1309

How to make oven long burning their hands

Baking slobozhanka is a stove long burning. It is ideal for heating greenhouses, garages, workshops, outbuildings and country houses. Its design is simple, and this stove is easy to assemble with your hands. Following our instructions, any handyman can handle this task.

A bit of theory to beginto achieve success in practice to understand the theory, you have to know the principle of operation of the device. This will help to understand the sequence of manufacturing a furnace of the type slobozhanka that will greatly simplify the whole process of its manufacture.

This type of sources of thermal energy refers to the type of furnaces of long burning. The device of the combustion chamber allows for a single fuel tab to get a large amount of emitted heat.

The fuel for this type of heaters are sawdust. You can use unprepared waste wood or compacted briquettes of the type of pellets. They should be sufficiently dried to the stove to function properly. Note that there are models that use other types of fuel, e.g. waste oil machines. Each model has their drawings, but the principle is the same everywhere.

How does slobozhanka? It introduces fuel and ignited. The fire engulfed the top layer of sawdust and the combustion comes from the top down and not Vice versa as in traditional furnaces. But the air to ensure the process of converting fuel into thermal energy is fed from the bottom. Depending on the furnace design it is either the tube located in the center of the body, or on the side walls. Due to this, they are well warmed up and give off heat efficiently.

In the combustion process, the flame propagates from the center to the walls, and rising air provides a better "assimilation" in the fire of fuel. This achieves very high efficiency (about 90%), making furnace of the type slobozhanka very beneficial in the household.SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/0/5/equlper3z0ca/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

Tools and materialsTo build the hearth of this type, your hands will need the following tools:

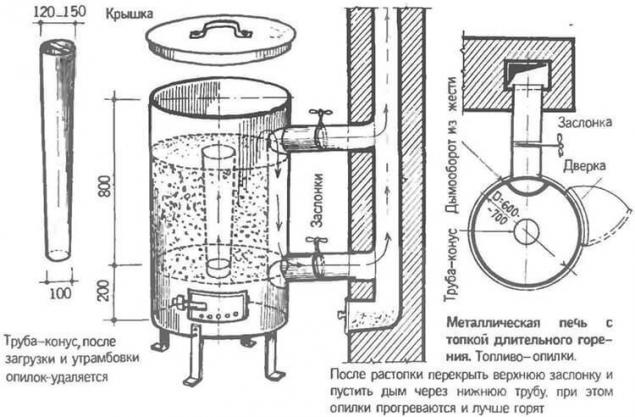

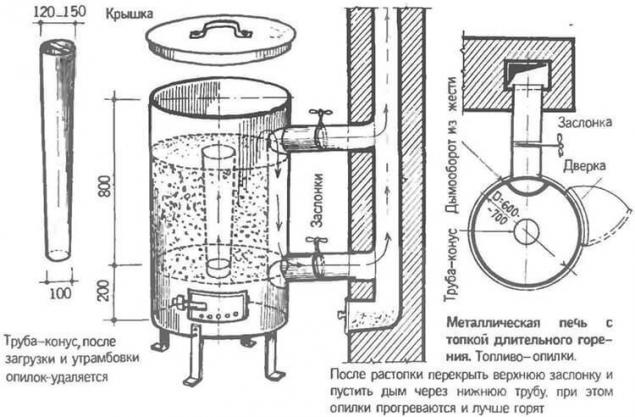

Do the oven step by stepthe First step is to build housing. To do this, you can also fragment the barrel or gas cylinder. He cut off the upper part, is the cylinder with the bottom. If the housing is made of sheet steel, rolled and welded cylinder bottom welded to the bottom. Take an arbitrary size, depending on how much room you need to heat.

Top, side cut out hole (not less than 10 centimeters) to the chimney. It is tightly welded to the hole. In the center of the bottom is also cut a hole with a diameter corresponding to the pipe size of the duct.

The second step is the fabrication of the feed system and the subsequent distribution of the air. To do this, take the pipe with thick walls and cut so that its length is equal to the height of the furnace. For the movement of air in the pipe wall grinder cut grooves-holes. To regulate the flow of air from sheet steel cut timber is equal to the diameter of the pipe. Fasten it on the pipe bottom so that it can move freely, opening and closing the hole. Subsequently, with the help of this device will be regulated by the flow of air in the combustion part.

Steel cut circle the diameter of the cylinder housing. In the center make a hole for the prepared tube, which welding apparatus is attached to the bottom, so that its end was performed at 20-30 cm

Device furnace "Slobozhanka"

Heat spreader made of sheet steel of thickness not less than 1 cm is cut in the form of a circle, whose diameter is a few centimeters smaller than the inner diameter of the housing. Because the lens freely removed and worn, it is attached the handle.

Then make a furnace casing, its outer hull. It is also called a convection shirt. To do this, the steel sheet rolled to a cylinder and sealed at the joint. The diameter of the casing, made by hand, 2-3 cm larger than the diameter of the furnace body part.

Outer case wear on the inside and attach it with a device of the following type. Of thick metal rod cut the cylinders honed heads. Their length corresponds to the distance between the walls of the inner and outer housings of the oven. In buildings, holes are drilled, into which insert the cylinders and clench with a hammer head.

Final stage — making the cover. This steel sheet cut out a circle that is welded to the top of the stove.Features of operationAs noted above, the principle of operation of slobozhanka based on the movement of cold air from the bottom up. Therefore, the case of such furnaces should be elevated above the floor surface not less than 20-25 cm to the walls is recommended to weld a strong frame made from rebar.

You can use the area, but of such width to allow sufficient space for air circulation.

The chimney is made of standard steel, its diameter shall not be less than 10 cm, It is also important, since it affects the velocity of air in the system.

As you can see, the build process furnace of the type slobozhanka is clear and accessible even for the layman. And it can be done by hand, using the available drawings and diagrams. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/0/8/kbcq9420v2lf/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: sdelaypechi.ru/vidy/firmennye/pech-slobozhanka.html

A bit of theory to beginto achieve success in practice to understand the theory, you have to know the principle of operation of the device. This will help to understand the sequence of manufacturing a furnace of the type slobozhanka that will greatly simplify the whole process of its manufacture.

This type of sources of thermal energy refers to the type of furnaces of long burning. The device of the combustion chamber allows for a single fuel tab to get a large amount of emitted heat.

The fuel for this type of heaters are sawdust. You can use unprepared waste wood or compacted briquettes of the type of pellets. They should be sufficiently dried to the stove to function properly. Note that there are models that use other types of fuel, e.g. waste oil machines. Each model has their drawings, but the principle is the same everywhere.

How does slobozhanka? It introduces fuel and ignited. The fire engulfed the top layer of sawdust and the combustion comes from the top down and not Vice versa as in traditional furnaces. But the air to ensure the process of converting fuel into thermal energy is fed from the bottom. Depending on the furnace design it is either the tube located in the center of the body, or on the side walls. Due to this, they are well warmed up and give off heat efficiently.

In the combustion process, the flame propagates from the center to the walls, and rising air provides a better "assimilation" in the fire of fuel. This achieves very high efficiency (about 90%), making furnace of the type slobozhanka very beneficial in the household.SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/0/5/equlper3z0ca/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

Tools and materialsTo build the hearth of this type, your hands will need the following tools:

- welding machine (gas or electric);

- angle grinder and a set of disks for metal (cutting, grinding);

- drill with set of drill bits for metal;

- hammer;

- chisel;

- roulette;

- chalk or a marker.

- gas bottle or metal barrel (body);

- pipe with thick walls (for air supply);

- sheet steel (not thinner than 5 mm).

Do the oven step by stepthe First step is to build housing. To do this, you can also fragment the barrel or gas cylinder. He cut off the upper part, is the cylinder with the bottom. If the housing is made of sheet steel, rolled and welded cylinder bottom welded to the bottom. Take an arbitrary size, depending on how much room you need to heat.

Top, side cut out hole (not less than 10 centimeters) to the chimney. It is tightly welded to the hole. In the center of the bottom is also cut a hole with a diameter corresponding to the pipe size of the duct.

The second step is the fabrication of the feed system and the subsequent distribution of the air. To do this, take the pipe with thick walls and cut so that its length is equal to the height of the furnace. For the movement of air in the pipe wall grinder cut grooves-holes. To regulate the flow of air from sheet steel cut timber is equal to the diameter of the pipe. Fasten it on the pipe bottom so that it can move freely, opening and closing the hole. Subsequently, with the help of this device will be regulated by the flow of air in the combustion part.

Steel cut circle the diameter of the cylinder housing. In the center make a hole for the prepared tube, which welding apparatus is attached to the bottom, so that its end was performed at 20-30 cm

Device furnace "Slobozhanka"

Heat spreader made of sheet steel of thickness not less than 1 cm is cut in the form of a circle, whose diameter is a few centimeters smaller than the inner diameter of the housing. Because the lens freely removed and worn, it is attached the handle.

Then make a furnace casing, its outer hull. It is also called a convection shirt. To do this, the steel sheet rolled to a cylinder and sealed at the joint. The diameter of the casing, made by hand, 2-3 cm larger than the diameter of the furnace body part.

Outer case wear on the inside and attach it with a device of the following type. Of thick metal rod cut the cylinders honed heads. Their length corresponds to the distance between the walls of the inner and outer housings of the oven. In buildings, holes are drilled, into which insert the cylinders and clench with a hammer head.

Final stage — making the cover. This steel sheet cut out a circle that is welded to the top of the stove.Features of operationAs noted above, the principle of operation of slobozhanka based on the movement of cold air from the bottom up. Therefore, the case of such furnaces should be elevated above the floor surface not less than 20-25 cm to the walls is recommended to weld a strong frame made from rebar.

You can use the area, but of such width to allow sufficient space for air circulation.

The chimney is made of standard steel, its diameter shall not be less than 10 cm, It is also important, since it affects the velocity of air in the system.

As you can see, the build process furnace of the type slobozhanka is clear and accessible even for the layman. And it can be done by hand, using the available drawings and diagrams. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/5/0/8/kbcq9420v2lf/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: sdelaypechi.ru/vidy/firmennye/pech-slobozhanka.html

Electric buggy and a 2000-strong hybrid wagon from Nikola Motor Company

Learn how to safely and quickly remove ticks