569

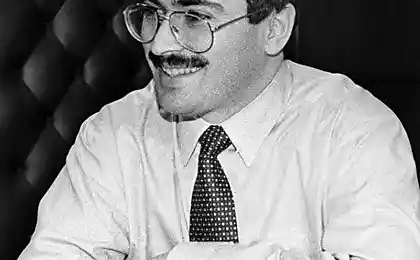

Michael Nikolaev: On the organization of production of hard cheese takes two years and three million euros

Italian and French cheeses – this is the sector of the dairy industry, in which import substitution is most problematic. What European cheeses can be produced in Russia without losing and what's needed, said Milknews Mikhail Nikolaev, the owner of the company "Nikolaev and sons."

Milknews: Many milk processors with the introduction of the embargo was thinking about setting up production of European cheeses in Russia. How is it really?

Nikolaev: If we're talking about the beginning of manufacture in Russia of cheeses to replace the European, it is necessary to divide them into several groups. The first group is brine cheeses: mozzarella, ricotta, burata with a small shelf life (5 to 20 days on average). The lack of these cheeses began to feel restaurateurs almost immediately after the embargo – they first disappeared from the shelves.

From the point of view of investment and technology to produce them easier, and it is usually a small production, where manual labor is used. They are the most interesting from the point of view of capital turnover. It is with these cheese and began to first experiment with the Russian manufacturers. There were precedents of manufacture and deliveries of cheeses of this group, but, as far as we know, the perfect full replace Italian cheese, in terms of quality and price for a year of sanctions and was not found.

Milknews: why not work? What is missing? Experience? Technology? Equipment?

Nikolaev: It is in large measure due to the lack of quality milk in Russia, and also with the specifics of production of these cheeses. In the original, in the production of the same mozzarella cheese-maker manually, formiruet pasta Gelato (cheese dough), so it is especially important the precision of the execution, even his mood and energy as in the confectionery business. Mozzarella produced in large factories that are already running in Russia, is very different in taste from original, Italian cheese. A small production, which already began to appear, you will not be able to fully satisfy demand from retailers and HoReCa segment.

Milknews: With semi-hard and hard cheeses in Russia like always was better...

Nikolayev: In the segment of semi-hard and hard cheeses in Russia is quite a strong tradition – we began to industrially produce this type of cheese in 1875, and the first production of that cheese-making was introduced by Peter I. in Russia were concentrated rennet cheeses such as cheese, Adyghe, Suluguni – which do not require heat treatment and Mature themselves. When Europe was already experimenting with heating, boiling the serum or milk, in Russia traditionally was just waiting for it to curdle and turn into cheese.

With the beginning of production of semi-hard and hard cheeses in Russia were local brands – poshekhonskoe, Uglich, Yaroslavl, Dutch, etc., with added local seasonings – herbs, garlic. It was considered a separate type of cheese. Once we have a product like cheese – in Europe it is part of the dishes, but never used separately. The culture of consumption of cheese type Camembert or brie, Dor blue we had. The demand for it has occurred recently, and it is small.

Since the XIX century in Russia began to produce processed cheese – they also relate to the preferences of Russian consumers.

Milknews: poshekhonskiy and Kostroma is certainly good, but the consumer wants Parmesan, brie, Camembert. With them how things are going?

Nikolaev: If we now want to establish production of European types of semi-hard cheeses need more time, and since the embargo was just for one year. This production becomes economically profitable, it can start to invest in it when the planning horizon is at least 5 years, since the inception of the idea to commissioning of the plant it usually takes about two years, with all the experiments on the production. A cheese plant capacity is about 20 tons per day to approximately 3 million euros. Such investments are justified if there is ahead at least a few years to gain space on the shelf, and we can be confident that the European manufacturer would not return only for the coming months until August 2016. You need to understand that as soon as the embargo lifted, European manufacturers will even dumping to regain shelf space. And Russian cheese now at a price comparable to the European. In the production of semi-hard and hard cheese aged from 2 months to half a year there is one caveat: in Europe there is a clear specialization. Farmers produce milk and sell it to cheese makers who produce cheese and sell it to offinance professionals for making cheese, which carry out storage, transport and communication (aging). It offinance sell the finished product to wholesalers, or directly to retail or HoReCa enterprises. In Russia there is even no understanding of the need for that third link. Production of semi hard and hard cheese is a low-turnover business, it is necessary much more time.

Milknews: is There a chance for a full import substitution in the cheese industry?

Nikolaev: Total import substitution in the production of cheese is quite complex, as now we have complete dependence on imported equipment not produced in Russia, no uniform or equipment, or even the packaging for the cheeses – all have to be purchased. To establish a Russian production of a complex product – multilayer wrapping paper for this cheese – if you have 5-6 customers all over the country is not economically profitable. There are difficulties with the starters – they either have to buy completely or using Russian counterparts still need to buy in Europe certain ingredients (70 -80%). If there is a demand from producers of cheese, then, perhaps, there will be Russian production of relevant equipment, starter cultures, paper, etc.

Milknews: Who is in Russia now produces high-quality analogues of European cheeses? Who is leading in this market?

Nikolaev: Among the leaders in the production of European cheeses in Russia include the following: "Nikolaev and sons" (Lefkadia), which specializiruetsya in the production of Camembert; Vitalat — Camembert CJSC "Tambolaka" (Belgorod region) – Camembert; Cheese Kokorin, who organized the production of cheeses with mold in the Smolensk district of the Altai territory; "Calorie" in the Krasnodar region produces the equivalent of Camembert cheese "Kuban plezir". published

Interviewed By Olga Kucherova

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: milknews.ru/interviu-i-blogi/interviu-i-blogi_227.html

Milknews: Many milk processors with the introduction of the embargo was thinking about setting up production of European cheeses in Russia. How is it really?

Nikolaev: If we're talking about the beginning of manufacture in Russia of cheeses to replace the European, it is necessary to divide them into several groups. The first group is brine cheeses: mozzarella, ricotta, burata with a small shelf life (5 to 20 days on average). The lack of these cheeses began to feel restaurateurs almost immediately after the embargo – they first disappeared from the shelves.

From the point of view of investment and technology to produce them easier, and it is usually a small production, where manual labor is used. They are the most interesting from the point of view of capital turnover. It is with these cheese and began to first experiment with the Russian manufacturers. There were precedents of manufacture and deliveries of cheeses of this group, but, as far as we know, the perfect full replace Italian cheese, in terms of quality and price for a year of sanctions and was not found.

Milknews: why not work? What is missing? Experience? Technology? Equipment?

Nikolaev: It is in large measure due to the lack of quality milk in Russia, and also with the specifics of production of these cheeses. In the original, in the production of the same mozzarella cheese-maker manually, formiruet pasta Gelato (cheese dough), so it is especially important the precision of the execution, even his mood and energy as in the confectionery business. Mozzarella produced in large factories that are already running in Russia, is very different in taste from original, Italian cheese. A small production, which already began to appear, you will not be able to fully satisfy demand from retailers and HoReCa segment.

Milknews: With semi-hard and hard cheeses in Russia like always was better...

Nikolayev: In the segment of semi-hard and hard cheeses in Russia is quite a strong tradition – we began to industrially produce this type of cheese in 1875, and the first production of that cheese-making was introduced by Peter I. in Russia were concentrated rennet cheeses such as cheese, Adyghe, Suluguni – which do not require heat treatment and Mature themselves. When Europe was already experimenting with heating, boiling the serum or milk, in Russia traditionally was just waiting for it to curdle and turn into cheese.

With the beginning of production of semi-hard and hard cheeses in Russia were local brands – poshekhonskoe, Uglich, Yaroslavl, Dutch, etc., with added local seasonings – herbs, garlic. It was considered a separate type of cheese. Once we have a product like cheese – in Europe it is part of the dishes, but never used separately. The culture of consumption of cheese type Camembert or brie, Dor blue we had. The demand for it has occurred recently, and it is small.

Since the XIX century in Russia began to produce processed cheese – they also relate to the preferences of Russian consumers.

Milknews: poshekhonskiy and Kostroma is certainly good, but the consumer wants Parmesan, brie, Camembert. With them how things are going?

Nikolaev: If we now want to establish production of European types of semi-hard cheeses need more time, and since the embargo was just for one year. This production becomes economically profitable, it can start to invest in it when the planning horizon is at least 5 years, since the inception of the idea to commissioning of the plant it usually takes about two years, with all the experiments on the production. A cheese plant capacity is about 20 tons per day to approximately 3 million euros. Such investments are justified if there is ahead at least a few years to gain space on the shelf, and we can be confident that the European manufacturer would not return only for the coming months until August 2016. You need to understand that as soon as the embargo lifted, European manufacturers will even dumping to regain shelf space. And Russian cheese now at a price comparable to the European. In the production of semi-hard and hard cheese aged from 2 months to half a year there is one caveat: in Europe there is a clear specialization. Farmers produce milk and sell it to cheese makers who produce cheese and sell it to offinance professionals for making cheese, which carry out storage, transport and communication (aging). It offinance sell the finished product to wholesalers, or directly to retail or HoReCa enterprises. In Russia there is even no understanding of the need for that third link. Production of semi hard and hard cheese is a low-turnover business, it is necessary much more time.

Milknews: is There a chance for a full import substitution in the cheese industry?

Nikolaev: Total import substitution in the production of cheese is quite complex, as now we have complete dependence on imported equipment not produced in Russia, no uniform or equipment, or even the packaging for the cheeses – all have to be purchased. To establish a Russian production of a complex product – multilayer wrapping paper for this cheese – if you have 5-6 customers all over the country is not economically profitable. There are difficulties with the starters – they either have to buy completely or using Russian counterparts still need to buy in Europe certain ingredients (70 -80%). If there is a demand from producers of cheese, then, perhaps, there will be Russian production of relevant equipment, starter cultures, paper, etc.

Milknews: Who is in Russia now produces high-quality analogues of European cheeses? Who is leading in this market?

Nikolaev: Among the leaders in the production of European cheeses in Russia include the following: "Nikolaev and sons" (Lefkadia), which specializiruetsya in the production of Camembert; Vitalat — Camembert CJSC "Tambolaka" (Belgorod region) – Camembert; Cheese Kokorin, who organized the production of cheeses with mold in the Smolensk district of the Altai territory; "Calorie" in the Krasnodar region produces the equivalent of Camembert cheese "Kuban plezir". published

Interviewed By Olga Kucherova

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: milknews.ru/interviu-i-blogi/interviu-i-blogi_227.html

The canadian students created a refrigerator that runs without electricity

Tesla wants to make their vehicles fully Autonomous