943

Thank you that you are still in Russia

How to grow potatoes: farm Michael Kolpakov

How often do we hear that the agriculture deal with troublesome, expensive and generally very profitable. How does the need to carry out their activities, to be considered the best economy for five years, and have enough money to build a school for 80 million?

Mikhail Petrovich Kolpakov, accomplished the feat by building their own in Vershinino innovative schools in their daily activities, the owner of the largest in the Tomsk region of the farm. Of the ten holdings accounting for 30% of the cultivated potato.

Will be 50 photos and comments. Source

2.Fermerskoe economy

The farm, located in the territory of two former state farms in the village Vershinino, you can call the family business: he controls all affairs Michael Kolpakov, he helped his son-in-law, wife, daughter and brother-in-law. In each of the two state farms had worked for fifteen experts, now it's become a household is headed by, in fact, four people.

It all began back in 1993. While Michael Kolpakov was chairman of the building society "Three heroes", but turn our gaze on agriculture, he was forced by two factors: the beginning of the country's problems "in cash" (more services offered to pay for barter), and the fact that his wife contributed the land share a 6 hectares in the collapse of the farm.

- What to do with him? We decided to try it, - says Mikhail. - Especially as potatoes, it seems, everyone knows how to plant. Well, not wheat as we were to sow, in fact. We must also say that while the government has provided real assistance to agriculture. Lend on technology, pay rates, and so on. So I went to Kemerovo, took out a loan, bought seeds. So it began. At that time, many people began to engage in agriculture. but how many of them do not even really having adjusted their production, starting to build their own houses, buy cars? And somewhere at the level of the first floor have the money ... And I ended before to build a house, built a store, bought a good seed potatoes technique ».

Today Kolpakova property is more than 400 hectares of land. Each year its economy is growing on it about 10 000 tons of potatoes.

3.Cleaning of crop

Mass cleaning potato starts in 20 days of August and the first tractor on the field with a special device with a laconic name KIR (kositel chopper rotor), in order to mow all the tops with grass. Behind him after some time released harvester who dig and gather the harvest.

All appliances in the import sector. Green came from the Netherlands, and the red «Grimme» from Germany.

4.

5.

6.- This processor is 8 million, and our - 750 thousand. We, though, and the Patriots, but chose it, - says Mikhail. - It leaves a much smaller potatoes on the field - 2-3%, in contrast to ours, losing 20, and even 30%. They were still going and going. The tubers from the ground cleans better, without damaging them in the process. Himself a stones throw away. And his performance is much higher. With all four of these combine, we remove the potatoes from an area of 400 hectares, and the Russian need fifteen or sixteen pieces for the same amount. So good value for money it still pays.

7.

8.

9.Kombayn designed in such a way that undermines the number located on the side of the tractor that pulls it. Thus, tractor rides for the pure land, less damaging potatoes and installed sensors on the combine lead him exactly on the ridge, giving stay on the desired number.

10.Dalshe unique system of screening conveyor separates undermine the potatoes from the earth, foliage and rocks. To achieve such a result in our technique is simply unrealistic, says Michael. Land on the upper conveyor in any event not less than 50%. In order to keep up with her to throw at the combine, you need to put 4-5. It also needs one.

11.- I won that soon began. While no one was buying imported equipment, - says Mikhail. - Director of the farm said that it is too expensive, it is much easier to spend a hundred thousand for repairs. In the end, where I worked as a harvester, they were four. This means that they must have four tractor and another of four per processor. Total turns twenty. Where do I need to just two - ten times less. And how much diesel fuel is burned four tractors per working day? A reliable technique? In the fall of even a single hour of downtime combine due to a fault - is a tragedy. You can simply do not have time to harvest, fall something short. Then rain, then snow, then the machinery to repair - and all is lost. We never leave the potatoes in the fields. Always have time to clean up the winter.

He worked in the field of people free food lunch and dinner. Meals are brought directly to the field, here are arranged tables. Supper is necessary because the last time in the autumn of up to ten, eleven o'clock. According to Mikhail, and people are interested in the fact that there was a good harvest, so are sensitive to nonstandard schedule. As long as the weather is, we have to work.

Hopper capacity to combine six and a half tons. Potatoes out of it overwhelmed for special dump carts brand «Miedema» and transported to the sorting station.

11. In a park of four farm carts come from Holland. Each of them at a time can take away 12 tons of cargo. Due to the hydraulic suspension, the potatoes in this semi receives minimal mechanical damage during transportation.

12.Sortirovka, cleaning and storage

Equipment operating in the sorting of potatoes, the same brand as the tipper wagons. For this reason, one complements the other as well as possible.

From the Russian equipment Mikhail refused immediately. According to him, in the beginning they used screening plant of domestic production, but experience it has been rather negative:

- Just bought a new sort, burned her six engine. We had naturally exhausted. Hardly a day passed without she threw some trouble: the chains tear, the tape, the shaft will break. This also works as a clock. You can safely go somewhere, knowing that nothing happens here.

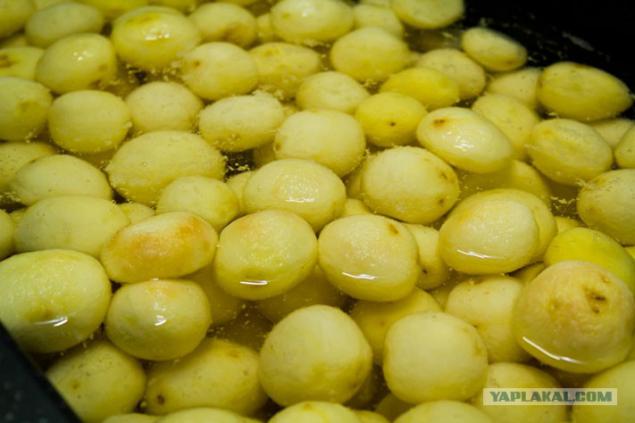

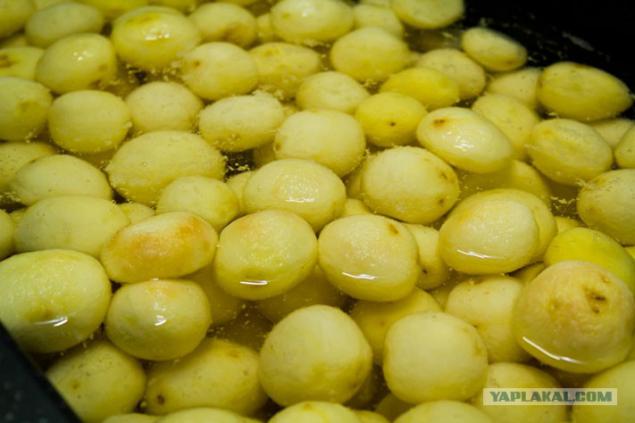

12.Iz dump carts potatoes first poured into the hopper. Further, it is divided into three streams. One way large, medium to another seed, in the third, with the land falls small.

13.

14.

15.

16.Krupny potatoes from this batch load into a container and sent to a special workshop on the revision. There will wash it first, and then part of the pack and razvezut of trading networks, and some will clean peel, pack the vacuum packaging and razvezut for kindergartens, canteens, schools and the food plant where it is made into dumplings. When the plant needs will be satisfied, will fill this warehouse.

Reconfigure the conveyor belt delivers the potatoes on the telescopic boom, which can be in automatic mode for a given program to fill in all the vault. Installed at the end of its sensors indicate that the potatoes in this place sufficient forcing to rotate from side to side.

17.Eto small store one hundred tons was one of the first who built a cap. Here on the grading of all four of the vault. Elsewhere, near the shop has settled on completion of five new stores over two thousand tons each:

18.Nebolshie "huts", hammered together from boards - ventilation ducts. In autumn, this room is filled to the top of the potatoes wooden boards on the sides and the floor partition off these boxes completely. The masonry along one wall made special ventilation openings. The air pumped therethrough by the fan flows through ducts and rises up through the entire bed of potato, preventing it from rot.

19.Na throughout the storage time of the operators follow the air circulation in the shoulder. In this they were helped by various thermometer showing the temperature of the room, on the street and in the thickness of the potato. Comparing the temperature, the operator can control the flow of air with the help of motorized valves directing it where necessary, and adjust its volume, ensuring that storage temperature was in the range of 3-4 degrees.

The new warehouse was attached directly to the shop by product refinement potatoes, which can significantly reduce the cost of its transportation. However, this operation has undergone the delivery of mechanization. The shoulder is exhausted conveyor ...

20 ... and potato conveyor belt is fed into the container. The container, a large wooden box, topples over into the hopper:

21.Ottuda potatoes supplied to the next conveyor. Going through it, it falls into the washing device, which is a barrel of water.

22.Datchik installed before it stops feeding if the drum fills.

23.Vnutri it rotates the drum with blades. It mixes uniformly with the potatoes, whereby the cleaned of dirt. At the exit of the barrel is the flap, which can be adjusted during washing, depending on the degree of contamination, and a shower with clean water, rinse the potatoes from the dirty water in the sink.

24.Dalee clean, but wet potatoes supplied to the wind shaft.

25.13 trees wrapped with a special cloth, rotating in one direction, wipe and dry the potatoes, handing it to the inspection table.

26.Na inspection table potatoes are selected presentation. Tubers with minor injuries are sent to the cleaners, and even and smooth - on the packaging. At the end of the table is another sensor which also turns off the entire line if the packing station is overloaded.

27.

28.Upakovka

Potatoes, the last control on the inspection table is applied to the weighing device - it consists of a vibrating table and weighing cups.

Due to vibrations, potatoes evenly distributed into cups. Next, the computer determines in which cups are desired weight. Accuracy of such device is quite high: it is capable of giving an error of up to 10 grams, and only in a big way.

29.

30.Dlya weighted potatoes are two options package. For each of them corresponds to your machine.

31.

32.

34.Proizvoditelnost a line: 28 packages per minute, every 2, 5 kilograms, which is 4 tons of potatoes per hour. The final stage of the quality of packaging is checked just in case, the finished product stack bags more, and is transported by commercial networks.

35.

36.Kartofel not last control on the inspection table, sent to the cleaners. First, the rough mechanical, where the barrel like a centrifuge, cleans potatoes peeled ...

37.

38.

39 ... and then manually rework:

40.Dalshe such potatoes packed in vacuum bags of five kilograms and sent to the warehouse.

Such processing "nekonditsiyu" to reduce the amount of waste in the shop almost to zero. What still remains, distributed free of charge to the public. For waste, usually visited by people involved in raising livestock.

- From time to time I ask, of course, to sell cleaning any farmer, but I prefer to keep the local population, workers in rural areas. People keep cattle, well, we encourage them: Hold on, guys.

41.Kolichestvo people working in the shop, depending on the season. The warmest autumn are working up to 20 people. All of them also free food dinners. On the second floor are made for the dining room, dressing room and shower room. Adjacent and study of Kolpakova.

This is only a small part of the available thanks and certificates.

42.Chut further there is another kitchen, lounge and shower especially for newcomers specialists. It happens that the equipment installers have to live here a week or more: the working time on a business trip often lasts from morning till night. To people not to wander away into the city and back, we decided to do for them is something like an apartment. They came, showered, slept, woke up in the morning, had breakfast and again for work.

47.Tseh finalization of potatoes was built in 2009. To equip it with all the necessary equipment had to spend 12 million rubles. Now through the shop it runs only 10-15% of the total weight of the potato, but in the economy are working on it and expect to gradually increase this share. The minimum wage in the shop of 15 thousand rubles. Pay, according to Michael, is stable, without delay. All workers are employed officially, paid vacation and sick leave. His people are helping to extinguish kredity.Seychas came here to to motivate and encourage the person to work by increasing his salary is not at the expense of the salary and bonuses due. During the autumn harvest workers paid additional wages and bonuses. The specific amount Mikhail did not articulate, but said that the money is good, even by urban standards, the farm they do not even earn in a year. But sometimes still have to deal with "educational" work: to come to a man, to talk, to persuade to give up drinking for the sake of the family and children.

48.

49.Realizatsiya

With the opening of a workshop for the finalization of the potato sector was to distribute its products through retail chains. Now it is a large part of the Tomsk spreads through a group of companies "Lama" (shops "apricot" and "Fudsiti"), a network of shops "Bystronom" and "Holiday". Eat Kolpakovsky potatoes and Seversk. But the first two years of his work shop brought nothing but losses. Unwashed potatoes are sold even more expensive than processed in the workshop. Kolpakov walked on it while holding the people and paying them a salary, because he saw the future, would like to go to the supermarket to press on the shelves of goods imported from other regions, "Even actuating zero, we were happy that we still Twenty-five people in the village have a job ».

According to Michael, "to go" in shopping online was not easy. At that time, supermarket shelves were occupied by imported potatoes brought from the neighboring regions of Novosibirsk, Kemerovo and Altai. To start Tomsk agriculture set the price for their products is almost two times lower than the competition. Gradually there was a preponderance on the shelves in favor Kolpakova. Potatoes its economy has increased, but the price for it, and still try to keep below imported.

50.- How can potatoes grown here cost more than brought from afar? Moreover, we have too much to keep a high price. The same to the potatoes we stayed, and we could not sell it until the following year, there was a very long time, - says Alexander, son of Michael Kolpakov, responsible for sales. - As a rule, it happens just the opposite: potatoes ends before we have time to collect the new crop. Sometimes in such cases, it is necessary even to buy more to keep supply contracts. For example, a food plant completely switched over to work with shelled potatoes. They even have their own capacity is not to be washed and cleaned.

Paul, who "rested" from work this year, several times over the summer plow tiller with grass growing up as she did not give seeds. This operation fertilizes the land, at the same time reducing the amount of weed in the fields.

One such tractor «John Deere» is three and a half million. Overall, these tractors on the farm - seven. Each has air conditioning, radio, visibility and easy operation, as foreign cars. Certain difficulties with recruitment, in this connection, of course, are available. Each tractor, each processor need to find a professional who will be able to work on it, be careful to treat it and not let you down at the crucial moment.

51.Mihail Kolpakov

"That's why I began to study the social sphere. If I had not built a Vershinino school, nobody ever is no longer to build, and after a while there is not only the technique of the people will not find anyone here at all will remain. A silent or pretend that nothing is happening - not to respect themselves. Last year, we had to fix another old state farm storage for two thousand tons, which has become dangerous to store potatoes, but I began to build a school. Subsidies promised to help in exchange for school Kress, who was then governor of the Tomsk region, left, and the new government school in the village was not necessary, accordingly, help economy, too, has no intention of providing. This year I had to reduce the area of land on 160 hectares just because of the fact that I have nowhere to put it. In terms of the money I lost at least 30 million rubles.

That's all. Thanks to all.

Source:

How often do we hear that the agriculture deal with troublesome, expensive and generally very profitable. How does the need to carry out their activities, to be considered the best economy for five years, and have enough money to build a school for 80 million?

Mikhail Petrovich Kolpakov, accomplished the feat by building their own in Vershinino innovative schools in their daily activities, the owner of the largest in the Tomsk region of the farm. Of the ten holdings accounting for 30% of the cultivated potato.

Will be 50 photos and comments. Source

2.Fermerskoe economy

The farm, located in the territory of two former state farms in the village Vershinino, you can call the family business: he controls all affairs Michael Kolpakov, he helped his son-in-law, wife, daughter and brother-in-law. In each of the two state farms had worked for fifteen experts, now it's become a household is headed by, in fact, four people.

It all began back in 1993. While Michael Kolpakov was chairman of the building society "Three heroes", but turn our gaze on agriculture, he was forced by two factors: the beginning of the country's problems "in cash" (more services offered to pay for barter), and the fact that his wife contributed the land share a 6 hectares in the collapse of the farm.

- What to do with him? We decided to try it, - says Mikhail. - Especially as potatoes, it seems, everyone knows how to plant. Well, not wheat as we were to sow, in fact. We must also say that while the government has provided real assistance to agriculture. Lend on technology, pay rates, and so on. So I went to Kemerovo, took out a loan, bought seeds. So it began. At that time, many people began to engage in agriculture. but how many of them do not even really having adjusted their production, starting to build their own houses, buy cars? And somewhere at the level of the first floor have the money ... And I ended before to build a house, built a store, bought a good seed potatoes technique ».

Today Kolpakova property is more than 400 hectares of land. Each year its economy is growing on it about 10 000 tons of potatoes.

3.Cleaning of crop

Mass cleaning potato starts in 20 days of August and the first tractor on the field with a special device with a laconic name KIR (kositel chopper rotor), in order to mow all the tops with grass. Behind him after some time released harvester who dig and gather the harvest.

All appliances in the import sector. Green came from the Netherlands, and the red «Grimme» from Germany.

4.

5.

6.- This processor is 8 million, and our - 750 thousand. We, though, and the Patriots, but chose it, - says Mikhail. - It leaves a much smaller potatoes on the field - 2-3%, in contrast to ours, losing 20, and even 30%. They were still going and going. The tubers from the ground cleans better, without damaging them in the process. Himself a stones throw away. And his performance is much higher. With all four of these combine, we remove the potatoes from an area of 400 hectares, and the Russian need fifteen or sixteen pieces for the same amount. So good value for money it still pays.

7.

8.

9.Kombayn designed in such a way that undermines the number located on the side of the tractor that pulls it. Thus, tractor rides for the pure land, less damaging potatoes and installed sensors on the combine lead him exactly on the ridge, giving stay on the desired number.

10.Dalshe unique system of screening conveyor separates undermine the potatoes from the earth, foliage and rocks. To achieve such a result in our technique is simply unrealistic, says Michael. Land on the upper conveyor in any event not less than 50%. In order to keep up with her to throw at the combine, you need to put 4-5. It also needs one.

11.- I won that soon began. While no one was buying imported equipment, - says Mikhail. - Director of the farm said that it is too expensive, it is much easier to spend a hundred thousand for repairs. In the end, where I worked as a harvester, they were four. This means that they must have four tractor and another of four per processor. Total turns twenty. Where do I need to just two - ten times less. And how much diesel fuel is burned four tractors per working day? A reliable technique? In the fall of even a single hour of downtime combine due to a fault - is a tragedy. You can simply do not have time to harvest, fall something short. Then rain, then snow, then the machinery to repair - and all is lost. We never leave the potatoes in the fields. Always have time to clean up the winter.

He worked in the field of people free food lunch and dinner. Meals are brought directly to the field, here are arranged tables. Supper is necessary because the last time in the autumn of up to ten, eleven o'clock. According to Mikhail, and people are interested in the fact that there was a good harvest, so are sensitive to nonstandard schedule. As long as the weather is, we have to work.

Hopper capacity to combine six and a half tons. Potatoes out of it overwhelmed for special dump carts brand «Miedema» and transported to the sorting station.

11. In a park of four farm carts come from Holland. Each of them at a time can take away 12 tons of cargo. Due to the hydraulic suspension, the potatoes in this semi receives minimal mechanical damage during transportation.

12.Sortirovka, cleaning and storage

Equipment operating in the sorting of potatoes, the same brand as the tipper wagons. For this reason, one complements the other as well as possible.

From the Russian equipment Mikhail refused immediately. According to him, in the beginning they used screening plant of domestic production, but experience it has been rather negative:

- Just bought a new sort, burned her six engine. We had naturally exhausted. Hardly a day passed without she threw some trouble: the chains tear, the tape, the shaft will break. This also works as a clock. You can safely go somewhere, knowing that nothing happens here.

12.Iz dump carts potatoes first poured into the hopper. Further, it is divided into three streams. One way large, medium to another seed, in the third, with the land falls small.

13.

14.

15.

16.Krupny potatoes from this batch load into a container and sent to a special workshop on the revision. There will wash it first, and then part of the pack and razvezut of trading networks, and some will clean peel, pack the vacuum packaging and razvezut for kindergartens, canteens, schools and the food plant where it is made into dumplings. When the plant needs will be satisfied, will fill this warehouse.

Reconfigure the conveyor belt delivers the potatoes on the telescopic boom, which can be in automatic mode for a given program to fill in all the vault. Installed at the end of its sensors indicate that the potatoes in this place sufficient forcing to rotate from side to side.

17.Eto small store one hundred tons was one of the first who built a cap. Here on the grading of all four of the vault. Elsewhere, near the shop has settled on completion of five new stores over two thousand tons each:

18.Nebolshie "huts", hammered together from boards - ventilation ducts. In autumn, this room is filled to the top of the potatoes wooden boards on the sides and the floor partition off these boxes completely. The masonry along one wall made special ventilation openings. The air pumped therethrough by the fan flows through ducts and rises up through the entire bed of potato, preventing it from rot.

19.Na throughout the storage time of the operators follow the air circulation in the shoulder. In this they were helped by various thermometer showing the temperature of the room, on the street and in the thickness of the potato. Comparing the temperature, the operator can control the flow of air with the help of motorized valves directing it where necessary, and adjust its volume, ensuring that storage temperature was in the range of 3-4 degrees.

The new warehouse was attached directly to the shop by product refinement potatoes, which can significantly reduce the cost of its transportation. However, this operation has undergone the delivery of mechanization. The shoulder is exhausted conveyor ...

20 ... and potato conveyor belt is fed into the container. The container, a large wooden box, topples over into the hopper:

21.Ottuda potatoes supplied to the next conveyor. Going through it, it falls into the washing device, which is a barrel of water.

22.Datchik installed before it stops feeding if the drum fills.

23.Vnutri it rotates the drum with blades. It mixes uniformly with the potatoes, whereby the cleaned of dirt. At the exit of the barrel is the flap, which can be adjusted during washing, depending on the degree of contamination, and a shower with clean water, rinse the potatoes from the dirty water in the sink.

24.Dalee clean, but wet potatoes supplied to the wind shaft.

25.13 trees wrapped with a special cloth, rotating in one direction, wipe and dry the potatoes, handing it to the inspection table.

26.Na inspection table potatoes are selected presentation. Tubers with minor injuries are sent to the cleaners, and even and smooth - on the packaging. At the end of the table is another sensor which also turns off the entire line if the packing station is overloaded.

27.

28.Upakovka

Potatoes, the last control on the inspection table is applied to the weighing device - it consists of a vibrating table and weighing cups.

Due to vibrations, potatoes evenly distributed into cups. Next, the computer determines in which cups are desired weight. Accuracy of such device is quite high: it is capable of giving an error of up to 10 grams, and only in a big way.

29.

30.Dlya weighted potatoes are two options package. For each of them corresponds to your machine.

31.

32.

34.Proizvoditelnost a line: 28 packages per minute, every 2, 5 kilograms, which is 4 tons of potatoes per hour. The final stage of the quality of packaging is checked just in case, the finished product stack bags more, and is transported by commercial networks.

35.

36.Kartofel not last control on the inspection table, sent to the cleaners. First, the rough mechanical, where the barrel like a centrifuge, cleans potatoes peeled ...

37.

38.

39 ... and then manually rework:

40.Dalshe such potatoes packed in vacuum bags of five kilograms and sent to the warehouse.

Such processing "nekonditsiyu" to reduce the amount of waste in the shop almost to zero. What still remains, distributed free of charge to the public. For waste, usually visited by people involved in raising livestock.

- From time to time I ask, of course, to sell cleaning any farmer, but I prefer to keep the local population, workers in rural areas. People keep cattle, well, we encourage them: Hold on, guys.

41.Kolichestvo people working in the shop, depending on the season. The warmest autumn are working up to 20 people. All of them also free food dinners. On the second floor are made for the dining room, dressing room and shower room. Adjacent and study of Kolpakova.

This is only a small part of the available thanks and certificates.

42.Chut further there is another kitchen, lounge and shower especially for newcomers specialists. It happens that the equipment installers have to live here a week or more: the working time on a business trip often lasts from morning till night. To people not to wander away into the city and back, we decided to do for them is something like an apartment. They came, showered, slept, woke up in the morning, had breakfast and again for work.

47.Tseh finalization of potatoes was built in 2009. To equip it with all the necessary equipment had to spend 12 million rubles. Now through the shop it runs only 10-15% of the total weight of the potato, but in the economy are working on it and expect to gradually increase this share. The minimum wage in the shop of 15 thousand rubles. Pay, according to Michael, is stable, without delay. All workers are employed officially, paid vacation and sick leave. His people are helping to extinguish kredity.Seychas came here to to motivate and encourage the person to work by increasing his salary is not at the expense of the salary and bonuses due. During the autumn harvest workers paid additional wages and bonuses. The specific amount Mikhail did not articulate, but said that the money is good, even by urban standards, the farm they do not even earn in a year. But sometimes still have to deal with "educational" work: to come to a man, to talk, to persuade to give up drinking for the sake of the family and children.

48.

49.Realizatsiya

With the opening of a workshop for the finalization of the potato sector was to distribute its products through retail chains. Now it is a large part of the Tomsk spreads through a group of companies "Lama" (shops "apricot" and "Fudsiti"), a network of shops "Bystronom" and "Holiday". Eat Kolpakovsky potatoes and Seversk. But the first two years of his work shop brought nothing but losses. Unwashed potatoes are sold even more expensive than processed in the workshop. Kolpakov walked on it while holding the people and paying them a salary, because he saw the future, would like to go to the supermarket to press on the shelves of goods imported from other regions, "Even actuating zero, we were happy that we still Twenty-five people in the village have a job ».

According to Michael, "to go" in shopping online was not easy. At that time, supermarket shelves were occupied by imported potatoes brought from the neighboring regions of Novosibirsk, Kemerovo and Altai. To start Tomsk agriculture set the price for their products is almost two times lower than the competition. Gradually there was a preponderance on the shelves in favor Kolpakova. Potatoes its economy has increased, but the price for it, and still try to keep below imported.

50.- How can potatoes grown here cost more than brought from afar? Moreover, we have too much to keep a high price. The same to the potatoes we stayed, and we could not sell it until the following year, there was a very long time, - says Alexander, son of Michael Kolpakov, responsible for sales. - As a rule, it happens just the opposite: potatoes ends before we have time to collect the new crop. Sometimes in such cases, it is necessary even to buy more to keep supply contracts. For example, a food plant completely switched over to work with shelled potatoes. They even have their own capacity is not to be washed and cleaned.

Paul, who "rested" from work this year, several times over the summer plow tiller with grass growing up as she did not give seeds. This operation fertilizes the land, at the same time reducing the amount of weed in the fields.

One such tractor «John Deere» is three and a half million. Overall, these tractors on the farm - seven. Each has air conditioning, radio, visibility and easy operation, as foreign cars. Certain difficulties with recruitment, in this connection, of course, are available. Each tractor, each processor need to find a professional who will be able to work on it, be careful to treat it and not let you down at the crucial moment.

51.Mihail Kolpakov

"That's why I began to study the social sphere. If I had not built a Vershinino school, nobody ever is no longer to build, and after a while there is not only the technique of the people will not find anyone here at all will remain. A silent or pretend that nothing is happening - not to respect themselves. Last year, we had to fix another old state farm storage for two thousand tons, which has become dangerous to store potatoes, but I began to build a school. Subsidies promised to help in exchange for school Kress, who was then governor of the Tomsk region, left, and the new government school in the village was not necessary, accordingly, help economy, too, has no intention of providing. This year I had to reduce the area of land on 160 hectares just because of the fact that I have nowhere to put it. In terms of the money I lost at least 30 million rubles.

That's all. Thanks to all.

Source: