874

Furnace long burning without a grate: stove with their hands

Are there ways to improve the efficiency of conventional stoves and stoves made out of barrels? How to make handmade oven long burning? What you need to know about the reactions taking place during the heat? The answers to these questions, and also step-by-step instructions you will find in our article.

We have repeatedly mentioned the low efficiency and large consumption of fuel of conventional stoves direct combustion. The reason for this is the direct access of oxygen and the free emission of exhaust gases. The initial stage of solution of this problem was given in the latest designs — from chimney heat exchanger. In addition, the following problems exist with the combustion of fuel:

Rapid uncontrolled combustion. If this lesion occurs too high temperature, and the metal quickly loses its properties.

Incomplete combustion of the material. This is especially true when recycling plastic and other polymers (in the trash). Acrid smoke from rubber and PVC, the thick exhaust of the car is the result of nadgorny of petroleum products.

Frequent (up to 1 times per hour) fuel loading and the risk of attenuation of the hearth. This oven will not leave for the night — goes out and cools down. It is worth noting that an important advantage of steel furnaces is their quick warm-up.

The main idea we will develop in this article, will be the adjustment of the oxygen supply for combustion. This will require a more accurate execution of the sealing (doors, dampers) and control (dampers, movable and rotary dampers) devices.

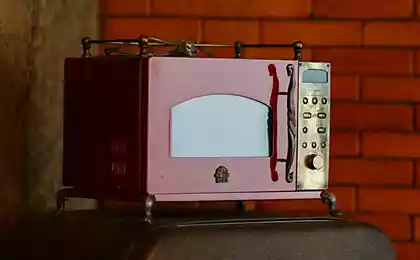

Butalongola furnace (OPF) with valve type "Buleryan"In fact, it's a stove, but without the grate. It fell in our classification because it has higher efficiency and requires the skill of a master. Despite the fact that this type of furnace uses less parts than the stove, she has one complicated element of the furnace door. This item is only generally similar to the parts "Buleryan" (but most important). The door shall be hermetically sealed, it is combined with the supply channel (podduvalom).

Design. The steel firebox of any shape — a cube, a parallelepiped, a horizontal or vertical cylinder with a door type "Buleryan" in the front lower part and a flue at the rear top.

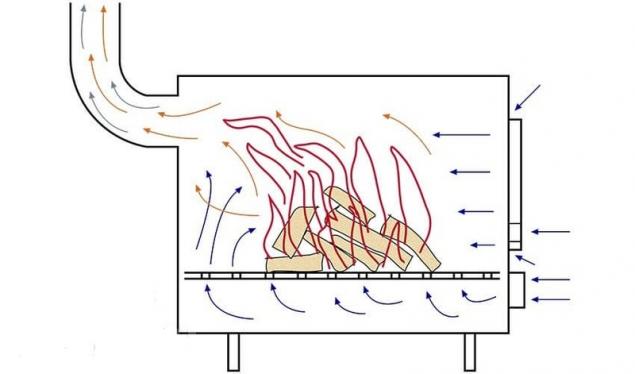

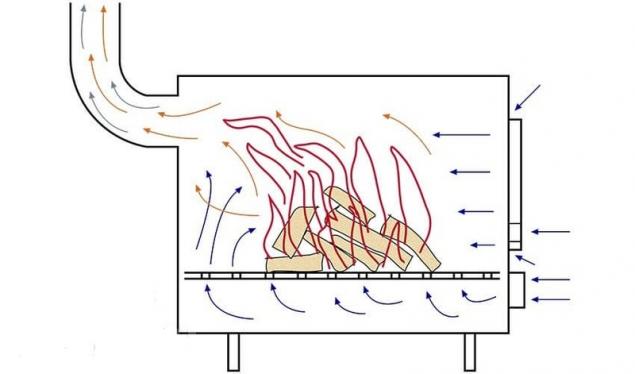

Effect. The grate in the furnace of the oxygen for combustion is supplied abundantly in the center of podkolodnovka space on all sides. This leads to intense burning, and rapid removal of the temperature of the cold stream of fresh air. The result is unburned products are excreted through the chimney.

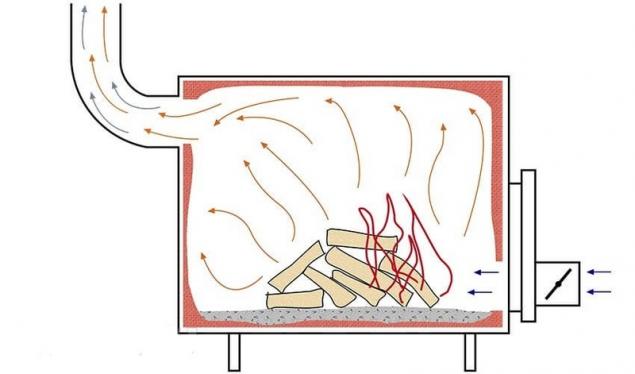

No lattice oxygen takes place only through the inlet channel, which quite accurately regulated. This increases the burning time and the food decompose. Thus, the hot gas is longer retained in the furnace and efficiently heats wall. As a result, more heat remains inside the room.

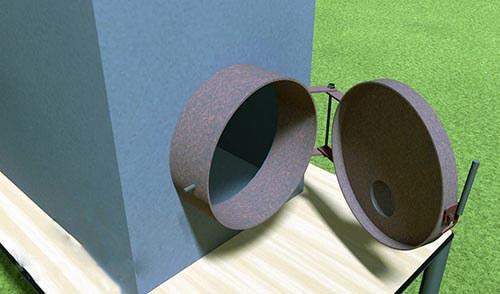

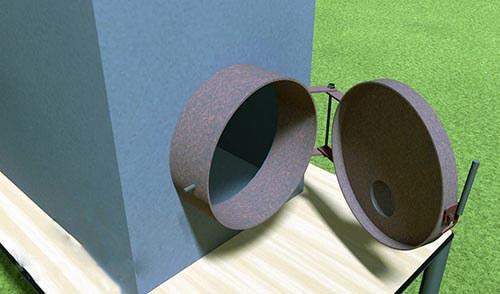

How to make BCP your handsthe Only secret of such a furnace is a sealed furnace door. It can be any shape, but usually make it round or square.

1. Pipe with a diameter of 200-350 mm (wall 2-4 mm) cut off the ring width of 50-100 mm. Align and clean the edges. This element is called "collar".

2. From a sheet of 3-4 mm cut out circle exactly on the outside diameter of the collar. It will be a door.

3. Based on the furnace dimensions, select the diameter of the flow channel (air channel VC). Can be divided BKP domestic purposes into 2 categories — small (0,13–0,18 cubic meters), medium (0.18 to 0.25 cubic meters). It will be enough for small diameter 76 mm, for the middle — 102 mm Size of rectangular channels is calculated using the cross-sectional area S = Пг2.

4. The VC must have the valve or the gate.

Valve:

Cut round the flap (metal 2-3 mm), covering the progress of the VC with an eye to the diameter of bolt thread (M10–12). Welded to it in front of the eyes the stem (the handle).

To the tube VK weld nut parallel to the course of the air flush with the outer edge.

Install the valve on the pipe to the VC on the bolt through the spring and fix lock nut.

The manufacturing process of the gate valve is more complex, with the convenience and the effect it has no advantages over the given valve. You can copy from factory copy.

5. Cut the door hole under VC.

Attention! Opening doors should not be less than the diameter of the VC. The channel itself needs to be shifted down from the center and the lower edge should be placed 20-30 mm from the cuff of the door.

6. The strip thickness of 2-3 mm and 20-30 mm wide take a segment equal to the circumference of the door.

7. Weld strip overlapping the circumference of the door.

8. Make a loopback device. To do this, four lengths of 60-70 mm strip drilled with the edge of one hole 6-8 mm. Put them on a flat wire pin 6 to 8 mm length of 100-150 mm. Pairs of weld strips to the door and cuff the furnace.

9. We manufacture a closure device. This element can be arbitrary — the castle of the inventory box, the tensioner of motorcycle chains or any type of Cam with a handle. Convenient and reliable to use movable screw tightening. Will approach the castle with the milk cans. The main task is to provide a clamp of the door cuff to the furnace.

10. In the corner of the door is formed by a cuff, placed on a heat-resistant sealant asbestos cord.

This hatch can be installed in any stove or steel tank, you get an efficient furnace. It should be located within 100 mm of the bottom of the furnace. That is, between the bottom charging port and the furnace floor should be at least 10 cm.

The main and most important rule for operation of BCP: at the bottom of the firebox should always be a layer of ash at least 80 mm thick. Otherwise the bottom will prikalivatsja and will soon be out of business.

Simple and convenient the chimneythe device of the horizontal output channel of the exhaust gas is not always convenient, especially when servicing the furnace. We present a way to make it more simple and convenient form:

In the rear part of the upper wall through a round or rectangular hole smaller than the cross section of chimney pipe at 20-30 mm.

Select a section of pipe exceeding the diameter of 20-30 mm with a length of 40-60 mm.

We it to the hole in the centered position.

Now this cuffs can be installed any pipe, and in the bosom (the gap formed by the diameter differences) should be made to cover and seal the dry clay. This will give reliable protection against leakage of smoke and simplify disassembly for maintenance.

Recall that one of the functions of the "basic" stove — possibility of heating water and cooking on the top wall of the firebox. BKP with door "Buleryan" retains this property — it is enough to load more fuel and a fully open VC.

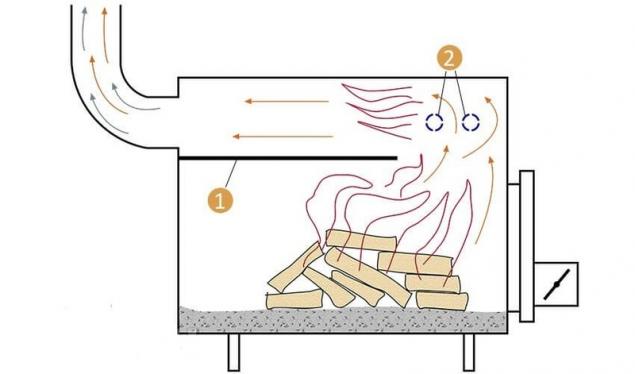

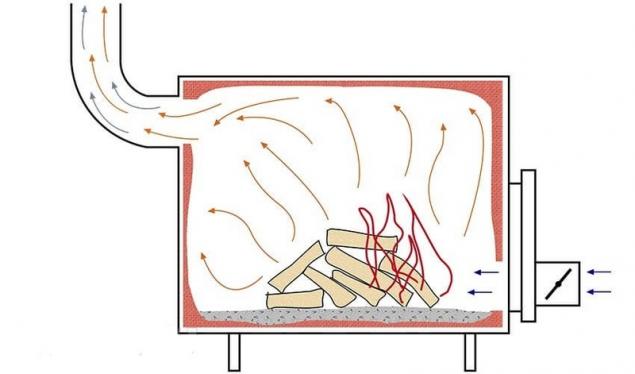

Furnace bulkhead could be the next step in upgrading beskonusnogo stoves. This cooler is in the form of a thick (5-8 mm) metal sheet located directly under the chimney and blocking 2/3 of the area of the furnace.

Effect. An even greater slowing down the hot gas. Additional accumulation of heat indoors.

For the full implementation of the BCP long burning as plates need to add another element on top of the injector. It's a hollow tube (or several) with the holes inside the furnace, which is in front of the furnace at the level of the center of the flue channel.

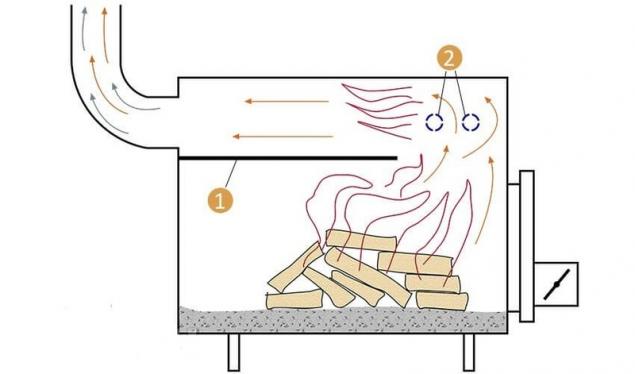

1 — furnace bulkhead; 2 — injection tube

Effect. The injector need to recharge the air "tongues" of flames and the reburning fuel. It is the place where the burning process is not complete yet and fume generation is about to begin. Feeding at this point, the oxygen (air) we are fueled by the combustion reaction, the heat of which warms the upper wall. This principle is used in modern pyrolysis solid fuel boilers.

The injector "automatically" comes into effect when in contact with flame. This is possible only if the focus is located in front of the furnace. In the long burning mode (when the source is closer to the center of the furnace), it remains untapped.

Additional modes of realization of the potential of a steel furnaceIn this case, there is one simple rule: the more the storage material (metal, water, stone), the more heat will remain inside the house:

If you assume even the periodic use of the oven as a plate, it is possible to arrange additional deployemnt on the top wall of the firebox. For this you need to weld on the inside of her angles or strips at the edge full length.

The same ribs on the sides will give 5 to 10% improvement. At the same time they reinforce the plane of the wall.

If you provide chimney of a steel tube, it is also possible to weld the corners along the length, which will remove part of the residual heat from the flue gases. That's an additional 3-5%.

Welded to the vertical side walls of the cutting round or shaped tubes create the effect that is used in modern furnaces of long burning. Constant heat ensures a continuous movement of air inside the pipe. Up to 20% increase in heat transfer.

Propped furnace with one or more sides of the brick without mortar, we will receive the stone heat accumulator and protect the walls from overheating. A variation of this method, baskets or bins with cobblestones around the furnace is used in the baths. Can give 15 to 20% improvement.

Household fan aimed at the oven, protect it from overheating and equalize the temperature of the air in the room and mix it. Adds 10-20%.

Applying all these methods together can increase performance of the heat exchanger, which in the baseline is furnace, for 50-75%. Described ways of improving performance, increasing the weight of the product. Keep this in mind when choosing a basis for the installation of the furnace.

Stoves without grates have a one for all because the ash pan. It combined function of accumulated ash serves to protect the bottom of the furnace from burning, used to clear the furnace during operation. On the other hand, long burning produces smaller quantities of solid waste, and this means that cleaning can be carried out much less frequently. The excavation of the ash is quick, and the room will not have time to cool down during this time. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.rmnt.ru/story/fireplaces/737343.htm

We have repeatedly mentioned the low efficiency and large consumption of fuel of conventional stoves direct combustion. The reason for this is the direct access of oxygen and the free emission of exhaust gases. The initial stage of solution of this problem was given in the latest designs — from chimney heat exchanger. In addition, the following problems exist with the combustion of fuel:

Rapid uncontrolled combustion. If this lesion occurs too high temperature, and the metal quickly loses its properties.

Incomplete combustion of the material. This is especially true when recycling plastic and other polymers (in the trash). Acrid smoke from rubber and PVC, the thick exhaust of the car is the result of nadgorny of petroleum products.

Frequent (up to 1 times per hour) fuel loading and the risk of attenuation of the hearth. This oven will not leave for the night — goes out and cools down. It is worth noting that an important advantage of steel furnaces is their quick warm-up.

The main idea we will develop in this article, will be the adjustment of the oxygen supply for combustion. This will require a more accurate execution of the sealing (doors, dampers) and control (dampers, movable and rotary dampers) devices.

Butalongola furnace (OPF) with valve type "Buleryan"In fact, it's a stove, but without the grate. It fell in our classification because it has higher efficiency and requires the skill of a master. Despite the fact that this type of furnace uses less parts than the stove, she has one complicated element of the furnace door. This item is only generally similar to the parts "Buleryan" (but most important). The door shall be hermetically sealed, it is combined with the supply channel (podduvalom).

Design. The steel firebox of any shape — a cube, a parallelepiped, a horizontal or vertical cylinder with a door type "Buleryan" in the front lower part and a flue at the rear top.

Effect. The grate in the furnace of the oxygen for combustion is supplied abundantly in the center of podkolodnovka space on all sides. This leads to intense burning, and rapid removal of the temperature of the cold stream of fresh air. The result is unburned products are excreted through the chimney.

No lattice oxygen takes place only through the inlet channel, which quite accurately regulated. This increases the burning time and the food decompose. Thus, the hot gas is longer retained in the furnace and efficiently heats wall. As a result, more heat remains inside the room.

How to make BCP your handsthe Only secret of such a furnace is a sealed furnace door. It can be any shape, but usually make it round or square.

1. Pipe with a diameter of 200-350 mm (wall 2-4 mm) cut off the ring width of 50-100 mm. Align and clean the edges. This element is called "collar".

2. From a sheet of 3-4 mm cut out circle exactly on the outside diameter of the collar. It will be a door.

3. Based on the furnace dimensions, select the diameter of the flow channel (air channel VC). Can be divided BKP domestic purposes into 2 categories — small (0,13–0,18 cubic meters), medium (0.18 to 0.25 cubic meters). It will be enough for small diameter 76 mm, for the middle — 102 mm Size of rectangular channels is calculated using the cross-sectional area S = Пг2.

4. The VC must have the valve or the gate.

Valve:

Cut round the flap (metal 2-3 mm), covering the progress of the VC with an eye to the diameter of bolt thread (M10–12). Welded to it in front of the eyes the stem (the handle).

To the tube VK weld nut parallel to the course of the air flush with the outer edge.

Install the valve on the pipe to the VC on the bolt through the spring and fix lock nut.

The manufacturing process of the gate valve is more complex, with the convenience and the effect it has no advantages over the given valve. You can copy from factory copy.

5. Cut the door hole under VC.

Attention! Opening doors should not be less than the diameter of the VC. The channel itself needs to be shifted down from the center and the lower edge should be placed 20-30 mm from the cuff of the door.

6. The strip thickness of 2-3 mm and 20-30 mm wide take a segment equal to the circumference of the door.

7. Weld strip overlapping the circumference of the door.

8. Make a loopback device. To do this, four lengths of 60-70 mm strip drilled with the edge of one hole 6-8 mm. Put them on a flat wire pin 6 to 8 mm length of 100-150 mm. Pairs of weld strips to the door and cuff the furnace.

9. We manufacture a closure device. This element can be arbitrary — the castle of the inventory box, the tensioner of motorcycle chains or any type of Cam with a handle. Convenient and reliable to use movable screw tightening. Will approach the castle with the milk cans. The main task is to provide a clamp of the door cuff to the furnace.

10. In the corner of the door is formed by a cuff, placed on a heat-resistant sealant asbestos cord.

This hatch can be installed in any stove or steel tank, you get an efficient furnace. It should be located within 100 mm of the bottom of the furnace. That is, between the bottom charging port and the furnace floor should be at least 10 cm.

The main and most important rule for operation of BCP: at the bottom of the firebox should always be a layer of ash at least 80 mm thick. Otherwise the bottom will prikalivatsja and will soon be out of business.

Simple and convenient the chimneythe device of the horizontal output channel of the exhaust gas is not always convenient, especially when servicing the furnace. We present a way to make it more simple and convenient form:

In the rear part of the upper wall through a round or rectangular hole smaller than the cross section of chimney pipe at 20-30 mm.

Select a section of pipe exceeding the diameter of 20-30 mm with a length of 40-60 mm.

We it to the hole in the centered position.

Now this cuffs can be installed any pipe, and in the bosom (the gap formed by the diameter differences) should be made to cover and seal the dry clay. This will give reliable protection against leakage of smoke and simplify disassembly for maintenance.

Recall that one of the functions of the "basic" stove — possibility of heating water and cooking on the top wall of the firebox. BKP with door "Buleryan" retains this property — it is enough to load more fuel and a fully open VC.

Furnace bulkhead could be the next step in upgrading beskonusnogo stoves. This cooler is in the form of a thick (5-8 mm) metal sheet located directly under the chimney and blocking 2/3 of the area of the furnace.

Effect. An even greater slowing down the hot gas. Additional accumulation of heat indoors.

For the full implementation of the BCP long burning as plates need to add another element on top of the injector. It's a hollow tube (or several) with the holes inside the furnace, which is in front of the furnace at the level of the center of the flue channel.

1 — furnace bulkhead; 2 — injection tube

Effect. The injector need to recharge the air "tongues" of flames and the reburning fuel. It is the place where the burning process is not complete yet and fume generation is about to begin. Feeding at this point, the oxygen (air) we are fueled by the combustion reaction, the heat of which warms the upper wall. This principle is used in modern pyrolysis solid fuel boilers.

The injector "automatically" comes into effect when in contact with flame. This is possible only if the focus is located in front of the furnace. In the long burning mode (when the source is closer to the center of the furnace), it remains untapped.

Additional modes of realization of the potential of a steel furnaceIn this case, there is one simple rule: the more the storage material (metal, water, stone), the more heat will remain inside the house:

If you assume even the periodic use of the oven as a plate, it is possible to arrange additional deployemnt on the top wall of the firebox. For this you need to weld on the inside of her angles or strips at the edge full length.

The same ribs on the sides will give 5 to 10% improvement. At the same time they reinforce the plane of the wall.

If you provide chimney of a steel tube, it is also possible to weld the corners along the length, which will remove part of the residual heat from the flue gases. That's an additional 3-5%.

Welded to the vertical side walls of the cutting round or shaped tubes create the effect that is used in modern furnaces of long burning. Constant heat ensures a continuous movement of air inside the pipe. Up to 20% increase in heat transfer.

Propped furnace with one or more sides of the brick without mortar, we will receive the stone heat accumulator and protect the walls from overheating. A variation of this method, baskets or bins with cobblestones around the furnace is used in the baths. Can give 15 to 20% improvement.

Household fan aimed at the oven, protect it from overheating and equalize the temperature of the air in the room and mix it. Adds 10-20%.

Applying all these methods together can increase performance of the heat exchanger, which in the baseline is furnace, for 50-75%. Described ways of improving performance, increasing the weight of the product. Keep this in mind when choosing a basis for the installation of the furnace.

Stoves without grates have a one for all because the ash pan. It combined function of accumulated ash serves to protect the bottom of the furnace from burning, used to clear the furnace during operation. On the other hand, long burning produces smaller quantities of solid waste, and this means that cleaning can be carried out much less frequently. The excavation of the ash is quick, and the room will not have time to cool down during this time. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.rmnt.ru/story/fireplaces/737343.htm