440

The soft elements of the design will allow you to create robots of a completely new class and destination

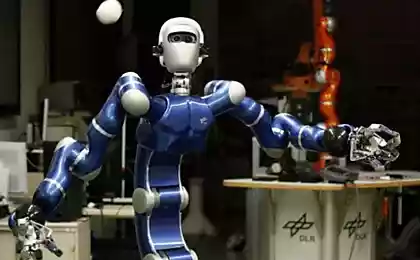

In the recent past, people imagined robots solely as human-like machines, be sure to have the torso, head, arms and legs. Currently, designers of robotic systems are paying more and more attention to the possibility of other living beings and the benefits that can be derived from this the robots of the future. We are already familiar with robots that can fly like a bird, run like cheetahs, swim like jellyfish and squid, and, in this case, slither like snakes. This idea was used by the researchers from the laboratory of Informatics and artificial intelligence (Computer Science and Artificial Intelligence Lab, CSAIL) Massachusetts Institute of technology, creating a pneumatic robot tentacle with a soft shell that can move the systems curved pipes, channels and burrows.

Snake, from the point of view of biomimicry robotic devices, is a very versatile model. The flexibility of the robot snake can be used in a variety of areas, ranging from repair and maintenance of equipment of nuclear power plant and ending assembling an incredibly intricate designs of planes aircraft. But, the existing robotic snakes in most cases have bodies made of rigid segments and with fixed joints that sufficiently restricts their opportunities.

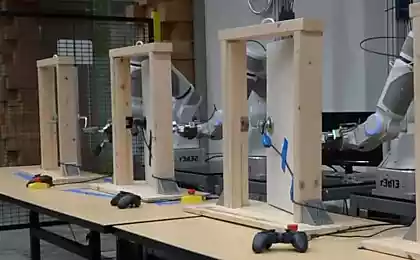

Snake robot is developed by the specialists of the laboratory and manufactured using three-dimensional printing technology, has a soft body and soft shell. Inside the robot body and under his carapace created isolated cavity in which by means of a system of tubes may be inflated using air under pressure. Pumping of separate cavities allows to give the robot body is virtually any shape, curving the body with any radius and any angle, which is impossible to achieve using mechanical drives of any type.

The possession of a soft body will allow the robot not getting stuck to slip into places where robots with rigid elements of the access essentially impossible. In addition, a robot with a soft body are not minor impacts and bumps, which increases its reliability.

Despite all of the above benefits, the design of any soft robot is not without its shortcomings. "Many soft robots anyway, there are still the solid elements, such as compressors, batteries, electronic control units and aluminum elements of the frame robots," says Andrew Marchese (Andrew Marchese), one of the developers of the soft robotic snake, "the Necessity of the use of solid components forces us to reduce the functionality of the soft robot. In addition, completely get rid of the solid parts of the construction robots will never work, because the robot is soft like a balloon, for example, cannot perform any useful work."

A soft robot due to the unusual nature of its design, requires special approaches and principles of management of movements. A separate group of experts from the laboratory CSAIL has developed a number of complex algorithms that control the "curvature" of the body parts of the robot that are required to perform various movements and displacements. "In order to get our robot to get to a certain point in space, you want to implement the exact sequence of changes of body shape, which in itself is very challenging," says Andrew Marchese, "And when moving in such a delicate space as the inside of pipelines, the robot is required to go through a sequence of calculated intermediate points. From the point of view of programming is an incredibly complex task."

Currently, researchers in the laboratory CSAIL engaged in the selection of components, such as actuators, compressors, sensors and electronic assemblies, in which the robot snake will be able to gain full independence, even at the expense of some reduction in the universality of its design. Lower level of functionality loss, the researchers plan due to maximize the use of flexible components, such as passive distribution valves and flexible electronic devices.

Source: www.dailytechinfo.org