process of making primitive. Of the tools used marking gauge, hand circular saw, router, belt and orbital sander, jig saw, band saw little, some hand tools.

Due to lack of space workshop had to use makeshift devices. That's the way looked manufacturing process.

Zapilivanie angles and connection details in an oblique spike

05

06

07

Production of compound curved parts and the individual elements along the curved profile.

09

10

11

And parts were connected at an acute angle

13

14

The contours of the details have been run-in templates

15

16

17

18

Next is the milling chamfers, slots under the stairs, steps and produced themselves were assembled

19

20

21

22

23

24

Sleepers were sawed back on the bandsaw, connected manually. The back is inserted in the dowel (3 on each side).

25

26

The whole structure is fixed in the folded state of the brass hook 3mm (homemade)

27

Outcome assembly

28

29

30

31

32

33

34

Source: